Recommendations for harvest and storage of pears

Learn about the harvest and long-term storage of pears. This technical information is for commercial fruit farmers.

ISSN 1198-712X, Published October 2023

Introduction

Pears can be harvested near ripe and sold for immediate consumption for fresh markets. However, most pears grown in Ontario are stored for a period of time and marketed throughout the fall season. Other countries that produce large amounts of pears often store most of the production and then market the pears for 6 to 8 months.

Long-term storage of pears can be a challenge. Many cold storage facilities in Ontario are outdated and not suitable for long-term storage of pears. Bartlett pear, which has been the number one pear for many years, must be harvested carefully and at the right maturity for long-term storage. Under Ontario conditions, storing Bartlett pears for longer than 1 to 2 months has often resulted in a high percentage of culls.

Cultivar improvements have given Ontario producers the opportunity to modernize the pear industry. New storage technologies have also revived optimism in storing and marketing pears for longer periods of time than in previous years.

Bartlett and Bosc were the 2 main pear cultivars in Ontario for over 50 years. Pears released from the Agriculture and Agri-Food Canada breeding program at Harrow — AC Harrow Crisp™, Harovin Sundown™ and HW620™ — have helped expand the pear industry in Ontario because of their resistance to fire blight, a destructive disease.

Maturity

Most pears reach optimum harvest maturity for storage while they are still green and hard. Therefore, pear maturity is primarily determined by firmness. Some pears destined for immediate sale might be left on the tree for several days longer, as they soften and begin to turn yellow.

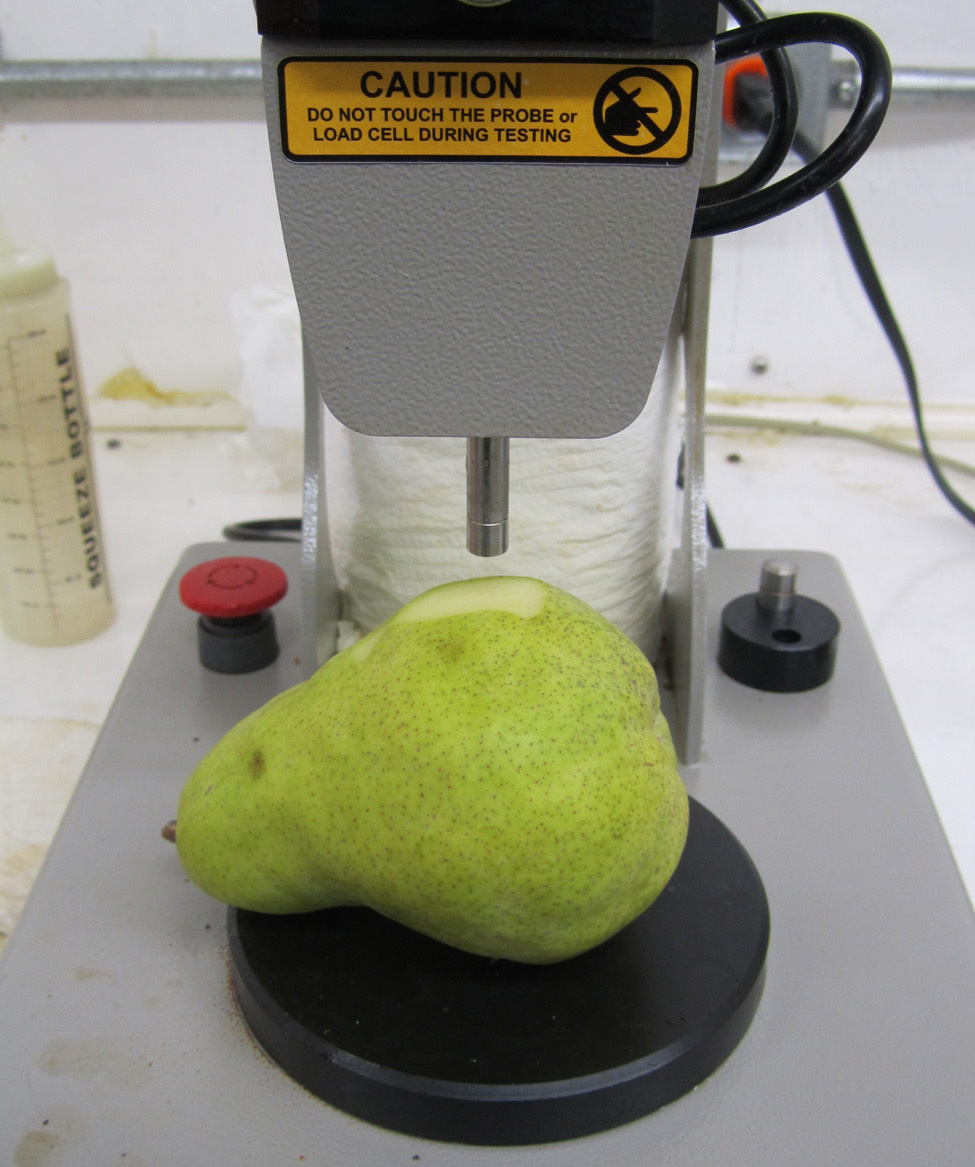

Fruit firmness testing is currently the main method used to determine pear maturity. Checking firmness involves sampling a number of pears in the orchard. Sample 10 pears for every acre, assuming that the block is uniform. Firmness is measured at 2 opposite sides on the equator of each pear after removing the peel, using a penetrometer with an 8-mm (5/16-in.) diameter tip (Figure 1).

As firmness decreases, the pear begins to soften and mature. Each cultivar has different firmness characteristics and different rates of softening as the pear ripens. For long-term storage, pears are harvested when very firm and less mature, compared to pears destined for immediate consumption.

Soluble solids concentration (SSC, °Brix) is another method of identifying maturity. SSC is affected by several factors, such as crop load, rainfall and temperatures prior to harvest, and location on the tree (exposure to more sunlight on the tree exterior usually causes pears to mature earlier). Generally, a minimum of 10% SSC at harvest is required to obtain the best pear quality.

The starch iodine test can also be used as an index for pear maturity. For example, Bartlett pears are ready to harvest when 60% of the maximum starch content remains. However, this does not appear to be an accurate measure for maturity of the new pear cultivars.

Days from bloom to harvest is often used as a guideline for predicting pear maturation. For example, Bartlett pears in the Niagara region generally bloom around May 18 and harvest is approximately September 5, which equals 115 days from bloom to harvest.

New methods for measuring pear maturity are currently being evaluated in pear-growing regions. Optical density, measured using a multiple wavelength light transmittance meter, is a method used in California for specific cultivars. A non-destructive DA meter can rapidly measure chlorophyll content using near-infrared spectrometry. However, its success for predicting maturity varies, depending on the cultivar.

Other important factors in determining pear maturity include colour, finish, percentage of blush and ease of separation of the pear from the spur. Heat units are generally not a good indicator of pear maturity.

Bartlett pears are the most predictable and understandable, and standard measurements for firmness have been well established for many years. However, there is a rapid loss of firmness during the harvest window, so it is best to get the pears off the trees quickly before they become too soft for commercial use. For long-term storage, harvest Bartlett pears around 81 to 85.5 N (18 to 19 lb) pressure. For short-term storage or immediate use, harvest at 67.5 to 76.5 N (15 to 17 lb) pressure.

Bosc pears typically store well for about 3 months. Harvest pears at around 72 to 81 N (16 to 18 lb) pressure for the best storage results. The firmer the pear, the longer it will maintain good quality in storage.

AC Harrow Crisp ripens 2 to 3 days after Bartlett. However, the best maturity index still needs to be determined, and it may not be firmness. Harrow Crisp typically begins to soften earlier in the season than Bartlett but tends to remain firm at 63 to 72 N (14 to 16 lb) pressure for a long period of time. Early-picked pears can be stored for 2 to 3 months, but storage life is reduced with later-picked pears (Such as, <54 N (<12 lb)).

Harovin Sundown typically ripens 2 to 3 weeks after Bartlett. This is another cultivar for which the best maturity index has yet to be determined. This pear typically begins to soften earlier than Bartlett, but tends to remain at 45 to 63 N (10 to 14 lb) pressure for a long period of time, up until harvest. In some cases, the colour of the pear starts to change from green to yellow, with a pink blush, while staying firm. Flavour is generally good, but there can be some astringency in the skin at harvest.

HW620 tends to ripen 3 or more weeks after Bartlett and within a week after Harovin Sundown. This selection needs more grower handling and experience to determine optimum maturity indices. HW620 usually begins to soften earlier in the season than Bartlett but then tends to remain at 54–63 N (12–14 lb) pressure for a long period of time until harvest. As these large pears mature, they can loosen from the spur and drop prematurely. The colour tends to remain a “deep” green as the pear matures, while maintaining the same firm pressure. Soluble solids are slow to rise as the pear matures and the harvest date nears.

Harvest and handling

There are only 5 to 6 main cultivars of pears in Ontario. The harvest season is from late August to early October. Most pears reach optimum harvest maturity for storage while they are still green and hard. Some of the recently released pear cultivars remain firm on the tree for longer periods of time and can be harvested with less firmness than Bartlett. Some cultivars have fruit that adhere to the spur and are difficult to remove, while others fall off quite easily.

Pears are generally picked directly into baskets or bags that are gently placed into large bins for storage. The most common bins used for harvest have been wood, and the use of plastic liners has helped reduce skin damage and scuffing. More recently, the industry has been changing to plastic bins to reduce damage to pears.

Preharvest practices for controlling storage rots are important for storage and pear quality. Once the pears are deemed ready for harvest, pick them as quickly as possible to maintain firmness. If harvesting continues over an extended period, separate loads of pears into long-term and short-term storage. Pears harvested near the end of harvest and with lower firmness tend to be susceptible to more diseases, decay and storage problems.

Mowing can reduce humidity in the orchard before harvest and reduce fungus populations, thereby reducing infection of the pears before harvest. Avoid harvesting during rain or early morning dews, so that pears are dry when placed in the bin, to help reduce the possibility of infection and disease development.

During harvest, have pickers wear gloves or cut sharp fingernails, which can lead to creating punctures and other entry points for decay fungi. Stem punctures (Figure 2) are very common during harvest, so have pickers place pears into the picking basket or bag carefully. Most decay enters pears through punctures or small cuts. Anything you can do to reduce skin breaks in pears will reduce storage rots. Ensure picking bags or baskets are free of any edges that can cut pear skin. The later the pear is harvested, the softer it is and the more prone to punctures and cuts.

Scuffing is caused when pears are rubbed or pressed against a rough surface (Figure 3). The damage appears as dark brown or black marks on the skin and increases as the pear gets softer. To reduce scuffing, use bin liners stapled to the outside of the bin. If liners are stapled to the inside, exposed staples are left when the liner is removed, leaving a source of punctures for the next time the bin is filled. Ensure bins are clean, dry and free of dirt and gravel that could cut or puncture pears. It is also important that tow-motor drivers keep soil and gravel out of bins and off bin rails. This debris can cut pear skin and also end up in the packing house and storage area where it can contaminate pears.

Pears are sensitive to bruising during harvest and handling. Physical or mechanical damage, such as scuffing, impact and compression bruising, does not always show up right away but can develop later in storage. Do not overfill picking baskets and bins, and take care when pouring the pears into the bins. Remind pickers not to press against the bin with their bags when emptying out the pears.

It is important to minimize vibration during transport from the field to the packing house. Grade orchard laneways, minimize the number of moves for full bins and use air ride suspension systems whenever possible to avoid bruising. Do not leave baskets and bins in direct sunlight, and cool pears as soon as possible for long storage life. Any unnecessary delays in cooling pears have a huge effect on their quality later during storage.

Grading pears in the packing house is another area where scuffing and bruising often occur. Pears moving on conveyer belts often come in contact with unprotected edges, machinery parts and other pears, which can cause damage. Protect pears during the packing process by reducing the number of drops, and cushion the area where the pear lands. A drop of 7.6 cm (3 in.) or more onto a hard flat surface damages pears. Use padded ramps, drapes and shallow transitions between belts.

Pears can either be packed a few days after cold storage, when field heat has been removed from the pears in the bin, or stored until they are ready for market, then graded and shipped to their destination.

Storage

Once harvested, pears begin to undergo the ripening process to develop full flavour. It typically only takes a few days to a couple of weeks at room temperature to ripen most cultivars. Firm green pears begin to soften as starch changes to sugar. The skin colour also begins to change from green to yellow. During this ripening period, the respiration rate increases, as does ethylene production. When the bulk of pear production will be marketed over a long period of time, it is important to store the pears to control ripening processes.

Cooling the pears prior to storage is one of the most important steps to ensure good fruit quality. The most common method of storing pears in Ontario is by traditional room cooling. The crop is taken from the field to the cold storage in either 10.4-L (11-qt) baskets or bins. This is a relatively slow method of cooling pears. Depending on temperatures during harvest, it can often take 48–72 hours to bring the temperature down to approximately 1°C. There are few controlled atmosphere (CA) storages that are used for long-term pear storage in Ontario. However, CA storage can extend storage life, using atmospheres ranging in 1% to 2% oxygen and 0% to 2% carbon dioxide, depending on pear cultivar.

Forced-air cooling is the most common method of rapid cooling for pears, especially in areas of large production. This can cool pears 5 to 8 times faster than traditional room cooling. Hydro-cooling is another effective and rapid method of cooling, but it may increase postharvest decay by spreading pathogens.

Some growers and packers grade and pack out culls shortly after the field temperature has been removed from the bin or basket. The pears are then packed directly into boxes, put back into storage and are now ready for market.

It is important to maintain very high humidity, at least 90% to 95%, during the storage period to reduce visible signs of shrivel on the skin. Most modern commercial storages can maintain adequate relative humidity; however, many older, smaller, on-farm storages designed for short-term storage likely cannot maintain such high relative humidity. Humidifiers can add moisture to reduce water loss in the pears. Wooden bins and packaging material naturally gain moisture as well, so it is important to monitor the relative humidity. To reduce water loss from bin absorption, replace wooden bins with plastic bins. Fogging or misting humid air into the storage room can also increase relative humidity. Wetting the floors is the least effective method to increase humidity.

The 2 most common storage rots are blue mould (caused by Penicillium expansum) and grey mould (caused by Botrytis cinerea). These are spread easily through the air in storages, so it is important to maintain a preharvest orchard spray program and monitor fruit regularly during storage. Handle pears carefully during and after harvest to minimize stem punctures, skin breaks and bruises, which act as infection sites for fungi. During storage and transportation, move the bins with minimal jolts and drops. Cool and refrigerate the pears as quickly as possible. Each storage room must have adequate refrigeration capacity. Using modern refrigeration facilities and controlled atmospheres reduces storage rot.

Sanitation in the handling and grading area is important. Remove rotted pears from the premises and property. Change the water used for dipping or drenching frequently. Postharvest treatment with fungicides can reduce disease incidence.

Refer to the Ministry of Agriculture, Food and Rural Affairs’ (OMAFRA) Crop Protection Hub for further information on disease control.

Senescent scald and storage scald are the main external physiological disorders that develop on pears in storage. Senescent scald develops when pears lose their ability to ripen, after extended storage durations. The pears turn yellow and eventually develop dark brown skin (Figure 4). The browning can start during storage or right after the pears are put into room temperature. Reducing the storage period and using all best management practices can reduce the chances of senescent scald. It can also be reduced if pears are stored in controlled atmosphere storage.

Storage scald (also known as superficial scald) develops during storage, but signs are not visible until pears are moved to warmer temperatures (Figure 5). This is strictly a surface disorder, which causes bronzing of the skin. Storage scald can be reduced if pears are stored in low-oxygen storage.

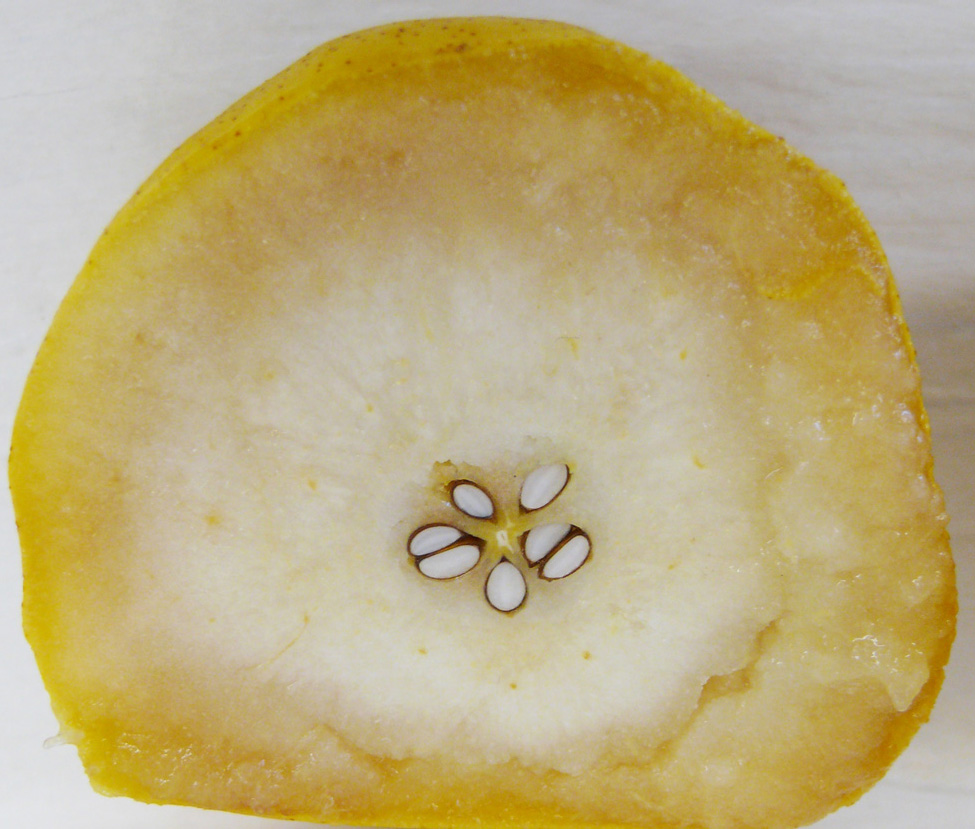

Core breakdown is a serious internal disorder, especially in Bartlett (Figure 6). It can only be detected by cutting into the pear. The pear becomes unmarketable, as the flesh in and around the core turns brown and soft. Late-harvested pears are usually more susceptible. Pears that tend to soften quickly, like Bartlett, are generally prone to this disorder. Maintaining proper temperatures from the time of harvest right through to retail marketing is important for controlling this disorder.

A technology was commercialized for delaying the ripening of apples and pears during storage. SmartFresh™ (1-methylcyclopropene, 1-MCP) inhibits the action of ethylene, the natural ripening hormone of pears. It has been shown to inhibit ethylene production, retard respiration rate, delay or prevent softening and substantially reduce storage disorders in various pear cultivars.

Conclusions from a review on the ripening of European pears indicate that there is still no clear understanding of the best combination of harvest maturity, SmartFresh concentration, application conditions (temperature and time) and storage time after SmartFresh treatment to adequately control softening and the development of physiological disorders, while simultaneously allowing the pear to ripen to good quality for marketing. However, work on Ontario pears has shown that an overnight treatment with the Canadian label rate of 300 ppb 1-MCP applied 3 days after harvest provides the best balance of reduced disorder development during storage and the ability of Bartlett pears to soften adequately thereafter. In other growing areas, especially on the West Coast, there continues to be a risk of excessive inhibition of ripening when using SmartFresh on European pears.

Bartlett pears are fairly predictable for softening during storage. If harvested at 81–85.5 N (18–19 lb) pressure, the pears will easily store for up to 4 months at 0.5°C and maintain a pressure around 54–58.5 N (12–13 lb). Once removed from storage and delivered to retail for sale, they quickly soften to around 22.5–31.5 N (5–7 lb) pressure after only a few days at room temperature. The colour of the skin also quickly changes from green to yellow. More disorders develop in pears harvested later (approximately 45–63 N (10–14 lb) pressure), which limits storage life.

The use of SmartFresh can improve firmness retention in Bartlett pears after removal from storage. Skin colour also remains greener for a longer period of time. Pears treated with SmartFresh can be 22.5 N (5 lb) firmer than untreated pears after storage. Senescent scald and internal breakdown are substantially reduced by using SmartFresh. Senescent scald has been reduced by 50–90% with SmartFresh, after 4 months of storage at 0°C and 5 days at 18°C–19°C, compared to untreated pears. Friction marking is also significantly reduced by SmartFresh.

Bosc pears typically store well for up to 4 months at 0.5°C. Softening of the flesh is not as rapid as in Bartlett pears. Although SmartFresh has had variable effects on Bosc, it can delay softening, ethylene production, acidity loss and colour change during cold storage plus another 14 days at room temperature. SmartFresh may also reduce the incidence of storage rots.

AC Harrow Crisp picked early can be stored for about 4 months, but storage life is reduced with later harvest. If kept too long or harvested too late (such as, <54 N (<12 lb)), it will deteriorate internally without external signs. It tends to be prone to developing internal cavities (Figure 7), as desiccation and browning within the flesh, especially after extended storage durations and in late-harvested pears. Harrow Crisp is also susceptible to scald, but it remains unclear whether it is senescent or storage scald (or both).

SmartFresh is very effective at delaying softening of Harrow Crisp pears. Pears harvested at 63 to 67.5 N (14 to 15 lb) pressure and treated with SmartFresh stayed firm after 2 months at 0.5°C plus 7 days at 21°C, while similar pears only lost 9 N (2 lb) pressure after 4 months at 0.5°C plus 7 days shelf-life. In comparison, non-treated pears lost 22.5 to 36 N (5 to 8 lb) pressure during the same period. Pears treated with SmartFresh and harvested later, at 54 to 63 N (12 to 14 lb) pressure, tended to soften more quickly than those from the earlier harvests. Colour change to yellow is also delayed by SmartFresh. In contrast to these beneficial effects, the incidence of internal cavities developing in the flesh can be increased with SmartFresh.

Harovin Sundown pears harvested early (green and around 63 to 67 N (14 to 15 lb) pressure) can be stored for about 4 months, whereas those harvested later (greenish-yellow and around 45 N (10 lb) pressure) have reduced storage life. Harovin Sundown appears to be susceptible to senescent scald, as well as an internal watery breakdown of the flesh (Figure 8). Internal cavities and flesh browning have also been observed occasionally. There are fewer storage disorders in pears harvested around 58.5 to 67.5 N (13 to 15 lb) pressure, suggesting that this is the appropriate harvest maturity for subsequent storage.

Treatment with SmartFresh slows softening and ripening of early-harvested Harovin Sundown pears but has little effect on those harvested late. In riper pears harvested around 45 N (10 lb) pressure, SmartFresh has no significant effect on the incidence of storage disorders. Slight incidence of internal cavities in the flesh has been observed in some pears treated with SmartFresh.

HW620 is typically very uniform at harvest, with little ethylene production and starch content, and a deep green skin colour. When harvested at 54 to 63 N (12 to 14 lb) pressure, it tends to stay firm during storage for about 4 months. HW620 appears to be susceptible to scald, core breakdown and internal browning.

SmartFresh treatment prevents softening in HW620 and the skin colour change to yellow during storage at 0.5°C for 4 months plus 7 days at 21°C. However, pears treated with SmartFresh usually begin to soften and turn yellow after 14 days at room temperature. Treated pears often have no scald or internal browning, whereas the non-treated pears have significant amounts. SmartFresh can also reduce the incidence of friction marking.

Summary

Harvest all pears destined to be stored for any duration at the proper maturity, and handle them with care during harvest. Cool pears as quickly as possible and store them at the proper temperature (–1°C to 0°C) with high humidity (90–95%). With SmartFresh, most pear cultivars will remain firmer during storage and for longer periods of time after being removed from storage. In addition, SmartFresh substantially reduces storage disorders.

Harvest Bartlett pears when firmness reaches 81 to 85.5 N (18 to 19 lb) pressure and Bosc at 72 to 81 N (16 to 18 lb). The later the pears are harvested and the softer the pear, the more likelihood there is of storage disorders developing. SmartFresh significantly delays softening, ethylene production, acidity loss and colour change, as well as improving firmness retention and controlling disorder development in Bartlett pears after removal from storage.

Harvest Harrow Crisp, Harovin Sundown and HW620 pears at around 58.5 to 67.5 N (13 to 15 lb) pressure. Similar to the dominant cultivars, the later the pears are harvested and the softer the pear, the more likelihood there is of storage disorders developing. SmartFresh treatment causes these pears to remain firmer in storage and stay firmer once removed from storage, compared to untreated pears or those harvested at a later maturity. SmartFresh reduces most storage disorders, such as senescent scald, internal browning, core breakdown and friction marking. However, the incidence of internal cavities developing in the flesh can be increased by the use of SmartFresh, especially in later-harvested Harrow Crisp.

Using all best management practices to reduce bruising and fruit injury in the field and during the packing process will help ensure good quality pears going into the storage. Maintain proper temperatures and high relative humidity during storage to reduce disorders and diseases, and permit pears to be stored for longer periods of time.

References

Slingerland, K., and W. McFadden-Smith. August 2011. Pear Production in Ontario. Ontario Ministry of Agriculture, Food and Rural Affairs.

DeEll, J., and B. Ehsani-Moghaddam. 2011. Timing of Postharvest 1-Methylcyclopropene Treatment Affects Bartlett Pear Quality after Storage. Can. J. Plant Sci. 91: 853–858.

DeEll, J., and B. Ehsani-Moghaddam. 2010. Storage to Help Extend the Seasonal Availability of Pears. Report for CanAdvance Project ADV-635.

DeEll, J., and K. Slingerland. 2009. Storage to Help Extend the Seasonal Availability of Pears. Report for CanAdvance Project ADV-635.

Mitcham, E.J., and R.B. Elkins. 2007. Pear Production and Handling Manual. University of California Agriculture and Natural Resources. Publication 3483.

This fact sheet was authored by Dr. Jennifer R. DeEll, fresh market quality specialist, OMAFRA, and Ken Slingerland, horticultural consultant. It was reviewed by Dr. Gale Bozzo, postharvest biochemistry and secondary metabolism, Department of Plant Agriculture, University of Guelph; Kathryn Carter, grape and tender fruit specialist, OMAFRA; and Colleen Haskins, on-farm food safety specialist, OMAFRA.