Landfill standards: A guideline on the regulatory and approval requirements for new or expanding landfilling sites

Regulatory and approval requirements for the design, operation, closure and post-closure care of new or expanding non-hazardous waste landfilling sites. This guideline is intended to help landfill owners, consultants, the public and other interested parties understand the new requirements.

Last Revision Date:

January 2012

Cette publication technique n'est disponible qu'en anglais

Copyright Queen’s Printer for Ontario 2010

This publication may be reproduced for non-commercial purposes with appropriate attribution

PIBS 7792e

Preface

This Guideline describes the regulatory and approval requirements for the design, operation, closure and post-closure care of new or expanding municipal (i.e. non hazardous) waste landfilling sites. The new regulatory requirements are contained in Ontario Regulation 232/98 made under the Environmental Protection Act. The new regulation takes effect on August 1, 1998.

The Guideline is intended to help landfill owners, consultants, the public and other interested parties understand the new requirements. The Guideline includes a description of the new regulatory requirements along with supporting approval guidelines for use when obtaining an Environmental Compliance Approval under the Environmental Protection Act.

The regulatory requirements are given in this Guideline for the convenience of the reader only. A copy of Regulation 232/98 should be obtained and used in conjunction with the Guideline.

1.0 Introduction

An efficient and effective waste management program can best be achieved when an integrated approach is taken in the delivery of waste management services. Although the Ministry of the Environment continues to emphasize the 3Rs (Reduce, Reuse and Recycle), landfilling remains a necessary component of waste management -- whether to manage 3Rs residuals or to dispose of wastes which are not amenable to reuse or recycling. To ensure Ontario landfills are state-of-the-art and fully protective of the environment, comprehensive new landfill standards have been established by the Ministry.

Ontario Regulation 232/98 made under Part V of the Environmental Protection Act takes effect on August 1, 1998 and contains detailed requirements for the design, operation, closure and post-closure care of municipal (i.e. non-hazardous) waste landfilling sites. The new requirements apply to new or expanding landfilling sites where the total waste disposal volume of the site is greater than 40,000 cubic metres. The requirements do not apply to small sites (i.e. sites smaller than -- or equal to -- 40,000 cubic metres) or to existing sites which are not being expanded. For small and existing sites, the existing requirements under the Act and Regulation 347 remain in effect.

This Guideline has been prepared to help landfill owners, consultants, the public and other interested parties understand the new standards. For each standard, the Guideline gives the regulatory requirements and provides approval guidelines containing further information or details on issues to be addressed in complying with the regulation and obtaining an Environmental Compliance Approval.

Chapter 2 of the Guideline briefly describes the legislative framework within which the landfill standards operate and provides a summary of the new standards. The new standards are described in detail in the remaining chapters, as follows:

- Chapter 3 - Application and Ownership

- Chapter 4 - Design

- Chapter 5 - Financial Assurance

- Chapter 6 - Operations

Users of this Guideline should note that the regulatory requirements have been included here for convenience only. A copy of Regulation 232/98 should be obtained and used in conjunction with the Guideline.

2.0 Legislation and Approvals

2.1 Environmental Protection Act

In Ontario, landfilling sites and other waste management activities are subject to Part V of the Environmental Protection Act and the regulations made under the Act. The basic legislative framework for waste management is defined in Part V and the regulatory requirements for the design and operation of waste disposal sites are included in Regulation 347. For new or expanding landfilling sites, these regulatory requirements are superseded by Regulation 232/98.

Section 27 of the Act requires that an Environmental Compliance Approval be obtained from the Ministry of the Environment for the establishment, operation, alteration or enlargement of a landfilling site. To obtain approval for a new or expanding landfilling site, a detailed assessment of the site as required by Regulation 232/98 must be carried out to identify any potential effects on the environment and to show how these potential effects can be satisfactorily addressed. The basis for this assessment and the requirements for site design and operation are given in Regulation 232/98. The Environmental Compliance Approval process takes the landfill standards and refines them as necessary to reflect the particular setting and conditions at each landfill. The resulting Environmental Compliance Approval will define how large the site is to be, the types of waste to be accepted, and any necessary conditions for design and operation. The approval will also describe how the site is to be closed and the measures to be taken following closure to ensure the site is properly maintained and monitored for the long term protection of the environment.

2.2 Regulation 347

Regulation 347 is the general waste management regulation under Part V of the Environmental Protection Act. Regulation 347 provides definitions of waste management terms, defines different classes of waste, and provides standards for the design and operation of landfilling sites (other than new or expanding landfilling sites now covered by Regulation 232/98) and other waste management facilities. For existing and small municipal waste landfilling sites (i.e. sites less than -- or equal to -- 40,000 cubic metres), the existing requirements given in Section 11 of Regulation 347 remain in effect. Additional or more detailed requirements for waste sites and systems are addressed as appropriate through the Environmental Compliance Approval process.

Regulation 347 also defines when waste is considered hazardous or non-hazardous. Hazardous waste is defined by listing some specific wastes as being hazardous, and by identifying certain hazardous waste characteristics and tests. Non-hazardous waste is called “municipal” waste in Regulation 347. The new landfill standards in Regulation 232/98 only apply to sites accepting “municipal” waste.

2.3 Other Acts and Approvals

The focus of this Guideline is on the regulatory and approval requirements under Part V of the Environmental Protection Act. Landfilling sites, however, may also be subject to approval under the Environmental Assessment Act. Many landfill proposals, particularly larger sites may require approval under the Environmental Assessment Act. Under the Environmental Assessment Act, a broader view of the environment is taken and issues beyond the effects on the natural environment must be addressed. For a municipally owned landfilling site, Regulation 334 pursuant to the Environmental Assessment Act (EAA) identifies when a proposal is subject to EAA approval. For private sector landfills, proposals are made subject to EAA requirements by being individually designated through regulation. Typically, sites larger than 40,000 cubic metres are designated, however, this may not always be the case. Once a landfill is subject to EAA approval, the decision to hold a public hearing and give approval for the undertaking rests with the Ministry. Regulation 101/07 under the Environmental Assessment Act also needs to be considered. This regulation defines what waste projects are subject to the EAA process.

2.4 Summary of the New Landfill Standards

The new landfill standards contained in Regulation 232/98 include requirements for design, operation, closure, post-closure care and financial assurance. The standards apply to all new or expanding municipal (i.e. non-hazardous) waste landfilling sites larger than 40,000 cubic metres. The new standards are effective on August 1, 1998 and cover issues such as:

- design specifications for groundwater protection including a site specific design option and two generic design options,

- mandatory air emissions control for sites larger than 3 million cubic metres,

- the assessment of groundwater and surface water conditions;

- design requirements for buffer areas, final cover design, surface water and landfill gas control, and the preparation of a site design report,

- operation and monitoring requirements for site preparation, groundwater and surface water monitoring, daily cover, record keeping and reporting,

- requirements for a leachate contingency plan,

- site closure and post-closure care provisions; and

- financial assurance requirements for private sector landfills.

The regulatory requirements concerning which sites the new standards apply to, the effective date of the Regulation, and the requirements for site ownership are described in Sections 3.1 and 3.2 of this Guideline. Definitions for certain terms used in the Regulation are included at the end of the Guideline.

The new standards are described in detail in Chapters 4.0 to 6.0 of this Guideline. For each of the standards, the Guideline describes the new regulatory requirements as given in Regulation 232/98 and provides additional information in the form of approval guidelines on the types of issues and details to be addressed through the Environmental Compliance Approval process. The approval guidelines in the Guideline complement the regulatory requirements and indicate the Ministry’s expectations with respect to these matters. The use of approval guidelines allows the site specific aspects of landfill design and operation to be tailored to the conditions of the particular site.

3.0 Application and Ownership

3.1 Application

The new landfill standards apply to new or expanding landfilling sites accepting municipal (i.e. non-hazardous) waste. The standards apply whether the site is owned by a municipality or a private landfill operator. The new standards do not apply to small landfills or to existing sites which are not being expanded. For purposes of the standards, a small landfill is considered to be a site with a total waste disposal volume of 40,000 cubic metres or less. For small or existing landfills, the existing requirements under Regulation 347 and the Environmental Protection Act (the Act) remain in effect. Once a site has received approval under the new standards, the site continues thereafter to be governed by these standards.

The new standards take effect on August 1, 1998. The standards do not apply to an application under Part 2.1 of the Act received by the Director prior to this date unless the landfill owner gives written notice asking that they apply. This notice must be provided prior to the issuance of the Environmental Compliance Approval or January 1, 1999, whichever comes first.

The regulatory requirements defining which landfilling sites are affected by the new standards and when the standards take effect are given in Sections 2 and 33 of Regulation 232/98, and are as follows:

Application

2.

- This Regulation applies to the following landfilling sites:

- Every landfilling site that comes into existence on or after August 1, 1998 and that is intended at the time it comes into existence to have a total waste disposal volume of more than 40,000 cubic metres and to accept only municipal waste for disposal.

- Every landfilling site for which an alteration, enlargement or extension is proposed on or after August 1, 1998 that involves an increase in the site’s total waste disposal volume, if the site is intended after the alteration, enlargement or extension to have a total waste disposal volume of more than 40,000 cubic metres and to accept only municipal waste for disposal.

- Subsection (1) does not apply with respect to a landfilling site in respect of which an application for a Certificate of Approval has been received by the Director under Part V of the Act before August 1, 1998, unless the operator or owner of the landfilling site gives written notice to the Director that the operator or owner wants this Regulation to apply.

- The notice under subsection (2) must be given before the earlier of the following dates:

- The date the Environmental Compliance Approval or provisional approval is issued.

- January 1, 1999.

- The standards, procedures and requirements set out in this Regulation do not apply to the extent that terms and conditions set out in a Environmental Compliance Approval.

Commencement

33. This Regulation comes into force on August 1, 1998.

3.2 Ownership

The party responsible for the landfilling site as discussed in Regulation 232/98 must have sufficient control of the site to ensure any necessary monitoring, maintenance, environmental control or remedial activities can be carried out to protect the environment. As a result, the applicant or holder of the Environmental Compliance Approval as required by Regulation 232/98 must own the entire site, including the waste fill area and the buffer area, unless the site is located on Crown land. In other cases, however, where additional land adjacent to a site is needed for the attenuation of contaminants (i.e. leachate or landfill gas), a Contaminant Attenuation Zone may be acceptable. To establish a Contaminant Attenuation Zone, the landfill owner must acquire property rights to use the adjacent land for purposes including contaminant attenuation, monitoring and remediation as required by Regulation 232/98. These rights must be held for the contaminating life span of the site.

The regulatory requirements concerning ownership of landfilling sites and Contaminant Attenuation Zones are given in Sections 3, 4 and 5 of Regulation 232/98 and are as follows:

Landfilling Site

3. The holder of an Environmental Compliance Approval for a landfilling site must own the entire site in fee simple, unless the site is on Crown land.

Contaminant Attenuation Zone

4.

- If a contaminant attenuation zone is necessary for proper operation of a landfilling site, the holder of an Environmental Compliance Approval for the landfilling site must own property rights respecting the contaminant attenuation zone, unless,

- the contaminant attenuation zone is on Crown land and the Crown has agreed in writing to the use of the land for that purpose; or

- the contaminant attenuation zone is on a public road and the road authority has agreed in writing to the use of the land for that purpose.

- The holder of the Environmental Compliance Approval must continue to own the property rights for all of the contaminating life span of the site.

- The ownership of the property rights must include the right to,

- discharge contaminants from the landfilling site into the contaminant attenuation zone;

- enter into the contaminant attenuation zone and onto the surface above the contaminant attenuation zone for purposes of testing, monitoring, intercepting contaminants and carrying out remedial work;

- install, operate and maintain works, for the purposes mentioned in clause (b), in or above the contaminant attenuation zone, including on the surface above the contaminant attenuation zone; and

- prevent the owner of the land in which the contaminant attenuation zone is located from paving, erecting a structure or making any use of land above or in the vicinity of the contaminant attenuation zone that would interfere with the functioning of the contaminant attenuation zone or with the exercise of any of the rights mentioned in this subsection.

Changes

5. The holder of an Environmental Compliance Approval or the applicant for an Environmental Compliance Approval for a landfilling site shall notify the Director in writing within 30 days after any change in his, her or its identity or status or any change in ownership of the site or ownership of property rights in the contaminant attenuation zone.

Contaminant Attenuation Zones are also discussed in Section 4.2 of this Guideline.

4.0 Design

4.1 Design Specifications

Regulation 232/98 was created to ensure that New or Expanding Landfilling Sites are:

- Are designed for groundwater and surface water protection;

- Minimize impacts to the environment from site operations; and

- To facilitate site closure and post-closure care.

To accomplish these goals, Regulation 232/98 requires that a report be prepared containing plans and specifications on the design of the site. The design report must address matters such as:

- the proposed site boundaries, buffer area, waste fill area and contours, surface water control works, on-site roads and structures, and final cover design,

- the design of any liner and leachate collection system or landfill gas control works needed for the site,

- monitoring facilities for groundwater, leachate and surface water,

- a contingency plan for leachate control, and

- site closure and post-closure care requirements.

The regulatory requirements for preparing a landfill design report and the issues to be addressed are described in Subsection 4.1.1 of this Guideline. In addition to the regulatory requirements described in Subsection 4.1.1, there are a number of other separate landfill standards dealing with specific aspects of landfill design as required by Regulation 232/98 which must be addressed. These other standards provide additional details on issues such as groundwater protection, surface water control, and subsurface migration of landfill gas. Where reference is made in these other standards to the preparation of a written report, the written report can be combined, as appropriate, with the design report described in Subsection 4.1.1. These other standards are dealt with in Sections 4.2 to 4.14 of this Guideline.

4.1.1 Regulatory Requirements

Regulation 232/98 requires that a design report be prepared for a landfilling site. This requirement is given in Section 6 of the Regulation and is as follows:

Design Specifications

6.

- A person shall not establish a new landfilling site or increase the total waste disposal volume of an existing landfilling site unless a written report has been prepared in accordance with this section.

- The report must describe the design of the landfilling site and must contain,

- a legal survey of the site;

- an up to date plan and description of the site and the area within 500 metres of the site that covers,

- all property and property boundaries,

- all buildings, roads and utility corridors,

- land contours, surface water drainage, water bodies, rights-ofway and other easements,

- forested areas,

- land uses and land use designations, and

- property conditions not otherwise covered in subclauses (i) to (v);

- detailed plans, specifications and descriptions for the design of the site, including,

- a plan and description of the waste fill area, base contours for waste disposal, base contours for any leachate collection system, top contours for waste disposal and top contours with final cover,

- the total waste disposal volume,

- a materials balance between the sources of soils, on or off the site, and the uses of soils on the site,

- a hydrogeological assessment of the suitability of the site for the landfilling of municipal waste that considers the geologic and hydrogeologic conditions of the site, the design of the site and the monitoring and contingency plans,

- a geotechnical assessment of the suitability of the site for the landfilling of municipal waste that considers bearing capacity, differential settlement and slope stability during construction, operation and after closure, and that addresses the potential effects on any liner or leachate collection system,

- a description of the expected quality and quantity of leachate,

- detailed plans, specifications and descriptions of any liner system necessary to control leachate, including construction and quality assurance and quality control procedures for the liner materials and liner system installation

- detailed plans, specifications and descriptions of any leachate collection, treatment and disposal system necessary to control leachate, including construction and quality assurance and quality control procedures for the system components and system installation,

- an assessment of the potential for subsurface migration of landfill gas at the site and of any control system necessary for monitoring or controlling the migration,

- detailed plans, specifications and descriptions of any system necessary for controlling landfill gas by venting it or by collecting and burning or using it, including construction and quality assurance and quality control procedures for the system components and system installation,

- an assessment of the potential impacts on surface water features that may be caused by the site or operations at the site,

- detailed plans, specifications and descriptions of the system for collecting, directing and discharging surface water, including details of any sediment control or other features and including construction, quality assurance and quality control procedures for the system components and system installation,

- detailed plans, specifications and descriptions of monitoring facilities for leachate, ground water, surface water and, where appropriate, landfill gas,

- an assessment of potential noise impacts due to operations at the site and to local trucking related to operations at the site, including an evaluation of any proposed noise control measures,

- an assessment of potential visual impacts on nearby properties due to the site and site operations,

- detailed plans, specifications and descriptions of the buffer area and ancillary facilities, including any screening, landscaping, fencing, weigh scales, buildings, structures, access roads, internal roads, holding areas for cover material, holding areas for rejected waste or materials for recycling, and other holding areas,

- detailed plans, specifications and descriptions of the contaminant attenuation zone, if one is necessary,

- an estimate of the contaminating life span of the site with respect to contaminants involved in the subsurface migration of landfill gas and an estimate of the service life of any engineered facilities associated with the subsurface migration of landfill gas,

- an estimate of the contaminating life span of the site with respect to contaminants in leachate, unless a new landfilling site is being established and the design for ground water protection features of the site meets the criteria set out in subsection 10 (4) or (5),

- an estimate of the service life of every engineered facility associated with leachate, which may be specified as the service life provided for in Schedule 1, 2, 3 or 4 if the engineered facility meets the relevant conditions set out in that Schedule,

- details of any facilities intended to control or change the contaminating life span of the landfilling site,

- contingency plans that can be implemented to control and dispose of leachate produced in a quantity greater than expected or with a quality worse than expected, including specifications and descriptions in sufficient detail to demonstrate the feasibility of the plans,

- contingency plans that can be implemented to control and dispose of landfill gas migrating in the subsurface in a quantity greater than expected or with a quality worse than expected, including specifications and descriptions in sufficient detail to demonstrate the feasibility of the plans,

- a description of the source, nature and quality of daily cover, including, with respect to material not normally used for daily cover, a discussion of its benefits and limitations, a description of quality assurance and quality control procedures for daily cover and a description of application rates and application procedures for daily cover, including the frequency and timing of application of daily cover if other than at the end of each working day,

- a description of the nature, quality and quantity of final cover, including construction details and quality assurance and quality control procedures for the materials to be used and their installation,

- a site closure plan, including details of the proposed end use of the site, the appearance of the site after closure, revegetation, landscaping, the construction of new facilities, and the removal of existing facilities to facilitate closure, post-closure care and site end use, and

- a summary of the main characteristics of the landfilling site, including the maximum daily quantity of waste that will be accepted for disposal, the estimated annual average quantity of waste that will be accepted for disposal, the area of the landfilling site, the area of the waste fill area, the total waste disposal volume, the estimated waste disposal capacity in tonnes, any subcategories of municipal waste that are not expected to be received or that will not be accepted for disposal, and the estimated date of site closure.

4.1.2 Approval Guidelines

As described in Subsection 4.1.1 above, Regulation 232/98 requires the preparation of a landfill design report and identifies the issues which are to be addressed. All the design features are typically discussed and shown in this report to show the features readily confirm that the design will be acceptable and its construction will be practical. Final, detailed construction plans and specifications would normally be dealt with through conditions of approval and not be required prior to the issuance of an Environmental Compliance Approval.

More detailed provisions dealing with specific aspects of landfill design are described separately in Sections 4.2 to 4.14 of this Guideline.

4.2 Buffer Area

The buffer area is the green belt or zone located on the site between the waste fill area and the site boundaries. The buffer area allows for contaminant attenuation and provides space around the perimeter of the waste area in which various monitoring, maintenance and environmental control activities can take place. The regulatory requirements for the minimum size of the buffer area are described in Subsection 4.2.1 of this Guideline. Additional information on the buffer area is included in the approval guidelines given in Subsection 4.2.2.

4.2.1 Regulatory Requirements

Regulation 232/98 sets a minimum requirement for the size of the buffer area at a landfilling site. This requirement is given in Section 7 of the Regulation and is as follows:

Buffer Area

7.

- The owner and the operator of a landfilling site shall ensure that the waste fill area is completely surrounded by buffer area in accordance with this section.

- The buffer area shall be at least 100 metres wide at every point.

- Subsection (2) does not apply to a buffer area if the buffer area is at least 30 metres wide at every point and a written report confirms that,

- the buffer area provides adequate space for vehicle entry, exit, turning, access to all areas of the site and parking;

- the buffer area provides adequate space on the surface of the site for all anticipated structures, equipment and activities; and

- the buffer area is sufficient to ensure that potential effects of the landfilling operation do not have any unacceptable impact outside the site.

- For the purpose of clause (3) (c), potential effects include surface runoff, litter, vectors, vermin, leachate, subsurface migration of landfill gas and aesthetic effects.

4.2.2 Approval Guidelines

A buffer area provides space around the perimeter of the waste area in which contaminant attenuation may occur, and various monitoring, maintenance and environmental control activities can take place. The buffer area may contain a site access road, site services and buildings, groundwater monitoring wells, landscaping and visual screening. The regulatory requirements described in Subsection 4.2.1 specify a 100 metre wide buffer area, but allow this to be reduced to not less than 30 metres if shown to be appropriate based on a site specific assessment. A minimum 30 metre buffer area has been established to ensure there is sufficient site access for site monitoring, maintenance and remedial measures.

As discussed in Section 3.2 of this Guideline, unless the site is located on Crown land, the landfill owner as required by Regulation 232/98 must own the entire landfilling site including the waste fill area and the buffer area. In some cases, however, additional land adjacent to the on-site buffer area may be needed for leachate or landfill gas attenuation. This off-site land is defined as a Contaminant Attenuation Zone and the landfill owner as required by regulation 232/98 must acquire the rights to use this land for purposes such as contaminant attenuation, monitoring and remediation. Ownership of these rights would have to be registered on title for the property containing the Contaminant Attenuation Zone. Contaminant Attenuation Zones are dealt with in Section 3.2 of this Guideline.

4.3 Hydrogeological Assessment

An assessment of the hydrogeologic setting of a landfilling site is necessary to properly design the site, and to ensure the site can be effectively monitored and an acceptable contingency plan can be developed. Regulation 232/98 includes a basic requirement that the geologic and hydrogeologic conditions of the landfilling site be assessed. The regulatory requirement is included in Subsection 4.3.1 of this Guideline. A more detailed description of the type of information typically included in the assessment, the kinds of analyses which are typically undertaken, and the issues typically addressed is included in the approval guidelines given in Subsection 4.3.2. The approval guidelines address both the regional area in which the site is located, and the detailed study of site conditions. For the detailed site study, the assessment deals with matters such as those detailed in Table 1.

| Item No. | Task |

|---|---|

| i. | the drilling of boreholes and obtaining samples to characterize soil or bedrock conditions at the site. |

| ii. | the measurement of groundwater levels and pressures to define groundwater flow characteristics. |

| iii. | the collection of groundwater samples to assess groundwater quality. |

| iv. | the interpretation of collected data including the preparation of site and piezometric contour plans, the determination of groundwater flow paths and contaminant attenuation capabilities, and the identification of any unstable soils or geologic conditions. |

| v. | an assessment of the suitability of the site for landfilling with respect to the design, monitoring and contingency plan requirements. |

A hydrogeological assessment is required for all landfilling sites including sites which are to be designed in accordance with the generic designs (refer to Section 4.5 of this Guideline) specified in the Regulation. Although the generic designs are fully protective of groundwater quality, a hydrogeological assessment is needed to ensure that the conditions for use of the generic designs are present, and to ensure that effective groundwater monitoring and leachate contingency plans can be developed for the site. A good understanding of the geologic and hydrogeologic conditions of a site is also needed for site construction purposes.

4.3.1 Regulatory Requirements

Regulation 232/98 requires that the geologic and hydrogeologic conditions of a landfilling site be assessed. This requirement is given in Section 8 of the Regulation and is as follows:

Hydrogeological Assessment

8.

- A person shall not establish a new landfilling site or increase the total waste disposal volume of an existing landfilling site unless a written report on the geologic and hydrogeologic conditions of the site and ground water protection for the site has been prepared in accordance with this section.

- The report must contain,

- plans, specifications and descriptions of the geologic and hydrogeologic conditions of the site and the area in which the site is located; and

- an assessment of the suitability of the site for the landfilling of municipal waste, taking into account,

- the design of the site, including existing features and features that will be implemented to control the expected production of leachate and the expected subsurface migration of landfill gas,

- regional and site specific geologic and hydrogeologic conditions,

- the ability to identify future impacts on the ground water by monitoring,

- the feasibility of contingency plans that can be implemented to control leachate produced in a quantity greater than expected or with a quality worse than expected, and

- the feasibility of contingency plans that can be implemented to control landfill gas migrating in the subsurface in a quantity greater than expected or with a quality worse than expected.

4.3.2 Approval Guidelines

The objectives of a hydrogeological assessment are to: determine the physical, hydraulic and chemical properties of the surficial materials (and bedrock where appropriate); define groundwater flow characteristics and potential contaminant plume migration pathways; determine the structural integrity of the subgrade to support the landfill (including its construction) and any overlying facilities; determine the availability and suitability of the soil for cover and liner uses; establish a groundwater monitoring network; and determine the feasibility of the contingency plans for contaminant control. The following guidelines provide a more detailed description of the information and analytical needs, and the types of issues which are typically addressed in the assessment.

The hydrogeological assessment of a landfilling site typically includes a discussion on the information identified in Table 2:

| Item No. | Task |

|---|---|

| a. | A general description of the geologic and hydrogeologic conditions of the (regional) area in which the site is located. This description should include a description of the stratigraphy, groundwater quantity and quality, groundwater movement, and should characterize the significance of groundwater resources and the use made of these resources. |

| b. | A detailed description of the geologic and hydrogeologic conditions occurring at the site based on a detailed investigation of the site which establishes soil, rock and groundwater conditions, including:

|

| c. | An interpretation of the results of the detailed investigation of the site, including the following plans, specifications and descriptions under existing conditions, during site construction and operation, and following site closure:

|

| d. | An assessment of the suitability of the site for waste disposal purposes considering the regional and site specific geologic and hydrogeologic conditions, the design of the site, the monitoring of potential groundwater impacts, and the contingency plans for the control of leachate and landfill gas. |

4.4 Surface Water Assessment

The assessment of the surface water conditions on and in the vicinity of a landfilling site, and of any surface water features which are to receive a discharge from the site is an important part in determining the suitability, design and monitoring requirements for the site. As described in Subsection 4.4.1 below, Regulation 232/98 includes a basic requirement that a surface water assessment be carried out. Further details on the type of information typically obtained and the analyses to be performed are included as approval guidelines in Subsection 4.4.2. The approval guidelines address matters such as:

- a description of the area (watershed) in which the site is located and the surface water features nearby the site,

- a detailed investigation and description of the surface water conditions on the site and any surface water features receiving a direct discharge from the landfilling site,

- a water quality assessment program, based on an extensive list of monitoring parameters, and

- an assessment of the suitability of the site for landfilling.

4.4.1 Regulatory Requirements

Regulation 232/98 requires that the surface water conditions at and in the vicinity of a landfilling site be assessed. This requirement is given in Section 9 of the Regulation and is as follows:

Surface Water Assessment

9.

- A person shall not establish a new landfilling site or increase the total waste disposal volume of an existing landfilling site unless a written report on the surface water conditions of the site and surface water protection for the site has been prepared in accordance with this section.

- The report must contain,

- plans, specifications and descriptions of the surface water features on the site, the surface water features that will receive a direct discharge from the site and the surface water features of the area in which the site is located; and

- an assessment of the suitability of the site for the landfilling of municipal waste, taking into account,

- the design of the site, including existing features and features that will be implemented to control the expected production of leachate, the flow of surface water, and erosion and sedimentation resulting from the flow of surface water,

- the surface water features on the site, the surface water features that will receive a direct discharge from the site and the surface water features of the area in which the site is located,

- the ability to identify future impacts on the surface water features by monitoring, and

- the feasibility of contingency plans that can be implemented to control surface water impacts resulting from the production of leachate in a quantity greater than expected or with a quality worse than expected.

4.4.2 Approval Guidelines

The objectives of the surface water assessment are to: define existing surface water conditions on and in the vicinity of the site; determine the potential effects of surface water coming onto the site; determine the potential effects of runoff discharging from the site; and establish a surface water monitoring network. The following guidelines provide further details on the information and analytical needs, and the types of issues which are typically addressed in the assessment.

The surface water assessment for a landfilling site typically includes a discussion on the information in identified in Table 3:

| Item No. | Task |

|---|---|

| a. | A general description of the surface water features of the area (watershed) in which the site is located. |

| b. | A description of the surface water features occurring within 500 m of the waste fill area of the site. This description should be based on contributing and receiving drainage, catchment, subwatershed or watershed areas that are sufficiently large to allow an assessment of the range and extent of potential effects. The description should include a description of surface water features such as flood plains, natural watercourses and water bodies, municipal drains, drainage paths and boundaries. |

| c. | A detailed surface water investigation to assess water quality, quantity and habitat conditions of the surface water features identified on the site, any surface water features flowing through the site, and any surface water features that are to receive a surface water discharge from the site, including:

|

| d. | An interpretation of the results of the detailed surface water investigation of the site, any surface water features flowing through the site, and any surface water features that are to receive a direct discharge from the site, including:

|

| e. | An assessment of the suitability of the site for waste disposal purposes considering the area in which the site is located, on-site and receiving surface water features, the design of the site, and the contingency plan for the control of leachate. |

4.5 Design Criteria for Groundwater Protection

Groundwater protection is fundamental to good landfill design. Groundwater is often the primary source of rural and urban water supply, and may be a significant contributor to streamflow. Preventing groundwater contamination is particularly important because of the difficulty and cost of restoration. Once contaminated, it may take many years to cleanup groundwater.

Regulation 232/98 includes two approaches for designing a landfill to protect groundwater quality. The first approach, called site specific design, allows the proponent to design the landfill to suit the local environmental setting provided the Ministry’s Reasonable Use limits for groundwater protection are met at the property boundary. The second approach allows the proponent to select one of two generic designs which have been specified in the standards. The generic designs have been developed such that they will meet Reasonable Use limits within a broad range of hydrogeologic settings, as defined for their use.

Reasonable Use Guideline

To protect groundwater resources, landfills must be designed to meet stringent contaminant limits in accordance with the Ministry’s Reasonable Use Guideline (1994) as described in Section 10 of Regulation 232/98. The Reasonable Use Guideline establishes limits for the allowable concentrations of contaminants based on background groundwater quality and the reasonable use of groundwater on adjacent property. The limits are set such that there would not be any significant effect on the use of the groundwater on the adjacent property.

As the reasonable use of groundwater is commonly drinking water, the Reasonable Use limits are typically set on this basis. As a result, the quality of groundwater may not be degraded by an amount in excess of:

- 50% of the difference between background and the Ontario Drinking Water Objectives for non-health related parameters (e.g. chloride), or

- 25% of the difference between background and the Ontario Drinking Water Objectives for health related parameters (e.g. lead).

In cases where the reasonable use of groundwater is other than drinking water, for example where background groundwater quality is poor, the Reasonable Use Guideline allows alternative concentration limits to be set. These alternative limits would be determined on a case-by-case basis.

The Reasonable Use Guideline has been incorporated in Regulation 232/98. The Reasonable Use requirements have been included directly as performance specifications for the site specific design approach, and have been incorporated in the development of the two generic designs.

Site Specific Design

The site specific design approach included in the Regulation gives the site owner flexibility to design the landfilling site to suit the local environmental setting, provided the Reasonable Use limits for groundwater protection are met. This is a performance based standard with the acceptability of a design judged on its ability to meet the Reasonable Use limits at the property boundary. The Regulation specifically sets out how these limits are determined, on the basis that groundwater is used for drinking purposes, but allows for the setting of other limits in other circumstances. Under this approach, a proponent may design a natural attenuation site, or an engineered site which incorporates a liner and leachate collection system. To obtain approval for the design, sufficient information on the site setting and the performance of the design as required in Regulation 232/98 must be presented to show that the Reasonable Use limits will be met.

To assist with site specific design, the Regulation also includes design criteria such as:

- identification of the chemical parameters to be used in design,

- waste and leachate characteristics for the identified parameters,

- decay constants (i.e. half-lives) for the organic parameters, and

- the service lives which can be used in design for certain liner and leachate collection systems.

These design criteria may be used in the design of a municipal waste landfilling site. A site which has been properly designed using these criteria will fully protect groundwater quality. Use of these criteria, however, is not mandatory and a proponent may use alternative design criteria where they can be shown to be appropriate. For example, alternative criteria may be more appropriate for the landfilling of a particular industrial waste, or for a site located in a geographic area where more representative leachate data is available. Design criteria have been included in the landfill standards as tools to help in landfill design. The criteria are not intended to prevent proponents from obtaining and using other, more representative criteria if they wish.

Generic Design Options

The Regulation includes two generic design options which incorporate specific liner and leachate collection system designs. To ensure the generic designs can be used within a broad range of hydrogeologic settings, the designs have been developed such that the Reasonable Use limits for groundwater protection will be met without reliance on contaminant attenuation in the landfill buffer area. In a hydrogeologic setting where there is significant natural groundwater protection, the level of engineering in the generic designs may not be necessary and the site specific design approach could be followed. Similarly, a site specific design could be undertaken where it can be shown that the design criteria for the proposed site (e.g. the expected leachate characteristics) are different from those given in the Regulation. The advantage of using the generic designs is the added certainty they bring to the approval process.

The two generic design options differ with respect to their level of engineering and the quantity of waste which they can accommodate. The double composite liner design (i.e. Generic Design Option II) allows a greater quantity of waste to be deposited at a particular site, but the level of engineering is greater. Where less complex engineering is desired and the site area is large enough to accept the total quantity of waste to be deposited, a proponent may wish to use the single composite liner design (i.e. Generic Design Option I). The choice between the two designs will depend on the particular circumstances of the proposal.

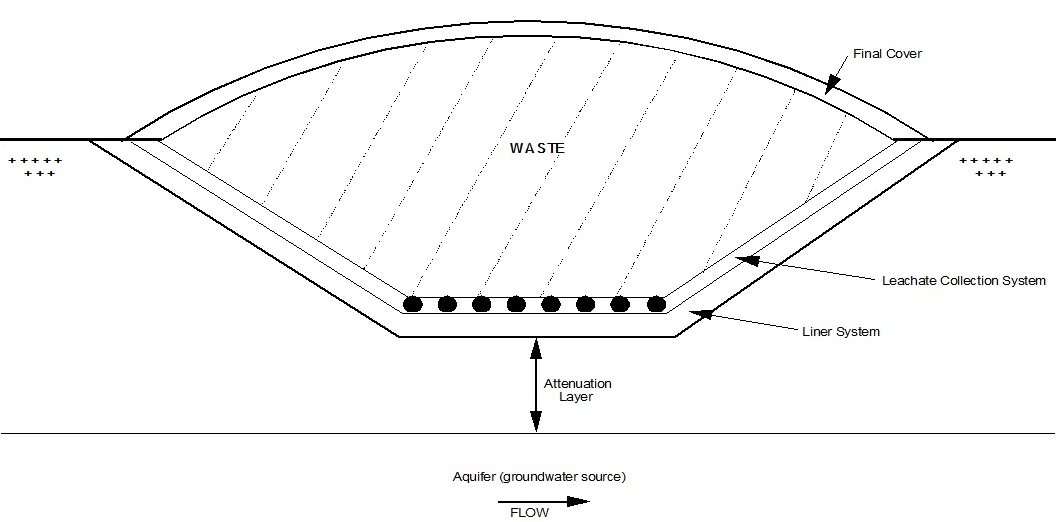

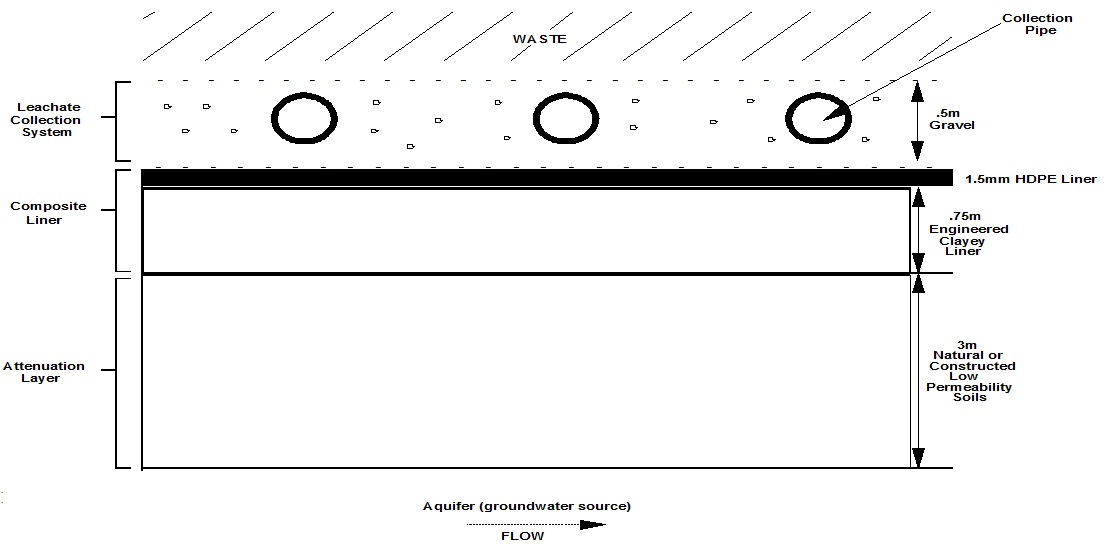

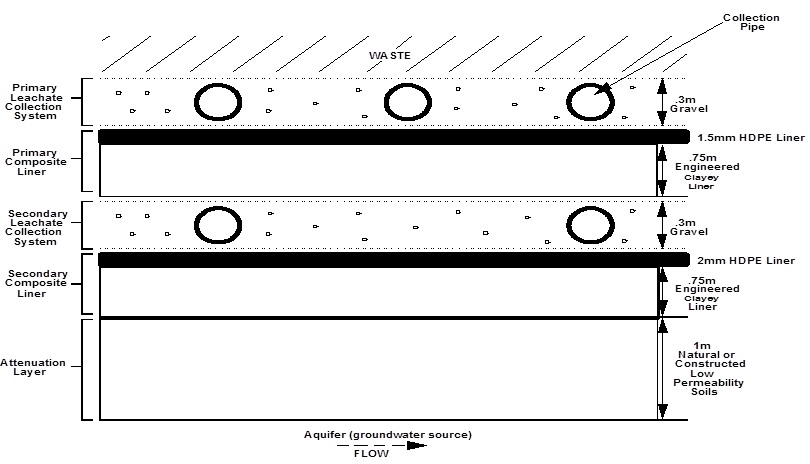

A schematic view of a landfill incorporating the generic design approach is shown in Figure 1. The components of the two generic designs are shown in Figures 2 and 3, and are as follows:

- Generic Design Option I - Single Liner

- a single composite liner consisting of a 1.5 millimetre (60 mil) thick high density polyethylene (HDPE) geomembrane liner, over a 0.75 metre thick compacted clayey liner;

- a natural, or constructed, 3 metre thick attenuation layer below the single composite liner; and

- a leachate collection system above the composite liner,

- provided the infiltration rate through the landfill cover is greater than or equal to 0.15 metres per year, and the maximum waste loading is no greater than the amount shown in Table 5 for the background chloride concentration for the site.

- Generic Design Option II - Double Liner

This generic design (shown in Figure 3) consists of the following components:- two composite liners with:

- a primary (upper) liner consisting of a 1.5 millimetre (60 mil) thick high density polyethylene (HDPE) geomembrane liner over a 0.75 metre thick compacted clayey liner; and

- a secondary (lower) liner consisting of a 2 millimetre (80 mil) thick high density polyethylene (HDPE) geomembrane liner over a 0.75 metre thick compacted clayey liner.

- a natural, or constructed, 1 metre thick attenuation layer below the lower composite liner; and

- two leachate collection systems with the first located above the upper composite liner, and the second located between the upper and lower composite liners, provided the infiltration rate through the landfill cover is greater than or equal to 0.15 metres per year, and the maximum waste loading is no greater than the amount shown in Table 5 for the background chloride concentration for the site.

- two composite liners with:

The generic designs have been developed using contaminant transport modelling to assess performance of the liner and leachate collection systems relative to meeting the Ministry’s Reasonable Use limits. Input parameters (design criteria such as waste and leachate characteristics) used in the computer modelling were the same as those included in the Regulation and referred to above under Site Specific Design.

Figure 1: Generic Design Approach

Figure 2: Generic Design Option I Single Composite Liner

Figure 3: Generic Design Option II Double Composite Liner

4.5.1 Regulatory Requirements

Regulation 232/98 includes two approaches to landfill design, either of which may be used for groundwater protection. The site specific design approach allows the owner to design the landfill to suit the local environmental setting provided the Ministry’s Reasonable Use limits are met. The generic design approach allows the owner to use one of two generic designs specified in the standards. The site specific and generic design approaches are given in Section 10 of the Regulation and are as follows:

Ground Water Protection

10.

- A person shall not establish a new landfilling site or increase the total waste disposal volume of an existing landfilling site unless a written report describing the design for the ground water protection features of the site has been prepared in accordance with this section.

- The design for the ground water protection features of the site must,

- if a new landfilling site is being established, meet the criteria set out in subsection (3), (4) or (5); or

- if the total waste disposal volume of an existing landfilling site is being increased, meet the criteria set out in subsection (3).

[Site Specific Design]

- The design for the ground water protection features of a landfilling site complies with subsection (2) if it meets the following criteria:

- The objective of the design must be that the site will not cause the concentration of any contaminant listed in Column 1 of Table 4 to exceed the maximum allowable concentration for the contaminant in the ground water at any point on any adjacent property.

-

For the purpose of paragraph 1, the maximum allowable concentration for a contaminant shall be determined in accordance with the following formula:

Cm = Cb + X(Cr - Cb),

where,

- Cm

- is the maximum allowable concentration for the contaminant,

- Cb

- is the background concentration of the contaminant in the ground water of the receptor aquifer,

- Cr

- is the health related drinking water objective for the contaminant or the aesthetic drinking water objective for the contaminant, whichever is applicable, as set out in column 5 or 6 of Table 4, and X is,

- 0.25, if Cr is a health related drinking water objective, or

- 0.50, if Cr is an aesthetic drinking water objective.

- The initial source concentration, mass as a proportion of total (wet) mass and half-life in leachate set out in Columns 2, 3 and 4 of Table 4 must be used for the purposes of evaluating the design with respect to the objective set out in paragraph 1.

- The design must consider both advective and diffusive contaminant transport and must include examination of the effect of the failure of any engineered facilities when their service lives are reached.

- A service life set out in Schedule 1, 2, 3 or 4 for an engineered facility may be used for the purpose of evaluating the design with respect to the objective set out in paragraph 1 if the relevant conditions set out in that Schedule are met.

- Despite paragraphs 1, 2 and 3, if it is appropriate because of the nature of the waste or because the reasonable use of the ground water on the adjacent property is other than for drinking water, the Director may,

- for the purposes of evaluating the design with respect to the objective set out in paragraph 1,

- require or permit the use of values specified by the Director for Cr and X in the formula set out in paragraph 2, instead of the values set out in that paragraph, and

- require or permit the use of an initial source concentration, mass as a proportion of total (wet) mass or half-life in leachate specified by the Director instead of the initial source concentration, mass as a proportion of total (wet) mass or half-life in leachate set out in Column 2, 3 or 4 of Table 4, or

- require or permit the objective of the design to be based in whole or in part on contaminants other than those listed in Column 1 of Table 4 and, for the purpose of evaluating the design with respect to that objective,

- require or permit the use of values specified by the Director with respect to each of the other contaminants for Cr and X in the formula set out in paragraph 2, and

-

require or permit the use of an initial source

concentration, mass as a proportion of total (wet) mass or half-life in leachate specified by the Director with respect to each of the other contaminants.

- for the purposes of evaluating the design with respect to the objective set out in paragraph 1,

[Generic Design Option I - Single Liner]

- The design for the ground water protection features of a new landfilling site that is being established complies with clause (2) (a) if it meets the following criteria:

- The maximum waste loading for any given background concentration of chloride in the ground water of the receptor aquifer must not be more than the value set out for that concentration in Column 1 of Table 5.

- The infiltration rate through the final cover of the landfilling site must be greater than or equal to 0.15 metres per year.

- There must be, at the base of the waste fill zone, a natural or engineered layer of soil in which attenuation of contaminants from the wastes in the site may take place and that meets the following conditions:

- The layer must be at least three metres thick.

- The layer must consist of material that is relatively homogeneous.

- The layer must have a hydraulic conductivity less than or equal to 1 × 10-7 metres per second.

- The waste fill zone must have a ground water protection system above the attenuation layer referred to in paragraph 3 and below the waste consisting of, from bottom to top,

- a primary liner consisting of,

- a clayey liner at least 0.75 metres thick that meets the conditions set out in Schedule 4 for an unlimited service life, has a hydraulic conductivity of not more than 1 × 10-9 metres per second, and has an organic carbon content of at least 0.1 per cent, and

- a high density polyethylene (HDPE) geomembrane liner at least 1.5 millimetres thick that meets the conditions set out in Schedule 3 for a 150 year service life, and

- a primary leachate collection system that meets the conditions set out in Schedule 1 for a 100 year service life.

- a primary liner consisting of,

[Generic Design Option II - Double Liner]

- The design for the ground water protection features of a new landfilling site that is being established complies with clause (2) (a) if it meets the following criteria:

- The maximum waste loading for any given background concentration of chloride in the ground water of the receptor aquifer must not be more than the value set out for that concentration in Column 2 of Table 5.

- The infiltration rate through the final cover of the landfilling site must be greater than or equal to 0.15 metres per year.

- There must be, at the base of the waste fill zone, a natural or engineered layer of soil in which attenuation of contaminants from the wastes in the site may take place and that meets the following conditions:

- The layer must be at least one metre thick.

- The layer must consist of material that is relatively homogeneous.

- The layer must have a hydraulic conductivity less than or equal to 1 × 10-7 metres per second.

- The waste fill zone must have a ground water protection system above the attenuation layer referred to in paragraph 3 and below the waste consisting of, from bottom to top,

- a secondary liner consisting of,

- a clayey liner at least 0.75 metres thick that meets the conditions set out in Schedule 4 for an unlimited service life, has a hydraulic conductivity of not more than 1 × 10-9 metres per second, and has an organic carbon content of at least 0.1 per cent, and

- a high density polyethylene (HDPE) geomembrane liner at least 2.0 millimetres thick that meets the conditions set out in Schedule 3 for a 350 year service life,

- a secondary leachate collection system that meets the conditions set out in Schedule 2 for a 1000 year service life,

- a primary liner consisting of,

- a clayey liner at least 0.75 metres thick that meets the conditions set out in Schedule 4 for an unlimited service life, has a hydraulic conductivity of not more than 1 × 10-9 metres per second, and has an organic carbon content of at least 0.1 per cent, and

- high density polyethylene (HDPE) geomembrane liner at least 1.5 millimetres thick that meets the conditions set out in Schedule 3 for a 150 year service life, and

- a primary leachate collection system that meets the conditions set out in Schedule 1 for a 60 year service life.

- a secondary liner consisting of,

[Background Concentration]

- (6) For the purpose of this section, the background concentration of a contaminant in the ground water of the receptor aquifer is the median value for that contaminant based on all ground water samples taken from the receptor aquifer in accordance with the following rules:

- At least five samples must be taken.

- The samples must be taken at or near the site boundary where the potential impact is being examined.

- The samples must not be taken from locations known to be or likely to be contaminated by human activity.

| Column 1 - Contaminant | Column 2 - Initial Source Concentration (mg/L) | Column 3 - Mass as a Proportion of Total (wet) Mass of Waste (mg/kg) | Column 4 - Half-Life in Leachate (years) | Column 5 - Health Related Drinking Water Objective (mg/L) | Column 6 - Aesthetic Drinking Water Objective (mg/L) |

|---|---|---|---|---|---|

| 1. Benzene | 0.02 | 0.014 | 25 | 0.005 | n/a |

| 2. Cadmium | 0.05 | 0.035 | n/a | 0.005 | n/a |

| 3. Chloride1 150,000 t/ha increasing to 250,000 t/ha | 1,500 increasing to 2,500 | 1,800 | n/a | n/a | 250 |

| 4. Lead | 0.6 | 0.42 | n/a | 0.01 | n/a |

| 5. 1,4 Dichlorobenzene | 0.01 | 0.007 | 50 | n/a | 0.001 |

| 6. Dichloromethane | 3.3 | 2.3 | 10 | 0.05 | n/a |

| 7. Toluene | 1 | 0.7 | 15 | n/a | 0.024 |

| 8. Vinyl Chloride | 0.055 | 0.039 | 25 | 0.002 | n/a |

Notes:

1. The initial source concentration of chloride is taken to vary linearly between 1,500 and 2,500 milligrams per litre with maximum waste loading between 150,000 and 250,000 tonnes per hectare.

2. Half-lives may be used in considering a decrease in source concentration with time and for estimating the contaminating life span.

| Background Chloride Concentration (mg/L) | Maximum Waste Loading (m3/ha) - Single Liner Design Option (Subsection 10(4)) | Maximum Waste Loading (m3/ha) - Double Liner Design Option (Subsection 10(5)) |

|---|---|---|

| 0 | 98,500 | 287,000 |

| 10 | 100,500 | 295,500 |

| 20 | 102,500 | 299,500 |

| 30 | 104,000 | 303,000 |

| 40 | 106,000 | 307,000 |

| 50 | 107,500 | 310,500 |

| 60 | 109,000 | 314,000 |

| 70 | 110,500 | 317,500 |

| 80 | 112,000 | 321,500 |

| 90 | 113,500 | 325,000 |

| 100 | 115,000 | 328,500 |

| 110 | 117,000 | 332,000 |

| 120 | 118,500 | 335,500 |

| 130 | 120,000 | 339,000 |

| 140 | 121,500 | 343,000 |

| 150 | 123,500 | 346,500 |

| 160 | 125,000 | 350,000 |

| 170 | 126,500 | 353,500 |

| 180 | 128,000 | 357,000 |

| 190 | 129,500 | 360,500 |

| 200 | 131,000 | 363,500 |

| 210 | 132,500 | 366,500 |

| 220 | 134,500 | 370,000 |

| 230 | 136,000 | 373,000 |

| 240 | 137,500 | 376,000 |

| 250 or more | 139,000 | 380,000 |

Note: If the Background Chloride Concentration falls between two values in Table 5, the appropriate limiting value shall be interpolated from the values in Column 1 or 2, whichever applies. These values are considered to vary linearly with the values for chloride.

4.5.2 Approval Guidelines

The regulatory requirements for groundwater protection are described above in Subsection 4.5.1. Both the site specific and generic design approaches incorporate the Ministry’s Reasonable Use limits and will ensure groundwater is protected. The Reasonable Use limits have been included directly into the specifications for the site specific design approach and were used in the development of the two generic designs. Regardless of which design approach is followed, a hydrogeological assessment (refer to Section 4.3 of this Guideline) is required by Regulation 232/98. In site specific design, a hydrogeological assessment is needed to determine what type of design is appropriate -- whether the site is to be a natural attenuation site, or an engineered site which incorporates a liner and leachate collection system. For the generic designs, although the designs will protect groundwater quality, a hydrogeologic assessment is still necessary to ensure that the conditions for use of the designs are met (i.e. attenuation layer and background chloride concentration). In both the site specific and generic design cases, a good understanding of the geologic and hydrogeologic setting is needed to ensure that effective groundwater monitoring and leachate contingency plans can be developed, and for site construction purposes.

Where a generic design is to be used, an owner must show how the generic design features (as discussed in Section 6 of Regulation 232/98) are to be incorporated in the design of the particular landfill (i.e. given the varying site sizes, depths, base side slopes, etc.). For example, the single composite generic design incorporates a primary leachate collection system which has a 100 year design service life. This collection system is expected to require replacement by some alternative system, such as a perimeter leachate collection system, to control leachate mounding and prevent leachate breakout at surface. For the double composite generic design, which incorporates a 60 year primary collection system, similar provisions would have to be made. Considerations such as these typically are addressed in the design report required for the site (refer to Section 4.1 of this Guideline).

For planning post-closure care activities for a site utilizing the single or double composite generic design, the contaminating life span for leachate impact on groundwater (based on the minimum infiltration rate of 0.15 metres per year) is 160 years and 360 years, respectively. By this time, the geomembrane(s) are assumed to have failed and the discharge rate through the compacted clayey liner(s) at the base of the site equals the infiltration rate (i.e. 0.15 metres per year) through the final top cover. The landfill can then be allowed to discharge passively into the groundwater environment.

4.6 Groundwater Protection System

As described in Section 4.1 of this Guideline, Regulation 232/98 requires that a design report be prepared for the site. The design report is to contain plans and specifications on the design of any liner or leachate collection system to be used for groundwater protection. A detailed description of the type of information to be provided on the liner and leachate collection system design is included in the approval guidelines given in Subsection 4.6.2 below. The information to be provided as required by Regulation 232/98 covers issues such as the site foundation, bottom liners (i.e. compacted clay, geomembrane, or geosynthetic clay liners), leachate collection systems, and construction quality control and assurance procedures.

4.6.1 Regulatory Requirements

The regulatory requirement to prepare plans and specifications for the groundwater protection system is included in the Design Specifications requirements in Section 6 of Regulation 232/98 as described in Section 4.1 of this Guideline.

4.6.2 Approval Guidelines

Information on the groundwater protection system as required by Section 10 of Regulation 232/98 must be included in the design report required for a landfilling site (refer to Section 4.1 of this Guideline). The following guidelines provide a detailed description of the information which is typically discussed in the reports. Irrespective of whether the groundwater protection system is designed in accordance with the site specific design approach or using one of the two generic designs (refer to Section 4.5 of this Guideline), where a liner or leachate collection system is to be constructed at a site, Regulation 232/98 requires the report on the design specifications for the site to include a discussion on the following plans, specifications and descriptions:

- Foundation and Clayey Liner Design

For the site foundation, and any clayey liner which is to be constructed at the site, the report typically discusses the information detailed in Table 6a:

| Item No. | Information |

|---|---|

| i. | A description of the foundation design and materials of construction, including a discussion of the capability of the foundation to support any expected static and dynamic loadings. |

| ii. | Data showing fluctuations in the depth of the water table and the seasonal high and low watertable in relation to the foundation or liner system. |

| iii. | Sufficient data to evaluate the engineering properties of the foundation and, if proposed, the clayey liner materials. This should include data relating to the Atterberg limits, organic carbon content, grain size distribution, mineralogy, strength, hydraulic conductivity, compressibility and, when appropriate, compaction curves. The report should also clearly indicate other parameters used by the designer (e.g., diffusion coefficients, partitioning coefficients [Koc], effective porosity, any other parameter used in the design or analysis) and provide data and/or references supporting the choice of these parameters. |

| iv. | To address the issue of clay/leachate compatibility, data showing that there will be no significant increase in hydraulic conductivity or reference given to tests that have been conducted on soil that is mineralogically similar using a leachate similar to that anticipated for the site. |

| v. | Engineering analyses, based on the data gathered through subsurface exploration and laboratory testing programs, that provide:

|

| vi. | A description of construction and installation procedures. If a compacted clayey liner is proposed, include details regarding the control of compaction water content, lift thickness, equipment to be used, scarification between lifts, limits on clod size, removal of stones, and procedures to avoid desiccation of the clayey liner. Liner test sections should be constructed to develop and confirm construction procedures. |

| vii. | A description of the inspection, monitoring, sampling and testing methods and frequencies to be employed to assure that the foundation and, where present, liner(s) meet the design requirements. |

| viii. | A description of any soil additives that are proposed, the concentrations to be added and the methods that will be used to mix and spread the material. |

- Geomembrane Liner

If a geomembrane liner is proposed, the information in Table 6b is also typically discussed in the report:

| Item No. | Information |

|---|---|

| i. | A description of the proposed geomembrane (type, thickness, texture, etc.). |

| ii. | The design requirements and technical specifications for the geomembrane (e.g. thickness, density, melt index, carbon black dispersion, tensile properties, tear resistance, puncture resistance, stress crack resistance, Oxidative Induction Time (both initial OIT and OIT after oven aging at 85 degrees C for 90 days), and ultraviolet resistance). |

| iii. | Requirements for delivery, storage, installation and sampling of the geomembrane. |

| iv. | Calculations of the physical stress, including those due to:

|

| v. | A statement on the chemical compatibility of the liner, (other than a high density polyethylene (HDPE) liner) and the leachate, and cite the basis for the statement. |

| vi. | A description of how the short-term stresses such as equipment traffic during installation and thermal effects during construction and operation will be taken into account. The liner must be able to withstand the stresses resulting from application of the protection layer placed between the liner and the leachate collection system. |

| vii. | A demonstration that there will be adequate friction between the components of the liner system so that slippage and sloughing does not occur on the slopes of the facility. Specifically, using design equations, evaluate:

|

| viii. | Installation specifications, including details regarding:

|

| ix. | Inspection activities, including both non-destructive and destructive quality control field testing of sheets and seams during installation of the geomembrane. Describe how the following will be taken into account:

|

| x. | A specification for liner strength and the calculations defining the minimum strength requirement considering:

|

| xi. | A specification for the geomembrane protection layer that will be placed between the geomembrane and the leachate collection system, including the method of placement. |

- Geosynthetic Clay Liner (GCL)

If a geosynthetic clay liner (GCL) is proposed for a site specific design, the information in Table 6c is typically discussion in the report:

| Item No. | Information |

|---|---|

| i. | A description of the proposed GCL including sufficient data to evaluate the engineering properties of the GCL. This should include data relating to Atterberg limits, organic carbon content, mineralogy, shear strength, hydraulic conductivity and hydrated thickness under field stress conditions (based on tests with a permeant with a chemical composition similar to the expected landfill leachate). The hydraulic conductivity tests supporting the design hydraulic conductivity must have been conducted on samples hydrated to simulate expected field hydration and permeated with a sufficient number of pore volumes of permeant such that either (a) the concentration of the parameter in the effluent chemistry exceeded 90% of that in the influent, or (b) it exceeds the number of pore volumes that could reasonably pass through the GCL during the contaminating life span of the landfill (whichever is less). The report should also clearly indicate other parameters used by the designer (e.g., diffusion coefficients, partitioning coefficients [Koc], effective porosity, any other parameter used in the design or analysis) and provide relevant data and/or references (i.e., for similar conditions) supporting the choice of these parameters. |

| ii. | A description of construction and installation procedures. Identify how the GCL will be hydrated in the field and provide installation specifications including details regarding:

|

| iii. | A description of the inspection, sampling and testing methods and frequencies to be employed to assure that the GCL meets the design requirements. |

| iv. | Demonstrate that there will be adequate shear strength both within the GCL and between the GCL and other components of the liner system so that slippage and sloughing does not occur on the slopes of the facility. |

- Leachate Collection System

If a primary or secondary leachate collection system is proposed, the information in Table 6d is typically discussed in the report:

| Item No. | Information |

|---|---|

| i. | A description of the proposed leachate collection system, including estimated leachate flows, drainage layer design, any pipe network and the leachate removal system. |

| ii. | Design specifications, calculations and descriptions of design and operational measures that demonstrate that the leachate collection system either meets the requirements of Schedules 1 and 2 or will provide the service life and leachate head control assumed in the assessment of groundwater impact for a site specific design b assessment of groundwater impact for a site specific design by addressing:

|

| iii. | A demonstration that the side slopes of the leachate collection system will be stable. Specifically, using design equations, evaluate:

|

| iv. | Installation specifications, including details regarding:

|

- Construction Quality Control and Assurance

The report typically includes a discussion on the quality assurance plan that addresses both construction material quality control (CQC) and construction quality assurance (CQA), as they pertain to (as applicable) the information discussed in table 6e below.

| Item No. | Information |

|---|---|

| i. | the foundation |

| ii. | compacted clayey liners |

| iii. | geosynthetic clay liners |

| iv. | avoiding desiccation of the compacted clayey liner prior to placement of waste over each part of the liner system |

| v. | geomembrane liners |

| vi. | protection layers for geomembrane liners |

| vii. | leachate collection systems |

| viii. | filter/separator layers for leachate collection systems |

This plan may include a discussion on the specification of the test methods to be adopted, the frequency of sampling, the use of blind samples, the acceptable range of data and the procedures to be adopted in the event that the data does not satisfy the specifications. A discussion on the rationale behind the plan is typically included in the report.

The CQC/CQA plan typically describes in detail the responsibilities of the construction quality control officer as they pertain to the information identified in Table 6f:

| Item No. | Information |

|---|---|

| i. | Communicating with the contractor. |

| ii. | Interpreting and clarifying project drawings and specifications with the designer, owner and contractor. |

| iii. | Recommending acceptance or rejection by the owner/operator of work completed by the construction contractor. |

| iv. | Submitting blind samples (e.g., duplicates) for analysis by the quality control laboratory and one or more independent laboratories. |

| v. | Notifying the owner/operator of construction quality problems not resolved on-site in a timely manner. |

| vi. | Observing the testing equipment, personnel and procedures used by the construction contractor to check for detrimentally significant changes over time. |

| vii. | Monitoring compliance with the procedures necessary to avoid desiccation of the compacted clayey liner prior to placement of waste over each part of the liner system. |

| viii. | Reviewing the quality control records, maintenance summary, and interpretation of test data for accuracy and appropriateness. |

| ix. | Reporting to the owner/operator on monitoring results. |

4.7 Leachate Disposal

Where a site has been designed to collect leachate, the collected leachate must be managed and disposed of in an appropriate manner as required in Regulation 232/98. Typically, leachate disposal would involve discharge to an existing sewage works, either by discharge to a sewer or by hauling it to the sewage treatment plant, or would involve on-site treatment and discharge of the treated effluent to a surface water body. Pretreatment of leachate may be necessary for discharge to an existing sewage works. As described in Subsection 4.7.1, Regulation 232/98 includes a basic requirement that a report be prepared on the management and disposal of any collected leachate. A more detailed description of the issues to be addressed and the type of information typically provided is included in the approval guidelines given in Subsection 4.7.2.

4.7.1 Regulatory Requirements

Regulation 232/98 requires that a report be prepared describing the procedures for disposal of any leachate collected at a landfilling site. This requirement is given in Section 11 of the Regulation and is as follows:

Leachate Disposal

11. A person shall not establish a new landfilling site or increase the total waste disposal volume of an existing landfilling site unless a written report containing plans, specifications and descriptions for the management and disposal of any leachate collected at the site has been prepared.

4.7.2 Approval Guidelines

Where a site has been designed to collect leachate, the leachate management and disposal plans for the site typically include discussions on the information listed in Table 7:

| Item No. | Information |

|---|---|

| a. | The handling, treatment and discharge of leachate directly to a waterbody such that the plans, specifications and descriptions provide a level of detail sufficient to demonstrate the feasibility of obtaining approval under the Ontario Water Resources Act; or |

| b. | the handling, treatment and discharge of leachate into an existing sanitary sewer, sewage works or system approved under the Ontario Water Resources Act,including:

|

4.8 Leachate Contingency Plans