Burning shelled corn as a heating fuel

Learn about heating your home using shelled corn, what equipment to buy and how to store the fuel corn. This technical information is for Ontario rural landowners.

ISSN 1198-712X, Published March 2011

Introduction

Corn stoves are again gaining interest as a means to heat homes, other out-buildings and even larger commercial buildings.

More than 20 companies make a range of sizes and models of corn-fuelled appliances such as stoves, furnaces and hydronic hot water furnaces, which can be tailored to specific needs.

The decisions to consider shelled corn as a fuel, which stove, furnace or boiler to buy and how to store the fuel corn are challenging.

Unlike other home heating systems where the fuel is delivered through a pipe or a wire, corn-fuelled appliances need corn fed into them manually in order to produce heat. The corn storage system can be very simple or more complex, with simple corn storage systems usually involving daily manual labour.

Corn — a hands-on heating fuel

Having a corn-burning appliance in the home requires daily attention — removing the clinker (residue) or delivering fuel to the unit. This process harkens back to the "good old days" and heating with a wood stove before the arrival of central heating systems in homes. These units can operate for a time unattended but do need attention to ensure fuel availability and routine cleaning of ash build-up to provide safe, efficient operation.

A number of manufacturers make stoves that burn shelled corn. Figures 1 and 2 show a corn-burning stove in a home. Although similar to wood stoves, these new stoves are specifically designed to burn a dry granular fuel, such as shelled corn. Corn-burning stoves usually have a combustion air fan and a corn delivery system, which is not required in standard wood stove construction.

Burning corn

There is an abundant source of dry shelled corn in Ontario. Corn used as a fuel in stoves can be of a lower quality than Grade No. 2. Where possible, use non-food grade corn.

There are some quality requirements for this corn fuel:

- Shelled corn must be dry, preferably 15% moisture content or less. Corn higher in moisture will have a lower heat value per unit weight than "dry" corn, causes flow problems through the fuel loading system and can spoil in storage, resulting in a significant reduction in quality. Figure 3 shows corn being off-loaded in the field.

- Shelled corn must be free of fines. Dirty corn, which has a lot of fines and cob pieces, will cause problems with the fuel delivery system. Prescreen shelled corn to remove fines and cob pieces. Figure 4 shows corn cleaning in progress.

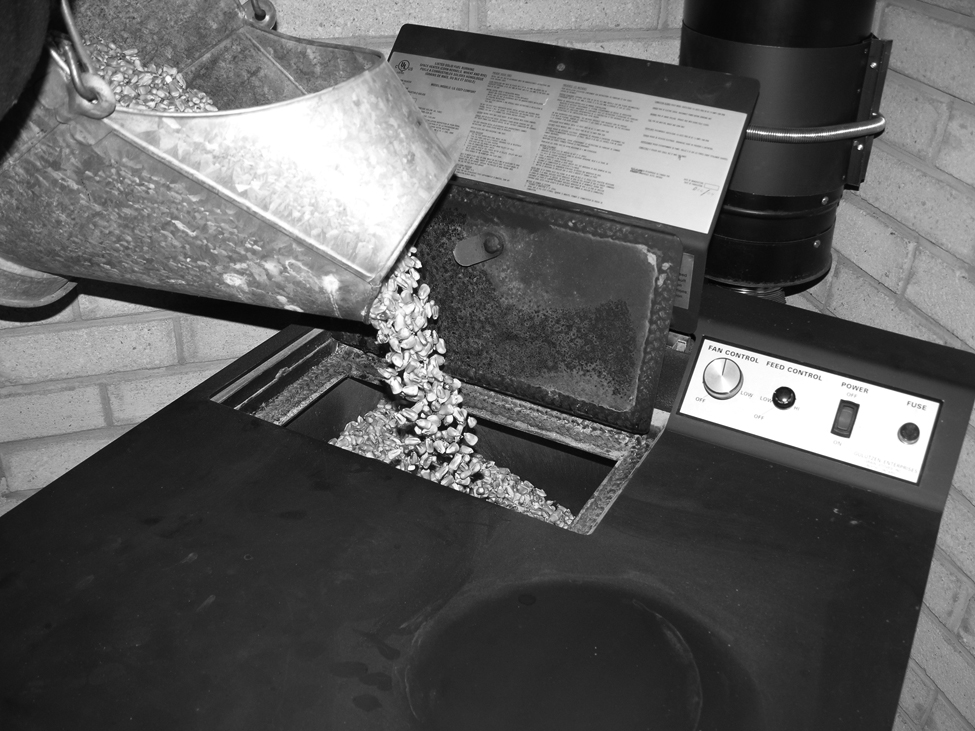

- Dirty corn may also cause bridging in fuel hoppers. Figure 5 shows corn being augered into the stove.

- Corn test weight does not affect burn quality. The heat content of shelled corn is based on the weight and moisture content of the corn.

Reddog is a reddish-pink, light, flakey material loosely attached to the base of corn kernels that is easily dislodged during drying and handling. Burnt reddog and ash can build up on heat exchanger surfaces and reduce stove efficiency. Clean heat exchangers regularly.

Every year, farmers harvest, dry, convey and store millions of bushels of shelled corn. A corn storage system for home heating made of augers, conveyors and hopper bottom storage bins is easy to build.

Shelled corn is attractive as a heat source, as it is easily handled and in plentiful supply. Shelled corn also has a high heat energy content per unit weight. Table 1 shows how shelled corn compares to other solid fuels.

| On-farm fuel source | Heat energy |

|---|---|

| Shelled corn | 7,000 BTU/lb (16,200 kJ/kg) at 15% moisture content |

| Straw | 6,550 BTU/lb (15,200 kJ/kg) air dried |

| Corn stover | 7,540 BTU/lb (17,400 kJ/kg) air dried |

| Wood | 8,000 BTU/lb (18,500 kJ/kg) air dried |

| Premium wood pellets | 9,000 BTU/lb (20,800 kJ/kg) kiln dried |

Table 1 shows that shelled corn has a heat energy value close to wood. Straw and corn stover are both of low density and are difficult to meter into a combustion chamber. Some new biomass burners and boilers use biomass in the form of briquettes, cubes and pucks. These systems are in the early development stages in North America.

Basics of corn stoves

Corn stoves are specifically designed to burn a small granular fuel. Because this fuel is metered into the burning chamber, most stoves have a storage hopper to hold a small supply of fuel. Corn-burning stoves are very similar to pellet-burning stoves. Both corn and pellets are very dense. Neither of these fuels will burn readily in an open pile in a fire chamber. However, wood pellets do not form ash clinkers that have to be removed daily. The bottom of the burning chamber of a corn-burning stove must allow the clinker to drop out.

Fuel, ignition and oxygen

To keep the shelled corn burning, manufacturers use a small combustion chamber into which a fan moves air for combustion. The corn is introduced into the stove with a top feeder or a bottom feeder fuel delivery system. The feed rate of the fuel delivery auger can be adjusted to regulate the amount of corn burned, which in turn determines the amount of heat produced. The auger "on time" is usually adjustable, while the short "off time" is preset by the manufacturer.

The second requirement for burning is ignition. Depending on the stove, the lighting process is either manual or automatic. The manual method involves lighting wood pellets, then starting corn delivery once the pellets are burning well. Automatic systems use a fuel-heating rod that ignites the corn.

The third requirement for burning to occur is oxygen. To support combustion, oxygen is blown into the combustion chamber by means of a small fan. The combustion air is usually brought in from the outside. This combustion chamber is actually quite small, about the size of a lunch box.

Inside the stove, a heat exchanger removes heat from the flue gases. A larger fan moves the room air through the heat exchanger in the stove, where it is warmed. This fan also helps move the heated air farther away from the stove.

Another style of corn stove does not use augers to supply the corn or fans to provide combustion air or move heated air to the room. These stoves burn corn at the bottom of a hopper and radiate heat to the surrounding room. Unlike the previous type, where electricity is used to stoke the fire and move the heat to the room, these stoves continue to operate and are not affected by electrical power outages.

The type of flue pipe required to vent the exhaust gases from the stove depends on the design of the stove or corn-burning appliance. These appliances can be direct vented through the wall or through a chimney, similar to a furnace. Through-the-wall vent pipes actually preheat the combustion air by scavenging heat from the exhausting flue gases. Follow the manufacturer's recommendations regarding the type and size of flue pipe required for a corn-fuelled appliance. It is best to keep the flue pipe as short and straight as possible and the number of elbows to a minimum to maximize the stove's performance.

Managing ash and clinkers

As corn burns, it produces a clinker. Because of the small size of the combustion chamber, the clinker must be removed at least once a day. Figure 6 shows clinkers stored in a metal pail. With practice, the removal of the clinker can be done without having to shut down, then relight the stove. Use a specially designed poker to upend the clinker and remove it with tongs. Remove ash and clinkers routinely from the stove and place them into a metal pail that sits on a non-combustible surface. There may still be live embers in the clinker that could reignite when introduced to the air.

Clinkers consist of incombustible ash and corn residue fused together by the heat into an irregular shape. Since no more combustible material remains, the clinker only occupies space in the combustion chamber. Remove the clinker regularly so incoming combustion airflow is not restricted and there is sufficient space for new fuel.

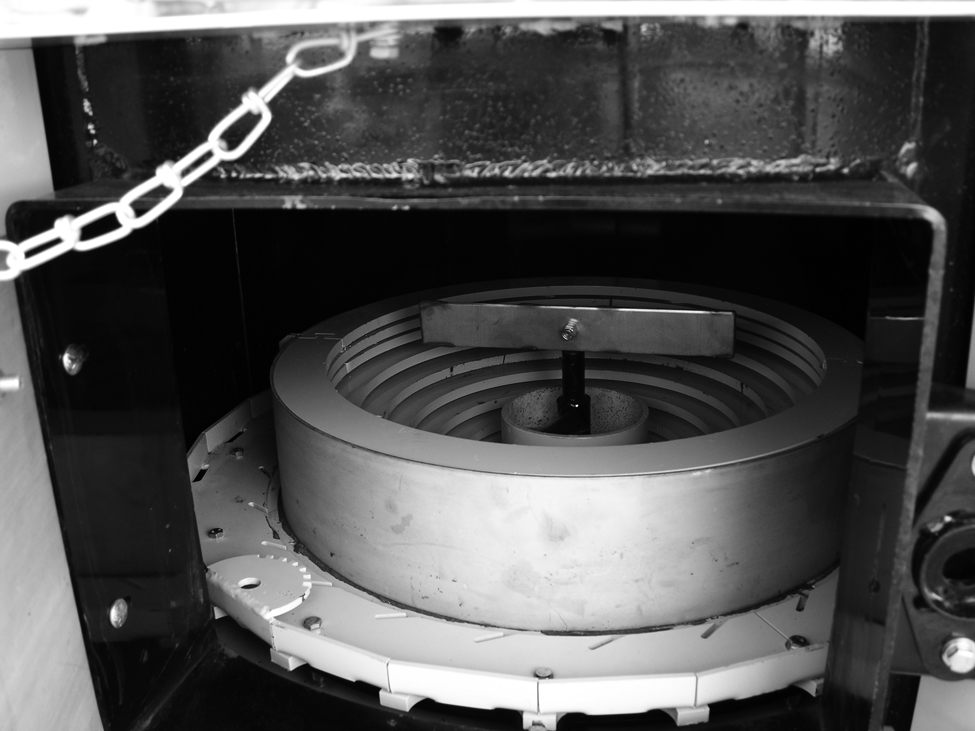

Some appliance designs reduce the formation of clinkers. Stoker or bottom-fed fuel delivery systems push fresh fuel from below. Since this fuel is always mushrooming upward, clinkers do not form. Burnt material rolls off the fuel mound and is caught in an ash tray where it is removed either by hand or automatically, in a larger system. A rotating fuel grate is used in some models; turning these grates routinely breaks up any clinkers, which then fall into a metal ash tray. Other designs reduce combustion chamber temperatures, thereby preventing clinker formation. See Figures 7 and 8.

Spread ground-up clinkers in gardens. The ash and clinkers are mostly composed of potash, a beneficial nutrient that plants use to grow.

Types of corn-fuelled appliances

A large number of manufactures are making corn-burning stoves, corn furnaces and corn-burning hydronic furnaces. They are available in a variety of sizes and styles:

- stove (some can be modified as a fireplace insert)

- space heater

- hot-air furnace

- hydronic furnace (hot water)

The size of fuel hoppers also varies greatly. Hopper sizes range from holding a 1–10-day supply of fuel. Figure 9 shows the fuel hopper mounted on the left side of a hot-air furnace. Auxiliary hopper bottom bins or hopper wagons can increase the fuel supply interval to 30 days or more.

Corn stoves have a fan that moves room air through the heat exchanger and blows it back into the room. Keep small children or pets away from the exposed metal parts of freestanding stoves or space heaters, which can get very hot. Always follow the manufacturers' recommendations for clearances from combustible wall or floor surfaces and add heat shields if indicated.

Price of corn

Carefully investigate prices charged for small quantities of corn before making a commitment to purchasing a corn-heating appliance. Smaller quantities command a higher price per bushel due to handling, packaging and delivery costs. Take advantage of lower costs per bushel of shelled corn by buying in larger volumes, if there is sufficient storage for the larger amount of corn on your property.

Cost of heating with corn

To accurately compare heating with corn to other heating fuels, consider a number of factors. While the price of fuel is important, take into account the heating efficiency of the heating system and the energy content of a unit of each fuel.

The following calculates the cost per million BTUs of usable energy for any fuel and any fuel-burning appliance. The formula takes into account these factors:

- cost/unit of fuel

- energy content/unit of fuel

- annual fuel utilization efficiency of the appliance

See Table 2 for additional information on heat content and heating efficiency of various fuels.

| Fuel type | Energy content per unit | Annual fuel utilization efficiency (AFUE)* |

|---|---|---|

| Shelled corn | 7,000 BTU/lb (16,200 kJ/kg) (392,000 BTU/56-lb bu) (336,000 BTU/48-lb bu) |

60%-80% |

| Furnace oil | 36,700 BTU/L (38,700 kJ/L) |

70%-95% |

| Propane | 25,300 BTU/L (26,900 kJ/L) |

70%–95% |

| Natural gas | 35,700 BTU/m3 (37,700 kJ/m3) |

70%–95% |

| Electricity resistance | 3,413 kJ/kWh (3,600 kJ/kWh) |

100% |

| Air source heat pump | C.O.P. = 3.0 | 300% ** |

| Water source heat pump | C.O.P. = 5.0 | 500% ** |

| Wood | 8,000 BTU/lb (18,500 kJ/kg) |

60% |

* The Annual Fuel Utilization Efficiency (AFUE) is a widely used measure of a furnace's heating efficiency. It measures the amount of heat actually delivered to the house compared to the amount of fuel that is supplied to the furnace. A furnace that has an 80% AFUE rating converts 80% of the fuel that is supplied into heat -— the other 20% is lost out the chimney.

** Note: The Coefficiency of Performance (C.O.P.) is how efficiencies of heat pumps are expressed. The coefficient of performance of a heat pump is the ratio of the heat output to the electrical energy input.

$ per million BTUs of usable energy

= Cost/unit of fuel x 1,000,000 / Energy content/unit of fuel x AFUE

Where:

Cost/unit of fuel is in dollars ($$)

Energy content/unit of fuel is in BTUs

Annual Fuel Utilization Efficiency (AFUE) is in decimal form (70% efficiency = 0.7)

Example:

Using corn at $4.00 per bushel, in a stove with an AFUE of 60%, calculate the cost per million BTUs of usable energy:

Corn cost = $4.00 per bushel

Energy content per bushel = 7,000 BTU/lb x 56 lb/bu = 392,000 BTU

AFUE = 60% = 0.6

$ per million BTUs of usable energy

= ($4.00 x 1,000,000) ÷ (392,000 x 0.6)

= $17.00

Therefore, to supply 1 million BTUs of usable heat to the house costs $17 when the stove operates at 60% efficiency, burning corn at $4 per bushel. The average older home requires approximately 100 million BTUs of usable energy for heating per year. Remember that the price charged per bushel of corn may vary from the market price when small quantities are purchased. Check the prices carefully before doing these calculations.

Limitations of burning corn for heat

The first and most important limitation of corn as a fuel is the stove or burning appliance. If the stove uses augers to feed the corn into the combustion chamber and fans to maintain combustion and move heated air to the room, an electrical power interruption will shut the stove down. With this style of stove, no electrical power means no heat from the corn stove. A battery back-up system allows the stove to work when electricity is interrupted. As a safety feature, most stoves require a manual restart after a power interruption.

Since most new home layouts do not allow for the free movement of air throughout the house, a centrally located stove will not heat the whole house. If the house does not allow convective air movement throughout all areas, size the stove to heat only the room(s) where the stove is located. Over-sizing the stove will result in the room housing the stove becoming unbearably hot.

Stove-buying criteria

Before purchasing a corn stove, answer these questions:

- What is the heat output of the stove? How much heat is required to maintain the heated space at the desired temperature?

- If trying to heat the whole house with a stove or space heater, does the house layout allow for the convective movement of heat through the whole house?

- What is the size of the fuel hopper? Will it require filling on a daily, weekly or biweekly schedule?

- What is the annual fuel utilization efficiency of the corn stove?

- Does the unit meet ULC and CSA standards?

- Are replacement parts and control components readily available?

- Does the unit have hot exposed surfaces that could cause burns to skin?

- What type of exhaust venting is required? Does it require a chimney with a flue liner or can a combination flue/fresh air vent pipe be used?

- Does the clinker need to be removed regularly and the heat exchanger cleaned of ash on a weekly basis?

- Will the stove handle granular solid fuels other than shelled corn? This is important in the event that the economics of burning corn become unattractive or an alternative low-cost pelleted fuel becomes available.

- Is this corn-burning appliance a primary heat source or a supplementary heat source? Stoves with small fuel hoppers will not keep a house warm for long periods of time, unattended.

- How and where will corn be stored for use during winter months?

- Is there a rodent and insect control plan in place for the corn storage?

- Does the stove have a small and large combustion chamber? The large chamber is for winter operation while the small combustion chamber allows for good operation during transition periods from fall to winter and winter to spring. During transition periods, some heat is needed but not a lot. Figure 10 shows different combustion chambers.

- Will the stove, furnace or boiler restart after a power interruption?

Corn storage

Shelled corn used as fuel is stored on site. The amount of corn stored depends on personal preference. For the small-volume user, corn in bags is the most practical option. Short-term storage of corn for a week in the house requires a container with a tight-fitting lid. Large wheeled garbage cans can serve as an indoor container to hold about a week's supply of corn. Once these containers are full, moving them on hard surfaces may require considerable effort. Old freezers can also serve as temporary corn storage. Consider how the storage container will be kept full and try to prevent manually handling the shelled corn twice.

Some rural homes have installed hopper bottom storage bins outside, near a basement window, to hold a month's fuel or more. Gravity carries corn through an enclosed pipe passing through the window opening, directly into the stove fuel hopper. Figure 11 shows an outdoor corn storage system. Routine monitoring is necessary to ensure that corn does not jam in the delivery pipe. One homeowner incorporated a corn storage system into one wall of his new house as it was being built.

Decide how much corn is to be stored in the house at any one time. Determine whether to get a whole winter's supply at one time, in bags or by truck as needed. Mechanizing the corn storage system is possible with equipment that is used to move grain on farms. Other options include bringing corn daily to the stove.

Storing corn in or near the home brings with it the risks of rodents and stored grain pests. Corn is a source of food to rodents. If storing shelled corn, bait the area to control mice and rats. Bait stations are available that are designed to be inaccessible to the family pet (dogs like the taste of shelled corn). A number of stored grain pests also find corn attractive as food and become active at warmer temperatures.

Burning wood pellets or other grains

Wood pellets are another granular fuel considered for use in corn-fuelled appliances. Before burning this fuel source, check with the burning appliance manufacturer to see if wood pellets, other grains or other granular fuels can be used. The Underwriters Laboratories of Canada (ULC) or Canadian Standards Association (CSA) certification may restrict the type of fuel(s) that can be used in this appliance. Corn tends to burn hotter than wood pellets and can cause damage to a stove designed to burn only wood pellets. If the stove has been tested and certified to burn a variety of pelleted fuel materials in addition to corn, then it is possible.

This fact sheet was revised by Helmut Spieser, P.Eng. (retired), Field Crop Conditioning and Environment, OMAFRA, Ridgetown, and reviewed by Steve Clarke, P.Eng. (retired), Energy and Crop Systems, OMAFRA, Kemptville, and Ralph Winfield, P.Eng., Glanworth.