Producing biomethane and renewable natural gas from farm and food-based biogas systems

Learn about the opportunities related to the production and use of biomethane and renewable natural gas from biogas systems at farms and food processing facilities in Ontario.

ISSN 1198-712X, Published April 2024

Introduction

This fact sheet describes the opportunities related to the production and use of biomethane and renewable natural gas (RNG) from biogas systems at farms and food processing facilities in Ontario.

Biomethane and renewable natural gas

Biomethane is a gaseous fuel that contains between 55% and 99% methane and is produced from biogas generated through the anaerobic digestion of organic materials or from landfill gas production. Biomethane is biogas that is cleaned by removing contaminants such as hydrogen sulphide and moisture. In addition, biomethane may be “upgraded” to almost pure methane by removing other contaminants, primarily nitrogen (N2), oxygen (O2) and carbon dioxide (CO2). Methane is the primary component of conventional natural gas. RNG is biomethane that has been cleaned to meet natural gas pipeline quality standards.

Read the Ministry of Agriculture, Food and Agribusiness (OMAFA) fact sheet Anaerobic digestion basics for more information on agricultural biogas production.

Energy in biomethane from manure

It is estimated that there is enough fuel from the manure of 1 milking cow to drive a pick-up truck roughly 5,000 km per year. This calculation assumes that the manure from a milking cow (including its offspring) produces 1,350 m3 of biogas per year, and that 60% of the biogas is methane.

On-farm production of biomethane

Biomethane is currently produced at several farm‑based biogas systems across Canada. The first farm-based biomethane biogas system became operational in 2010 in British Columbia (Figure 1). Biogas is produced in four anaerobic digester tanks that are fed liquid manure, corn silage and food wastes from the nearby communities. Biogas is upgraded to natural gas quality on a continuous basis, producing about 90,000 gigajoules per year. The upgraded gas (RNG) is sold to the local gas utility company.

Using biomethane

Once biomethane has been created, it can be managed and used as a replacement for natural gas or other gaseous fuels. Some of the common uses for biomethane include:

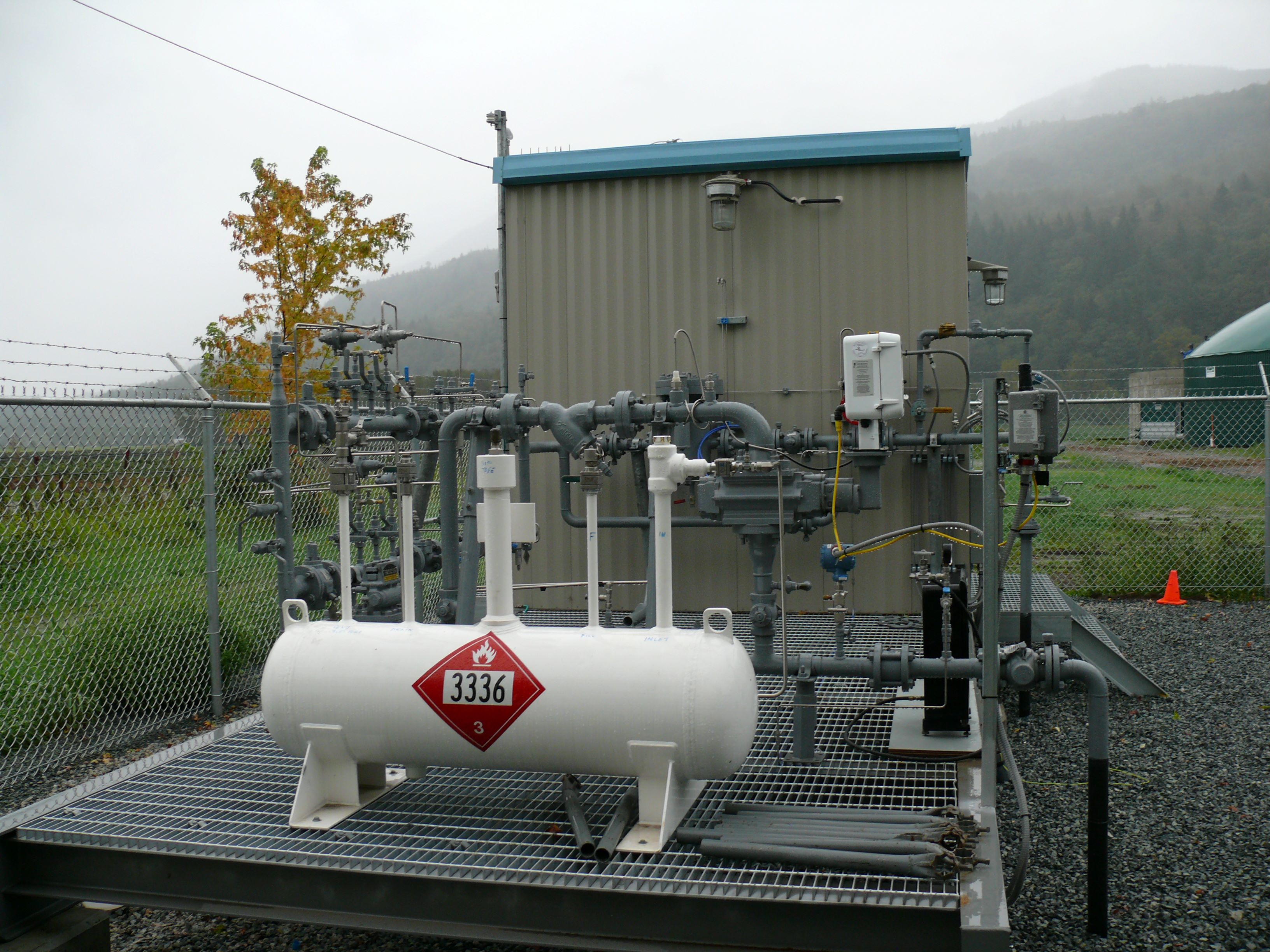

- Injection into the natural gas pipeline: Biomethane that has been upgraded into RNG must meet specific minimum or maximum levels for certain gases, moisture and other constituents in order to be added into the pipeline. It must be pressurized and it must meet a variety of safety and metering rules (Figure 2). Once RNG is added to the pipeline, it is considered to be no different from natural gas, though there may be environmental attributes or credits associated with it that give it extra value. Depending on contractual models, it could be purchased by an end user or by the gas utility. In Ontario, the process of pipeline injection is regulated by the Ontario Energy Board. If the biogas system is not located near a suitable pipeline, biomethane or RNG can be transported in trailer-mounted pressurized cylinders to a central injection point.

- Compressed for non-pipeline customers: Biomethane or RNG can be compressed as a gas and stored in pressurized containers to be used on-site or at remote locations. This may be attractive to fuel users who currently have more expensive fuel alternatives, for instance, when heating livestock facilities or greenhouses.

- Biomethane: In some cases, biogas with only 60% methane content can be used to replace other fuels. To do so, some contaminant gases and water vapour must be adequately removed from the biogas. The remaining 40% of gas volume (other than methane) is made up primarily of carbon dioxide, meaning the fuel has a lower energy density than pure methane. This can be accounted for in a properly designed fuel system, appliance or engine. Figure 3 shows a prototype agricultural tractor that is designed to run on 60% methane biogas. The engine can operate on a blend of biogas and diesel (called a dual fuel system). The prototype gets 70–80% of its 110 horsepower from cleaned biogas (containing 60% methane and 40% carbon dioxide).

Source: Valtra and AGCO.

On-farm biomethane or RNG systems

A farm-based biogas system built for biomethane or RNG production will appear in most aspects like conventional biogas electricity-based systems already found in Ontario. There are a few key differences at RNG biogas systems (beyond the absence of electricity generation equipment):

- Location near a natural gas line: For systems supplying RNG to the natural gas pipeline, construction of the facility within piping distance of a natural gas pipeline will be necessary. Throughout many areas of rural Ontario there is no natural gas service, therefore pipeline injection may not be viable for many livestock farms simply due to their location. Such locations may compress and transport the RNG by truck in tube‑trailers to centralized injection stations on the natural gas pipeline.

- Large size: In general, the upgrading technology currently on the market requires a higher gas production rate than would be available from most farm-based biogas systems built in Ontario today. In Ontario, acquiring enough inputs to feed a sufficiently large system may be achieved with blends of off-farm materials, energy crops or crop residues, and/or importing manure from multiple farms to produce enough biogas.

Advantages of biomethane or renewable natural gas

There are a number of reasons biomethane or RNG production may be considered at biogas systems today:

- RNG is not a fossil fuel: Most importantly, agricultural renewable natural gas is derived from renewable biomass, food wastes and manure, not a fossil fuel source. This reduces the greenhouse gas impacts of using natural gas. Fuel consumers may desire to purchase a fuel that has a lower greenhouse gas footprint than conventional fossil fuel–based natural gas. Natural gas vehicle fuelling with RNG results in a significant reduction of the carbon intensity of the fuel compared to diesel.

- Efficient use of biogas: When biogas is generated for other purposes (waste management, wastewater treatment), upgrading biogas to RNG allows for an efficient use of the energy in the fuel, resulting in nearly all the energy in the gas being converted for energy purposes. In comparison, using biogas or RNG in a cogeneration system to produce electricity may result in losses and inefficiency if there is not an on-site use for excess heat from a cogeneration system.

- Availability of gas line connection: An RNG biogas system may be located in an area that does not have sufficient electrical grid capacity to establish or expand an electricity-producing biogas facility.

Benefits of using RNG from farm and food-based biogas systems

In addition to the climate change benefits associated with using methane from a non–fossil fuel source, when markets for RNG exist, the operation of farm and food-based biogas systems results in benefits that include:

Material treatment

- Emissions reduction: The storage, land application or disposal of untreated manure and food waste can produce greenhouse gas or smog-forming emissions. By harvesting the carbon in a biogas system and using it as RNG, emissions from conventional processes are avoided.

- Odour reduction: Manure and food waste used in biogas systems might otherwise have contributed to odour emission when handled in other conventional manners. Digesting these materials in a biogas system results in odour reduction, contributing to reduced nuisance issues in rural and urban-fringe areas.

- Pathogens: Operating a biogas system with manure as a primary input results in a reduction in pathogens (such as E. coli). Reducing pathogens at the source adds another barrier to reduce risk for surface and groundwater drinking sources, contributing to source water protection objectives in the province.

Waste management for food wastes and by‑products

- Avoid land filling: By using food waste as a biogas input, food waste and food processing by-products that are currently land-filled can be diverted into energy production facilities. While a portion of the methane emissions from landfills can be captured once a landfill is capped, it is much more efficient to harvest this methane directly and fully in a biogas system.

- Reduced waste management costs for the food sector: Directing food waste and by‑products to biogas systems will generally result in lower handling costs for food waste compared to other management approaches (landfill, compost and land-application). Conventional waste management approaches can be expensive since food wastes can be large in volume, wet, odorous and may be generated through the winter, requiring storage solutions. Biogas systems have the ability to deal with all of these issues and potentially be a good destination at a lower cost. The result is that Ontario’s food sector can avoid some costs and strengthen competitiveness.

- Recycling of nutrients and carbon to the land: When food wastes are digested in biogas systems and the digestate effluent is returned to agricultural fields and spread like manure, the result is that agricultural nutrients such as nitrogen, phosphorous and potassium are returned to the soil. The indigestible carbon component in food wastes will also contribute to soil health, building up organic matter. This is an improvement compared to land filling or sewer discharge of food wastes, where these nutrients and carbon are lost or become costly to manage.

Rural economic development

- Local fuel production: Instead of sourcing energy from other jurisdictions, local companies become generators of fuel, meaning that energy dollars are kept in the province.

- Local synergies: Locating biogas systems near the waste sources or near the destination for effluent end products means that jobs, transportation and tax revenue stay local. This approach closes the loop on the farm and food production system.

- Revenue from carbon markets: The low carbon intensity of RNG makes it an important commodity for utilities, governments and businesses to reduce their greenhouse gas emissions. Renewable energy policies and programs enable biogas facilities to market the RNG under contract, which allows the buyers to meet renewable content and greenhouse gas emission targets. The revenue opportunities support significant construction, jobs, investments and economic diversification on farms.

Conclusion

This fact sheet provides an introduction to biomethane and renewable natural gas production. The potential markets for biogas may be a new pathway to capture the environmental and economic benefits associated with farm and food‑based biogas systems. The demand for renewable natural gas is increasing as businesses, the energy sector and jurisdictions seek to meet greenhouse gas emission targets and energy security, and to find alternatives to fossil fuels. Anaerobic digestion, organic waste management and renewable energy production have been proven to work well on farms. Provincial and federal policies continue to evolve to support this valuable waste to renewable energy value chain.

Author credits

This fact sheet was written by Jake DeBruyn, P. Eng., new technology integration engineer, OMAFA and Chris Duke, program analyst, OMAFA.