Electricity generation using small wind turbines for home or farm use

Learn about the basics of small wind systems: site selection, system choice, technical considerations and approval requirements. This technical information is for Ontario rural landowners.

ISSN 1198-712X, Published January 2018

Introduction

This fact sheet provides information about the basics of small wind systems: site selection, system choice, technical considerations and approval requirements.

Using small wind turbines to generate energy:

- takes up little land (landowners can continue to crop while harvesting the wind energy)

- uses a local, renewable resource

- reduces carbon emissions

Landowners often choose to use small wind power based on a combination of economic incentives, being located in an area with a strong local wind resource and interest in generating their own electricity.

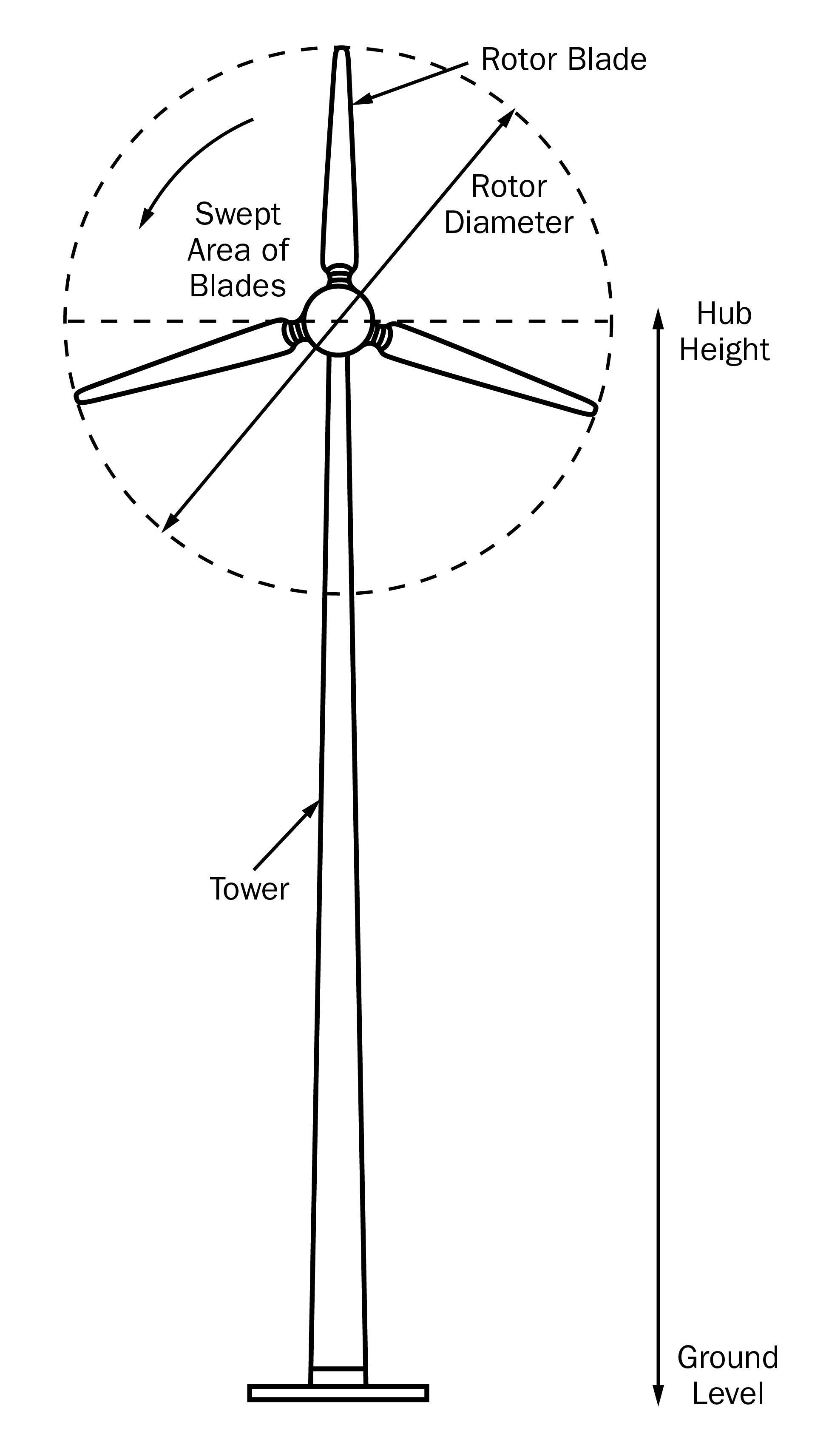

A small wind turbine (Figure 1) is a turbine that produces no more than 50 kilowatt (kW) of electricity. Some jurisdictions define “small” wind turbines as producing up to 100 kW. They are designed for use in homes, farms and small businesses, either as a source of back-up electricity or to offset the use of the electrical power grid, resulting in reduced electricity bills. The blades rotate at an average speed of 175–500 revolutions per minute (rpm) with some going as high as 1,150 RPM.

Source: Anton Schoenberger, Ontario Wind Smith.

Micro wind turbines (<1 kW) are used to charge batteries in recreational vehicles (e.g., motorhomes, sailboats), electric fencing and water irrigation systems. The majority of systems have lifespans of 10–15 years and come with a 5-year warranty. Micro wind turbines can be purchased from retail stores or online.

A small wind turbine can be a practical and economical source of electricity for the home or farm in the following situations:

- the property has a good wind resource

- the turbine height is greater than 18.2 m (60 ft)

- the turbine is certified by the Small Wind Certification Council or a Canadian equivalent

- the property does not have easy access to utility lines (i.e., off the electrical power grid)

- the investor is comfortable with making long-term investments and has an interest in reducing electricity bills

Wind availability

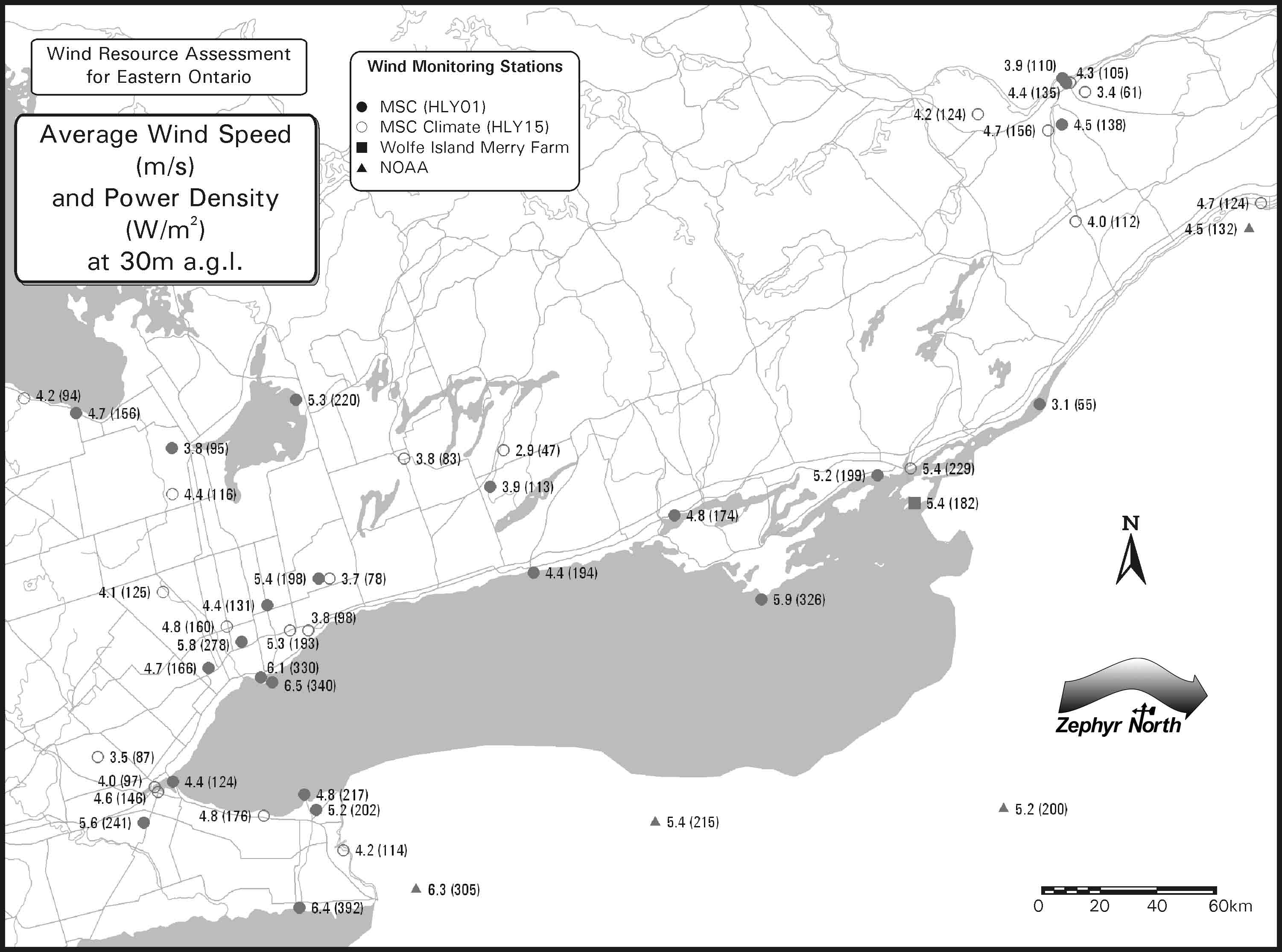

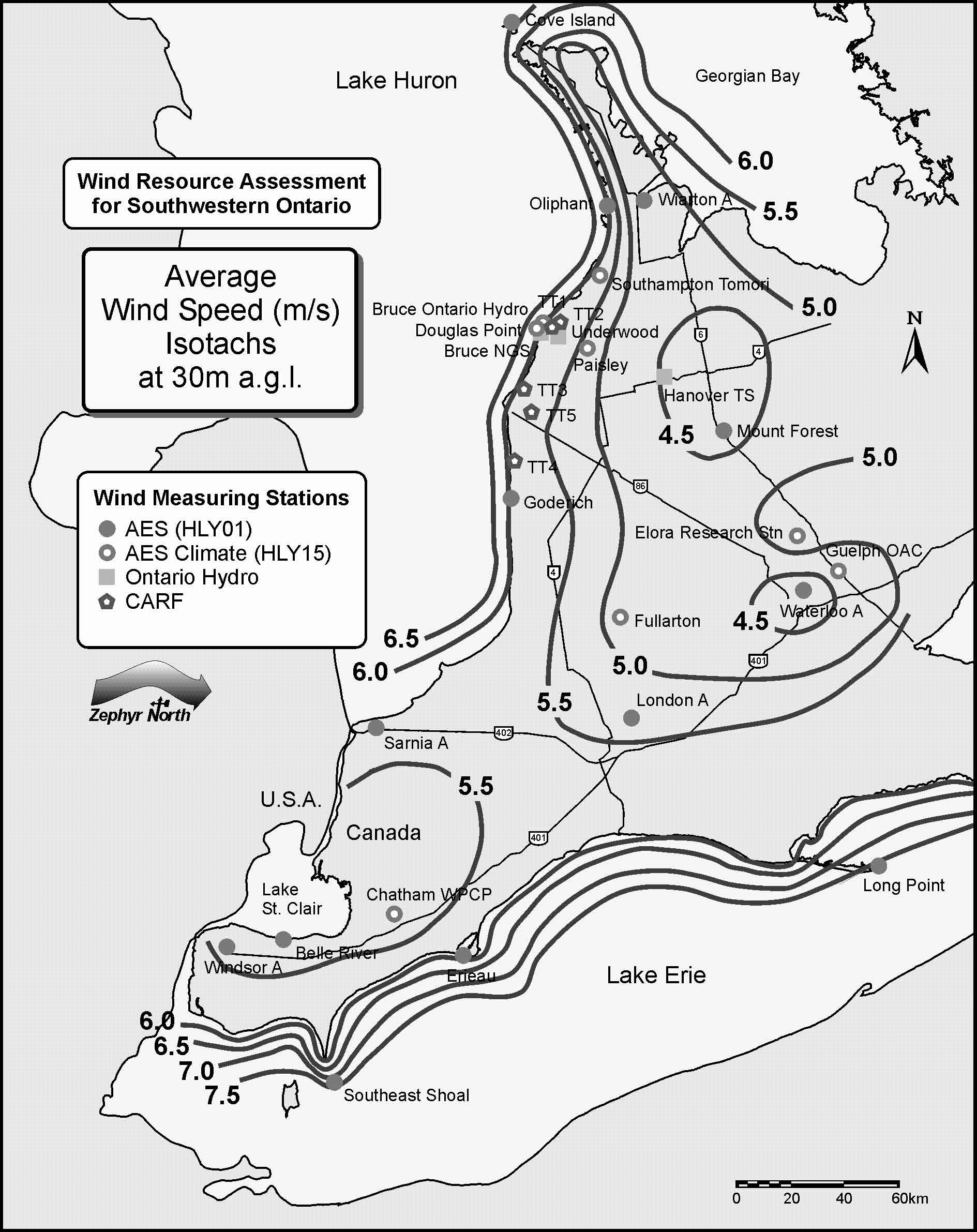

The quality of the local wind conditions is a significant factor in determining if a turbine will be economically viable for the home or farm. Average annual wind speeds of at least 4.0–4.5 m/s or 14.4–16.2 km/h (9.0–10.2 mph) are needed for a small wind turbine to operate at optimal power output levels. A useful resource for evaluating a site for its potential wind energy is a wind map (Figures 2 and 3).

Source: Wind Resource Assessment in Eastern Ontario from CANMET, Natural Resources Canada.

Source: Wind Resource Assessment in Southwestern Ontario from CANMET, Natural Resources Canada.

The Canadian Wind Energy Atlas (CWEA) is available online through an interactive wind map that produces wind speed data for a site with 200-m (656-ft) resolution. Another source of wind information is Ontario’s Renewable Energy Atlas.

The atlas is an interactive web application providing users with the ability to create and view custom maps of wind speed and wind power density and zoom into a location to look at wind speeds at different heights.

It is useful to check wind speed measurements that have been recorded at a local weather station, as they provide a baseline of wind speed information for the area. Remember to consider the influence of siting factors at these weather stations (e.g., nearby trees and buildings), as they can influence measured wind data.

For the most precise evaluation of wind speed, a wind resource evaluation system is recommended. While wind resource evaluation systems can be expensive, if the property is hilly and has unusual terrain features, the evaluation system will make it easier to record precise data for the desired site.

No matter what measurement system is used for a small wind turbine, record data for a minimum of 1 year and compare it with another source of wind data. It is very important that the measurement equipment is set high enough to avoid turbulence created by trees, buildings or other obstructions. Readings are most useful if they are taken at hub height (i.e., the elevation at the top of the tower where the wind turbine is going to be installed) (Figure 4).

If there is a small wind turbine system in the area, it is possible to save time and effort by requesting information from the owners about the annual electrical output of the system and wind speed data. This information is extremely valuable as an alternative to installing a wind resource evaluation system.

Understanding wind turbine costs

A wind turbine costs, on average, C$8,000–C$11,000/kW (US$6,000–US$8,200/kW) to install. So, a turbine that can generate 10 kW can cost between C$80,000 and C$110,000.

However, the system costs can be 50% higher or more, due to site conditions, remote location, interconnections costs, permits and fees. The cost of wind power, unlike other sources of electrical power, is almost entirely due to the cost of purchasing and installing the system. Once the turbine is installed, there is no fuel cost associated with its operation — only the cost of maintaining the wind turbine.

To make or save money

Generating electricity from renewable resources to offset electricity use or provide a source of power for off-grid applications can provide savings benefits, if the overall cost to produce the electricity is less than the cost of electricity from other sources. Self-generated electricity can either be entirely consumed by the property owner or exported to a local distribution grid for credit on the property owner’s power bill under a net metering arrangement with an electricity distributor.

Net metering

Under a net metering arrangement, an electricity customer, such as a property owner or business, can generate electricity from a renewable source for their own use while still drawing electricity from the local distribution grid when needed. Net-metered customers receive credits on their electricity bill when they send their excess electricity to the grid at times when they generate more electricity than they consume.

Each billing period, the electricity distributor will credit the bill for the value of the electricity supplied to the grid, applying the credit to offset the value of the electricity used from the grid. If the value of the electricity supplied to the grid is greater than the value of the electricity used, a credit will appear on the bill that can be carried over to the next billing period (for a period of up to 12 months).

The electricity bill will be calculated based on the difference between the dollar value of electricity consumed from the grid and the dollar value of the electricity sent to the grid from the renewable energy system. The customer is responsible for the fixed portions of the bill to maintain access to a reliable power source from the grid.

These dollar values are calculated on the basis of “per unit of electricity” rates ($/kilowatt-hour or $/kilowatt) applicable to the customer class. Fixed charges ($/month) are not included in the calculation and are therefore not affected by net metering.

As of July 1, 2017, any size renewable generation system may be eligible for net metering, subject to the electricity generated being for the property owner’s own use and available connection capacity on the local distribution system. Energy storage equipment can also be paired with eligible net metered generation facilities to potentially enhance technical capabilities, such as back-up power or shifting a customer’s electricity demand.

Electrical grid capacity constraints in some parts of the province limit the amount of generation (including net metering systems) that can be connected to a local distribution system. Contact your local electricity distributor to find out more information about net metering opportunities and connecting a renewable generation system. To find an electricity distributor, visit the Independent Electricity System Operator (IESO) website.

Approvals for small wind turbine systems

Renewable energy projects can be subject to a variety of approvals and permits, depending on project type and size. Before proceeding, be sure that the project meets all regulatory requirements.

The Renewable Energy Approval (REA) is an approval process administered by the Ontario Ministry of the Environment and Climate Change (MOECC) that applies province-wide standards, transparency and mandatory public, indigenous and municipal consultation to most large wind, solar and bioenergy projects developed in Ontario. The REA regulation (O. Reg. 359/09) provides clear, consistent rules and standardized technical requirements to protect human health and the environment.

Small wind projects less than or equal to 3 kW do not require an REA, however, an REA may be required for wind projects larger than 3 kW. The REA process provides streamlined requirements for small wind energy projects larger than 3 kW but less than 50 kW. More information on Renewable Energy Approvals requirements is available.

Inspection by the Electrical Safety Authority (ESA) is required for all systems that generate electricity. Check their website for information on Renewable Generation Safety.

If connecting to the Ontario electricity grid, contact the local electricity distributor for more information on grid connection requirements.

Depending on the location and nature of the project, there may be other approvals, permits and/or authorizations required from other ministries and approving bodies. Municipal building permits may be required. Check with the local municipal building/zoning department for more information on building permit /zoning requirements.

For more information on renewable energy project approvals, contact the Ontario Ministry of Energy’s Renewable Energy Facilitation Office (REFO) at

Choosing a wind turbine system

This section provides information on system components, electrical requirements, choosing a manufacturer, understanding system performance, choosing the right size of turbine and locating the turbine.

Components of wind energy systems

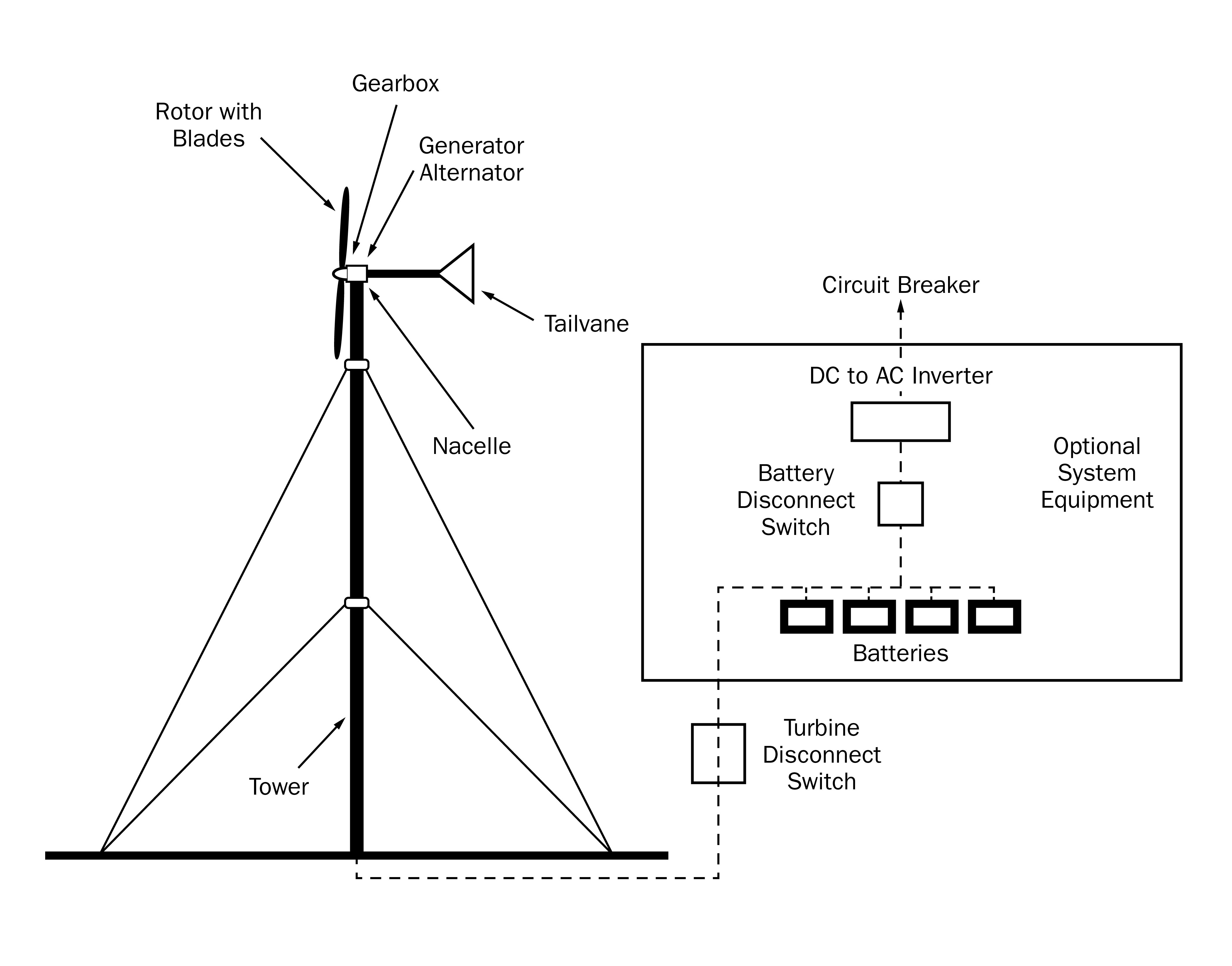

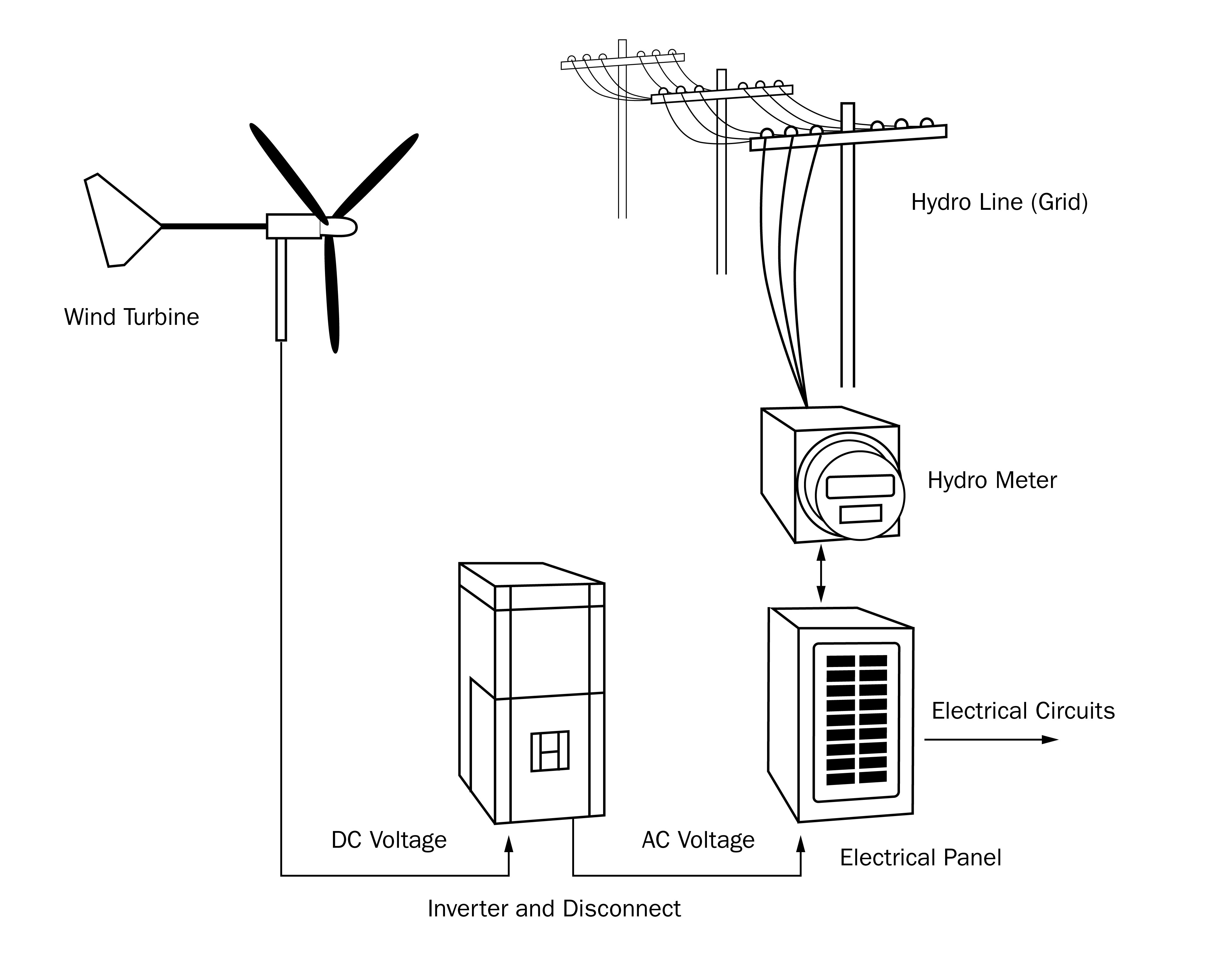

The basic components of a wind energy system are shown in Figure 5 and include:

- A rotor consisting of blades with aerodynamic surfaces. When the wind blows over the blades, the rotor captures the kinetic energy of the wind and starts to turn, converting the kinetic energy into motion. This motion causes the generator or alternator in the turbine to rotate and produce electricity.

- A gearbox that matches the rotor speed to that of the generator/alternator. The smallest turbines (e.g., smaller than 10 kW) usually do not require a gearbox.

- An enclosure (or nacelle) that protects the gearbox, generator and other components of the turbine from the elements.

- A tailvane (or yaw system) that aligns the turbine with the wind.

Source: Stand-Alone Wind Energy Systems, Natural Resources Canada.

There are two basic types of wind turbines (Figure 6):

- Horizontal-axis wind turbines are the most common wind turbine. They must be aimed directly at the wind. They come with a tailvane that will continuously point them in the direction of the wind.

- Vertical-axis turbines work in whatever direction the wind is blowing but require a lot more ground space to support their guy wires than horizontal axis wind turbines.

A horizontal-axis wind turbine will need a tower on which to mount the turbine. The tower raises the turbine to an altitude with higher wind speeds. It also places the turbine above any turbulence that may exist from obstructions such as houses, trees and hills.

Vertical-axis turbines are usually built on the ground.

Several types of towers are available:

- Guyed lattice towers are permanently supported by guy wires (e.g., a radio broadcast tower). These towers tend to be the least expensive but take up a lot of space in a yard.

- Guyed tilt-up towers can be raised and lowered for easy maintenance and repair or protection from extremely high wind speeds (e.g., hurricanes, tornadoes).

- Self-supporting towers do not have guy wires. These towers tend to be the heaviest and most expensive, but they do not take up as much space in a yard.

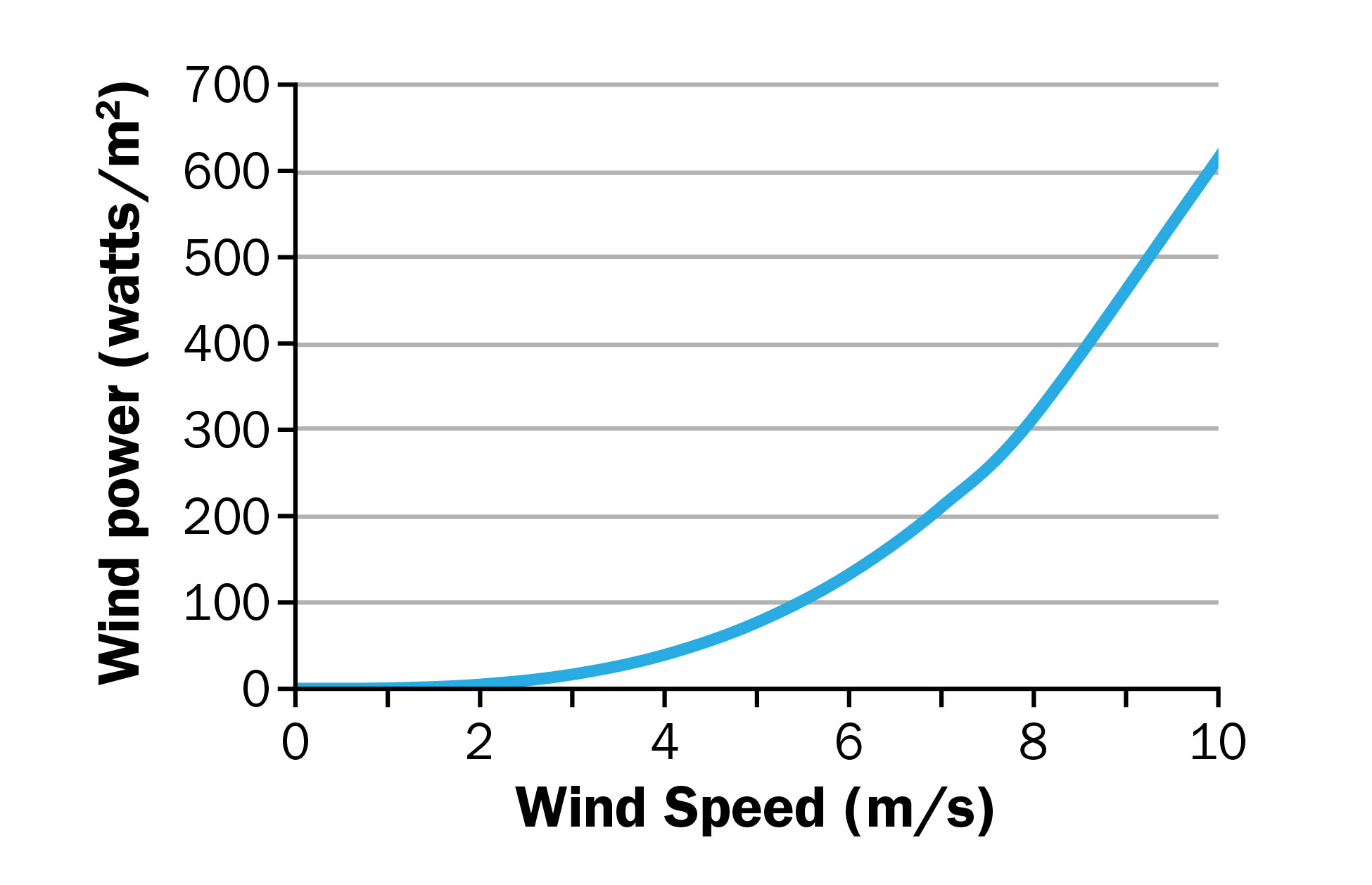

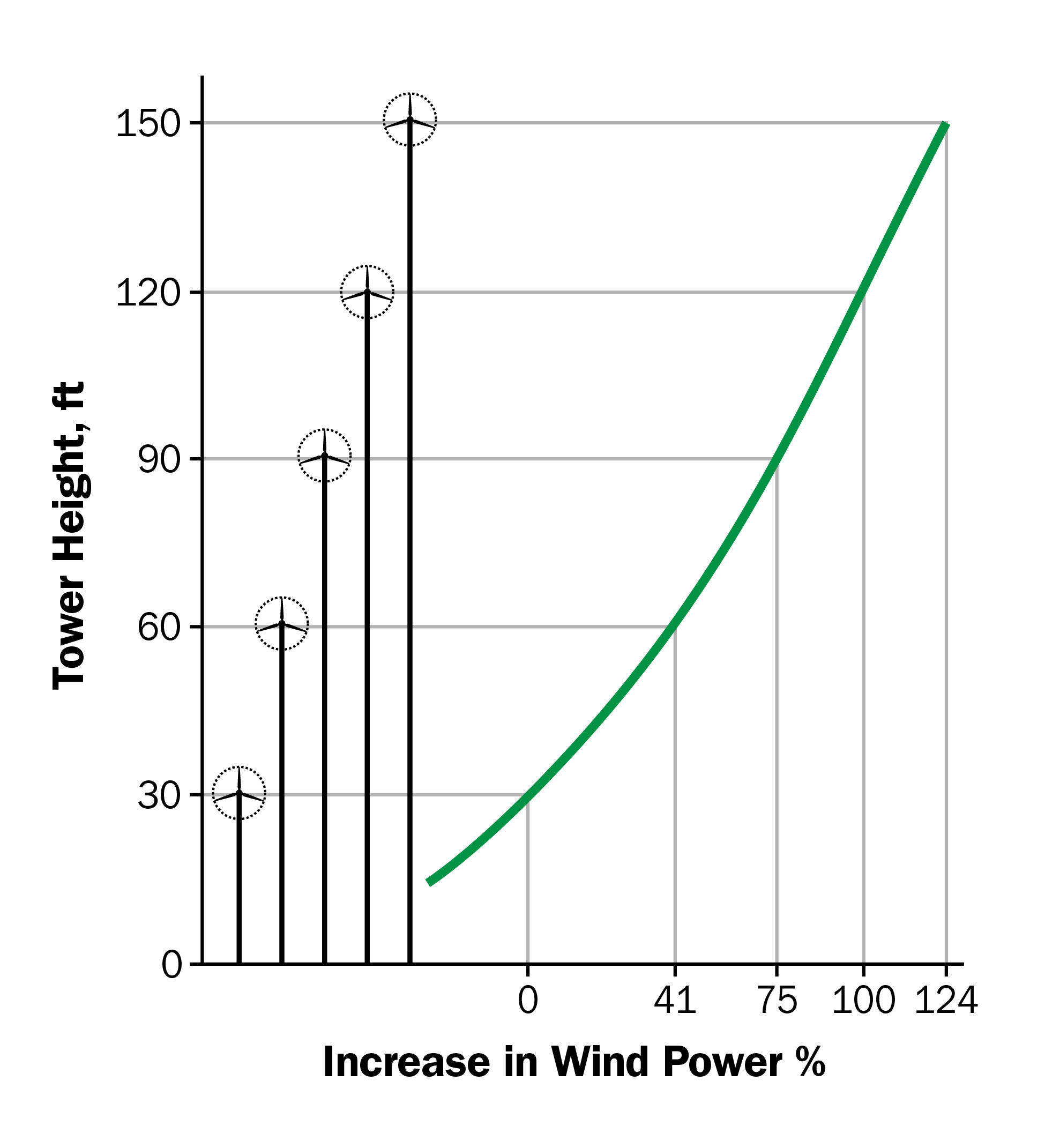

Since wind speed increases with height, increasing the tower height can mean enormous gains in the amount of electricity generated by a wind turbine (Figure 7). The power available in the wind is proportional to the cube of its speed. This means that if wind speed doubles, the power available to the wind generator increases by a factor of 8 (2 x 2 x 2 = 8) (Figure 8).

Source: Small Wind Electric Systems — A U.S. Consumer’s Guide.

Ideal tower height is typically between 24–37 m (60–120 ft) high. Installing a wind turbine on a tower that is too short is like installing a solar panel in a shady area. At a minimum, mount a wind turbine high enough on a tower that the tips of the rotor blades remain at least 9 m (30 ft) above any obstacle within a horizontal distance of 90 m (300 ft).

Choosing a certified manufacturer

Certification by manufacturers enables consumers to compare turbines and be assured that they meet minimum performance and safety standards.

To become certified, small wind turbines are tested for:

- power curve

- annual energy performance curve

- sound pressure levels

- strength and safety test (pass/fail)

- duration test (pass/fail)

Several independent certification bodies verify that small wind turbines meet or exceed the performance standards, durability and safety requirements of the American Wind Energy Association (AWEA) Small Wind Turbine Performance and Safety Standard 9.1 – 2009, or equivalent Canadian standard. These include the Small Wind Certification Council, Intertek and the Wind Energy Institute of Canada.

Understanding wind turbine system performance

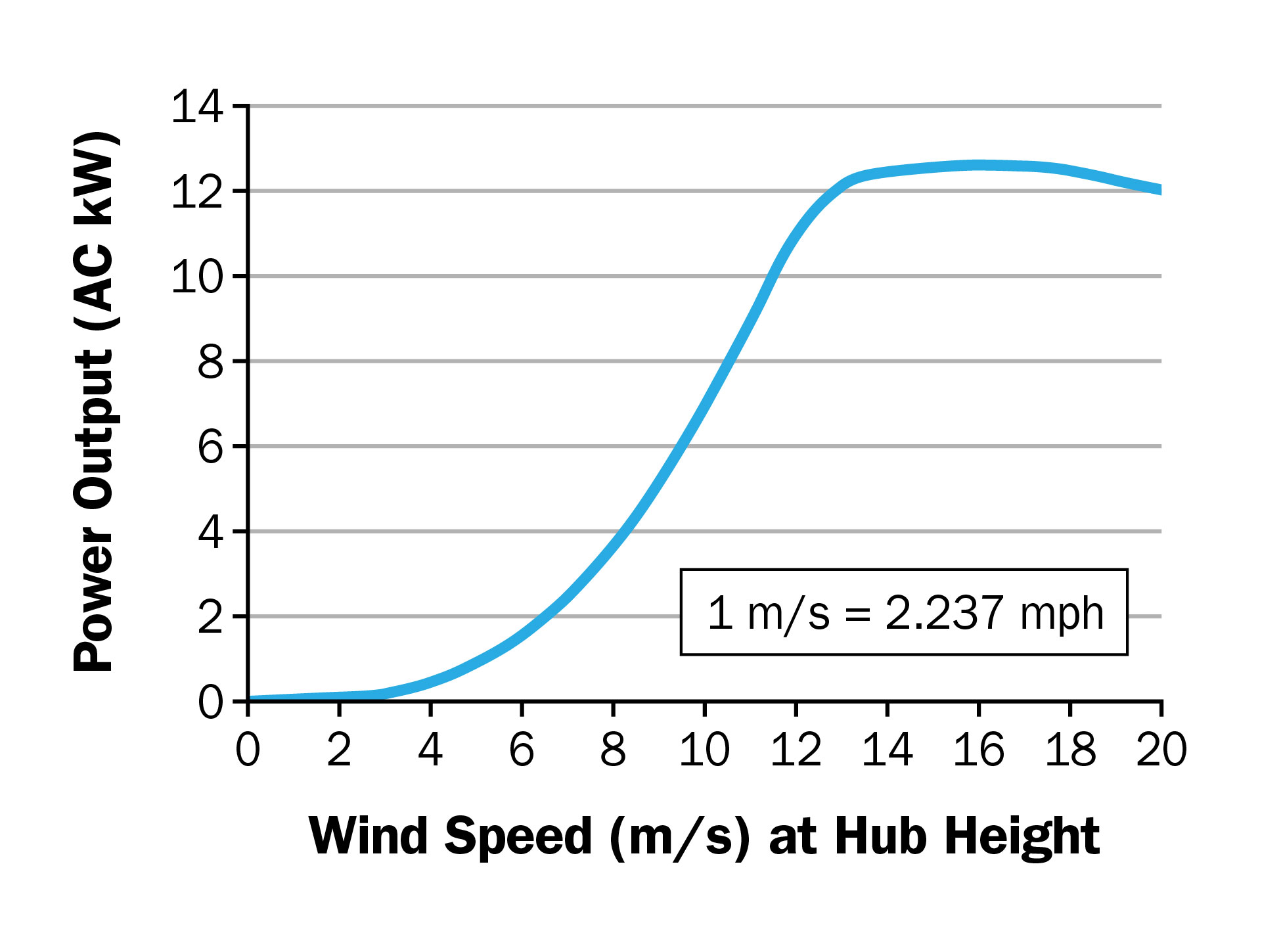

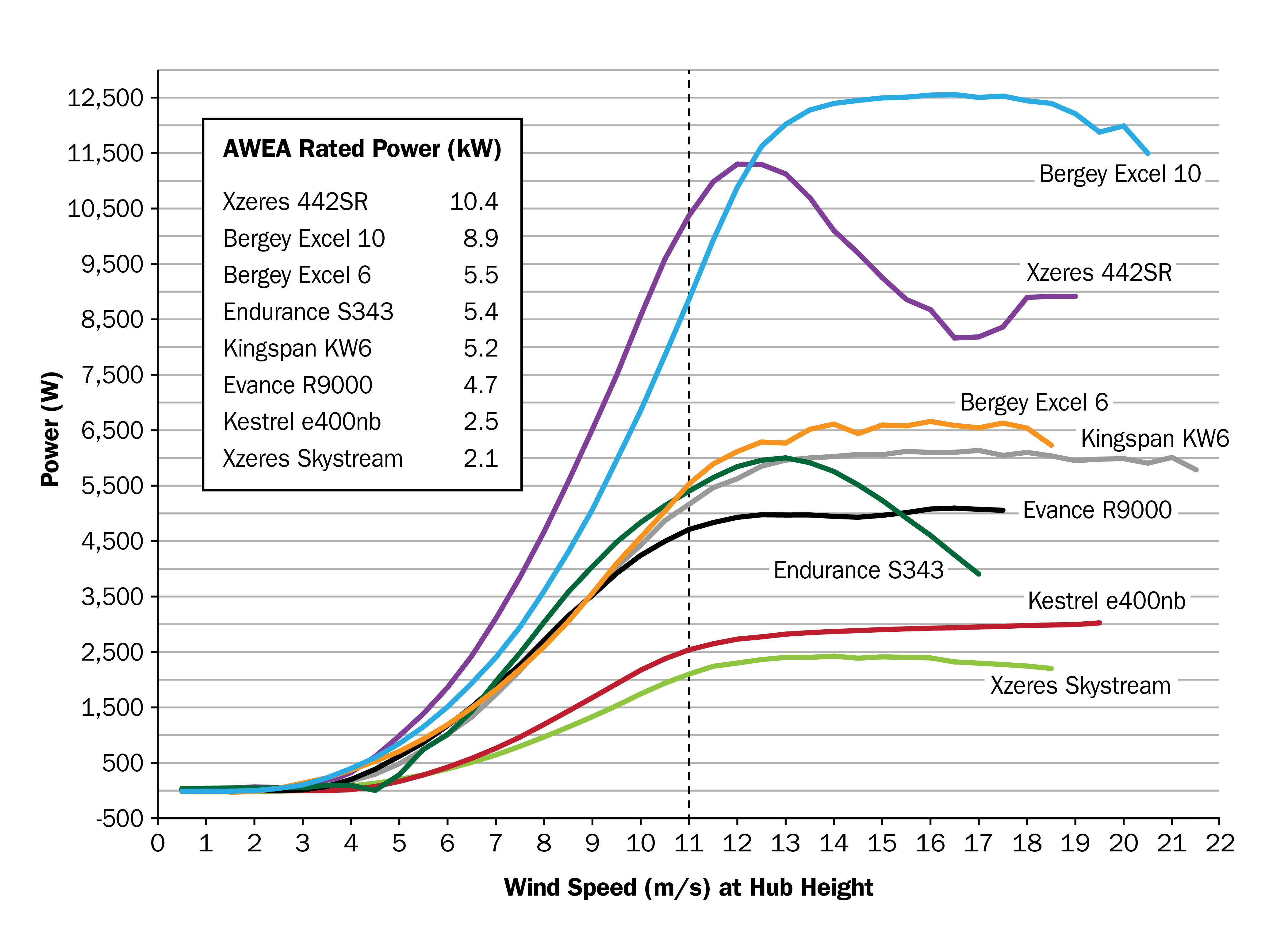

The performance of a wind turbine is normally described using a performance curve of power output versus wind speed, called a power curve (Figure 9).

Source: Bergey Windpower.

Various websites will give a cost and power output estimate for a certain size of wind turbine. Estimators provide an idea of how much power will be generated and how much potential power could be sold back to the grid. From these calculations, an estimate of the payback period, along with the proper size of wind turbine required, can be determined.

RETScreen International is free software from Natural Resources Canada that provides an evaluation of energy production, savings, cost, greenhouse gas emission reduction potential and the financial viability of installing a wind turbine.

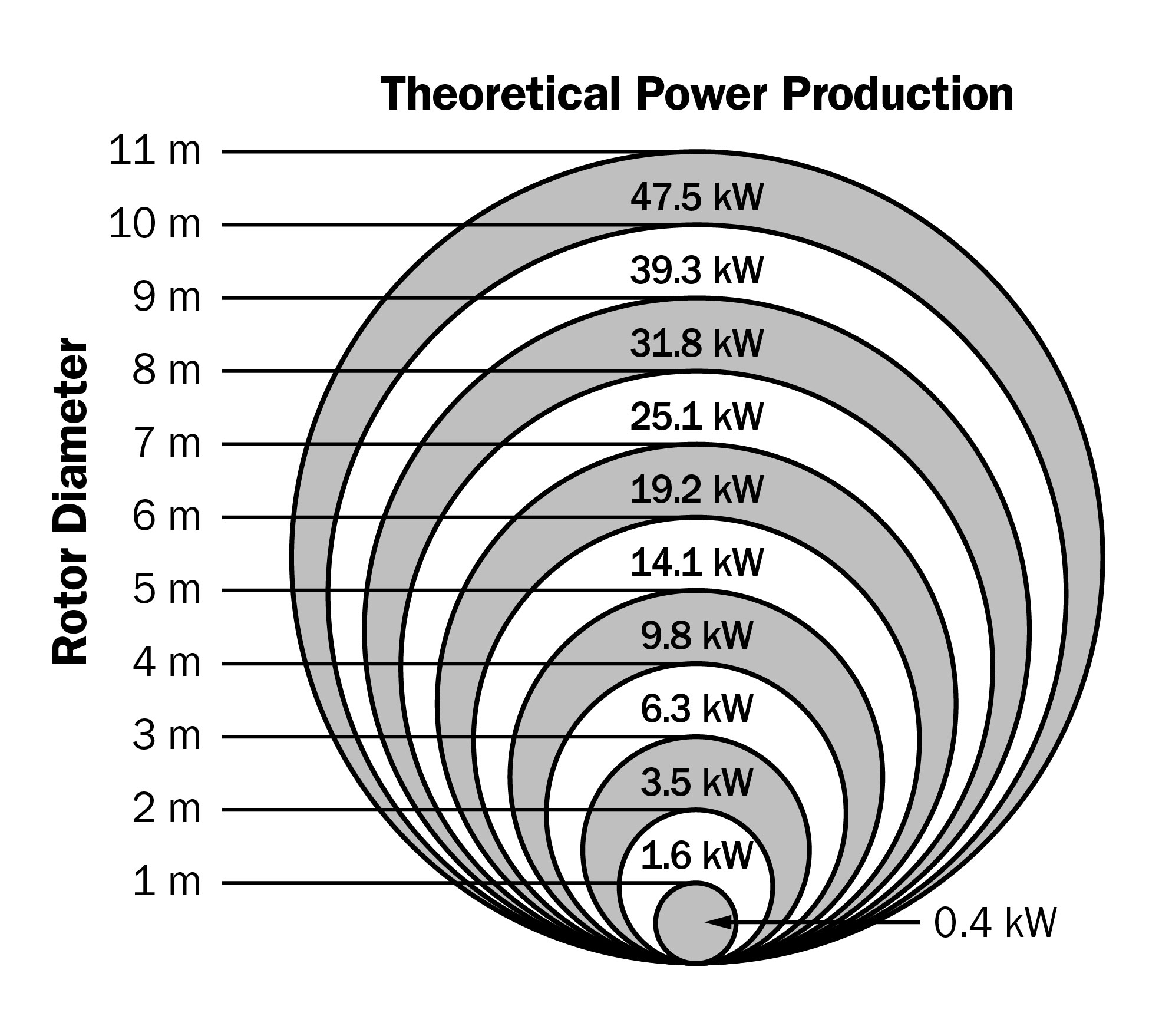

Another method for comparing turbines is to look at swept areas of turbines, which is a function of the rotor diameter. A modest increase in the rotor diameter will lead to significant increases in both the swept area of a turbine and the amount of electricity that the turbine generates (Figure 10). The actual power production from a wind turbine is also influenced by factors such as:

- the efficiency of the wind turbine to extract energy from the wind

- the elevation at which the turbine is located

- other design characteristics of the wind turbine

Power curves are the signature performance curves for wind turbine models showing power output versus wind speed. Produced in real winds under standardized conditions, they provide the basis for all energy output calculations. Figure 11 shows examples of power curves of SWCC-certified small wind turbines.

Source: Small Wind Certification Council.

Choosing an appropriate size

Before determining which wind turbine size to select, figure out how much energy can be saved by installing energy-efficient measures in the home or on the farm (e.g., appliances, lighting, fans, etc.). A more energy-efficient home/farm will require a smaller wind turbine, which will have a lower associated cost. Most small wind turbines are installed to supply a portion of the energy used on the property.

To determine the appropriate size of wind turbine to use, review the monthly electricity consumption in kilowatt-hours (kWh) for the home and/or farm. Compare this total to estimates of the power production for different wind turbines available from a wind turbine dealer.

To get a preliminary estimate of the performance of a particular wind turbine, use the formula:

AEO = 1.64 D2 V3

Where:

AEO = annual energy output, in kWh/year

D = rotor diameter, in metres

V = annual average wind speed, in m/s

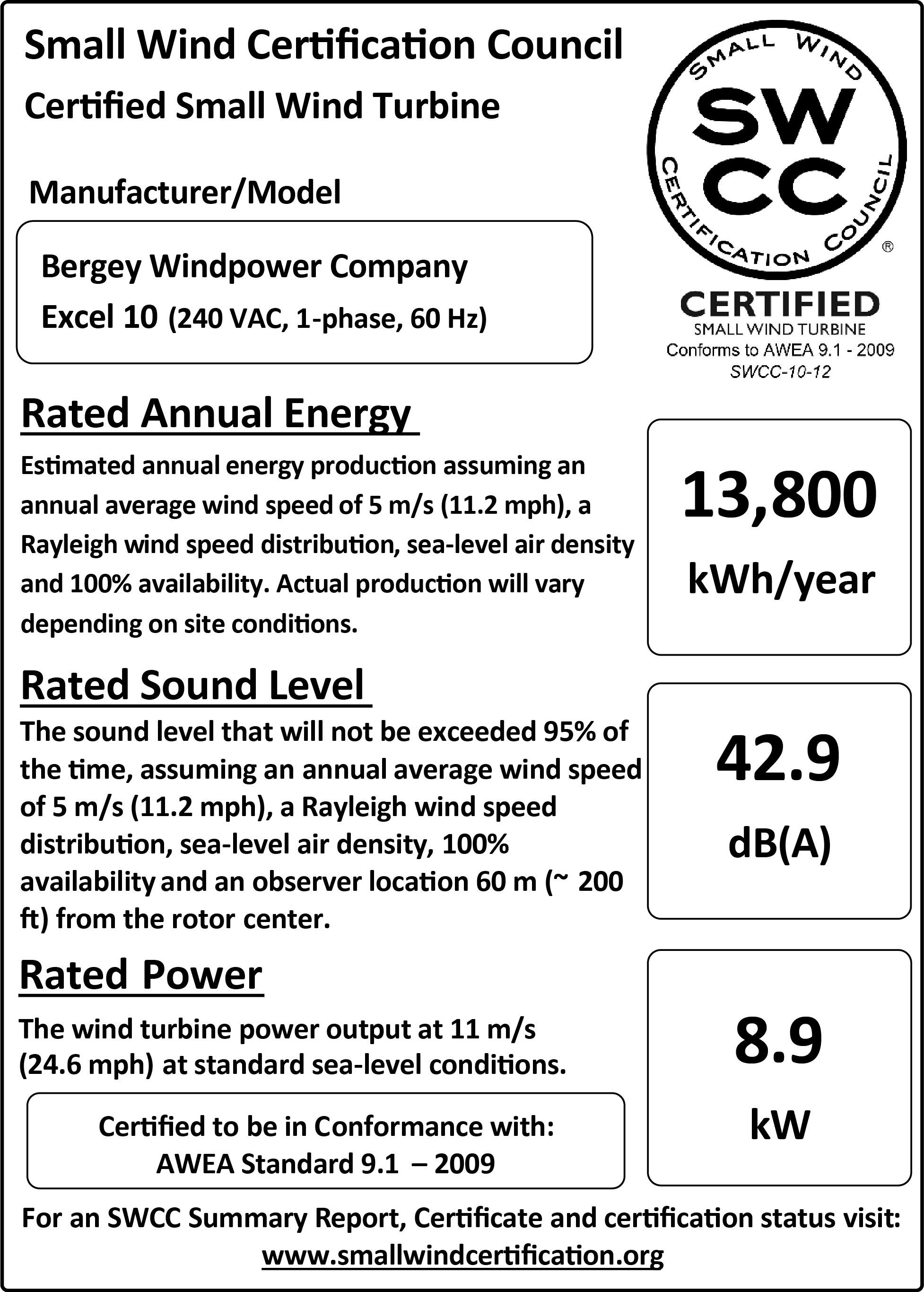

To determine the output required from the wind turbine, multiply the annual electrical consumption (kilowatt-hours) for the home or farm by the percentage of power intended to be provided by using wind energy. This value is the output required (in kilowatt-hours) from the wind turbine. Compare this value with the one calculated using the AEO formula or compare it to the rated annual energy output listed on certified wind turbines from the Small Wind Certification Council (Figure 12). Results are based on an average wind speed of 5 m/s.

Source: Small Wind Certification Council.

The single-number rating found on the SWCC consumer label for a wind turbine allows the consumer to compare turbine models based on energy, power and sound. The rated sound level provides the consumer with an estimate of the sound an observer will experience in high winds and at a typical distance away.

The standard SWCC label displays three test results:

- estimated annual energy production in kW/year, assuming an annual average wind speed of 5 m/s (11.2 mph)

- rated sound level at 60 m (~200 ft) from the rotor centre that will not be exceeded 95% of the time, assuming an annual average wind speed of 5 m/s (11.2 mph)

- rated wind turbine power output in kW at 11 m/s (24.6 mph) at standard sea-level conditions

Pick the best location

Choosing where to install the wind turbine is important. If nearby houses, tree lines and silos obstruct the full force of the wind from the turbine, it will not generate as much power. Consider the following:

- wind speeds are always higher at the top of a hill, on a shoreline and in places clear of trees and other structures

- trees grow over time and wind turbine towers do not

- informing neighbours of the plan to erect a wind turbine can prevent conflict later on

- siting the turbine as far away from neighbours as possible can avoid noise complaints

- setbacks may be necessary when siting a wind turbine (see Approvals section)

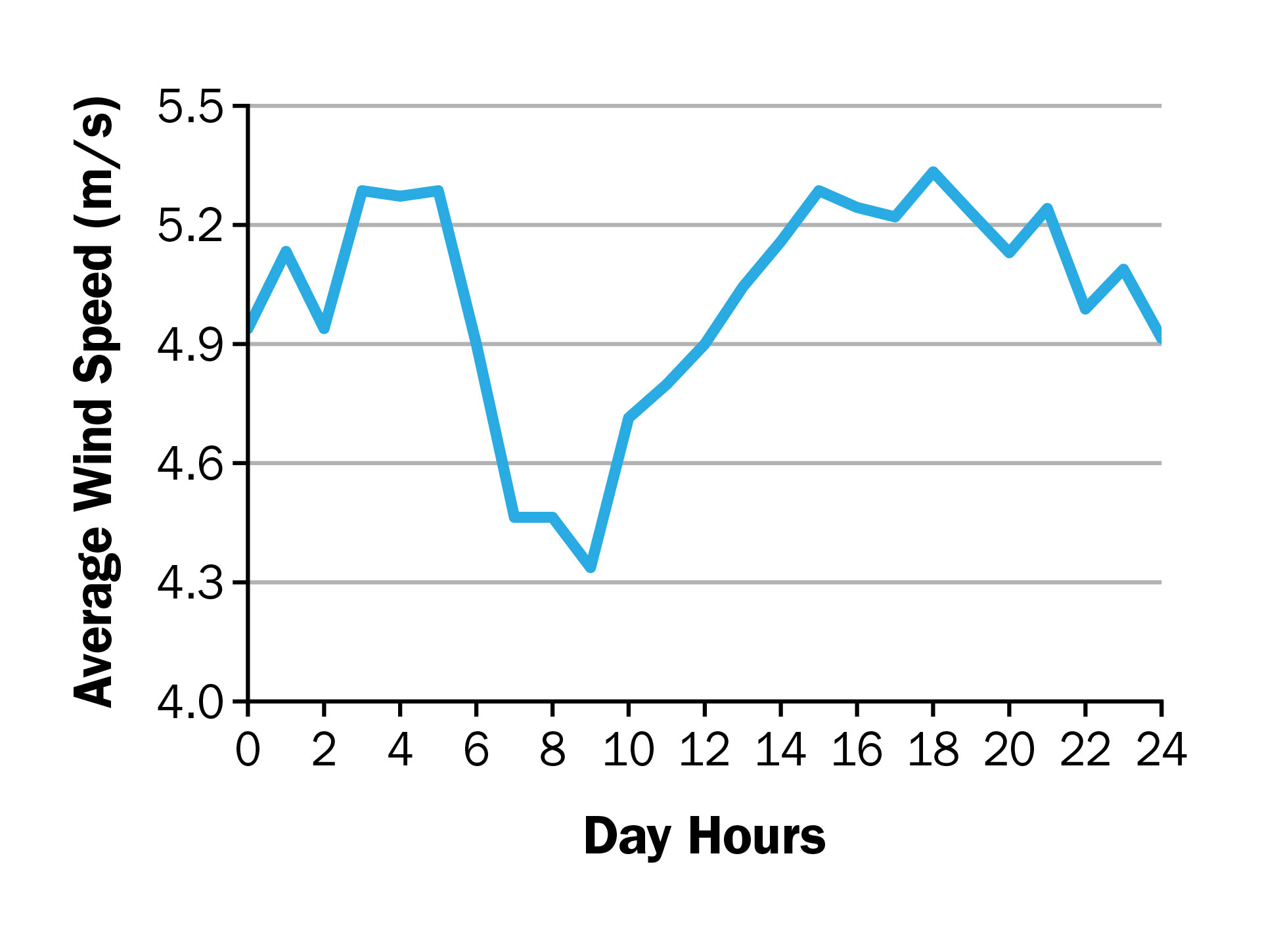

Do not expect the wind turbine to generate the same amount of power all the time. The wind speed at a single location will vary considerably, which can have a significant impact on the power produced (Figure 13). Even if the wind speed varies by only 10%, the power produced from a wind turbine can vary by up to 25%.

Source: National Renewable Energy Laboratory.

Mounting turbines on rooftops is not recommended. Wind turbines tend to vibrate and transmit the vibration to the structure on which they are mounted. As a result, turbines mounted on a rooftop could lead to both noise and structural problems with the building and rooftop.

Other technical and electrical requirements

Have a licensed electrical contractor perform all electrical work to ensure it is done safely and meets the requirements of the Ontario Electrical Safety code.

Use a tower approved by the wind turbine manufacturer, otherwise the warranty on the turbine may become invalid. Also ensure the tower is grounded for protection in case of a lightning strike.

A disconnect switch is required that can electrically isolate the wind turbine from the rest of the wind energy system. An automatic disconnect switch is necessary to prevent damage to the rest of the system in case of an electrical malfunction or a lightning strike. It also allows for maintenance and system modifications to be safely made to the turbine (Figure 14).

Isolated systems (i.e., not connected to the grid) may require batteries to store excess energy generated by the wind turbine. Because energy is stored in the batteries as DC power, an inverter is needed to convert the power from the batteries to the AC power required to run electrical appliances in the home or on the farm.

Most small wind turbines have a passive mechanical method of speed control. The turbines furl their rotor out of the wind. Furling is a fairly simple method that works but it has some disadvantages. When the rotor is turned out of the wind, power production is reduced. Also, the wind hitting the blades at an angle can cause increased noise.

Maintenance requirements

A wind turbine requires periodic maintenance such as oiling, greasing and regular safety inspections. An annual check-up should include:

- checking and tightening bolts and electrical connections

- checking wind turbines for corrosion

- checking the guy wires supporting the tower for proper tension

Paint wooden turbine blades to protect them from the elements. Apply a durable leading-edge tape to protect the blades from abrasion due to dust and insects in the air. If the paint cracks or the leading-edge tape tears away, the exposed wood will erode quickly. Moisture penetrating into the wood causes the rotor to become unbalanced, stressing the wind generator. Inspect wooden blades annually and do any repairs immediately.

After 10 years, blades and bearings may have to be completely replaced. With proper installation and maintenance, the turbine can last 20–30 years or longer. Proper maintenance will also minimize the amount of mechanical noise produced by the wind turbine.

Canada’s cold climate may cause ice to form on the blades during the winter months. If ice accumulates on the blades, it will reduce power output and increase the load on the rotor, which may cause premature failure.

To reduce damage caused by ice:

- minimize the downtime period of the wind turbine, which also maximizes the power output from the stronger winter winds

- keep the rotor turning, limiting ice growth on the blade

- de-ice as required

Other considerations

Be a good neighbour

Many people feel strongly about the need to preserve the landscape, scenic view, history and quiet surroundings of their neighbourhoods. Discuss plans to build a wind turbine with the neighbours. Understand their interests and be prepared to respond to concerns.

Wind turbine noise

No matter the size of the wind turbine, the potential for turbine noise to affect other people exists.

Consider the potential for noise when selecting and siting the system. Wind turbines must also meet any applicable noise requirements under relevant approval processes.

Wind turbines are capable of the following types of noises:

- Aerodynamic noises may be made by the flow of air over and past the blades of the turbine. These noises tend to increase with the speed of the rotor. The interaction of wind turbine blades with atmospheric turbulence can result in a “whooshing” type sound. Review the rated sound levels when selecting a small wind turbine system for the property and seek appropriate approvals.

- Mechanical noises may also be produced by components of a wind turbine. Normal wear and tear, poor component design or lack of preventive maintenance may affect the amount of mechanical noise produced. Take care to maintain the system to minimize any potential for mechanical noise.

Table 1 shows that sound levels for some small wind turbines (examples are given) are in the range of 40–56 dB(A) when measured at a distance of 60 m (200 ft) from the turbine.

| Small wind turbine | AWEA-rated sound |

|---|---|

| Bergey Excel 10 | 42.9 dB(A) |

| Bergey Excel 6 | 47.2 dB(A) |

| Kestrel e400nb | 55.6 dB(A) |

| Kingspan KW6 | 43.1 dB(A) |

| Endurance S343 | 46.6 dB(A) |

| Evance R9000 | 45.6 dB(A) |

| Endurance E3120 | 42.5 dB(A) |

| Xzeres Skystream | 41.2 dB(A) |

Source: Small Wind Certification Council, 2014 data

Note: AWEA-rated sound levels are the sound pressure level of a listener located 60 m (200 ft) from the rotor during a wind speed of 9.8 m/s (i.e., the wind speed that is not exceeded 95% of the time, assuming an average wind speed of 5 m/s).

In comparison, Table 2 shows sound levels for various common activities and noise sources. Most small wind turbines make less noise than a residential air conditioner. At the hub of the wind turbine, the sound pressure is 75–100 dB(A).

| Decibels (dB(A)) | Activity |

|---|---|

| 0 | Threshold of hearing for humans |

| 15 | Normal threshold of hearing for humans |

| 20 | Calm human breathing; very soft whisper |

| 30 | Calm room, library, empty church, secluded woods |

| 40 | Rural ambient background sound: 7 pm–7 am |

| 45 | Rural ambient background sound: 7 am–7 pm |

| 50 | Inside an average home, refrigerator hum |

| 55 | Low volume of TV or radio |

| 60 | Normal conversation |

| 65 | Sleep disturbance |

| 70 | Busy business office |

| 80 | Curb side of a busy road |

| 90 | Barn full of finisher pigs at feeding, gas lawnmower |

| 100 | Chainsaw, circular saw, ATV, irrigation pump |

| 110 | Grain dryer fan and burner under full load |

| 120 | Threshold of discomfort, rock and roll concert |

| 130 | Threshold of pain, jet engine at 25 m (82 ft) away |

Conclusion

Small wind power systems may be economical if there is a strong local wind resource and the system can offset electricity bills. It is a good practice to purchase a certified system to ensure that a small wind turbine is robust, and the energy produced will provide value. Pay attention to the rated sound of wind turbine models to help decide whether a model is best suited for a location near neighbours (e.g., lower-rated sound level) or out by the barn, farther away from neighbours (e.g., higher-rated sound levels).

Resources

- American Clean Power Association

- Canadian Wind Energy Association

- Bergey Windpower

- CANMET, Natural Resources Canada

- Distributed Wind Energy Association

- Electrical Safety Authority (ESA)

- Environment and Climate Change Canada Wind Atlas

- Independent Electricity System Operator (IESO)

- Intertek

- National Renewable Energy Laboratory, Field Verification Project for Small Wind Turbines, Quarterly Report, April 2002, 2nd Quarter Issue 5

- Ontario Ministry of the Environment and Climate Change, Renewable energy approvals

- Ontario’s Renewable Energy Atlas

- RETScreen International

- Small Wind Certification Council

- Small Wind Electric Systems: A U.S. Consumer’s Guide, U.S. Department of Energy

- Small Wind World Report, 2014, World Wind Energy Association

- Stand-Alone Wind Energy Systems, Natural Resources Canada

- U.K. Microgeneration Certification Scheme

- Wind Energy Institute of Canada

- Wind Market Report, 2014, U.S. Department of Energy

- Wind Works

This factsheet was written by Steve Clarke, P.Eng. (retired), Energy and Crop Systems, OMAFRA, Kemptville, and reviewed by Paul Gipe, Wind Works.