On-farm generators: operating safely

Learn how to safely connect, operate and maintain an on-farm generator during a power outage. This is technical information for Ontario producers.

ISSN 1198-712X, Published June 2020

Introduction

We all depend on electricity for our livelihoods. This is especially true of farmers with cows to milk and livestock to feed. Extended power outages may be uncommon, but they do occur. Protect your farm with emergency back-up power systems and operate them safely to prevent economic loss.

Every farm can benefit from a generator. A generator protects valuable production by ensuring a stable power supply in emergencies. Understand how to operate the generator safely to protect workers, family and the farm itself. Service the generator and test it regularly to ensure it will operate properly in an emergency.

Learn how to connect, operate and maintain a generator safely during a power outage. Keep a copy of this factsheet where it will be handy when there is a power outage (e.g., generator shed, tractor, farm office). See OMAFRA factsheet, On-Farm Generators for Emergency Use, for information on sizing and purchasing a generator system.

This factsheet is not intended to replace specific information or professional advice supplied by manufacturers, distributors and licensed electrical contractors, nor does it supersede the Ontario Electrical Safety Code in any way.

Use proper connectors and receptacles

Portable generators are connected to power systems using cables and connector plugs (Figure 1). Many generator plugs may look similar, but do not assume a generator can be connected to a power system just because the plugs match!

- the connectors could be wired in a non-standard way; or

- the connectors could be installed in different positions (e.g., upside-down).

Improperly wired connectors are a safety hazard. Always have an electrician verify wiring before you connect a generator to a power system.

Warning

Do not share generators from farm to farm even if the connectors appear to be compatible, unless all wiring and connections have been checked by a licensed electrician!

Never use makeshift wiring or connections (e.g., clamps or vice grips), even in an emergency!

Connect a generator safely

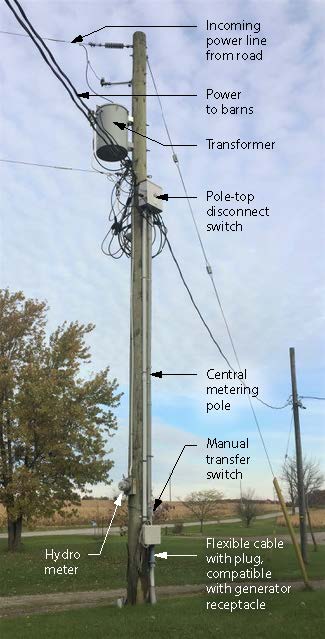

Generators are normally connected at the main hydro pole on a farm (Figure 2). When connecting a generator:

- check for downed power lines

- check with the utility on the expected length of the outage

- disconnect all outside power sources using the transfer switch

- use only approved connection and grounding cables

- use only approved connectors and receptacles

- ensure proper alignment of PTO shaft from tractor to generator

- set tractor brakes before operating generator

Safe start-up and operation

When starting a generator:

- check all fluid and fuel levels

- start tractor or generator and adjust speed to proper RPM

- place transfer switch in emergency position

- turn on electrical loads, one at a time

- adjust tractor or generator speed to maintain power at 60 Hz

- for continuous operation, run generator at no more than 80% capacity

- always keep a tractor or generator fully fuelled at all times

- monitor voltage and frequency continually

- after utility power is restored, return transfer switch to normal

- allow 5 minutes for generator to cool down before turning off

- disengage PTO lever or shut off generator engine

- remove connector power cable

- store PTO shaft with generator (if applicable)

Be aware of safety hazards

Electricity can be dangerous, and generators need to be operated safely. Watch for the following hazards when operating a generator:

- Never use portable generators indoors where people reside or work, because of the risk of carbon monoxide poisoning.

- Always follow all Electrical Safety Code requirements.

- Never use makeshift wiring or connections with clamps or vice grips.

- If the generator is used inside a building:

- ventilate excess heat; at least 500 cm2 (0.5 ft2) of inlet and outlet air opening for each 1 kW of generator capacity is needed

- direct all exhaust piping outdoors

- keep exhaust pipes at least 15 cm (6 in.) away from combustible materials

- Do not remove radiator caps when engines are running.

- Securely mount tractor-driven PTO generators; a PTO can produce enough torque to spin the whole generator.

- Keep children and others, as well as livestock and pets, away from the generator.

- Always keep PTO shields in place.

- Monitor the tractor’s gauges and use an automatic shutdown system to stop the tractor if there is a problem.

Maintain the generator

Maintain the generator properly to ensure it is ready in an emergency. Cover all openings on the generator with 5-mm (1⁄4-in.) galvanized steel mesh, to keep out rodents and birds. Have a qualified generator service company perform regular service and testing. Use Tables 1 and 2 as a reference and consult the generator owner’s manual for additional maintenance information.

| Component (as applicable) |

Maintenance procedure: Check/test |

Maintenance procedure: Clean/replace |

|---|---|---|

| Gearbox oil | every use | 6 months/250 hours |

| Shaft lubrication | every use | every use |

| Shields/guards | every use | N/A |

| Component (as applicable) |

Maintenance procedure: Check/test |

Maintenance procedure: Clean/replace |

|---|---|---|

| Cords and plugs in good condition | every use | N/A |

| All fluid levels | every use | as required |

| Fuel levels | every use | 3 months |

| General condition | 3 months | N/A |

| Loose or broken wires | 3 months | N/A |

| Voltage regulator | 3 months | N/A |

| Control panel | N/A | 3 months |

| General cleanliness (e.g., dirt build-up) | N/A | 3 months |

| Brush length, contact | 6 months | 6 months |

| Commutator, slip rings | yearly | yearly |

| Rotor and stator | yearly | yearly |

| Bearings | yearly | yearly* |

| Bearing grease | yearly | yearly* |

| Exciter | yearly | yearly |

| Resistance of windings | yearly | N/A |

*Replace if necessary

Exercise the generator

Exercise the generator every 90 days to ensure it will operate properly in an emergency. Use the sample log sheet (in the PDF) to record one year’s worth of generator tests. Follow this general procedure:

- follow proper connection and start-up procedures

- run the generator at rated speed for 5 minutes with no load

- operate the generator under at least 50% load for 30 minutes

- check for any problems, and remedy as necessary

- remove load and run for a 5-minute cool down period

- record results in log sheet. Store log sheets for future reference and possible insurance needs.

Conclusion

A well-maintained generator protects valuable production and prevents economic loss by ensuring a stable power supply even in emergencies. Protect farm workers, livestock, crops/produce and infrastructure by understanding and preventing safety hazards, and by connecting and operating the generator safely. Always consult a licensed electrical contractor to ensure the generator system meets all Electrical Safety Code requirements and can operate safely.

This information has been compiled in consultation with the generator industry, farm organizations, other stakeholders and farm surveys.

This factsheet was revised by James Dyck, P.Eng., Engineering Specialist, Crop Systems and Environment, OMAFRA, Vineland, and Steve Clarke, P.Eng., Engineering Specialist, Energy and Crop Systems, OMAFRA, Kemptville, and reviewed by John Van de Vegte, P.Eng., Engineering Specialist, BMP Technical Integration and Transfer, OMAFRA, Elora, and Jim Zyta, Vice-President Loss Prevention, Heartland Farm Mutual, Waterloo.