Deadstock disposal options on-farm

Learn about options for disposing of deadstock on-farm according to the Nutrient Management Act, 2002. This is technical information for Ontario livestock and poultry producers.

ISSN 1198-712X, Published October 2023

Introduction

Dealing with mortalities is an inevitable part of raising livestock. Livestock producers regularly review their production and handling practices to reduce the incidence of livestock mortality. Livestock producers must equip themselves with knowledge, proper planning and the technology necessary to deal with dead farm animals (deadstock).

Disposal and management options are outlined in O. Reg. 106/09 under the Nutrient Management Act, 2002, which includes standards designed to protect the environment and the food supply. They include:

- collector service

- composting

- incineration

- disposal vessel

- burial

- delivery to a licensed disposal facility under the Food Safety and Quality Act (FSQA)

- delivery to an approved waste disposal site

- delivery to an approved anaerobic digester

- delivery to a veterinarian for post mortem (and subsequent disposal)

There are several things to consider when determining which disposal option to choose:

- What is typical number of deaths at that time of year? For example, a higher number of deaths are more common at birthing time.

- What is the size of the animal? What is the easiest way to handle it?

- Is pick-up by a collector an option? At what price? Is there a common collection bin where deadstock can be taken and then picked up by a collector?

- What equipment is necessary and available for the options chosen?

- On rented properties, will the landowner allow disposal of deadstock on the farm or will transportation elsewhere for disposal be required?

- Is a cold storage or freezer available to store deadstock? Storing deadstock in this manner can make the pick-up and/or disposal more economical.

Ensure that whatever option is chosen is compliant with all legal requirements. Remember that there are federal regulations governing the transport, storage and disposal of dead cattle.

Disposal of deadstock on the farm

O. Reg. 106/09 under the Nutrient Management Act, 2002, applies to the following farm animals (and their hybrids) if they are bred, produced, raised or kept by a person who owns or operates a farm operation, producing food or animal products:

- alpacas, bison, cattle, deer, elk, goats, llamas, sheep and yaks

- swine

- chickens, turkeys, geese, ducks, guinea fowl, quails, pigeons, pheasants and partridges

- ratites, such as emus or rheas

- horses, ponies and donkeys

- rabbits, other than ones kept as pets

- fur-bearing animals, such as mink

It also applies if the animals are kept for the person’s personal use or boarded by that person.

Dispose of all deadstock within 48 hours of its death or immediately, if it begins to putrefy before 48 hours have passed. These timelines may be extended if the deadstock is held for post-mortem or loss adjustment. Deadstock may also be stored in cold storage for up to 14 days and in frozen storage for up to 240 days before disposal.

Each on-farm disposal option has specific requirements under the regulation. Review the requirements, consider your management practices and choose the appropriate method for your farm operation.

Collection

Deadstock may be picked up on the farm or delivered to the collector or to a common container, where deadstock from multiple farms are temporarily stored for pick-up. Common containers increase the efficiency of collection services. Movements of bovine carcasses, as well as certain treatment activities, require federal specified risk material (SRM) permitting.

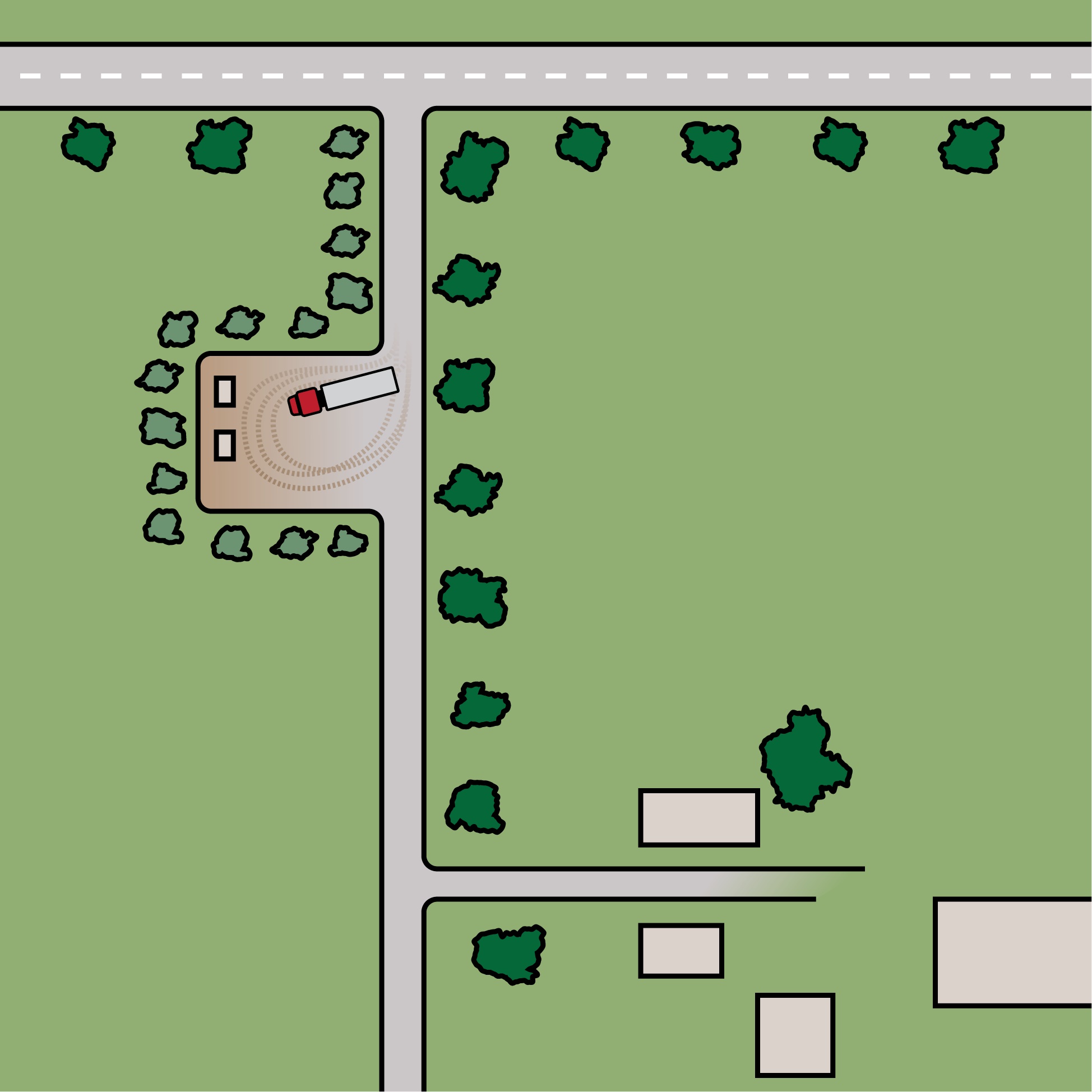

Store any deadstock awaiting pick-up so that it is concealed from public view (Figure 1), and so that any liquids from the animal cannot escape onto the ground. Not only does improper storage of dead farm animals result in complaints from the public, it may attract scavengers and predators and pose biosecurity risks for the farm.

There are areas of the province where no collection service is offered, and there are some species of livestock that are not picked up in some areas of the province. Compare the costs of collection to the operational and management costs of on-farm disposal.

Composting

On-farm composting can provide an excellent source of organic matter and crop nutrients when land applied to cropland. Proper composting kills pathogens and stabilizes the organic and nutrient content of the finished compost. Composting done improperly can result in odours, scavenging and potentially negative environmental impacts.

Federal regulations govern the transport and disposal of composted dead cattle off the site of the animals’ death. Refer to the Canadian Food Inspection Agency for more information.

The availability and price of substrate may affect the choice to compost deadstock. The allowed substrates are:

- sawdust, shavings or chips from wood that is clean, uncontaminated, untreated and has not come into contact with any chemicals

- straw made from dried stalks and leaves of cultivated grain, corn or beans

- clean hay or silage

- a mixture containing only livestock manure (other than poultry manure) and any or all of the bedding materials described above, provided that the mixture is at least 30% dry matter, by weight

- poultry litter

Because the site must be accessible year-round, the volume and size of the deadstock to be composted will affect the choice of location. The site must not be more than 600 m2, and each composting site should not contain more than 600 m3 of deadstock and substrate (Figure 2). Multiple outdoor sites can be established with a 100-m setback between them to reduce the cumulative impact of leaching.

Composting is considered complete when there is:

- no soft animal tissue at all

- no bones or bone fragments larger than 15 cm in any dimension

- no other animal matter larger than 25 mm in any dimension

- no offensive odours

There are several different methods of composting, including a 3-bin system (Figure 3), windrow composting, which is more suited to planned culls, (Figure 4) and in-vessel (Figure 5).

Incineration

Incinerators are a viable option for the disposal of smaller species. Incinerators used for deadstock disposal must have a Verification Certificate issued by the Environmental Technology Verification Program (ETV Canada), certifying that it has a secondary chamber that is capable of maintaining the gases that enter it from the primary chamber at 1,000°C or higher for at least 1 second, or 850°C or higher for at least 2 seconds. High temperatures in the secondary chamber will decrease the contaminants in the emissions. Figure 6 shows an example of a commercially available unit.

Disposal vessels

Disposal vessels were developed in response to predation problems on sheep farms. They are an inexpensive and non-labour-intensive method of disposing of smaller-sized deadstock. Disposal vessels may be useful for farms with few or inconsistent livestock mortalities.

Locate a leakproof and impervious container either on the ground surface, partially buried or fully buried in the ground. Position a hatch on the vessel in such a way that deadstock can be easily deposited into the vessel (Figure 7). A vent or duct allows insects to enter and aid the decomposition, while restricting access to scavengers.

A vessel’s capacity, the volume of deadstock put into it and the rate of filling determine how long it can be used. Decomposition will allow its continued use over many years. When the disposal vessel is no longer needed, fill it with soil and close the hatch.

Burial

Under the regulation, standards for burial pits have been expanded to protect ground- and surface water and prevent scavenging. The standards require that deadstock placed in a burial pit be covered with a least 0.6 m of soil at all times while the burial pit is open (Figure 8). Burial is not permitted in areas where the bottom of the burial pit is less than 0.9 m above bedrock or an aquifer.

A maximum of 2,500 kg of deadstock is allowed per burial pit, measured immediately before burial. Multiple burial pits on the same site are permitted, provided there is adequate separation distance between them to reduce the risk of groundwater contamination through leaching.

The regulation requires that the burial pit be monitored regularly for 1 year following the date that it is closed to ensure that the ground does not sink or show evidence of scavenging. Should this occur, pile additional soil on the area. When the burial pit is closed, mound the ground over the pit to facilitate runoff of precipitation.

The burial option is more difficult when the ground is frozen.

Every part of a burial pit must be at least 6 m from a field drainage tile. If the pit is 6–15 m from a drainage tile, the dead animals must be placed lower in the pit than the lowest point of the tile.

Anaerobic digesters

Farmers may also choose to dispose of deadstock in an anaerobic digester. Any anaerobic digester must be:

- approved and operated under the Nutrient Management Act, 2002; or

- operating under a certificate of approval under the Environmental Protection Act

Costs may include tipping charges for use of anaerobic digestion facilities owned by others, as well as the cost of transport and processing.

Transportation

Producers may transport their own deadstock on a public highway to locations such as:

- a container located at common collection point for collector pick up (Figure 1)

- a site approved under the Environmental Protection Act, 1990, such as a landfill or anaerobic digester

- a disposal facility licensed under the FSQA, such as a salvaging plant or rendering facility

- a veterinarian for a post mortem

- a permissible storage location (for example, cold or frozen storage facilities owned by the operators)

During transport, deadstock must be concealed from public view, and the vehicle, trailer or transport container in which it is transported must be designed to prevent leakage. Operators must be able to clean and sanitize the container after transport to reduce the potential for biosecurity problems.

Producers should also be aware of federal rules regarding the transport of cattle as they cannot be moved without a federal SRM permit.

Plan ahead and consider which disposal options work best for your farm. Incorporate the disposal of deadstock into the farm’s emergency (or contingency) plan. Additional information on the requirements of specific disposal methods is available from Deadstock management of farm animals in Ontario.

Disclaimer

The information in this fact sheet is provided for informational purposes only and should not be relied upon to determine legal obligations. To determine your legal obligations, consult the relevant law. If legal advice is required, consult a lawyer. In the event of a conflict between the information in this fact sheet and any applicable law, the law prevails.

This fact sheet was updated by Dan Ward, P. Eng., poultry and other livestock housing and equipment. It was originally written by Jacqui Laporte, environmental specialist, and reviewed by Ben Hawkins, P. Eng., BMP technical integration and transfer, Ministry of Agriculture, Food and Rural Affairs (retired).