Effect of greenhouse light abatement curtains

Learn how light abatement curtains can be used and their effect on the greenhouse environment. This technical information is for commercial greenhouse operators.

Introduction

Ontario greenhouse producers use supplemental lighting to:

- grow vegetables and fruits in winter

- boost production in the summer

- control flowering in ornamental and medicinal plants

They also use light abatement and blackout curtains to reduce night-time light emissions associated with supplemental lighting. This is in part in response to bylaws enacted by a number of municipalities across the province that regulate greenhouse light emissions.

“Managing nighttime greenhouse light emissions,” written by the Ministry of Agriculture, Food and Rural Affairs (OMAFRA), outlines some of the research conducted by research institutions in the province to study the amount of light emitted by Ontario greenhouses using supplemental lighting at nighttime.

It concludes that greenhouse light emissions were associated with:

- light intensity

- gapping of light abatement curtains

- the amount of vegetation in the growing space

It also recognized that the use of light management curtains can impact the climate in the greenhouse, which in turn can negatively impact plant growth and yield. Therefore, it was identified as important to research production practices and technologies that can address potential humidity and temperature concerns.

The information on this page details the results from recent research projects that investigated the effect of light abatement curtains on the greenhouse environment.

Research summary

- When light abatement curtains were deployed, air temperature stratification occurred between colder air in the attic above the curtains and warmer air below the curtains where plants are grown.

- A lighting strategy that adopts a long photoperiod (24 hours) with low light intensity sometimes resulted in less temperature fluctuations under light abatement curtains than a typical 16-hour lighting strategy.

- Light abatement curtains increased the greenhouse air temperature and plant temperature when supplemental lights were on and off.

- Using supplemental lighting with a typical 16-hour lighting strategy before sunrise rather than after sunset reduces the amount of time light abatement curtains are in use.

- Increases in temperature and humidity caused by growing with lights under light abatement curtains can be managed to reduce impacts on production by:

- gapping ceiling light abatement curtains to ventilate the greenhouse

- using through-curtain ceiling fans as shown in managing nighttime greenhouse light emissions

- employing a 24-hour, low-intensity lighting strategy

- shortening the amount of time light abatement curtains have to be used by lighting before sunrise rather than after sunset

Research is ongoing into how different greenhouse fans affect air circulation under light abatement curtains, the effect of gapping light abatement curtains on the greenhouse environment and crop physiology of plants grown under light abatement curtains.

What greenhouse curtains are and how they are used

Ceiling curtains are commonly used in greenhouses to:

- diffuse and scatter sunlight for more even distribution of light

- reduce sunlight intensity

- control the temperature within the greenhouse

Some of the primary uses for greenhouse curtains are light diffusion, energy conservation and shade.

Many curtains have multiple functions. For example, some curtains retain thermal energy at night and provide cooling shade to the crop during the day.

Greenhouse shade curtains are intended to allow a certain amount of sunlight through. Light abatement curtains are designed to prevent light from passing through the curtain. This keeps light produced by supplemental lighting fixtures from escaping the greenhouse. Light abatement curtains are mainly used to reduce light pollution when supplemental lights are on during nighttime hours.

Ceiling light abatement curtains span the gap between the walls above the crop production area. They act as a semi-permeable barrier between the lower portion of the greenhouse and the attic. Some light abatement curtains are specifically designed for sidewalls and endwalls of greenhouses. These wall light abatement curtains are placed vertically on greenhouse walls to reduce light emissions from the side of greenhouses (Figures 1 and 2). Wall light abatement curtains are typically heavier than ceiling light abatement curtains, but their light transmission and energy saving properties are similar, depending on the model.

Source: Gene Ingratta, Allegro Acres.

Source: Gene Ingratta, Allegro Acres.

Greenhouse light abatement curtains are made from an opaque material with reflective properties. They are composed of polyester, polyolefin or a mixture of the two.

These materials are resistant to:

- water

- wind

- light

- heat

They combine well with other fibers allowing them to be more easily modified to suit unique needs. Producers should verify that all their curtains are fire retardant and are installed and operated as per manufacturer's instructions.

When light abatement curtains are being installed in a greenhouse, they may have additional features like fastening strips, zippers or magnetic closures to minimize light leakage from gaps. They may be layered on top of other curtains to provide greater versatility according to the needs of the producer. Light abatement curtains are typically installed with an automated deployment system that is controlled by the greenhouse environment management computer system.

When they are fully deployed (100% closed), light abatement curtains can reduce light emissions by more than 99%. They also function as an energy or thermal curtain by reducing heat loss from the greenhouse to the nighttime environment by around 50%. Furthermore, the reflective surface facing the interior of the greenhouse reflects light emanating from supplemental lighting back to the crop, resulting in improved light use and therefore more energy savings. Light transmission and energy savings properties of ceiling and wall light abatement curtains vary depending on the model.

Effect of light abatement curtains on the greenhouse environment

Stratification of air temperature

Modeling was conducted by researchers at the University of Guelph to understand the potential effect of light abatement curtains on the greenhouse environment. They investigated potential differences that could occur between the air layers above and below fully deployed (100% closed) light abatement curtains. The model assumed 1.0 air changes per hour and the simultaneous use of a light abatement curtain and an energy curtain.

Fully deployed curtains created a barrier between the attic area above the curtains and the growing area below the curtains resulting in differences in air temperature and humidity. This climate heterogeneity within the greenhouse (variations in climate between the upper and lower portions of the interior) can lead to abnormal or inefficient growth.

During cold weather periods with curtains deployed, attic air can become much cooler overnight than air below the curtains in the growing area

The location of air vents in the greenhouse and the amount of gapping in the curtains will impact the degree and nature of air stratification. When curtains are deployed, roof air vents located above the curtains, which are typical in modern greenhouses built for high-wire vine crops, allowed mixing of the air layer above the curtains but not below the curtains. Conversely, in greenhouses with air vents located in walls below the curtains, it is possible to observe mixing of the lower air layer and not the layer above the curtains

Some modeling results were verified with a case study using air temperature data from a commercial vegetable greenhouse in southwestern Ontario. Similar to the model, this site also used an energy curtain and light abatement curtain simultaneously. As expected, stratification of air temperature developed when the curtains were fully deployed.

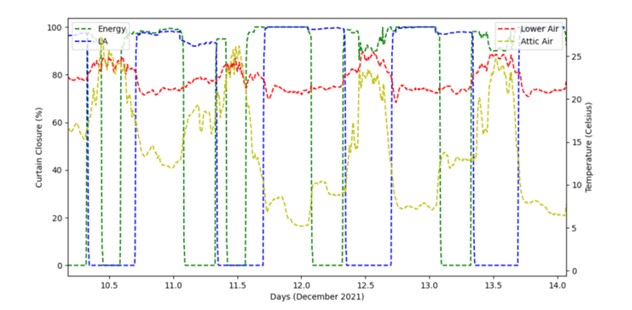

At night, warmer air was present in the growing environment below the curtains and cooler air was present in the attic above the curtains. The temperature of the air in the attic and the growing environment converged when the curtains were retracted (Figure 3). This air temperature stratification was more pronounced during months when curtains were used more frequently compared to those months when curtains were used less frequently

Source: A. Nauta, University of Guelph. 2022.

Increase in greenhouse air temperature and plant temperature

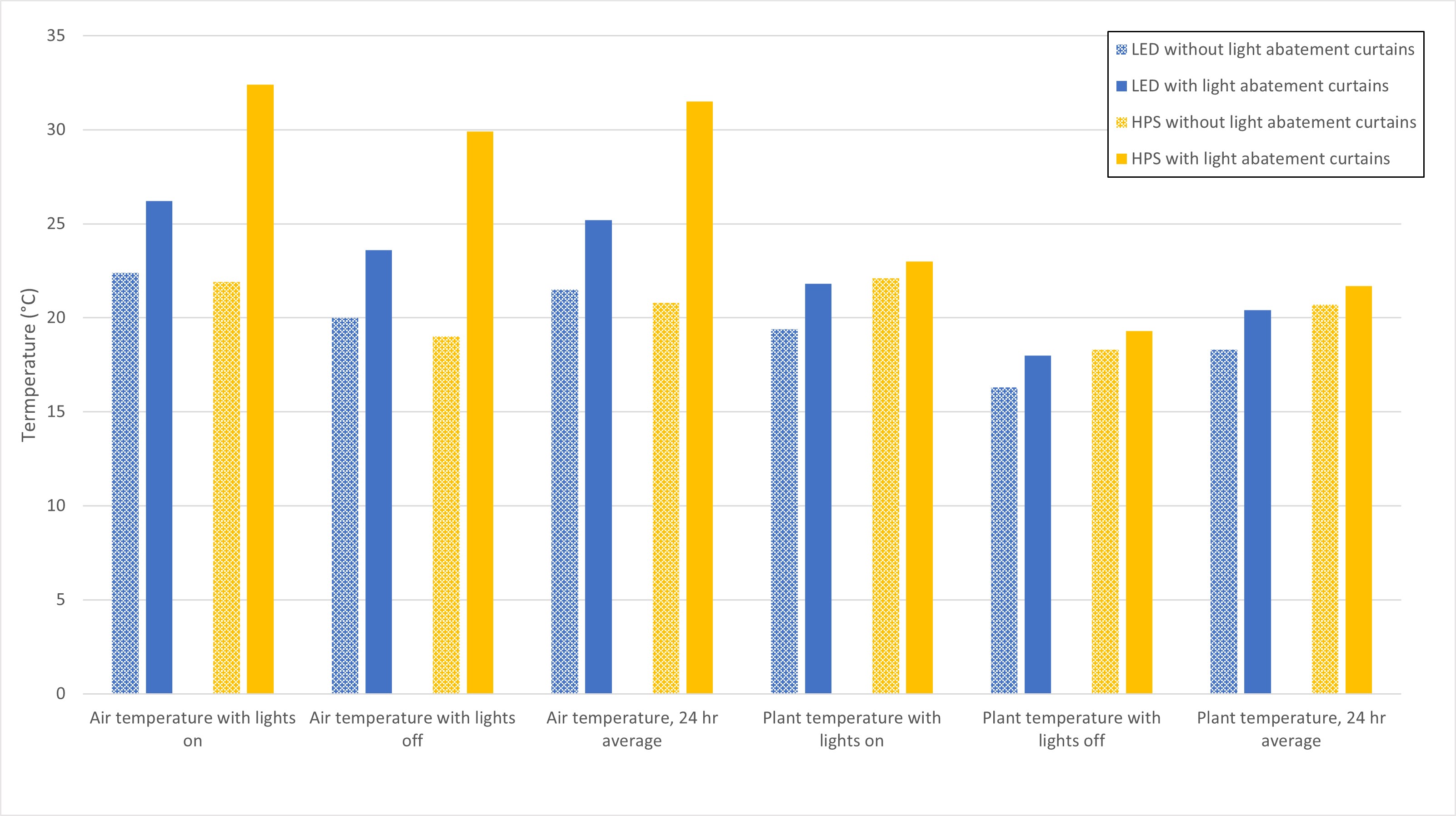

To investigate the effects of light abatement curtains on greenhouse air temperatures and plant temperatures, researchers at Agriculture and Agri-Food Canada’s Harrow Research and Development Centre (Harrow) used 4 mini-greenhouses (50 m2 each) outfitted with light abatement curtains to grow tomatoes in the winter of 2021–2022 (December 2021–April 2022):

- 2 mini-greenhouses had high pressure sodium (HPS) lights

- 2 had light-emitting diode (LED) lights

1 mini-greenhouse with HPS lights and 1 with LED lights used light abatement curtains. The other 2 mini-greenhouses did not use light abatement curtains. The light abatement curtains were fully deployed when the lights were on between 2:00 a.m. and 6:00 p.m.

Increases in air temperature were observed under both HPS and LED lights when light abatement curtains were deployed. As expected, this increase in air temperature was more pronounced under HPS lights as compared to LED lights.

The temperature of the tomato plants was also higher when grown under light abatement curtains as compared to plants that were not grown under light abatement curtains. This increase in plant temperature was observed under both HPS and LED lights.

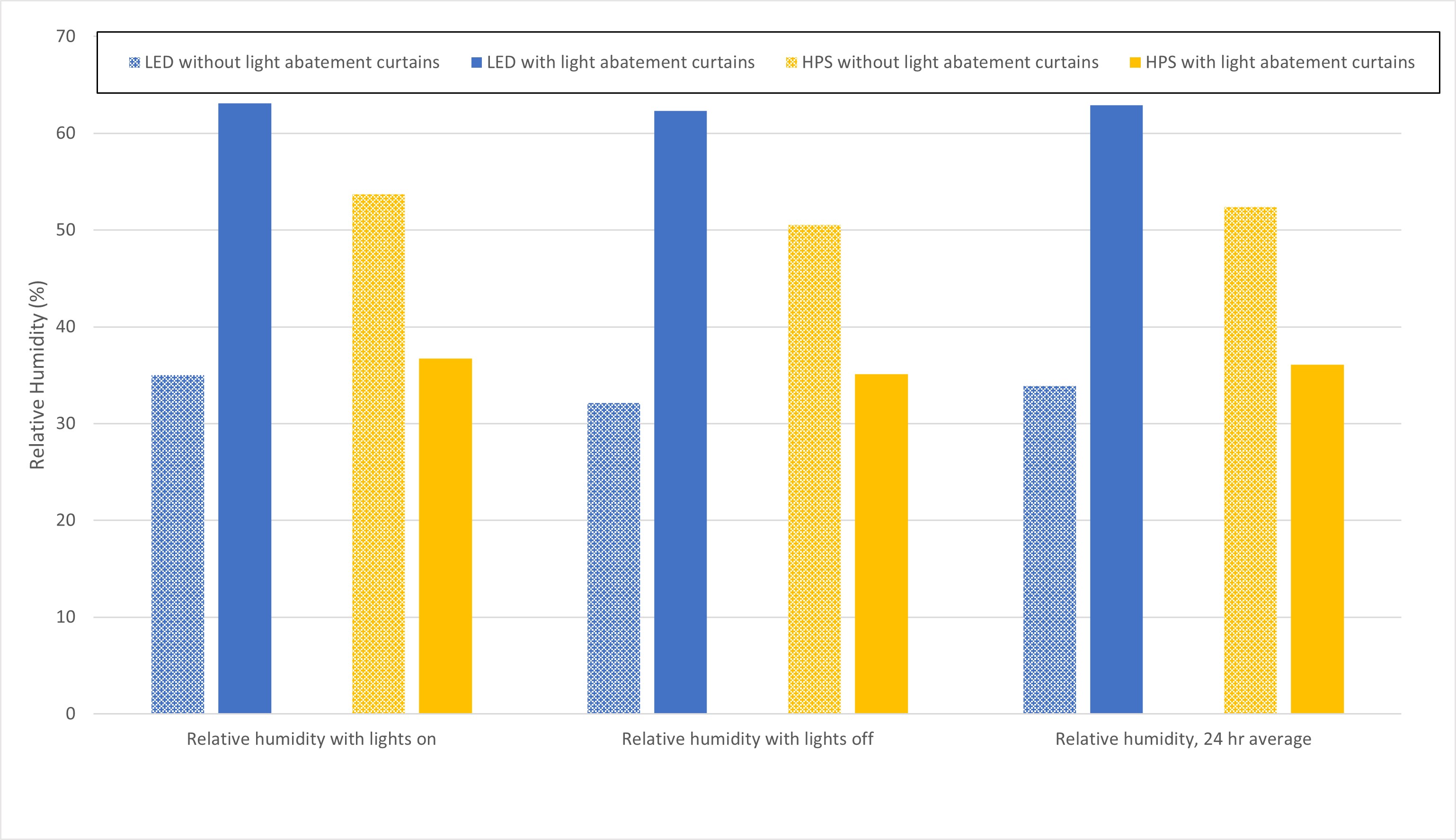

The increase in air and plant temperatures under LED lights and light abatement curtains was accompanied by higher levels of relative humidity, whereas under HPS lights and light abatement curtains there was a drop in relative humidity levels (Figures 4 and 5)

Source: Q. Digweed, Canadian Greenhouse Conference, 2022.

Source: Q. Digweed, Canadian Greenhouse Conference, 2022.

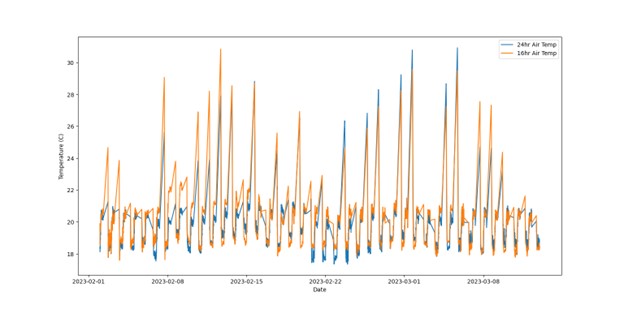

Between December 2022 and May 2023, another experiment was conducted in Harrow, where 2 mini-greenhouses with LED lights and light abatement curtains used different lighting strategies. One mini-greenhouse had a typical 16-hour lighting strategy (2:00 a.m. to 6:00 p.m. with 250 µmol per m2 per second) and the other had a long photoperiod (24-hour) low intensity lighting strategy (2:00 a.m. to 6:00 p.m. with 200 µmol per m2 per second and 6:00 p.m. to 2:00 a.m. with 100 µmol per m2 per second). The daily light integral (DLI) in both mini-greenhouses was equal (14.4 mol per m2 per day), and the light abatement curtains were fully deployed between sunset and sunrise for both lighting treatments. There were fluctuations in air temperature under both treatments between warmer daytime temperatures and colder nighttime temperatures, but the fluctuations under the longer photoperiod low intensity lighting strategy was less pronounced during some days (Figure 6). The yield of the tomato plants grown in both greenhouses were similar

Source: Q. Digweed and S. Sawan, Proceedings of 2023 Engineering to Adapt Symposium, 2023.

Lighting before sunrise reduced use of light abatement curtains

Most vegetable greenhouses in Ontario use supplemental lighting between 2:00 a.m. and 6:00 p.m. during winter production, but some producers prefer to extend the daylength after sunset rather than before sunrise.

Researchers in Harrow used sunrise and sunset data for southwestern Ontario to find out if extending the day — by lighting before sunrise or after sunset — affected the length of time that producers need to:

- deploy their light abatement curtains

- manage the changes in the greenhouse environment caused by the curtains

Researchers calculated how long light abatement curtains would be deployed under each scenario. It was assumed that:

- light abatement curtains would be deployed only when lights were on between sunset and sunrise

- that lights were on from 2:00 a.m. to 6:00 p.m. in the “before sunrise” scenario and 8:00 a.m. to midnight for the “after sunset” scenario using a typical 16-hour photoperiod

The length of time that light abatement curtains would be deployed was calculated for each month between October 2022 and March 2023.

It was found that using supplemental lighting before sunrise reduced the amount of time that light abatement curtains would be used in each month.

The biggest difference was observed in December when using supplemental lighting before sunrise resulted in light abatement curtains being deployed 1 hour and 25 minutes less than using supplemental lighting after sunset.

When the researchers looked at the outside temperature for the same period of time under the two lighting scenarios, it was found that there was a greater difference in temperature between the greenhouse environment (assumed to be 21°C) and the temperature outside the greenhouse before sunrise as compared to after sunset.

This temperature gradient suggests it would be easier for producers to reduce the heat buildup in their greenhouses under light abatement curtains if they use supplemental lighting before sunrise rather than after sunset (Table 1)

| Month and year | Average sunrise time (a.m.) | Average sunset time (p.m.) | Length of time light abatement curtains deployed (lights on 8:00 a.m. to midnight) | Length of time light abatement curtains deployed (lights on 2:00 a.m. to 6:00 p.m.) | Average outdoor air temp when light abatement curtains deployed (°C) (lights on 8:00 a.m. to midnight) | Average outdoor air temp when light abatement curtains deployed (°C) (lights on 2:00 a.m. to 6:00 p.m.) | Average temperature difference between outside and inside the greenhouse (assumed to be 21°C inside, lights on 8:00 a.m. to midnight) | Temperature difference between outside and inside the greenhouse (lights on 2:00 a.m. to 6:00 p.m.) |

|---|---|---|---|---|---|---|---|---|

| October 2022 | 6:56 | 7:20 | 4 hours, 40 minutes | 4 hours, 56 minutes | 14.1 | 12.9 | 6.9 | 8.1 |

| November 2022 | 6:20 | 6:30 | 5 hours, 30 minutes | 4 hours, 20 minutes | 4.4 | 2.7 | 16.6 | 18.3 |

| December 2022 | 6:35 | 6:00 | 6 hours, 0 minutes | 4 hours, 35 minutes | 2.8 | 1.9 | 18.2 | 19.1 |

| January 2023 | 6:45 | 6:10 | 5 hours, 50 minutes | 4 hours, 45 minutes | -6.0 | -7.0 | 27.0 | 28.0 |

| February 2023 | 6:30 | 6:30 | 5 hours, 30 minutes | 4 hours, 30 minutes | -2.7 | -4.0 | 23.7 | 25.0 |

| March 2023 | 6:50 | 7:30 | 4 hours, 30 minutes | 4 hours, 50 minutes | 2.4 | 0.7 | 18.6 | 20.3 |

Note: This assumed that light abatement curtains were only used when lights were on between sunset and sunrise.

References

Advancing Cultivation Technology Summit. 2021. Greenhouse Light Abatement By-Laws: Now What?

Digweed Q. 2022. Lighting and Abatement. Presentation at the 2022 Canadian Greenhouse Conference.

Digweed Q and Sawan S. 2023. Impact of Phase Change Material on Greenhouse Energy Balance Under Light Abatement Curtains. Proceedings of 2023 Engineering to Adapt Symposium. Windsor, Ontario, Canada. June 22-23, 2023.

Hohenstein J.A. 2021. Light Abatement Bylaws in Effect – Now What? Greenhouse Canada.

Footnotes

- footnote[1] Back to paragraph Nauta A. 2022. Development of a New Dynamic Energy Model for Commercial and Small-scale Greenhouses: Validation and Practical Applications. Master of Applied Science in Engineering Thesis. University of Guelph.

- footnote[2] Back to paragraph Nauta A. et al. 2023. Performance Evaluation of a Commercial Greenhouse in Canada Using Dehumidification Technologies and LED Lighting: A Modeling Study. Energies.16(3):1015.

- footnote[3] Back to paragraph Digweed Q. 2022. Lighting and Abatement. Presentation at the 2022 Canadian Greenhouse Conference.

- footnote[4] Back to paragraph Digweed Q and Sawan S. 2023. Impact of Phase Change Material on Greenhouse Energy Balance Under Light Abatement Curtains. Proceedings of 2023 Engineering to Adapt Symposium. Windsor, Ontario, Canada. June 22-23, 2023.