Cull cow body and carcass composition

Learn about Canada’s grading system for cull cows. This technical information is for beef farmers in Ontario.

ISSN 1198-712X, published September 2015.

Terminology

Canadian carcass grading system for cows

Canada's grading system categorizes cull cow carcasses into grades D1, 2, 3 and 4 based on the following:

- D1

- excellent muscling, with less than 15mm of firm, white or amber coloured backfat

- D2

- medium to excellent muscling, with less than 15mm of white to yellow backfat

- D3

- deficient muscling with less than 15mm of backfat

- D4

- deficient to excellent muscling with greater than 15 mm of backfat

Unlike the grading system for fed cattle, the cull cow grading system does not grade cows for marbling nor is it well used for establishing payment for cull cow carcasses. While live auction markets may describe D1, D2 cow prices, it is terminology adopted to describe live cows predicted to have the highest carcass value, even though the cow carcasses have not been graded.

Body condition scoring (BCS)

In Canada body condition scoring is a visual rating of fatness on a scale of 1 to 5, with 1 being the extremely lean cow and 5 being the extremely fat one. In the U.S. the scoring is on a scale of 1 to 9. BCS does not describe muscling and is terminology often used to describe cow condition for managing feeding systems. It is safe to predict that a BCS 1 cow would, using the cull cow carcass grading system grade D3 and a BCS 5 cow would grade D4.

Cull cow body composition

Cull cow body composition varies considerably in terms of carcass weight and percentages of fat, muscle and bone. The percentages in Figure 1 are ranges where the majority of animals will fall, but there are always individual cases that will be outside these ranges.

Use the information in Figure 1 to predict the weight of saleable lean meat. Start with the live weight, make estimates of body fill, fat thickness and muscling, and then apply these predictions to the percentage ranges listed in Figure 1. Results should be within a couple percentage points of actual muscle and fat content.

Figure 1. Predicting carcass components of cull cow.

- Live weight (LW)

- Starting at the point of slaughter, live weight is reduced to hot carcass weight (HCW) by eliminating the hide, head, feet, tail, entrails and gut fill. Variables that affect this weight reduction in cull cows are stage of pregnancy, udder size and gut fill.

- Hot carcass weight (HCW): 44% to 55% range of LW

- HCW can range from 44% to 55% of live weight with the very lean, poorly muscled cows at the bottom of the range and fat, heavy muscled cows at the top of the range. Some Jersey cows will dress as low as 35%.

- Cold carcass weight (CCW): Approximately 99% of HCW

- Cold carcass weight (CCW) is the weight of the carcass after chilling. CCW is about 1% less than HCW and is due to the loss of water content during the cooling period. Very lean carcasses will have greater moisture losses than fat carcasses.

- CCW – Percentage of bone, fat and muscle content

- Content of bone, fat and muscle as a percentage of the CCW varies with fat cover and muscling of the carcass.

- Bone: 17%–32%

- Bone can range from 17% to 32% of the CCW. Fat, well-muscled cows are at the lower percentage range whereas very lean, poorly muscled cows are at the top of the range.

- Fat: 7%–30%

- Fat can range from 7% to 30% of the CCW. The greater the backfat on the cow the greater the percentage fat will be.

- Muscle: 49%–63%

- Muscle content of the CCW can vary from 49% to 63%, but it is not the same linear relationship as exists with fat and bone. Percent muscle is lowest with fat cows and highest for cows that are heavily muscled, with an ideal body condition score. Very lean, poor muscled cows fall in the 58%–60% range.

Carcass content of cull cows

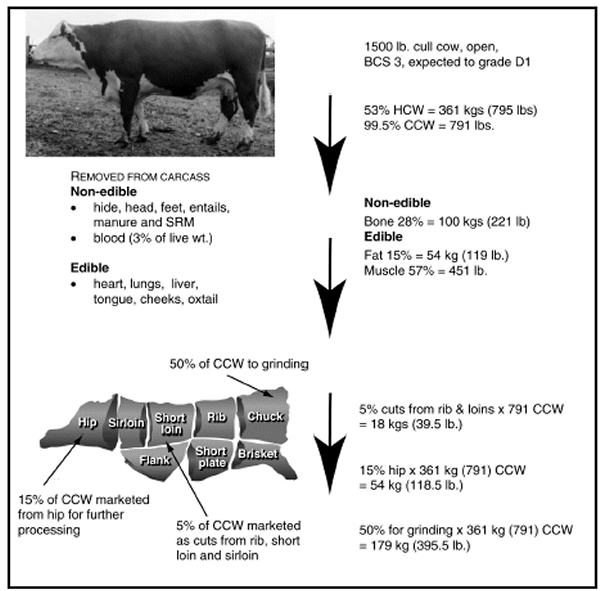

Products and estimated weights are shown in Figure 2.

Edible and non-edible products from cull cows

At slaughter the hide, head, feet, blood, entrails and their contents are removed from the cull cow carcass. A weight difference exists between beef and dairy cows for the udder, which is removed with the hide. Understandably, dairy cows have a much higher udder weight. Edible products from the removed components are the heart, liver, lungs, tongue, cheek and oxtail. Any animal deemed to be 30 months of age or greater must have Specified Risk Materials (SRM) removed from the carcass. SRM include the skull, brain, eyes, tonsils, spinal cord, and clusters of nerve cells connected to the spinal cord and part of the small intestines. SRM cannot be used in any by-products such as pet foods and must be disposed of.

Prior to and following slaughter qualified persons carry out health inspections. Carcasses that pass health inspection are chilled rapidly to ensure control of any pathogen loads. Hot carcass weights are recorded before cooling and after an overnight chilling cold carcass weights are recorded and carcasses graded if required. Carcasses are then fabricated by completely deboning.

Edible products with location derived from carcass:

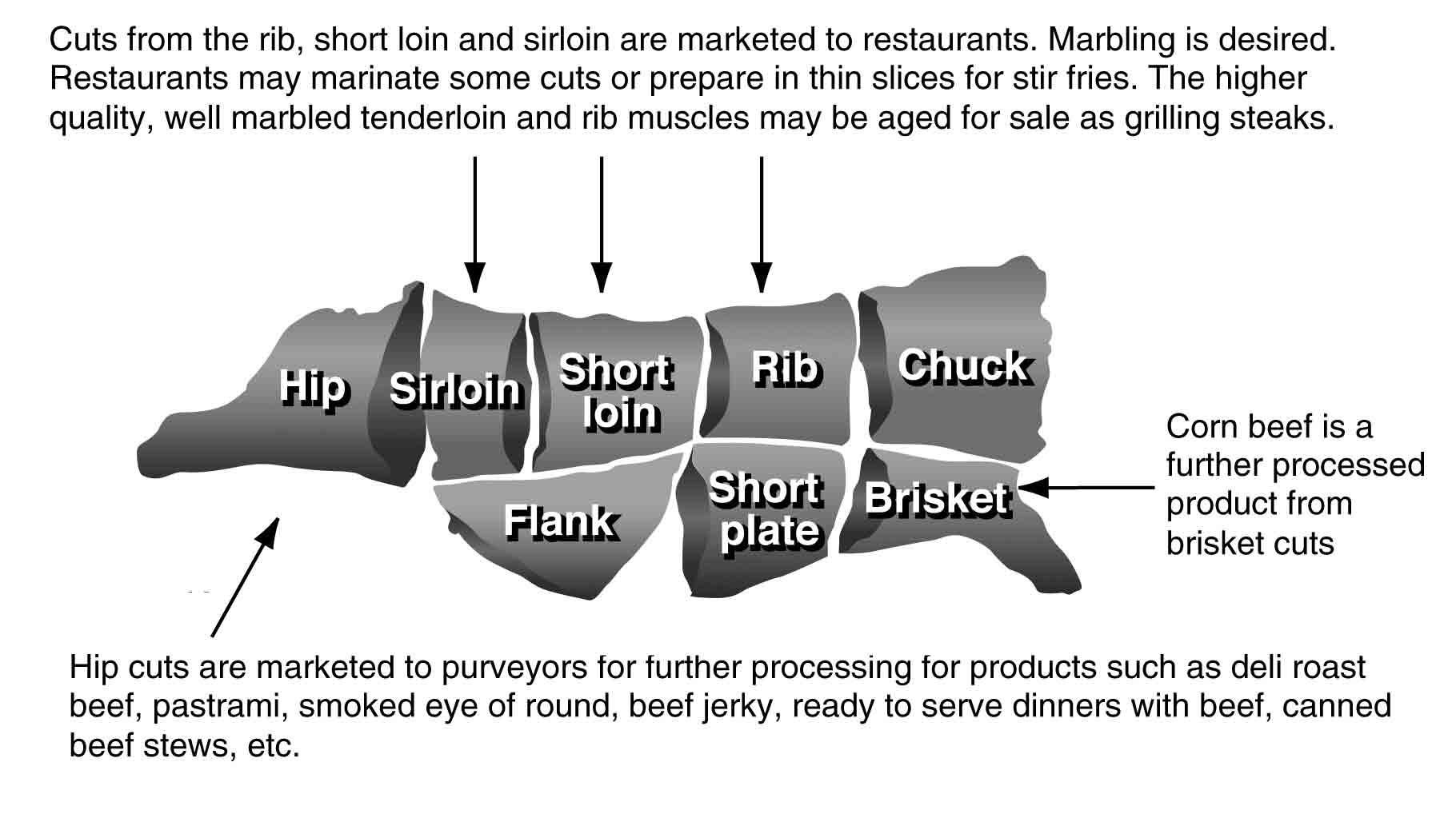

The majority of the carcass is sold as trimmings for grinding. Fat is included with trim as fat carcasses will be balanced out with lean carcasses. Most of this will be sold in products such as ground beef burgers, meat balls, meat loaf, taco filling, etc. (See Figure 3).

Carcass deficiencies

Carcass deficiencies can reduce the value of cull cow carcasses. Canadian National Beef Quality audits show injection site lesions, bruising and condemnations as contributing factors in reducing the value of carcasses.

- Injection site lesions continue to be at the top of the list resulting in economic losses to the industry. While the promotion of neck injections over the past 10 years has decreased the incidence of injection site lesions in finished cattle, this is not the case for cull cows. Lesion areas must be cut out of carcasses and discarded. This is not as important in cull cows as with finished cattle where higher valued cuts cannot be sold with holes in them. Deep muscle lesions are a big concern as they often reach the consumer undetected. Most consumers lose their appetite for beef when encountering these lesions.

- Bruising continues to result in losses to the beef industry. Bruised areas must be trimmed from carcasses. The larger the bruise the greater the weight trimmed. Bruising is more frequent in cull cows than finished cattle. One reason is that finished cattle tend to go directly from farm to packing plant and are therefore handled less than cull cows - that move from farm to sale barn then to slaughter. Cull cows also have less fat to cushion bumps in handling systems. To reduce bruising, it is essential to have well planned handling systems for moving and loading cattle. Cattle should also be transported according to accepted good handling practices.

- Condemnations of whole carcasses, heads and livers will be reduced in the future when regulation changes prevent downer animals from being delivered to slaughter facilities. In the past downer cows had a much higher frequency of condemnations. Cows with advanced cancer eye, lump jaw or other visible signs of abnormalities are presently not being accepted at some slaughter plants and bring virtually nothing if marketed through the live auction ring. The producer is advised to euthanize these animals on-farm. Carcasses with visible problems are condemned immediately. Suspect carcasses are tested and must be held from any further processing until test results are returned to determine condemnation status. Heads, livers or lungs could be condemned without the complete carcass being condemned.

Reasons for condemnations

Carcasses

- emaciation

- lymph gland cancer

- peritonitis

- pneumonia

- cancer eye

- edema

- arthritis

- blood poisoning

- bruising

- other cancers

- lameness

Summary

To achieve maximum returns when marketing cull cows, it is vital that producers have knowledge of cull cow body and carcass composition, and the edible and non-edible products that can be marketed from the carcass. Knowing weights, body condition and muscling, a producer can predict the value of saleable products from the cull cow carcass.

References

- Apple, J., Davis, J.C. and Stephenson, J. (1998) Arkansas Animal Science Department Report, Influence of Body Condition Scores on By-Product Yields and Value from Beef Cows

- Apple, J., Davis, J.C., Stephenson, J., Beaty, S. and Rakes L. (1998) Arkansas Animal Science Department Report, Influence of Body Condition Scores on Carcass Composition of Culled Beef Cows

- Canadian Cattlemen - Quality Starts Here, Canadian Beef Quality Audit, June 1996

- Canadian Food Inspection Agency - Specified Risk Materials

- Johnson, D. and Bryan, T. Cull Cow Value Determination

- O'Mara, F.M., Williams, S.E., Tatum, J.D., Hilton, G.G., Pringle, T.D. and Williams, F.L. Prediction of Slaughter Cow Composition Using Live Animal and Carcass Traits

This fact sheet was written by Don Blakely, former beef quality assurance program lead, OMAFRA.

Accessible image descriptions

Figure 2. Products and estimated weights of products derived from an example cull cow

1500 lb cull cow, open BCS 3, expected to grade D1

53% HCW = 361 kg (795 lb) 99.5% HCW = 791 lb

Non-edible:

- Bone 28% = 100 kg (221 lb)

Edible:

- Fat 15% = 54 kg (119 lb)

- Muscle 57% = 451 lb

Removed from carcass - non-edible:

- hide, head, feet, entails, manure and SRM

- blood (3% of live weight)

Removed from carcass - edible:

- heart, lungs, liver, tongue, cheeks, oxtail

Meat cuts:

- 50% of CCW to grinding

- 15% of CCW marketed from hip for further processing

- 5% of CCW marketed as cuts from rib, short loin and sirloin

- 5% cuts from rib & loin × 791 CCW = 18 kg (39.5 lb)

- 15% hip × 361 kg (791) CCW = 54 kg (118.5 lb)

- 50% for grinding × 361 kg (791) CCW = 179 kg (395.5 lb)

Figure 3. Retail meats cuts derived from wholesale cuts of a cull cow carcass

Cuts from the rib, short loin and sirloin are marketed to restaurants. Marbling is desired. Restaurants may marinate some cuts or prepare in thin slices for stir fries. The higher quality, well marbled tenderloin and rib muscles may be aged for sale as grilling steaks.

Corn beef is a further processed product from brisket cuts.

Hip cuts are marketed to purveyors for further processing for products such as deli roast beef, pastrami, smoked eye of round, beef jerky, ready to serve dinners with beef, canned beef stews.