We've moved this content over from an older government website. We'll align this page with the ontario.ca style guide in future updates.

Respirators

By its nature asbestos operations take place under conditions where permanent engineering controls cannot be used to protect workers. Construction, renovation, and demolition projects, for example, are constantly changing and the work is often done under physically challenging conditions. Maintenance and repair work is intermittent and the use of permanent engineering controls is not usually practicable. Instead, reliance is placed on temporary measures, such as enclosure of, and restricted entry to, the work area, the maintenance of negative air pressure within the work area, and the use of personal protective clothing and equipment.

Respirators play a very important role in the protection of workers, and it is essential that both workers and employers understand how to use them properly.

The respirator requirements for Type 1, Type 2, and Type 3 operations are summarized in Table 2 of the Regulation. There is also a very easy-to-use chart of respirator requirements available in PDF format from the Construction Safety Association of Ontario.

All respirators must be approved by the U.S. National Institute for Occupational Safety and Health (NIOSH). The Regulation permits the use of both air-purifying and supplied air respirators, depending upon the work being performed. Powered air purifying respirators (PAPRs) are commonly used types of respirators in Type 2 and Type 3 operations. Supplied air respirators are used for dry removals or removals of sprayed on insulation containing asbestos other than chrysotile.

What are the types of respirators?

Respirators fall into one of two general categories: air purifying and supplied air.

Half-face mask

This style is widely used with air-purifying respirators and with some supplied air systems.

Full face mask

Full face masks can be used with air-purifying, powered air-purifying and supplied air respirators. They cover the entire face and provide more protection than other face masks.

Air-purifying respirators

Air-purifying respirators use filters, cartridges, or canisters to remove particulate, vapour and/or gas contaminants from the air. This type of respirator may be equipped with powered or non-powered half or full-face masks, or powered helmets or hoods. If an air-purifying respirator is used, it must be suitable for protection against asbestos. An N-100, P-100, or R-100 or HEPA filter is required.

Non-powered respirators depend upon the breathing action of the wearer. This can result in negative pressure within the face piece and the inward leakage of contaminated air. There may also be noticeable resistance to inhalation, which can make these respirators difficult to wear for long periods of time or in hot environments.

These problems can be overcome by using a powered respirator. Powered air purifying respirators (PAPRs) contain a blower that passes the contaminated air through a filter and supplies filtered air at positive pressure to the face piece, hood or helmet. PAPRs are not supplied air respirators.

Supplied air respirators

Supplied air respirators, as the name implies, provide clean air from an independent source either carried by the user (self-contained breathing apparatus or SCBA) or delivered to the user through an air supply line or hose.

Supplied air respirators can receive air from a compressed air source or an ambient air blower. They can be equipped with a variety of face pieces: half or full-face pieces, helmets or hoods, although the Regulation specifies that tight-fitting half or full-face pieces be used, depending upon the work. They may supply air only on "demand" or as a continuous flow. Leakage is a problem with demand devices because inhalation creates a negative pressure that allows contaminated air to enter the face piece. Continuous flow and pressure demand devices create a positive pressure within the mask that is independent of the wearer's breathing, although there is a risk that workers may create a negative pressure inside the face piece during extreme exertion.

The Regulation requires that negative pressure or demand supplied air respirators be equipped with a full face piece, while continuous flow supplied air respirators may be equipped with tight fitting half or full face pieces. The use of pressure demand supplied air respirators equipped with a full face piece is allowed during Type 3 operations involving non-friable ACM, and equipped with a half-mask (please see Table 2 in the Regulation) during Type 3 operations involving the wet removal of friable, sprayed on ACM that contains a type of asbestos other than chrysotile. Pressure demand supplied air respirators used during the dry removal of friable ACM must be equipped with full face pieces. To minimize the inward leakage of contaminated air, a minimum air flow must be maintained; six cubic feet per minute (170 L/min) for loose-fitting hoods or helmets and four cubic feet per minute (130 L/min) for tight-fitting face pieces.

Powered air purifying respirators which can be used in Type 1 and some Type 2 operations

Source: Construction Safety Association of Ontario

Respirator fit

Subsection 13(1) (a) requires that respirators used in Type 1, 2 and 3 operations be fitted so that there is an effective seal between the respirator and the worker's face unless the respirator is equipped with a hood or a helmet. In general, this means that the respirator must be of an appropriate size for the worker's face and that facial hair and scars or other irregularities must not interfere with the seal and that these devices are not to be worn unless the worker has passed an appropriate qualitative or quantitative fit test.

Are there different methods to test the fit of respirators?

There are two methods of testing the fit of respirators. One is "qualitative", where simple tests are used to check for signs of leakage; the other is "quantitative", where tests actually measure the leakage using special instrumentation. There are also procedures for field checking and testing of the respirator seal.

Appendix B of the Canadian Standards Association (CSA) Standard Z94.4-02, Selection, Use, and Care of Respirators lists four protocols for Qualitative Respirators Fitting Tests:

- isoamyl acetate protocol;

- saccharin solution aerosol protocol;

- bitter aerosol protocol; and

- irritant smoke protocol.

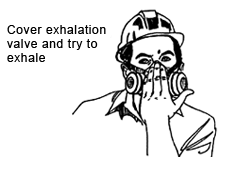

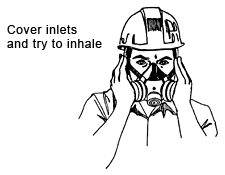

Positive and negative pressure user seal checks

Negative-pressure and positive-pressure user seal checks are conducted on tight-fitting electrometric face pieces to check the respirator seal in the field. These two test procedures are outlined in CSA Standard Z94.4-02, Appendix A. They are simple and quick, and can be performed by the wearer to check the respirator fit at any time during a work shift. The positive-pressure test is conducted by covering the exhalation valve, usually located on the bottom of the respirator, with the palm of the hand and exhaling gently. The face piece should puff slightly away from the face without allowing air to escape. The negative-pressure test involves covering the air inlets and then inhaling. A slight collapse of the face piece with no air leakage indicates a satisfactory fit.

Positive and negative pressure fit checks

Source: Construction Safety Association of Ontario

Respirator maintenance

Respirators must be maintained in good operating condition if they are to be effective. The maintenance program should follow the manufacturer's instructions and include provisions for the following use:

- Cleaning and disinfection

- Inspection and maintenance

- Storage

- Replacement of damaged/deteriorated parts, and

- Proper fit

Written procedures

Respirators must be selected, used and maintained following written procedures that are put in place by the employer and these procedures must be consistent with the manufacturer's specifications.

Subsection 13(3) of the Regulation requires the employer to establish written procedures for the selection, use and care of respirators. A copy of these procedures is to be given to and reviewed with every worker who is required to wear a respirator.

Cleaning and disinfection

The Regulation requires that respirators be cleaned and disinfected after use on each shift, or more often if necessary, if they are used exclusively by one worker. They must be cleaned and disinfected after each use if they are used by more than one worker.

Inspection and repair

After being cleaned and disinfected, each respirator must be inspected to determine if it is in proper working condition. Where the inspection indicates that parts are damaged or deteriorated, they must be replaced before the respirator is used again.

Storage

The Regulation requires respirators that are not in use to be stored in a clean, convenient, and sanitary location. The storage area should protect the equipment from dust, sunlight, heat, extreme cold, excessive moisture and damaging chemicals. It is recommended that individual respirators be placed in plastic bags or closed containers and stored in a manner that will prevent distortion of rubber or plastic parts.

Breathing air requirements

Subsection 13(2) sets out the requirements for breathing air that is used with supplied air respirators. Compressed breathing air must meet the standards set out in Table 1 of CSA Standard Z180.1-00, Compressed Breathing Air and Systems. If an oil-lubricated compressor is used to supply breathing air, a continuous carbon monoxide monitor equipped with an alarm must be provided. An audible alarm is preferred. If an ambient breathing air system is used the air intake must be located in accordance with Appendix B of CSA Standard Z180.1-00, Compressed Breathing Air and Systems. The intake must be located in a clean area outdoors away from vehicle and building exhausts.

Training

Section 19 outlines the duties of an employer with regard to worker instruction and training, including the use of respirators. Subsection 8(3) paragraph (e) places a similar obligation on an owner. The instruction, in the case of an employer, is to be provided to every worker in a Type 1, 2 or 3 operation, and in the case of an owner, to every worker employed by the owner who is likely to work with or near ACM mentioned in the record required by section 8.

The Regulation does not require the employer to do the actual instructing but only to ensure that it is provided by a competent person.

The instruction and training related to the use of respirators must cover the following:

- the limitations of the equipment;

- inspection and maintenance of the equipment;

- proper fitting of a respirator; and

- respirator cleaning and disinfection.

Physical ability to use a respirator

The use of a respirator places extra physical demands on the wearer. Air-purifying respirators make breathing more difficult; any respirator is an added weight to carry (more than 25 pounds in the case of a self-contained breathing apparatus (SCBA)); an air-line respirator requires, in addition, a length of hose to be dragged around.

The Regulation requires that a worker not be assigned to an operation requiring the use of a respirator unless physically able to perform the work while using the respirator. Where there is doubt about a worker's ability to work with a respirator, the worker should seek the advice of a physician. The physician's examination should concentrate on conditions that affect the worker's ability to breathe. Heart problems and conditions such as claustrophobia can also make the wearing of a respirator ill-advised. It is recommended that in the case of a worker required to wear SCBA, the weight of the respirator should be considered in judging the ability of a worker to perform the work.