Changing management decisions to reduce soil compaction

Learn about soil compaction, yield losses by depth of compaction and weights of machinery.

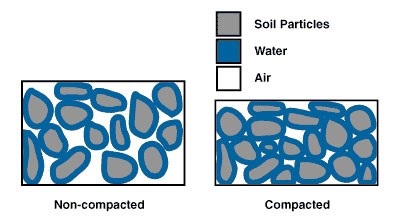

In the way that we decide as farm managers what crop and variety to plant, when and how to plant it, and how to support it through the season, we decide to have or not have compaction! Compaction in its purest sense can be defined as "an applied pressure/force exerted on a landscape that reduces pore space within the soil matrix" (Figure 1). It's more complicated than this, but it gets the point across. If we were to do nothing on our fields they would not be compacted. But that is impossible since we need to plant the ground to have a crop! However, the decisions we make impact the occurrence and severity of compaction.

Figure 1. The difference in porosity between compacted and un-compacted soils (Jodi DeJong-Hughes, University of Minnesota, 2001)

One of the biggest learnings from this spring to remember is that the goal of achieving early planting dates has to be coupled with the requirement that the soil is "fit" for those field operations to occur. Otherwise you may be setting yourself up for compaction and potentially a multi-year impact on crop productivity. There are ways to reduce the risk and severity of compaction by deciding when the soil is "fit", and then what equipment configuration will minimize the risk of inflicting compaction (size, tire technology, inflation pressure, weight distribution, etc).

Compaction has always been troublesome. We know we have it but we do not know how to deal with it. Compaction has likely accelerated in the last couple of decades and the ease with which we can deal with it has become more complex. Things have changed dramatically in farming in Ontario and across the continent. Some of the big changes have been shifts from mixed livestock and crop operations to more specialized farms, increasing farm and field sizes, fewer acres of perennial forage, fewer acres receiving manure, and increases in the size and weight of equipment.

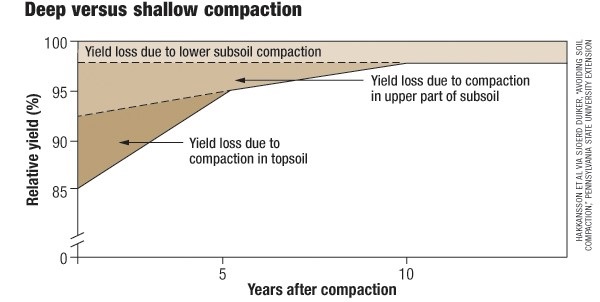

As a result of these changes in farming, the fields are under more stress from compromised soil health and the intensity of equipment use and traffic across fields. To manage this effectively we have to work towards continually building our soil health through tillage management, longer crop rotations, incorporating cover crops and other soil amendments, and choosing the right equipment that is configured in the best way and is used when conditions are suitable. As an example, after considerable investments are made on combines, headers and grain buggies, which place a very heavy weight on the field as per Table 1, we should be ensuring we spend the money to equip them with the best tires (size, technology, and inflation pressures) that allow us to lower our risk of compaction. Tied to this is finding the patience to put the equipment on the fields only when the conditions are suitable. Being almost ready is not the same as being really ready. The damage done by working in fields that are too moist can have long term consequences as shown in Figure 2. Depending on soil type and weather, waiting for "fit" soils can range from a few hours to several days. That can be frustrating, but the damage we can do can stay with us for a long time.

Figure 2. Relative Yield Impact Level and Duration from Soil Compaction. (Hakaansson and Reeder (1994) and Duiker (2004).

Figure 2 suggests that once soil compaction is driven down into the subsoil, that loss, although small (3-5%), may never be recaptured. Even compaction into the upper portion of the subsoil may take upwards of 10 years to recuperate the additional 5% or more of yield loss, and the figure does not account for accumulative compaction. Therefore the goal should be to avoid compaction, or at the very least to minimize it.

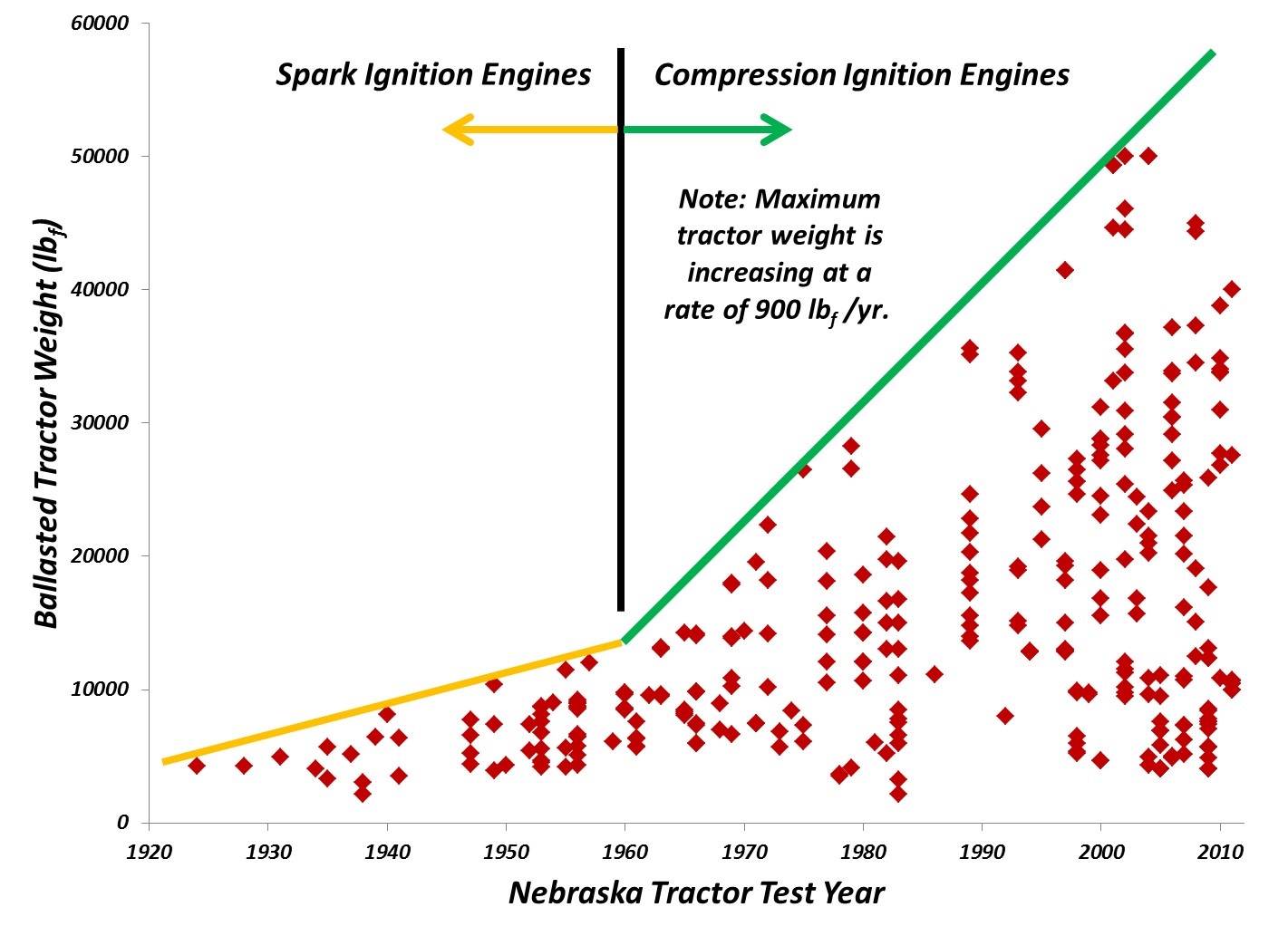

A look at the historical results of the Nebraska Tractor Test Laboratory program shows how the size and weight of equipment has increased (Figure 3). Tractor weights have increased by, on average, 900 lbs/year for tractors purchased on North American farms. The weight and capacity of equipment (thus loaded weight) has reached astounding levels. Ironically when you look at these weights in relation to the 10 ton/axle limit on Ontario roads, a purpose built infrastructure to withstand weight and excessive use, it seems peculiar that we don't give more thought to putting much greater weights onto our delicate farm fields.

Figure 3. Increase in average tractor weights over time (Shearer, Ohio State University, Columbus OH)

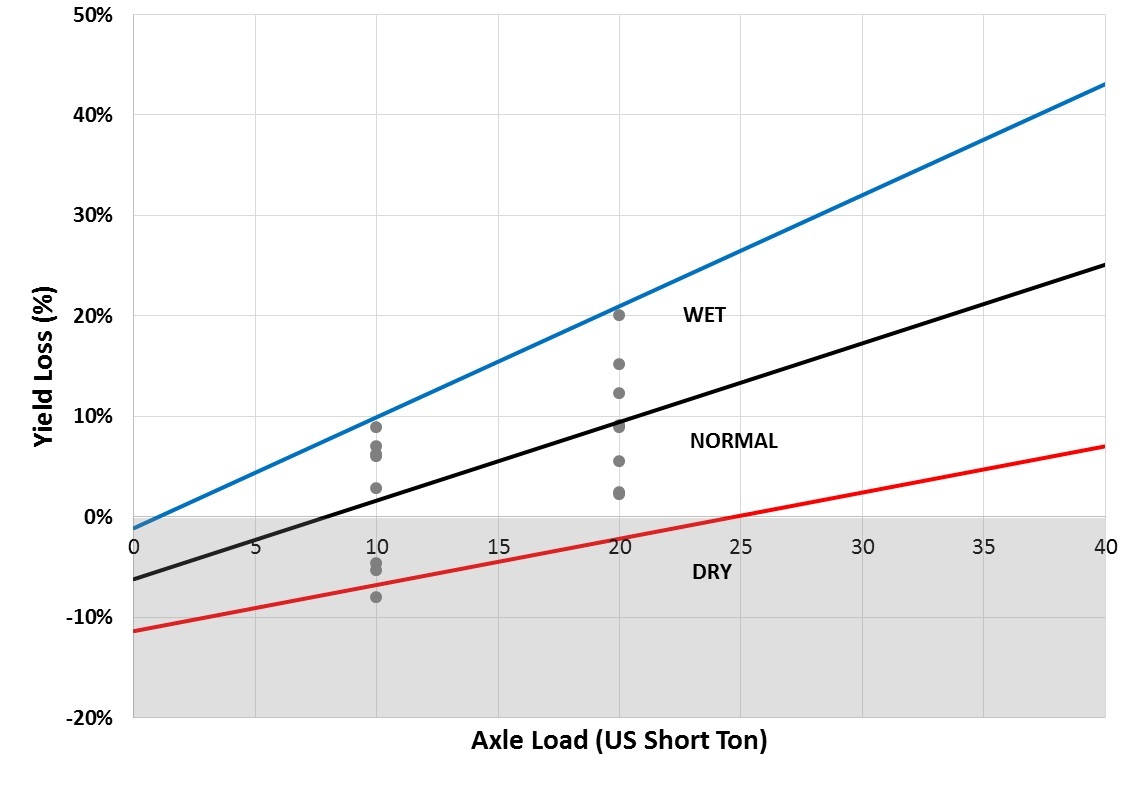

Table 1 and Figure 4 show the typical weights of equipment being put into the field these days, and the impact of that equipment on crop yield resulting from compaction under different soil conditions. These trends make it difficult to manage compaction since many exceed the 10 tons/axle threshold that in general leads to soil compaction under moist soil conditions, and the judgement on what constitutes moist soil can vary widely.

Figure 4. Impact of compaction resulting from various axle loads under different soil conditions at time of operation (Shearer and Fulton, Ohio State University, Columbus OH @ CompactionSmart 2017)

When you compare the equipment axle weights in Table 1 to the impact on yields shown in Figure 4, it is very telling how important soil "fitness" is when equipment is put on the soil. At 20 tons/axle the yield impact is in the 20% range on the crop the following year.

Table 1. Typical weights of current farm equipment - Common Field Equipment Axle Loads (Jodi De Jong - Hughes, University of Minnesota)

|

Equipment Type

|

Tons/Axle

|

|---|---|

| 4WD tractor, 200hp, Front Axle |

7.5

|

| 4WD tractor, 325hp, Front Axle |

13

|

| 4WD tractor, 530hp, Front Axle |

18

|

| TerraGator, Rear Axle |

12-18

|

| Slurry Tanker, 4,200 gal. |

10-12

|

| Slurry Tanker, 7,200 gal. |

17-18

|

| Class 9 Combine, 590hp, 360 bu tank |

20

|

| 12 - row Combine, full with head |

24

|

| Grain Cart, 720 bu, full 1 axle |

22

|

| Grain Cart, 1,200 bu, full 1 axle |

35-40

|

Loads greater than 10 tons/axle will cause subsoil compaction when the soil is wet.

While we do have to plant the crop, the when, where, and how we do that has a direct impact on the occurrence and severity of compaction. Other management decisions also contribute to compaction or alleviating it, including rotations, cover crops, reduced and timely tillage, etc.

Using this spring as an example, most farmers felt constrained by the weather delaying field work and the long history of being encouraged to achieve early planting dates to capture optimum yield potential. It was difficult to remain patient to get into the fields when conditions were suitable. This decision along with the selection of equipment and its weight dictates whether we avoid compaction or at least lower its severity. One of the biggest learnings from this spring is to remember that the goal of achieving early planting dates has to be coupled with the requirement that the soil is "fit" for those field operations to occur. Otherwise you may be setting yourself up for compaction and potentially multiyear impact on crop productivity. There are ways to reduce the risk and severity of compaction by deciding when the soil is "fit", and then what equipment configuration will minimize the risk of inflicting compaction (size, tire technology, inflation pressure, weight distribution, etc).