Ultraviolet radiation in the workplace

Learn about the hazards of ultraviolet (UV) radiation from the sun and other sources and how to prevent overexposure.

Overview

Ultraviolet (UV) radiation, also called ultraviolet light, is a form of electromagnetic radiation. Other forms of electromagnetic radiation include:

- radio waves

- X-rays

- visible light

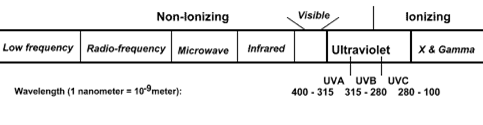

On the electromagnetic spectrum, UV radiation comes between visible light and X-rays. This means its wavelengths are shorter than the wavelengths of visible light and longer than those of X-rays. UV radiation is divided according to its effects on living tissue into three wavelength bands:

- UVA

- UVB

- UVC

Most UV radiation sources also emit visible light. This is usually brilliant white, but it sometimes has a purplish hue. UV lasers emit UV radiation without producing any visible light.

Figure 1: The Electromagnetic Spectrum

Common UV sources in the workplace

Please note that the following summary of hazard (overexposure) potential is intended as guidance only and is not comprehensive. The actual UV exposure levels in a workplace depend on the conditions there. A UV radiation survey would be required to determine the actual exposure levels at a particular workplace.

Operations that use artificial UV sources may expose workers to excessive UV radiation. These include:

- welding

- processes involved in printing

- curing of inks, paints, adhesives, etc.

- non-destructive testing (NTD) and material inspection

- UV disinfection in hospitals and laboratories

Outdoor workers may easily be overexposed to UV radiation from the sun during spring and summer. They include workers in:

- construction

- open-pit mining

- logging

- landscaping

- road building and maintenance

- agriculture

The sun

Potential for overexposure is very high.

UV from the sun is highest in spring and summer from 11 a.m. to 4 p.m. UV guidelines can be exceeded in 15 minutes on a clear summer day. Clouds may do little to reduce UV levels.

Review precautions to prevent overexposure to the sun.

Electric welding arcs

Potential for overexposure is very high.

Welding arcs can exceed the UV guidelines in seconds within a few meters of the arc which can overexpose:

- workers

- bystanders

- passers-by

For safety advice, refer to:

UV curing lamps

Potential for overexposure is medium.

These lamps are usually inside cabinets, but substantial UV radiation can escape through openings.

For safety advice, refer to:

Black lights

Potential for overexposure is medium to low.

These lamps are low-power UVA lamps usually used in non-destructive testing (NDT), insect control, and entertainment.

For safety advice, refer to:

Germicidal lamps

Potential for overexposure is high.

These lamps are UVB- and UVC-emitting lamps usually used to sterilize work areas in hospitals and laboratories.

For safety advice, refer to:

UV lasers

Potential for overexposure is high.

These lamps are a source of intense UV radiation at a single wavelength, with no visible light.

For safety advice, refer to:

- Laser safety in the workplace

- ANSI Z136.1 Safe Use of Lasers

- ANSI Z136.3 Safe Use of Lasers in Health Care

- CAN/CSA-Z386:20 Safe Use of Lasers in Health Care

- IEC 60825-1 Ed. 3.0 Safety of Laser Products Part 14

Lighting

Potential for overexposure is low.

These lamps usually emit little or no UV radiation.

No safety precautions are needed under normal conditions.

Tanning lamps

Potential for overexposure is high.

These lamps emit mostly UVA radiation. They must exceed guidelines in order to cause tanning.

Safety precautions would include preventing exposure to the UV radiation such as by the worker leaving the room prior to the tanning bed being turned on by the customer.

Health effects of UV exposure

Although exposure to small amounts of UV radiation can have beneficial effects, such as vitamin D synthesis in the skin, overexposure can cause serious health effects, including:

- acute (short-term) effects

- chronic (long-term) effects

Acute effects

Sunburn

(medical name: erythema)

This is a reddening of the skin, with blistering and peeling in severe cases. Of the three UV bands, UV-B is most effective in causing sunburn.

Your skin will tan to protect itself against UV radiation. The pigment that gives the skin its colour becomes darker as more of it is produced. Prolonged exposure to UV radiation causes a thickening of the skin's outer layer. Since people with lighter skin, hair and eyes have less pigment, they are more sensitive to UV exposure.

Damage to the skin accumulates over the day, and the injury does not become obvious until a few hours later. Given time, sunburned skin repairs itself.

Welders' flash, also known as arc-eye and snow-blindness

(medical name: photokeratoconjunctivitis)

This is a painful irritation of the cornea and the conjunctiva (the membrane connecting the eyeball with the inner eyelid). There is a feeling of "sand in the eye" and sensitivity to light.

UVB is most effective in causing this "sunburn of the eye”. The eye is more sensitive than the skin to UV radiation because it lacks the skin's outermost layer and protective pigment.

Symptoms appear from six to 24 hours after exposure and usually disappear within the following 48 hours. No permanent damage to the eye results unless a severe exposure has occurred.

Retinal injury

Retinal injury, possibly resulting in loss of sight, may be caused by UV radiation in people who have had the lens of an eye (the crystalline) removed, for example due to cataracts. This can be prevented with UV-absorbing lens implants or eyeglasses. In the normal eye, the retina is protected from UV injury because the lens filters out UV radiation.

Chronic effects

Skin cancer

Excessive exposure to UV radiation over many years has been shown to increase a person's risk of developing skin cancer. The most common types of skin cancer, basal cell carcinoma and squamous cell carcinoma, are not usually life-threatening if treated early. Malignant melanoma is a rarer but much more dangerous form of skin cancer.

A person's chance of getting skin cancer increases with the lifetime UV dose, that is, the total UV radiation they have received. The risk of getting malignant melanoma also increases with the number of blistering sunburns experienced during childhood.

Lighter-complexioned people are more likely to develop UV-related skin cancers than darker-complexioned people, so they should be particularly careful to minimize their UV exposure.

Photoaging

This is the premature aging of the skin caused by chronic exposure to UV radiation. The resulting changes in the skin include:

- excessive wrinkling

- dark spots

- loss of elasticity

- a leathery appearance

Senile cataracts

A senile cataract is a clouding of the lens of the eye in older people, often impairing vision and eventually requiring surgery. Long-term UV exposure has been shown to be an important factor in the development of this disease.

Immune system effects

Recent research indicates that exposure to UV radiation can adversely affect the immune system. For example, over-exposure to sunlight (UVB in particular) may cause an immune response, such as an eruption of cold sores (herpes simplex).

Hypersensitivity to UV radiation may result from either:

- the use of certain prescription drugs, such as tetracycline (a common antibiotic)

- exposure to some industrial chemicals, such as coal-tar distillates

Workers who may be exposed to UV radiation should ask their physicians about the possibility of sensitization when given any new prescriptions.

Lime juice is also known to be a photosensitizer. It reacts with the UVA radiation in sunlight to cause “margarita burn” or phytophotodermatitis, which can result in burning, redness and blisters.

Exposure guidelines

The Ministry of Labour, Immigration, Training and Skills Development's Radiation Protection Service applies the threshold limit values (TLVs) recommended by the American Conference of Government Industrial Hygienists (ACGIH) for occupational exposure to UV radiation. These limits are enforced in Ontario workplaces by the ministry under section 25(2)(h) of the Occupational Health and Safety Act. For workplaces in the mining industry, there are specific requirements for protecting workers who perform welding, burning, or cutting operations from radiation and electric arcs. These are found under section 194(3) of R.R.O. 1990, Reg. 854: Mines and Mining Plants.

Exposure limits are based on UV doses that normally do not produce sunburn or eye irritation (such as welder's flash). They consider the varying biological effects of different wavelengths of UV radiation. The guidelines limit the “effective Actinic UV irradiance” to three millijoules per square centimetre, accumulated over an eight–hour period.

Additionally, the total irradiance of “UVA Spectral Region (315 to 400 nm)” on the unprotected eye is limited to 1.0 milliwatt per square centimetre for periods greater than 16.7 minutes and to 1.0 joule per square centimetre for shorter periods. (See Ultraviolet Radiation in the ACGIH's Threshold Limit Values. There is a fee for the booklet.)

These guidelines do not apply to UV lasers or to workers exposed to hypersensitizing substances.

Where applicable, an employer should retain the services of a qualified person to complete the following steps using appropriate equipment:

- measure UV radiation

- determine exposure levels

- determine allowable exposure times

- enforce compliance with the guidelines

Control measures

The following control measures can help to prevent the overexposure of workers to UV radiation. The measures used will depend on each situation.

Engineering controls

UV radiation should be contained or confined to a restricted area whenever possible.

Contain UV radiation easily with opaque materials, such as cardboard or wood. Transparent materials, such as glass, PVC (polyvinylchloride), plexiglass and perspex, block UV radiation to varying degrees.

Generally, carbonated plastics provide adequate UV protection. Some kinds of clear glass (including some kinds of window glass and optical glass) transmit significant amounts of UVA radiation.

A high-power UV source should have interlocked access so that it is shut off when the protective enclosure is open.

Administrative controls

Whenever UV radiation cannot be contained or confined, worker exposure should be minimized by limiting exposure times and increasing the distance between workers and the sources. Measurements are required to determine safe working distances and exposure times.

Areas where exposure to UV radiation is possible should have appropriate warning signs.

Personal protection

Workers exposed to UV radiation more than the above guidelines should use all the following personal protective equipment:

- UV-blocking safety eyewear (goggles, spectacles, face shields, welding shields, etc.) with side-shields where applicable

- long-sleeved, tightly woven clothing that covers as much of the body as practicable

- sunscreen with a sun-protection factor (SPF) of 30 or higher and effective against UVA and UVB on all exposed skin

Preventing overexposure to UV radiation from the sun

In Ontario, during the midday hours on clear summer days, UV radiation from the sun can easily exceed the exposure limits quoted above. Outdoor workers should limit their exposure to solar UV radiation by either:

- making use of natural or artificial shade or

- scheduling alternative tasks when the sun is most intense

Working in direct sunlight

While working in direct sunlight when UV levels are high, outdoor workers should:

- limit the amount of time they work outdoors in the sun, especially between 11 a.m. and 4 p.m.

- seek shade as much as possible, especially during breaks

- wear a wide brim hat (8 cm or more)

- attach a back flap and visor to a construction helmet

- wear tightly woven clothing covering as much of the body as is practicable

- apply broad-spectrum sunscreen (including lip balm) with a SPF of 30 or higher and effective against UVA and UVB on exposed skin. Reapply at noon and often if perspiring heavily

- wear eyeglasses that effectively filter UV rays. The ANSI Z80.3–2001 standard for non–prescription sunglasses should be followed as applicable

The use of UV safety measures should not lead to other safety risks, such as the risk of head injuries from using hats with inadequate impact protection or the risk of heat stress from wearing heavy clothing in hot environments.

When workers have been overexposed

Provide first aid

For UV overexposure of the eye, place a sterile dressing over the eye and get medical attention.

For UV overexposure of the skin, apply cold water or ice to the skin burns and get medical attention.

Carry out a UV safety audit

- Identify the sources and circumstances that produced the overexposure.

- Discontinue their use to prevent other incidents or, where this is not practicable, determine UV exposure levels and make sure that adequate controls are put in place.

Organizing a program to prevent overexposure

- Step 1: Prepare a list of UV sources in the workplace. Note their wavelength range and output power (if applicable) and determine their hazard (overexposure) potential.

- Step 2: Review work processes and identify those that may cause UV exposure.

- Step 3: Have a qualified person do a UV radiation survey. Determine exposure levels, allowable exposure times, safe viewing distances and the need for personal protective equipment.

- Step 4: Put in place adequate UV control measures.

- Step 5: Update your workplace UV-safety program as new sources are introduced.

Resources

Threshold Limit Values (TLVs) for Chemical Substances and Physical Agents and Biological Exposure Indices (BEIs). American Conference of Governmental Industrial Hygienists (ACGIH). 1330 Kemper Meadow Dr., Cincinnati OH 45240.

American National Standards Institute Z80.3–2018 Opthalmics - Nonprescription Sunglasses and Fashion Eyewear Requirements 1819 L Street, NW, 6th Floor Washington, DC, 20036.

American National Standard Z136.1–2014 for Safe Use of Lasers. American National Standards Institute (ANSI). 25 West 42rd St., 4th Floor New York NY 10036.

Guidelines for Tanning Equipment Owners, Operators and Users - Canada.ca

Contact us

For more information about UV radiation and radiation protection in the workplace, please call the Health and Safety Contact Centre at

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply and enforce these laws based on the facts they find in the workplace.

We have included links to other websites, but this does not mean that we endorse all of their information as compliant with the OHSA or the regulations.