Peach training systems

Learn about peach training systems to manage trees for maximum fruit size, yield and quality.

Introduction

Training systems are designed to manage trees for maximum fruit size, yield and quality. Training systems that produce early yields, high quality fruit and labour efficient production will help to improve the economic viability of peach production. While apple planting systems have changed rapidly in the past 10 years, training and pruning of peaches have been slow to change. As land costs and labour costs rise, some growers are looking at high density orchards to help keep them competitive in the market.

Peach trees in Ontario have a short productive life (15 years) and low production levels compared to other growing areas with warmer climates. The economic viability of peach production is linked directly to orchard productivity and management efficiency. Orchard productivity is dependent on tree survival, managed vigour, and achieving good marketable yields over the expected lifespan of the orchard. Research in other peach growing areas in the North east suggests that high density peach production (400-600 trees/acre) can be more productive and profitable than the traditional low density systems. The four most commonly discussed training systems for peach include: Open Centre (OC), Central leader (CL), Perpendicular V (PV), Hex V (HV) and Quad V (QV).

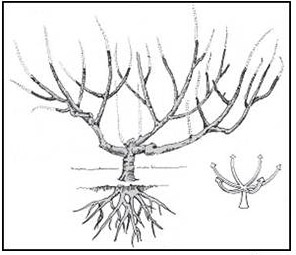

The Open centre (OC) or Vase system

The Open centre system (Figure 1) is the most common planting system used in Ontario peach orchards.

Major characteristics

The open center tree has 3 to 5 major scaffolds branching from the trunk. This system has a tree density of 173 trees per acre (14 ft between trees x 18 ft between rows).

Advantages

- This system has the lowest number of trees used per acre making it the lowest cost system to establish.

- The OC system produces larger fruit during drought than any of the other types of training systems.

- This system produces most of the fruit in the upper third of the canopy and as a result may fare better when early season frosts occur as compared to other training systems (PV).

Disadvantages

- There are fewer trees in this system so tree loss can have considerable effects on yield.

- Wide plant spacing means that trees come into production more slowly.

- Yields are lower than high density systems when the trees rows are filling in. Yield differences between different densities may be negligible once the tree row is filled in.

- The shape of the canopy limits the use of mechanical thinners and platforms.

- Sunlight exposure is less than other systems, affecting fruit colouring and resulting in multiple picks at harvest.

- Trees are smaller than high density trees and as a result may be prone to more damage than QV and PV during radiation frost events.

Central leader system (CL)

The Central leader system (CL) (Figure 2) is being used in some peach orchards, especially by apple growers who are comfortable with the training system.

Major characteristics

This system is similar to the central leader training system commonly used in apple orchards. The tree has four distinctive parts: a strong central trunk, a vigorous apical bud, four major scaffolds arising from the lower portion of the trunk, and numerous small renewable branches along the upper portion of the trunk. The tree density ranges from 538 to 210 trees per acre (at a spacing of 4.5-11.5 ft between trees and 18 ft between rows respectively).

Advantages

- With the CL system the majority of the fruit is produced on the four permanent lower tier scaffolds that are close to the ground, reducing labour costs associated with pruning, thinning and harvesting.

- Produces higher yields than OC, and QV, but lower production then PV.

- Average fruit size is smaller than OC and QV, but larger than PV.

- Fruit is exposed to more sunlight, so fruit colour is better than that in the OC and similar to the QV and PV. Harvest is likely reduced by one picking.

- If a branch is lost to canker then only a small portion of the bearing area is lost, as compared to OC or Quad V.

- If tree is pruned to keep it narrow, platforms and possibly mechanical thinners can be used.

Disadvantages

- Regular pruning is needed due to the close in row spacing, and the need to promote a strong leader.

- Peaches upright growth habit can cause scaffolds to be too upright and crotch angle management can be difficult.

- Tight crotch angles can case canker formation on the main trunk resulting in tree girdling and loss.

Perpendicular V system (PV)

The Perpendicular V system (PV) (Figure 3) is a moderately high density planting system that was developed by the University of California's Kearney Agricultural Centre for peach and nectarines grown on standard rootstocks.

Major characteristics

This system involves training the trees to have only 2 scaffolds. There are 484 trees/acre (at a spacing of 5 ft between trees and 18 ft between rows).

Advantages

- PV system produces greater yields than OC.

- The narrow tree spacing means that this system produces early and provides sustained fruit cropping.

- Fruit exposure with this system is better than OV and results in high fruit quality.

- Ease of adjusting the crop load due to the uniformity of the system.

- Allows for the use of labour saving devices such as mechanical thinners and platforms.

Disadvantages

- The low number of scaffolds in this system means that winter injury, canker, or improper thinning (excessive fruit) can cause scaffolds to break reducing yields by up to 50%. If the primary scaffolds break at the point of attachment, the entire tree can be lost.

- Produces fruit throughout the canopy, making it more susceptible to frost during bloom. As a result, frost protection is essential when using this system.

- Fruit size is lower in this system then other training systems (OC, Hex V and Quad V).

- The high number of trees per acre makes this system more expensive to plant than OC.

- Summer pruning is essential to maintain fruiting wood and fruit quality along the scaffolds. If summer pruning is done too late in the season, flower buds may not be produced, reducing the crop in subsequent years.

- This system requires a reliable irrigation system during periods of drought.

- Taller tree height means the use of platforms (or ladders) are needed for pruning and thinning. Research shows that when platforms are used for thinning the labour costs are similar to those in an OC system. In orchards without platforms labour costs for thinning may be increased due to tree height.

The Hex V system

The Hex V system (Figure 4) is another high density training system.

Major characteristics

This system involves training the tree to have six scaffolds. There are 242 trees per acre, and the tree spacing is 10 ft between trees and 18 ft between rows.

Advantages

- Trees produce earlier then the OC system and PV. Come into production at the same time as QV.

- Yields in this system are second only to the QV system.

- This system is second only to OC with respect to fruit size

- This system is considered to be the most profitable system

- The moderate number of trees per acre means this system is cheaper than QV and PV to establish, but more expensive then OC.

- Fruit exposure with this system is better than OV and results in high fruit quality.

- This system allows for the use of labour saving devices such as mechanical thinners and platforms.

- Pruning is easy to do (not complex).

- 2nd highest yield efficiency (yield per trunk cross sectional area) of the systems (QV was highest).

Disadvantages

- More expensive than the OC system to establish due to the number of trees.

- Fruit size is smaller than the OC system.

- Taller tree height means the use of platforms (or ladders) are needed for pruning and thinning. Research shows that when platforms are used for thinning the labour costs are similar to those in an OC system. In orchards without platforms labour costs for thinning may be increased due to tree height.

The Quad V system

The Quad V system (Figure 5) is another high density training system used in peaches.

Major characteristics

This system has four scaffolds per tree. There are 346 trees per acre, and the tree spacing is 7 ft between tree and 18 ft between rows.

Advantage

- The yields in the QV system are greater than all of the other training systems.

- Trees produce earlier then the OC system and PV system and come into production at the same time as HV.

- Pruning is easy to do (not complex) and can be used to managing crop load.

- Allows for the use of labour saving devices such as mechanical thinners and platforms.The 2nd highest profitable system.

- Highest yield efficiency (yield per trunk cross sectional area) of the systems.

- Greater cumulative number of large size peaches as compared to the OC, PV, HV.

Disadvantages

- However fruit size is below that of OC and HV.

- This system has the 2nd highest number of trees per acre so the costs to plant are greater than for other training systems.

- Improper thinning (excessive fruit) can cause scaffolds to break reducing yields by up to 50%

So which system is best?

The answer to this question varies depending on the orchard, the trees and market. Each system has its pros and cons. A recent study by Dr. Jim Schupp looking at the various different systems found that while all of the systems generated positive returns some did better than others.

- The ranking in order of profitability, high to low, of the various training systems was hex V, quad V, perpendicular V, and open vase.

- Key advantages of the high-density systems included early yields, simple pruning, and the ability to adjust to mechanization-both platforms and the Darwin blossom thinner.

- Growers who are not able to invest in tools for mechanization (mechanical thinners) may find the high density systems to be a disadvantage since the trees are higher, requiring more ladders.

- Growers without access to irrigation and require large sized fruit to meet market demands may not benefit from high density systems. However in areas where land costs are high and growers are interested in getting earlier production and increasing yields and are able to invest in labour saving devices (platforms and blossom thinners) and irrigation may benefit considerably from the early and high yields associated with high density plantings.

If you are considering trying some higher density plantings Dr. Desmond Layne has some things to remember:

- Do your homework ahead of time and understand the training system.

- If possible visit someone who has been successful in implementing the system.

- Start on a small scale and learn the system first.

- Take into consideration your existing equipment and the skill of your labour force when deciding to change to a new system.

- Can you justify the increased cost of trees during the establishment phase?

- Is the availability and cost of land a concern so that you might need as high a profit as early as possible?

References

- Peach Training Systems for the Mid-Atlantic. Jim Schupp, Penn State FREC.

- More profitable and productive peach planting systems. Stephen A. Hoying, Terence L. Robinson, and Robert L. Anderson, Cornell University.

- If peach trees have a full crop and are not thinned properly what can happen. Clemson University.

- Central Leader Pruning of Peach Trees. OMAFRA.