Growing industrial hemp in Ontario

Learn about growing industrial hemp in Ontario including uses and production.

ISSN 1198-712X, Published November 2022

Introduction

Industrial hemp (Cannabis sativa) is one of the oldest cultivated plants in the world. The crop is grown for its many diverse uses, which include food and beverages, feed, nutritional supplements, cosmetics and personal care products, textiles, construction and insulation materials, animal bedding and cannabinoids (for example cannabidiol (CBD)), for therapeutic and medicinal health products. Industrial hemp is currently witnessing interest from growers and industry because of the potential additional economic benefits of growing hemp as a source of cannabinoids such as CBD. This fact sheet provides information on growing industrial hemp as a source of grain or fibre for traditional uses and/or flowers for cannabinoid extraction.

Cannabis vs. industrial hemp

Cannabis (Cannabis sativa and Cannabis indica) and industrial hemp (Cannabis sativa) are related. Health Canada regulates production of both cannabis and industrial hemp and distinguishes between them based on their Δ9- tetrahydrocannabinol (THC) content. Over 100 cannabinoid compounds have been identified in cannabis, with the psychoactive THC and the non-psychoactive CBD, being of most interest. To be classified as industrial hemp, the leaves and flowering heads must have total THC levels less than 0.3% of the weight of the flower tissue. Conversely, Health Canada defines cannabis as having THC levels greater than 0.3%.

Regulations and licensing

In 1998, Canada created the first Industrial Hemp Regulations under the Controlled Drugs and Substances Act. These regulations provide strict conditions for the controlled production, sale, movement, processing, exporting and importing of industrial hemp and hemp products.

New industrial hemp regulations came into force on October 17, 2018. Industrial hemp and cannabis regulations are now regulated under Bill C-45, the Cannabis Act, which provides a legal framework for the possession, production, distribution and sale of industrial hemp and cannabis in Canada.

Under these regulations, licensed industrial hemp producers can carry out any of the following activities:

- sell industrial hemp

- import or export seed or grain

- cultivate industrial hemp for commercial or research purposes

- in the case of a plant breeder, propagate industrial hemp

- possess seed or grain for the purposes of cleaning it

- possess grain for the purpose of processing it

- obtain seed by preparing it

- grow, harvest, dry, sell industrial hemp inflorescence (flower bud) to licensed cannabis extraction facilities

Details on permitted activities can be found in the Industrial Hemp Regulations.

Only cultivars of industrial hemp approved by Health Canada can be grown in Canada. A cultivation licence holder (other than as a plant breeder) must sow only certified, pedigreed seed of an approved cultivar. Farm-saved hemp seed from previous crops cannot be used for planting. Government compliance officers may require growers to produce the official pedigree tags for the seed used to plant their current hemp crop. The list of approved cultivars is available on the Health Canada website. Industrial hemp plant breeders can only cultivate or propagate the cultivar of industrial hemp or the germplasm whose name or number is set out in their licence.

Sale of hemp plants (flowers, leaves and branches) to licensed cannabis processors is now permitted, to provide a source of low THC, high CBD cannabis products. Extraction of the cannabinoids from the flowering heads, leaves and branches of industrial hemp falls under the Cannabis Regulations. This activity requires a separate cannabis processing licence that is distinct from an industrial hemp production licence. Hemp producers may not extract the CBD themselves, unless they also have a cannabis processing or research licence.

The Industrial Hemp Licensing Application User Guide provides information on the licensing requirements for both industrial hemp production and processing licences. Licence applications are made through the online Health Canada Cannabis Tracking and Licensing System (CTLS). The User Guide for Industrial Hemp Licence Applications outlines the steps necessary to register a user account in the CTLS, provides a detailed walkthrough of the online application form and highlights important other information and requirements. For additional questions, such as those related to the Cannabis Act and its Regulations or to the CTLS, contact Cannabis Legalization and Regulation by e-mail at cannabis@canada.ca or by phone at

Crop production insurance

Agricorp offers production insurance for industrial hemp seed and fibre production (not CBD production) for Ontario farmers. Contact Agricorp by e-mail at contact@agricorp.com or phone at

Uses for industrial hemp

Industrial hemp is known for the quality of its bast fibre, which has excellent fibre length, strength and durability. These bast fibres are used to manufacture textiles, bio-composites for automotive parts, packaging and structural materials for use in the construction and building industry. The inner core hurd/shive of the hemp stalk has excellent absorbency and can be used for livestock bedding, oil and gas spill clean up, or combusted for green energy production.

Hemp oil meal and the de-hulled hemp grain, known as hemp nut, are used to make food products such as granola bars, snack foods and cookies. Unless processed within Canada, whole hemp grains must be rendered non-viable for all other uses, including export.

Hemp oil contains a unique mixture of omega 6 and omega 3 fatty acids, as well as gamma linolenic acid (GLA), an essential fatty acid involved in the synthesis of prostaglandins in the body. Hemp seed oil is used in health and beauty products or consumed as a food or dietary supplement. The industrial hemp regulations dictate that the level of THC in hemp seed oil must be less than 10 micrograms/g. For clarification, hemp seed oil is not the same as the CBD oil extracted from the flowering heads (buds or inflorescence) of industrial hemp plants.

There has been increasing interest in non-psychoactive CBD derived from hemp to be used in the therapeutic, medicinal, biopharmaceutical, natural health product, recreational and foods supplement sectors. Pre-clinical studies suggest CBD has potential anti-inflammatory, anti-seizure, pain relief, anti‑nausea and anti-psychotic effects and medicinal use for the treatment of anxiety disorders. Prescription drugs containing THC and/or CBD are approved for use by Health Canada. Health Canada provides additional information on CBD.

Hemp production facts

Cultivars

- Visit Health Canada’s List of approved cultivars.

Soil

- well-drained, loamy is best

- avoid wet, compacted clay soils

- pH: 6.0–7.5

Seedbed

- fine, firm, level

- seed depth: 2–3 cm

Planting date

- late April to late June

Seeding rate

- fibre: 45 kg/ha

- grain: 23–28 kg/ha

- CBD: no established seeding rates

Plant population

- fibre: 200–250 plants/m2

- grain: 100–150 plants/m2

- flower: 6,000–7,350 plants/ha

Fertility

- nitrogen (N): 70–110 kg/ha

- phosphate (P2O5): up to 80 kg/ha

- potash (K2O): 40–90 kg/ha

Adjust to account for a recent soil test for winter wheat.

Weed control

- Limited registered herbicide options. Consult Health Canada’s Pest Management Regulatory Agency (PMRA) Registered Products Database.

Diseases*

- Sclerotina sclerotiorum (white mould)

- Botrytis cinereal (grey mould)

- powdery mildew

- root and crown rots (pythium and fusarium)

- foliar diseases (septoria and brown leaf spot)

- alfalfa mosaic virus

- cucumber mosaic virus

Insects*

- grasshoppers

- Bertha armyworm

- European corn borer

- corn earworm

- cutworms

- lygus plant bugs

- blister beetle

- Japanese beetle

Animals

- birds

- deer

Harvest date

- fibre: during pollination (approximately 70–90 days after seeding)

- grain: when approximately 70% of seed is ripe, 22%–30% moisture (approximately 100–120 days after seeding)

- flowers/leaves: when flower heads are fully mature and beginning to ripen and dry

Monitoring CBD levels by laboratory testing can help determine the best harvest timing for maximum CBD concentration.

Field retting for fibre

- takes 14–21 days, during which the stalks are turned over at least once

Storage

- stalk moisture: <15%

- grain moisture: <12% (8%–10% for long-term grain storage)

- flower/leaves/chaff: harvested material must be dry enough to prevent mould growth (10%–12%)

*Registered pest control products can be found on Health Canada’s PMRA.

Crop description

Industrial hemp is made up of cultivars of Cannabis sativa that contain less than 0.3% THC, as described earlier. It is an annual broadleaf plant with a taproot and is capable of very rapid growth under ideal growing conditions. In well-structured and well‑drained soils, the taproot may penetrate 15–30 cm deep. In compacted soils, the taproot remains short, and the plant produces more lateral fibrous roots.

The female flowers and seed set are indeterminate. Since the seeds continue to develop and mature over an extended period, there are both ripe and immature seeds on the same plant at time of grain harvest.

When grown as a fibre crop (Figure 1), hemp may grow to a height of 2–4 m without branching. In dense plantings, the bottom leaves atrophy due to the exclusion of sunlight. Male plants die back after shedding pollen.

The outer bark of the stem contains long, tough bast fibres that give the quality and strength for which hemp is renowned. The inner woody core, also known as hurds, is composed of short fibres that are similar to hardwood fibres and can be useful in other applications such as particleboard manufacture or livestock bedding.

Hemp grain cultivars often display more branching than fibre cultivars and are typically shorter, reaching heights of only 2–3 m. Tall plants do not necessarily produce more grain than short ones and shorter plants are preferred for combining.

When growing industrial hemp for CBD, the field will ideally contain only female plants generated from feminized seeds, or clonal cuttings. In general, hemp plants are naturally dioecious, meaning each plant has either male flowers that produce only pollen, or female flowers that produce only ovaries.

Pollination of the female flowers (Figure 2) leads to seed production, which is not desirable when growing hemp for CBD production, as seed production reduces the overall CBD content. Pharmacologically active compounds (such as cannabinoids) are produced in secretory glands, which are hair-like structures located at the highest densities on the modified leaves (bracts) that encase the flower (Figure 2). When the flowers are fertilized, these encasing bracts expand, reducing the density of the secretory glands and thus the yield of cannabinoids per gram of plant tissue. For this reason, it is common practice in the cannabis industry to grow only plants that produce female flowers. This is done by cloning female mother plants through tissue culture or regeneration of plants from cuttings, or by growing plants from feminized seed.

Female plants can be manipulated by chemical or environmental treatments to generate pollen, which results in self-fertilization and the production of feminized seed that produces only female plants. New certified seed has to be purchased each year.

Cultivars

Industrial hemp cultivars have been developed based on small plot research and performance trials suitable for the local production region. Seed breeding companies (for example, Uniseeds, Phytogene Resources and CBD Baker Inc.) have developed hemp grain and fibre cultivars suitable for Ontario and are now developing new cultivars with higher CBD levels. As mentioned above, industrial hemp cultivars are either monoecious (for example Anka, Alyssa) or dioecious (for example, Finola, Petera) types.

In dioecious cultivars, the male plant pollinates the female plant and then dies, leaving only the female plants to mature for harvest (Figure 3). A third type, known as “female predominant,” is a dioecious type that has 85%–90% female plants. Some research suggests this type can produce a higher yield of grain.

Dual-purpose cultivars

Dual-purpose cultivars are bred to produce both grain and biomass (Table 1).

| Type | Cultivar | Average height |

|---|---|---|

| Grain | Anka | 1.6–1.8 m |

| Fibre | Altair | 1.4–1.6 m |

| Dual purpose | Altair, carmagnola | 1.4–3.0 m |

Industry trends are moving toward growing cultivars that are specifically grain, fibre or female predominate with high CBD levels. A list of registered cultivars is available from Health Canada (List of approved cultivars). Breeding efforts to increase the CBD concentration to greater than 8% have begun but face the significant challenge of also maintaining THC levels below the mandated 0.3%.

Soil conditions

Hemp grows best in well-drained, loam soils, with a neutral to slightly alkaline pH of pH 7.0–7.5 being ideal. The higher the clay content of the soil, the lower the yield of fibre or grain produced. Clay soils are easily compacted, and hemp is very sensitive to soil compaction. Young plants are also very sensitive to wet soils or flooding during the first 3 weeks or until growth reaches the fourth internode (about 30 cm tall). Water-damaged plants will remain stunted, resulting in a weedy, uneven and poor crop.

Poorly structured, drought-prone sandy soils provide very little natural fertility or support for the plant. Accordingly, extra nutrients and water are required to achieve maximum yields on these soils. In a dry year, the cost of irrigation on sandy soils may make production uneconomical.

Seedbed preparation and planting

For optimum germination, industrial hemp seed requires good seed-to-soil contact. The seedbed should be firm, level and relatively fine (Figure 4), similar to seedbeds prepared for direct-seeded forages.

Source: Shutterstock

The soil can be worked and planted as soon as the ground is dry enough to avoid compaction. A shallow, firm seedbed allows seed to be placed at a uniform depth, resulting in a more even seedling emergence. Industrial hemp is normally sown using a standard grain drill. Plant seed at a depth of 2–3 cm. Optimum soil temperature at that depth for rapid germination is 8–10°C, although hemp seed will germinate at 4–6°C.

Industrial hemp planted for fibre is usually sown in 15–18-cm rows, using every run of the drill. The optimum final stand is 200–250 plants/m2. This high seeding rate is necessary to produce stands of tall, thin plants. These have more fibre per plant than do larger plants with thicker stalks. Early seeding (as soon as soil conditions are appropriate) is recommended. The typical seeding rate for fibre production is 45 kg/ha, but this can vary depending on germination rate and seed size (Figure 5).

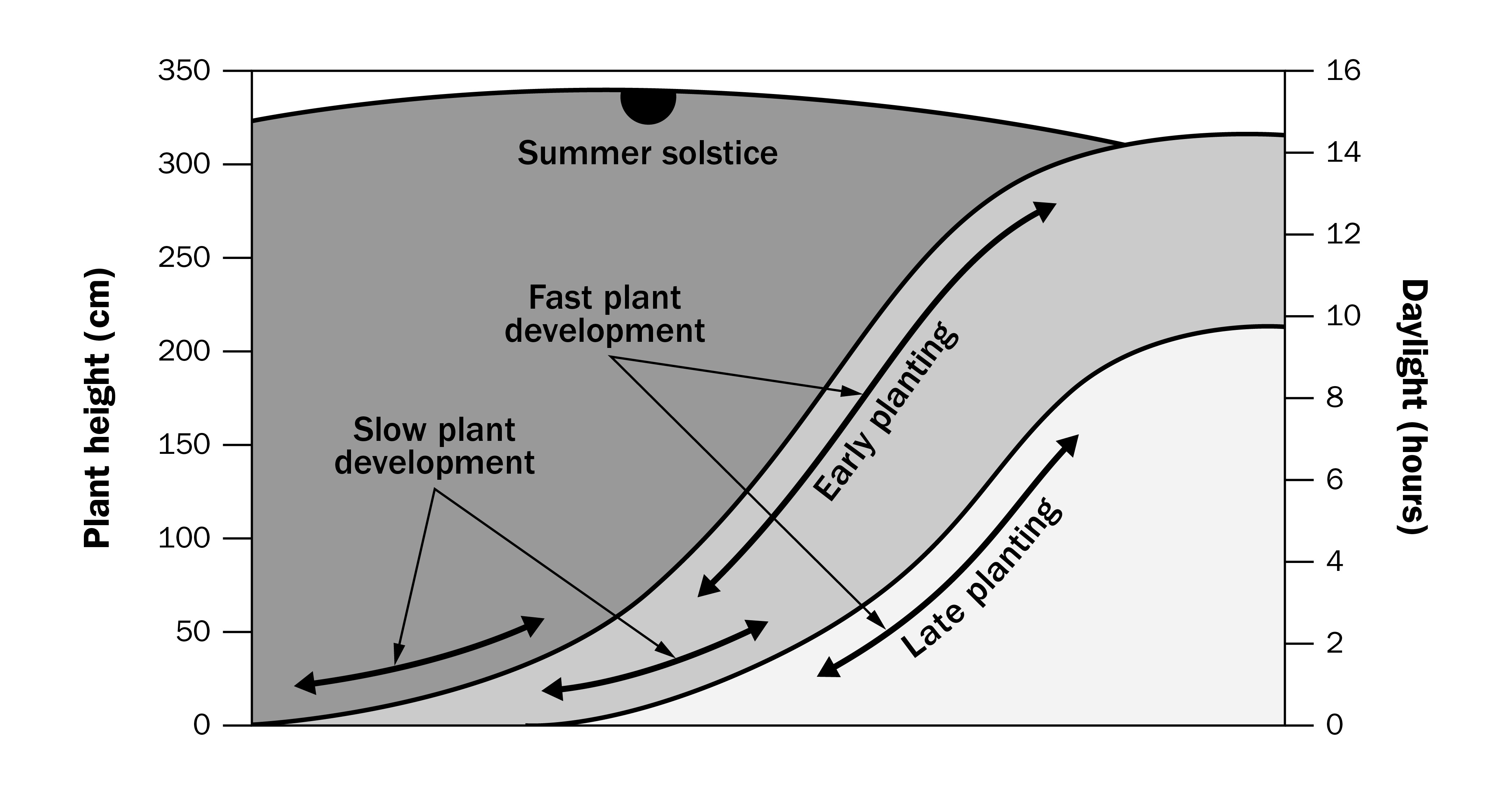

Industrial hemp is day-length sensitive, resulting in greater vegetative growth if planted earlier, as shown in Figure 6. As days become shorter, 4–5 weeks after the summer solstice (June 21), vegetative growth slows, and flower development is triggered. Early planting takes advantage of this feature by increasing the vegetative growth phase. This results in taller plants with higher fibre yields but does not change the harvest date significantly.

For grain production, the desired final plant population is 100–150 plants/m2. For grain production, the recommended seeding rate is 23–28 kg/ha. Like fibre hemp, seeds are still planted in 15–18-cm rows. Soil temperature determines the optimum planting date. This date may range from late April in Southwestern Ontario to late May in Northern Ontario. Planting after the first week of June is not ideal, as the shorter vegetative growth phase can negatively affect yields. Observations in Northern Ontario indicate that grain yield may not respond as positively to early planting as does fibre yield, but early planting may help advance the harvest date.

When growing hemp for CBD production, growers should consult with the seed supplier to select approved cultivars with high CBD content and, if possible, available as feminized seed. The presence of male plants will result in fertilization of the females, which reduces overall CBD yield from the crop. Any male plants found in the field should be removed prior to pollen release.

Recommendations for seeding rates are being developed as experience with growing industrial hemp for CBD grows. A seeding rate slightly lower than that used for hemp grain, 28–33 kg/ha, will allow for a wider between-row spacing of greater than 15–18 cm to encourage branching for additional flower head formation.

Climatic conditions

Hemp requires a significant amount of moisture to produce maximum yields. Research conducted at the University of Guelph, Ridgetown College campus, indicated the crop ideally needs 300–400 mm of rainfall equivalent. Since that amount of rainfall seldom occurs during the growing season, it is important to make use of early soil moisture and to obtain early ground cover to reduce surface evaporation, as well as to maintain good weed control. About half of this moisture is required during flowering and seed set to produce maximum grain yields. Drought during this stage reduces seed set and produces poorly developed grain heads. Continued drought results in low yields of light grain. During the period of vegetative growth, hemp responds to daytime high temperatures of 25–28°C. After the third pair of leaves develops, hemp can survive daily low temperatures as low as -0.5°C for 4–5 days.

Fertility

There are no Ontario fertility recommendations for industrial hemp. It is important to recognize that research and recommendations from outside Ontario do not necessarily apply to Ontario growing conditions. Fertility recommendations for industrial hemp grown for seed production are typically the same as would be used for a high-yielding spring wheat crop. Regular tissue analysis of the crop will provide accurate measurements of nutrient status that can be used to adjust the crop fertilization schedule. Apply up to 110 kg/ha of N, depending on soil fertility and past cropping history. Phosphorous and potassium levels should be at target soil test levels (12–18 ppm P and 100–130 ppm K).

If soil phosphorous and potassium levels are below target ranges, incorporate these nutrients into the soil ahead of planting, at rates that meet the crop removal rate plus an amount that will build up the soil test over time. Read Ministry of Agriculture, Food and Rural Affairs (OMAFRA) Publication 811, Agronomy Guide for Field Crops, fertilizer guidelines, Chapter 9, Soil fertility and nutrient use. These rates should be adjusted to account for the existing soil nutrient levels determined using soil tests and for any other sources of nutrients such as manure or incorporated cover crops (green manure).

To interpret soil test information, follow the N, P2O5 and K2O recommendations for winter wheat in OMAFRA Publication 811, Agronomy Guide for Field Crops. Growers in Northwestern Ontario may benefit from adding sulfur at 20–30 kg/ha. It is important to balance the nutrients applied with the crop requirements and with each other. Excessive N, combined with inadequate K2O, for example, can result in stalk breakage and loss of the crop.

About 42% of the plant’s biomass returns to the soil in the form of leaves, roots and tops. These contain over half of the nutrients applied to the crop. Many of these nutrients will be available to help feed the following crop.

Weed control

If hemp is planted in well-drained, fertile soil under nearly optimum temperature and moisture conditions, it will germinate quickly and reach 30 cm in 3–4 weeks. At this stage it will give 90% ground shade. Weed growth is suppressed by the exclusion of light from the soil. It appears that rapidly growing hemp, at a final population of 200–250 plants/m2 (fibre), will suppress nearly all weed growth, including twitch grass. For preplant site preparation guidelines, visit the Ontario Crop Protection Hub. A list of weed control products can be found on Health Canada’s PMRA Registered Products Database.

Weed suppression is not a permanent condition. Weeds may appear in the same field next year if the field is rotated out of hemp production. Perennial grasses may be weakened or killed if hemp is grown a second year on the same ground. However, this practice increases the opportunity for crop diseases to develop. Under grain or CBD production conditions (fewer than 150 plants/m2), weed suppression may be less complete. Lower plant populations or uneven stands allow more light to penetrate the canopy, aiding the germination of weed seeds. Cross-seeding may improve canopy distribution and subsequent weed control where very early, shorter cultivars are grown. Early planting, as soon as the soil is warm enough, is a recommended weed control strategy. For organic hemp production, good tillage or intercropping may be viable weed control options.

Diseases and pests

More than 50 different viruses, bacteria, fungi and insect pests are known to affect the hemp crop. However, hemp’s rapid growth rate and vigorous nature allow it to overcome the attack of most diseases and pests. As the acreage of industrial hemp and alternative disease hosts increases in a given area, the population of disease or pest organisms will tend to increase.

There is a limited number of fungicides and insecticides registered for use on hemp. A list of pest control products can be found on Health Canada’s PMRA Registered Products Database. Crop rotation is a necessary good cultural practice to avoid disease build-up until more is known about hemp’s susceptibility to disease organisms.

The following pests have been noted in hemp fields in Ontario:

- Botrytis cinereal (grey mould) (Figure 7) and Sclerotinia sclerotiorum (white mould) (Figure 8) are common moulds affecting industrial hemp. Sclerotinia also affects edible beans, canola and sunflowers and has been found on more than 10% of plants where industrial hemp followed canola. Sclerotinia spores (sclerotia) may be spread by combines, other harvesting equipment and straw. A 4-year rotation is recommended. Do not grow hemp on the same fields following canola, edible beans, soybeans or sunflowers.

- Fusarium, the pink mould found on corn and wheat, has been seen on the roots of hemp plants. The effect that an additional host crop will have on the viability of these crops may not be known until industrial hemp is grown more intensively in bean- and canola-growing areas.

- European corn borer and corn earworm have affected some stands in Southern Ontario, and grasshoppers have damaged hemp crops in Northern Ontario.

- Bertha armyworm (Mamestra configurata) has been a pest in Manitoba and could find its way to industrial hemp crops in Northwestern Ontario. Other diseases and pests with varying degrees of severity have been identified in other provinces.

Wind and hail damage can cause significant crop loss, and tall plants with abundant upper leaf mass can be easily bent by mid-to late-summer storms. Broken plants will recover partially if not broken too low, but this can result in significant variability in plant height and maturity at seed harvest time. Small plants damaged by hail could recover quickly if they were not severed below the first node. Weather stresses may also result in higher THC levels in the remaining crop.

Bird damage has been severe in some areas of Ontario and in extreme cases, the entire grain crop has been lost. Deer have been observed browsing on the tender plants during the vegetative growth phase.

Harvesting and drying for CBD

From peak flowering, growers can monitor cannabinoid (THC, CBD) levels by sending flower samples to an accredited lab for testing. This will allow harvest to be done when CBD level is highest, but testing can take a week or more, so this may impact harvest date.

There are different possibilities for harvesting hemp for CBD production:

- A cutter with a head designed to harvest/cut the flower head with minimum damage should be used. The flower heads would be collected into a hopper and transported for drying and storage prior to processing. After the flower harvest, the remaining stalks could be cut down with a disc mower or swather.

- If the hemp crop is grown for both grain and CBD, the chaff material (leaves, flower heads) is collected in a hopper wagon pulled behind the combine when the grain is harvested. This chaff will have to be dried and stored until processed. The concentration of CBD in the chaff will be lower than in the plant material collected from hemp plants specifically grown for CBD. Following the grain harvest, the hemp stalks are cut and baled.

Additional research is needed on all aspects of growing hemp as a source of CBD on a commercial scale. For example, identifying the optimum harvest time, development of harvest equipment that captures the maximum value of the hemp plant economically and efficiently, and efficient post‑harvest storage practices are all areas that require further study.

Harvested hemp flowers should be dried to prevent mould damage, which can lower the yield and quality of CBD and other extractable chemical compounds. The methods chosen will depend on the amount and type of material harvested. One option is to dry the flowers in large ventilated barns with industrial fans running for air circulation. Flowers can also be dried at low temperature in drying chambers such as tobacco kilns. Dried plant material can only be processed by a licensed cannabis processor (LPs) as per the industrial hemp and cannabis regulations.

Source: Shutterstock

Combining grain hemp

Combining hemp provides a special challenge to both the combine and the operator. In tall cultivars, large quantities of plant material are put through the combine (Figure 9). Hemp straw contains very tough fibres that tend to wind around moving parts. Fine fibres work into bearings, causing friction that can lead to bearing breakdown and combustion. These factors cause heavy machinery wear, high maintenance costs and a great deal of time loss and frustration on the part of the operator.

Industrial hemp seed is harvested when the seed begins to shatter. At the optimum harvest time, about 70% of the seeds are ripe and about 22%–30% moisture, which is approximately 100–120 days after seeding. Later combining results in increased grain losses due to shattering, bird feeding and lower quality grain. In addition, mature fibres tend to wrap more tenaciously around moving parts on the combine. Raising the cutting blade to about 1 m, or as high as the header will cut effectively, reduces the amount of material entering the combine. With shorter cultivars, use a “closer to normal” header position. The header knife must be kept sharp to minimize winding of fibres on the sickle bar.

Proper setting of the combine improves the yield and quality of the grain and reduces wear on the combine, but settings (for example, ground speed, concave openings, air and cylinder speeds) will depend on the type of combine used for harvest.

Reported grain yields in Ontario have ranged from 300–1,300 kg/ha at 12% moisture, after harvesting and cleaning. Higher yields may be possible as cultivars and production technology improve.

After harvest, the priority is to dry the grain to 8%–10%. Excess moisture during storage can promote bacterial and mould growth. For long-term storage in silos, grain should be slowly dried at low temperatures to prevent damage and spoilage to the grain.

After drying and cleaning, how the grain is processed further depends on its ultimate end use. Processing can include:

- de-hulling to produce shelled hemp hearts for consumer culinary use

- mechanical cold pressing the seed to produce an unrefined crude oil for culinary food use (solvent extraction methods can be used instead to produce a more refined oil for food or industrial products uses)

- further processing of the hemp seed or meal into hemp flour and protein products (efforts are under way to have hemp seed meal registered as an approved livestock feed ingredient)

Some “volunteer” hemp will likely appear in the fall or spring following the hemp crop. These plants are illegal and must be removed as per the Cannabis Act regulations. Thorough cultivation and seedbed preparation are effective ways to control these volunteer plants. They can also be controlled with herbicides containing glyphosate.

Harvesting fibre

Air-dried yields in Ontario have ranged from 2.6–14.0 tonnes of dry, retted stalks per hectare at 12% moisture. Research has shown that earlier planting, optimum production management and more suitably adapted cultivars can result in higher yields. Approximately 1 tonne of bast fibre and 2–3 tonnes of core material can be decorticated from 3–4 tonnes of good-quality, dry retted straw. Fibre yield depends on the fibre content and total stalk yield per hectare. Cultivars differ in fibre content and in the ratio of bast fibre to core materials (hurds). Further processing may be required to attain the quality of fibre needed for some end uses. For textile applications, hemp is harvested during the early flowering stage prior to seed set, which is approximately 70–90 days after seeding.

Fibre that is cut after seed harvest will have lignified considerably and is usable only in some non-woven industrial fibre applications. In dioecious cultivars, the male plants die back after shedding pollen. This results in lower fibre yields if the straw is cut after grain has matured.

On small acreages, good quality sickle-bar mowers and hay swathers have been used to cut hemp. Frequent plugging has been a constant problem with this equipment. Most older model combines will require some modification to prevent plant fibres from wrapping around moving parts. Knives must be kept sharp and in good repair at all times. As acreage increases, more sophisticated equipment may have to be imported or developed.

When industrial hemp is grown for both grain and fibre, it is necessary to re-cut the tall stalks after combining. A combine can be modified to perform both functions at the same time by mounting a sickle-bar mower under the header to operate close to the ground. It is expected that, as markets for grain and fibre begin to differentiate, dual harvesting will cease to be a common practice. Growers of small acreages will most likely continue to combine and cut stalks as two separate operations. If straw is to be harvested after combining, it is important that the weather conditions are suitable for drying the stalks prior to baling. The fibre from the mature stalks after grain harvest will be lower in quality and higher in lignin than that obtained from hemp grown specifically for fibre. This lower-quality fibre would be suitable for manufacturing into composites, non-woven mats, particleboard and possibly for pulping.

Fibre retting and turning

Retting is the process of allowing plant material to break down, which makes it easier to separate the bast fibres from the hurds and other plant tissues. Retting is done either in the field (Figure 10), taking advantage of the natural elements of dew, rain and sunlight, or under controlled conditions using water, enzymes or chemicals. The method chosen depends on the end use of the fibre. Research to develop suitable industrial processes for water and chemical retting is ongoing. It is important that the retting process be complete before baling, so that the fibres reach the desired colour, and do not rot or discolour in storage.

Baling and storing

Baling can be done with any kind of baler. Large round (Figure 11), soft-core balers may be most satisfactory in allowing bales to dry more quickly in storage. For some industrial processes, the buyer may require a uniform large, square bale to fit into the processing system. This may present a challenge in preventing spoilage if the bales are stored for later delivery, because square bales are packed more tightly, allowing less air passage, than round bales. If available, sisal or hemp twine should be used to tie bales because polyester and plastic twines become contaminants in the processing of hemp fibres. To stop the retting process and prevent further degradation of the fibres, bales must be stored indoors under dry conditions. Hemp straw absorbs moisture quite readily, even if stored on deep gravel floors indoors. Stalk moisture should be less than 15% at time of baling, and should continue to dry to about 10%, preferably under covered storage.

Source: Shutterstock

Mechanical processing/decortication of hemp fibre

A decorticating machine can be used on hemp stalks to separate the outer fibrous bast fibre (Figure 12) from the inner core hurd/shive. The bast fibre is then further refined, processed and cleaned for end uses such as insulation, auto parts, textiles and other applications. The inner hurd, which is a woody material, is cleaned, dedusted and typically used for livestock bedding or compressed into pellets for combustion to produce green energy. Newer uses include incorporation into biocomposites such as building materials or automotive parts.

Marketing

Growers should develop a marketing plan prior to planting. Additional information on marketing can be found on the OMAFRA specialty cropportunities website.

Markets for hemp fibres and seed products continue to develop, but access to commercial grain and fibre decorticating/processing infrastructure is important for growth of the industry. Transportation of raw hemp feedstocks is a significant cost factor in the manufacture of goods, so location of the processing facilities close to the production areas is critical to minimizing transportation costs. Each industrial hemp cultivar has its own set of characteristics, such as:

- days to harvest

- bast fibre content

- seed yields

- small or large seed

- higher or lower oil content

- different oil chemical composition

Growers should secure contracts before planting industrial hemp as a cash crop in Ontario and be aware that, as markets develop, contracts to grow industrial hemp may specify the exact cultivars that will be grown to meet specific market needs, either for grain, fibre or CBD.

This fact sheet was written by crops staff with the Agriculture Development Branch of OMAFRA.

Reference

Canadian Hemp Trade Alliance (CHTA) Hemp Production eGuide.