Biosecurity recommendations for commercial poultry flocks in Ontario

Learn how to prevent the introduction of infectious diseases into poultry flocks. This technical information is for commercial poultry producers in Ontario.

ISSN 1198-712X, Published October 2016

Avian Influenza surveillance, diagnostics and control zones

The Canadian Food Inspection Agency (CFIA) establishes control zones in areas where avian influenza has been identified. Visit the CFIA website to learn about them or view maps of current control zones in Ontario and Canada.

For sick birds and concerns with high mortality, contact your local CFIA District Office or your private veterinarian.

Introduction

Infectious diseases such as Avian Influenza (AI) and Infectious Laryngeotracheitis (ILT) pose a constant threat to commercial poultry production.

By implementing and diligently maintaining a sound biosecurity program, poultry producers can minimize the risk of introducing infectious diseases to their flocks, or spreading them to other flocks. Outbreaks of AI in Ontario, British Columbia and the United States emphasize the need for producers to implement a sound biosecurity program.

Common sources of infection

Birds can contract diseases via direct contact with infected birds, and/or indirect contact through exposure to contaminated people, animals or items. The most common sources are:

- infected wild or domestic birds (birds can be infectious, but not show clinical signs)

- wild or domestic animals (for example, cats and dogs)

- vermin (for example, rodents and insects)

- contaminated people carrying the virus on their hands, clothing, footwear and hair (for example, employees, visitors, veterinarians, vaccination crews, catching crews, haulers, meter readers, deadstock pickup, input suppliers)

- contaminated vehicles and other farm equipment (for example, manure trucks and spreaders, tractors, feed trucks, turkey loaders, barn cleanout equipment)

- contaminated poultry equipment (for example, hauling/transport equipment, catching equipment, feeders and waterers)

- contaminated water, feed, bedding, soil and manure

- airborne dust, dander and feathers

The ultimate goal of biosecurity protocols is to control and/or minimize these sources of contamination.

Major components of a good biosecurity program

A good biosecurity program must consider all aspects of the operation including:

- environmental contamination

- farm management

- disease prevention

- nutrient management

- visitor control

Additionally, the program must be both practical and scientifically sound, to ensure consistent and effective protection against costly contagious diseases. Biosecurity is based on two main concepts:

- exclusion: keeping the disease out of the flock

- containment: if introduced, preventing disease from spreading within or between premises

An effective biosecurity program should encompass both exclusion and containment. This is often done in three components referred to here as Access Management, Health Management and Operational Management. This is in accordance with the National Avian On-Farm Biosecurity Standard. The biosecurity risks are unique for every poultry operation, thus individual programs should be customized with the help of a veterinarian.

Access management

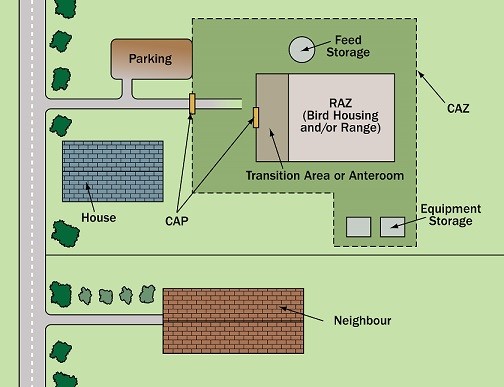

Preventing the introduction of pathogens into your flock is the first step. It is essential to follow proper protocols for movement of people, equipment and birds onto and within the farm. The best approach is to create two zones:

- An outer area commonly referred to as Controlled Access Zone (CAZ), which encompasses the entire area where poultry are kept or handled.

- The Restricted Access Zone (RAZ) is a more restricted area, located inside the CAZ, where access is more tightly controlled.

- Each access point to the CAZ or RAZ is referred to as a Controlled Access Point (CAP). These entrances are used by all traffic, such as workers, equipment, feed trucks, etc.

The following recommendations are designed to control access to the flock:

Designation of zones

- Install a biosecurity sign at each CAP (for example, the farm gate and the entrance of each poultry production area) to instruct unauthorized people not to enter the premises.

- Install visibly defined barriers and access points with clear written instruction to be followed within the access zone (CAZ or RAZ) for all areas where poultry are kept or handled.

- Lock all doors to the poultry houses at all times. Ropes, stakes, gates and fences are also effective barriers for the CAZ. Allow only certain authorized and necessary personnel to enter poultry production area. Regardless of the method used, it is very important to ensure that access to the CAZ can be closed/blocked if necessary.

- Ensure everyone is clear about the biosecurity protocol, including what the rules are and why they are in place.

- Prior to entering the RAZ, have well-maintained facilities in place for hand washing, changing and/or covering of footwear and clothing. Ideally, a transition room or anteroom should be provided (Figure 2).

- A shower-in, shower-out policy for all visitors and employees is the most effective approach. This may be more practical for breeder and primary breeder flocks.

Photo A. Enter the barn by the Danish Entry system. Stop when you reach the barrier.

Photo B. Remove clothing and hang on hooks.

Photo C. Disinfect hands using sanitizer.

Photo D. Take off your outside boots, swing your feet over the bench and on the clean side put on barn coveralls and boots.

Photo E. Enter the barn.

Entry, movement and exit controls

- All vehicle traffic should be kept at a minimum distance from buildings. Designate an area for visitor parking away from poultry barns, outside the CAZ.

- Locate a drop box at a sufficient distance from the barn for or courier deliveries, bills and receipts.

- All movements onto, off of and within the premises should be recorded, including movement of people, poultry, vehicles, manure, feed, equipment, etc.

- Keep a visitor log. For visitors to record their names, the nature of their business and their contact information.

- Ensure all farm personnel and visitors have not been in contact with other birds within 24-hours of entering the premises.

- Ensure all visitors and farm personnel wear personal protective equipment (PPE). This includes clean coveralls (disposable is preferred), mask, hair protection (cap) and disposable footwear (if boots are used, have designated boots for each barn and thoroughly clean and disinfect after each visit). Separate attire should be used for each poultry production area. Clothing worn on farm should be washed separately from household laundry using hot water and heated drying.

- Wash hands with soap and water or sanitizer before and after each visit. Wear disposable gloves.

- If using a footbath, follow label instructions to ensure the disinfectant concentration and contact time are sufficiently satisfied for proper sanitation. Footbaths must be changed regularly; dirty foot-baths increase the risk of pathogen spread. Scrub boots so that they are free of organic material before stepping into the footbath.

- Clean and disinfect (C&D) any equipment that is used in the production area before entering and after leaving. This is especially important for catching equipment if only part of the flock is shipped to the processing plant (thinning out or partial pick up) or if the equipment is used in more than one production area.

- Ensure that all disposable PPE is left on the farm for all visitors, including catching crews and other service industry personnel.

- All biosecurity protocols must be followed by all who enter the farm.

Managing Flock Health: It is important to know the health status of your flock, in order to effectively recognize disease conditions and take appropriate action.

Animal introduction, movement and removal

- To minimize the risk of disease, it is preferred to have an "all-in, all-out" system (single age flock at any given time). To be considered "all-in, all-out" placement or shipping periods cannot exceed 7 days.

- If an "all-in, all-out" system is not possible, additional precautions are necessary for multi-age flocks:

- Always visit from youngest to oldest and from healthy to sick flocks.

- Allow for adequate separation and quarantine of at least 28 days for new poultry being added to an existing flock.

- Purchase and introduce only birds with known health status and updated health records.

- Maximize downtime between flocks, as follows:

- dry cleaning, plus clean and disinfect: at least 7 days

- dry cleaning only: at least 14 days

- no manure removal, dry cleaning, or clean and disinfect: at least 21 days

- after a disease outbreak, a complete clean and disinfect should be performed

Ongoing monitoring of health status

- A daily flock check is important for early identification of sick birds. Be aware of signs of disease in birds. Early detection can limit the impact of a disease outbreak and allow for a faster return to normal operation. Signs that may indicate disease include (but are not limited to):

- high mortality

- drop in egg production

- reduced feed/water consumption

- "snicking", swollen sinuses, lethargy, diarrhea with other symptoms

- Remove dead birds daily and cull compromised birds.

- Maintain daily records of mortality and culls.

- Establish a written flock health program with your veterinarian, including vaccination and medication protocols.

- Have a biosecurity protocol for employees that hunt waterfowl or have contact with other wild avian species.

Other considerations

- Minimize contact with other poultry, including neighbouring backyard flocks.

- Do not allow any farm employees to keep backyard or pet birds, or attend live bird shows or markets.

- Keep pets out of the poultry production area.

Operational management

Mortality management

- Develop an action plan to direct day-to-day handling of dead birds and keep it easily accessible. Any dead or culled birds should be considered infectious and handled accordingly to ensure the containment of potential pathogens.

- Dead birds should only be moved and stored in isolated, sealed containers (such as, pails with lids, freezers, barrels with lids) away from poultry production areas.

- Carcass disposal, including on-farm disposal (such as, incineration, composting and burial) should be done in accordance with the Nutrient Management Act (2002) and any other federal, provincial and municipal regulations and guidelines. If rendering is used, minimize biosecurity risks by keeping deadstock pick up away from production facilities.

- Clean and disinfect all used equipment (such as barrels) at the end of carcass pick up.

- If carcasses are not frozen for pick up, permanently dispose of them within 48 hours.

- Preventing the scavenging of deadstock is critical for prevention of disease transmission from wild to domestic animals, domestic to wild animals, and from farm to farm.

Manure management

- Federal, provincial and municipal regulations must be followed.

- Never use manure from an unknown source on poultry farms.

- Control the manure storage site by limiting access, locating it away from barns and preferably compost the manure before spreading onto land, especially in disease situation.

- If manure is removed from the farm at the end of each flock, manure should be damped and tarped before leaving the farm.

Premises, building, equipment and vehicle sanitation

- Clean and disinfect (C&D) poultry barns between flocks especially if infectious disease was present in the previous flock. Barns should be free of litter and debris; pressure washed with warm water and detergent, and allowed to dry before applying disinfectant.

- At cleanout, empty feed lines, boots and hoppers.

- Water and ventilation systems must also be part of the C&D procedures.

- If barns are connected, include any middle room or hallway in all cleaning and disinfection procedures.

- Avoid borrowing or lending farm equipment. If equipment is shared, clean and disinfect before and after use. Complete removal of any organic material before disinfection is very important.

Facility maintenance and water, feed and bedding management

- Ensure buildings and storage facilities are regularly maintained including ventilation, watering and feeding systems.

- Drinking water must be potable. Regular testing and proper sanitation is essential, especially if using surface water source. There are different methods of water sanitation. If applying chlorine, monitor the level of active chlorine and water pH for effective chlorination. Consult with your veterinarian to implement a water sani-tation program.

- Clean and disinfect water lines completely between flocks to avoid build up of biofilm that can harbor pathogens and inactivate some disinfectants.

- Obtain all bedding and feed from reputable suppliers and store properly.

- Keep storage areas free of moisture, pests and protected from the elements.

Pest control program

Insects, rodents, wild birds and other wildlife can act as disease vectors. In order for pest management to be effective, proper production management as well as mechanical and chemical control methods must be implemented and monitored.

- Screen all building inlets, fans and ledges. Plug or repair any gaps and holes in the structure.

- Clean feed and water spills in the farm environment, especially outside poultry facilities. Ensure feed bins are covered and feeding systems are closed.

- On ranges, provide sufficient fencing and covered space to house poultry during seasonal risk times to protect against predators, pets and other livestock.

- Maintain a 1 m (3 ft) apron of gravel/crushed stone around the perimeter of barns.

- Develop a management plan to deter wild birds.

- Keep vegetation and debris cleared around poultry houses, as these will attract rodents.

This fact sheet was originally written by Al Dam, provincial poultry specialist, Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), Guelph; Csaba Varga, DVM, lead veterinarian, disease prevention — poultry, OMAFRA, Guelph; Dan Ward, P.Eng., poultry and other livestock housing and equipment, OMAFRA, Stratford; and Amanda Bordin, Sabrina McDonald, Sarah Buttle and Gillian Greaves, poultry summer research assistants.