Technical Standard and Safety Authority: field approval of oil-fired maple syrup evaporators

Learn about the process of obtaining field approval for existing oil-fired maple syrup evaporators. This technical information is for Ontario rural landowners.

ISSN 1198-712X, Published August 2023

Introduction

This fact sheet explains the process of obtaining Technical Standard and Safety Authority (TSSA) field approval for existing oil-fired maple syrup evaporators. It includes sample drawings and photographs to explain the type of information required for submission.

Continued use of unapproved appliances violates Fuel Oil Regulation 213/01 and may result in fuel oil suppliers refusing to supply fuel oil to the appliance until resolved.

Technical Standards and Safety Act, 2000

Currently, the use of hydrocarbon fuels (fuel oil) is regulated under the Technical Standards and Safety Act, 2000 (TSSA Act) and its subsequent Fuel Oil Regulation 213/01, which came into effect in 2001. The TSSA enforces this regulation throughout Ontario.

The TSSA Act improves public safety in Ontario by:

- stating the basic rights, duties and responsibilities of persons governed by the Act

- providing for the efficient and flexible management of technical standards for hydrocarbon fuels

Fuel Oil Regulation 213/01

This regulation lists important duties and responsibilities for all parties involved in activities with appliances, equipment, components and accessories where fuel oil is used for fuel purposes. This includes oil-fired evaporators used in the maple industry.

It places conditions on the initial activation, use, maintenance and inspection of appliances, such as:

- No person shall operate or permit to operate an appliance or tank system unless it is maintained in a safe operating condition and complies with the regulation.

- No person shall install, alter, purge, activate, repair, service or remove any appliance or any equipment unless the person is the holder of a certificate for that purpose under O. Reg. 215/01 (Fuel Industry Certificates).

- Distributors, certificate holders and owners have certain duties and responsibilities concerning any “unacceptable conditions” of an appliance or installation.

- All appliances, equipment, component or accessory must be approved. Approval is gained by using an appliance that is certified by an organization such as ULC, CSA, ETL or WH that is accredited by the Standards Council of Canada or by having the appliance field-approved by TSSA. When such equipment is approved, it bears the organization’s approval label.

- It is the responsibility of the owner/operator of the equipment to ensure it is properly maintained.

Note: The TSSA field approval includes installation and, except for portable appliances, is valid only for the site where the appliance is installed. Field-approved appliances that are relocated must be re-approved in their new location.

Ontario Installation Code for Oil-burning Equipment, 2015

The code describes the minimum standards and requirements for work on the appliances, including:

- The owner of the oil-burning equipment shall ensure that it is maintained annually in accordance with the appropriate codes and the manufacturer’s instructions.

- The fuel storage system (tank) and lines, and the venting system must be inspected and be in proper working order.

- Tests include: ascertaining proper functioning of the operational and safety controls; checking the temperature of the flue gasses, pump pressure, smoke density and draft; and combustion analysis.

These procedures and tests help ensure the safe and efficient operation of the equipment. A properly tested and adjusted burner can result in a substantial savings in fuel consumption over the season.

One producer achieved fuel savings of almost 20% after his equipment was adjusted, tested and modified to meet the Code. A safe and efficiently operating appliance will also minimize the emission of greenhouse gasses into the environment.

This information is not a complete list of all the requirements for fuel-oil fired equipment. Contact a local fuel oil contractor to determine the requirements of your specific equipment.

Correcting non-compliant oil-fired evaporators

To resolve the current non-compliance situation, the TSSA has a process where existing oil-fired equipment can be field approved to meet the Code.

It is anticipated that manufacturers selling new equipment into Ontario will get this equipment certified by a Standards Council of Canada accredited certification organization (CSA or ULC) before offering it for sale.

Application for field approval process

The TSSA Application for Field Approval of Appliances or Equipment form is a one-page document that can be downloaded from TSSA.

The application requires specific technical information about fuel system components and the control system to explain the technical workings of the equipment and the operation of the safety features.

To obtain TSSA field approval of an appliance, the applicant is required to submit a completed application form and the required application fee to TSSA prior to them reviewing the documents. TSSA staff will perform a technical review of the documents submitted prior to visiting the site. Submission of an incomplete application or having TSSA visit the site prematurely without a complete technical review of the documentation will cost the producer time and money as this may involve a request for more information from TSSA and an additional site visit. TSSA is a not-for-profit company whose principle mandate is public safety. As such, they bill the applicant for any costs incurred to deliver the service, for example, time and travel costs to inspect and certify the equipment.

The simplest way to minimize the costs of obtaining a TSSA Field Approval is to hire a qualified Oil Burner Technician and to submit a complete application package the first time.

The applicant must hire a certified oil burner technician (OBT) to assist with the completion of the field approval application. There are several levels of oil burner technicians (OBT 1, OBT 2 or OBT 3). The size of the appliance will dictate which technician level is required to perform the work. For equipment with a firing rate under 26.5 L/hour (7 US gal/hour), an OBT 2 is required. For equipment with a firing rate in excess of 26.5 L/hour, an OBT 1 is required.

The oil burner technician is required to inspect and test existing equipment to determine if there are any Code deficiencies in the fuel delivery system, equipment controls, the venting system and the evaporator. The technician will make any necessary alterations to the equipment to meet the Code. Following equipment alteration, the technician must re-test the equipment to ensure it is operating within the standard.

The technician will help complete a TSSA field approval submission summary prior to a site visit by TSSA field staff. The technician must be present during the TSSA field approval visit to demonstrate the equipment operating before the TSSA will certifying the equipment.

Gather these documents before submitting an application to the TSSA:

Required documents:

- electrical control diagram

- valve train diagram/bill of materials

- purge calculation

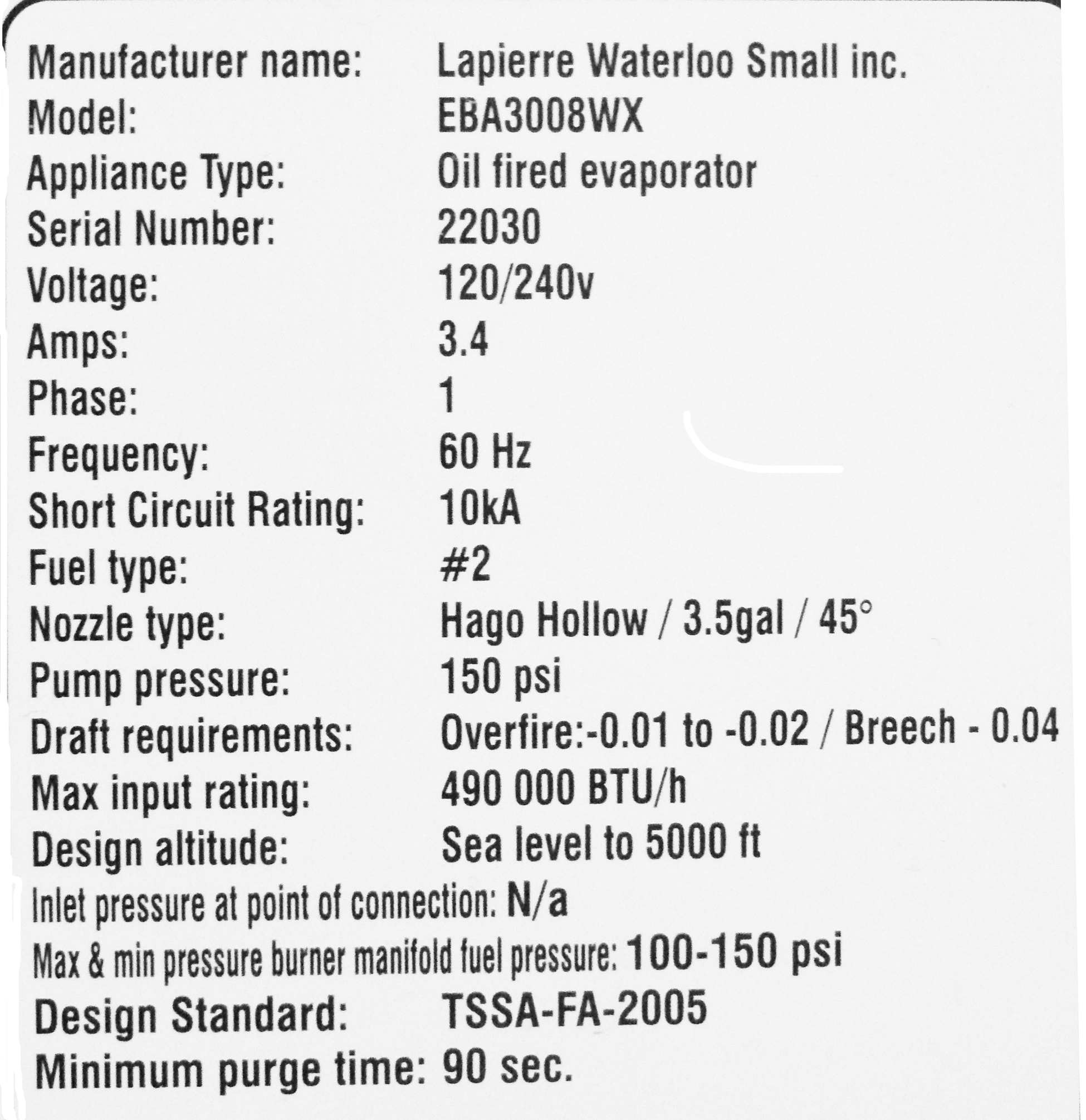

- picture of the rating plate

Optional documents:

- electrical approval

Required documents

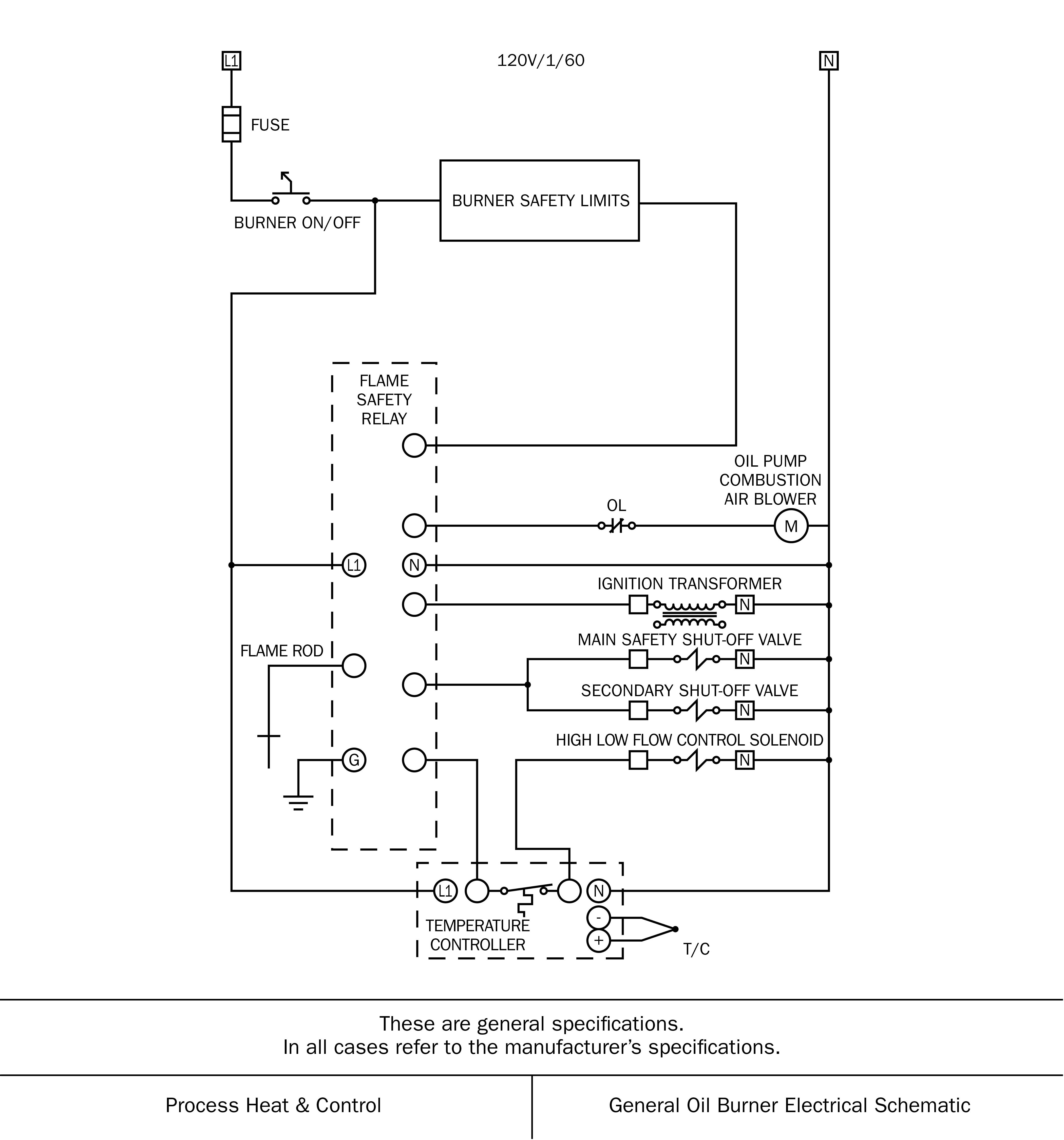

1. Electrical control diagram

Provide a diagram of the electronic control system for the equipment. The OBT may have to consult with the equipment manufacturer to obtain this diagram, or the technician may draw it to show how the automatic safety features are configured (Figure 1).

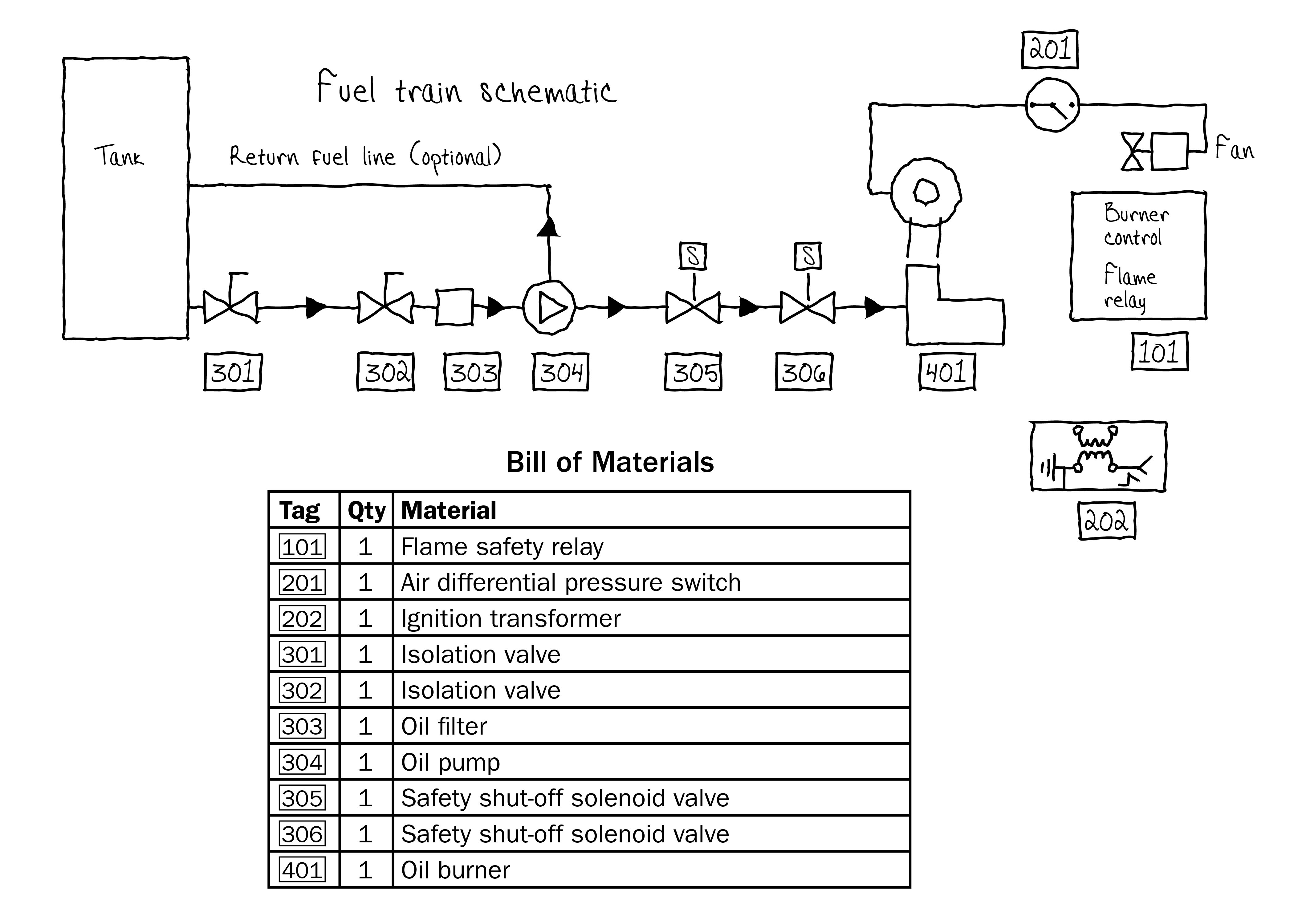

2. Valve train diagram/bill of materials

Provide a valve train diagram of the fuel supply equipment delivering fuel from the fuel storage vessel to the oil-burning appliance. The diagram must show the various safety features in the fuel delivery system to interrupt the flow of fuel to the burner in case of equipment failure or maintenance tasks. A bill of materials description must also be included (Figure 2).

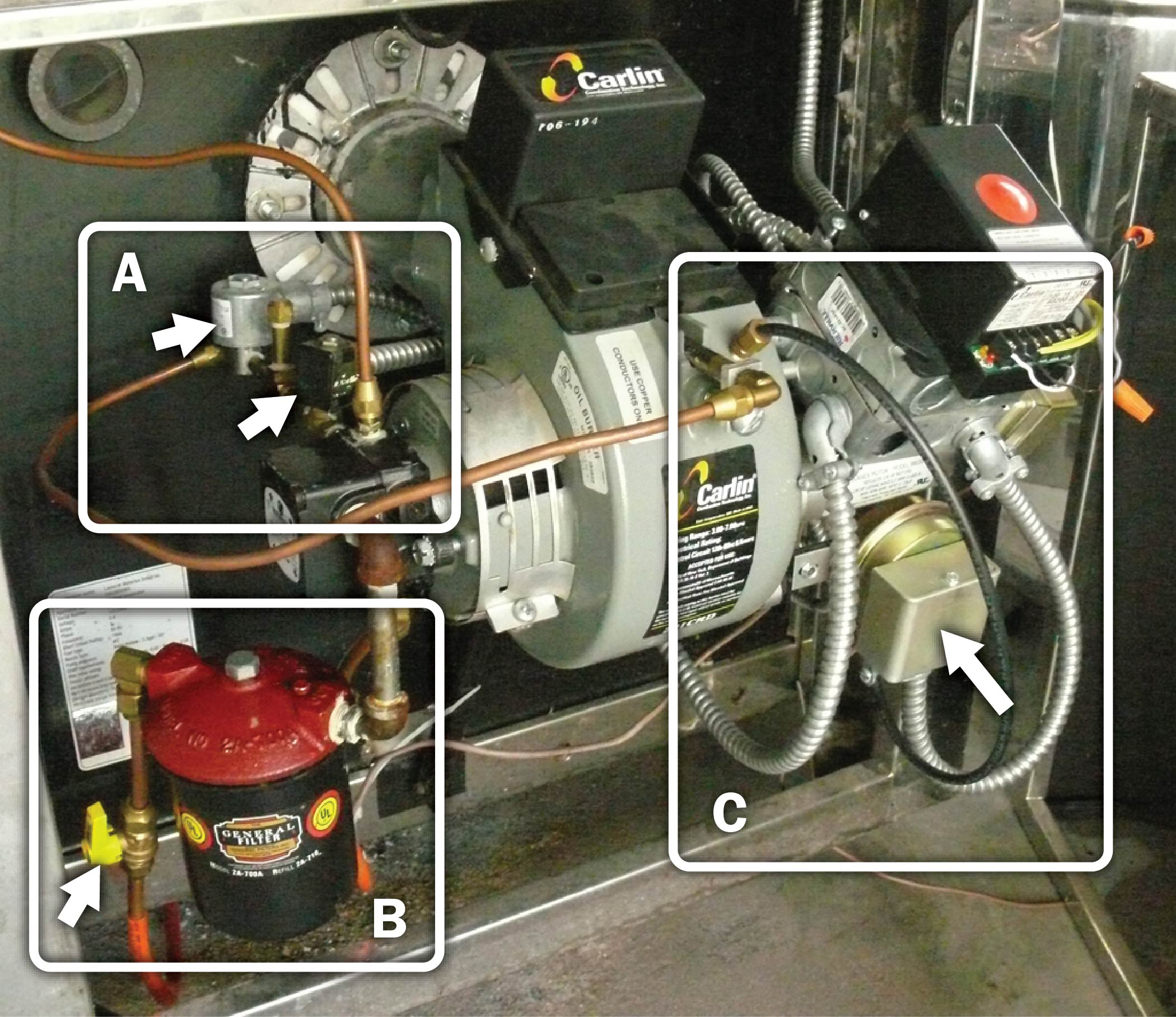

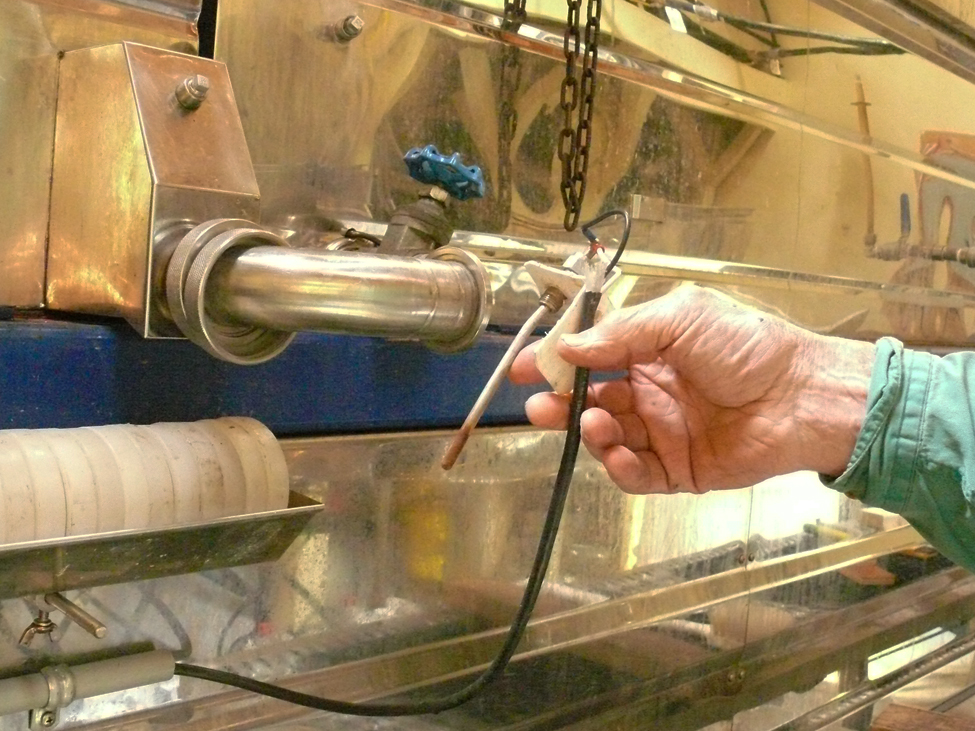

Figures 3 and 4 show the components of the valve train diagram in Figure 2.

Figure 4. An oil-fired maple syrup evaporator as seen in the valve train diagram in Figure 2.

- 2 solenoid valves located after the oil pump can shut off fuel flow to the burner if necessary. (#305, #306, Figure 2).

- Fuel line on the left leads from the fuel tank to the filter and the oil pump (note isolation valve #302 prior to filter).

- Combustion air differential pressure switch mounted on the oil burner assembly. Black hose connected to the burner measures the air pressure sensor connected to the switch that will activate the wall fan (#201, Figure 2)

If there is insufficient air for proper operation of the oil burner in the room (the room is too airtight), add additional air to the room. A combustion air differential pressure switch on the burner will sense if the burner is being starved of oxygen and will activate a wall fan to bring fresh air into the room housing the appliance.

3. Purge calculation

Provide a copy of the purge calculations for the combustion chamber, that is, length of time the blower fan must run to provide four air changes in the chamber before the burner is allowed to ignite.

For example, if the burner fires into its combustion zone that measures 2.5 ft wide by 2 ft deep and is 9 ft long before entering the vent, then the total volume would be: 2.5 × 2 × 9 = 45 ft3.

Since 4 air changes are required, 45 × 4 = 180 ft3 of air is pushed through the burner prior to ignition.

If the fan on the burner is capable of moving 120 ft3 of air per minute (CFM), then the purge time is 180/120 = 1.5 minutes (90 seconds).

The information required for these calculations can be obtained from the equipment manufacturer or the burner manufacturer.

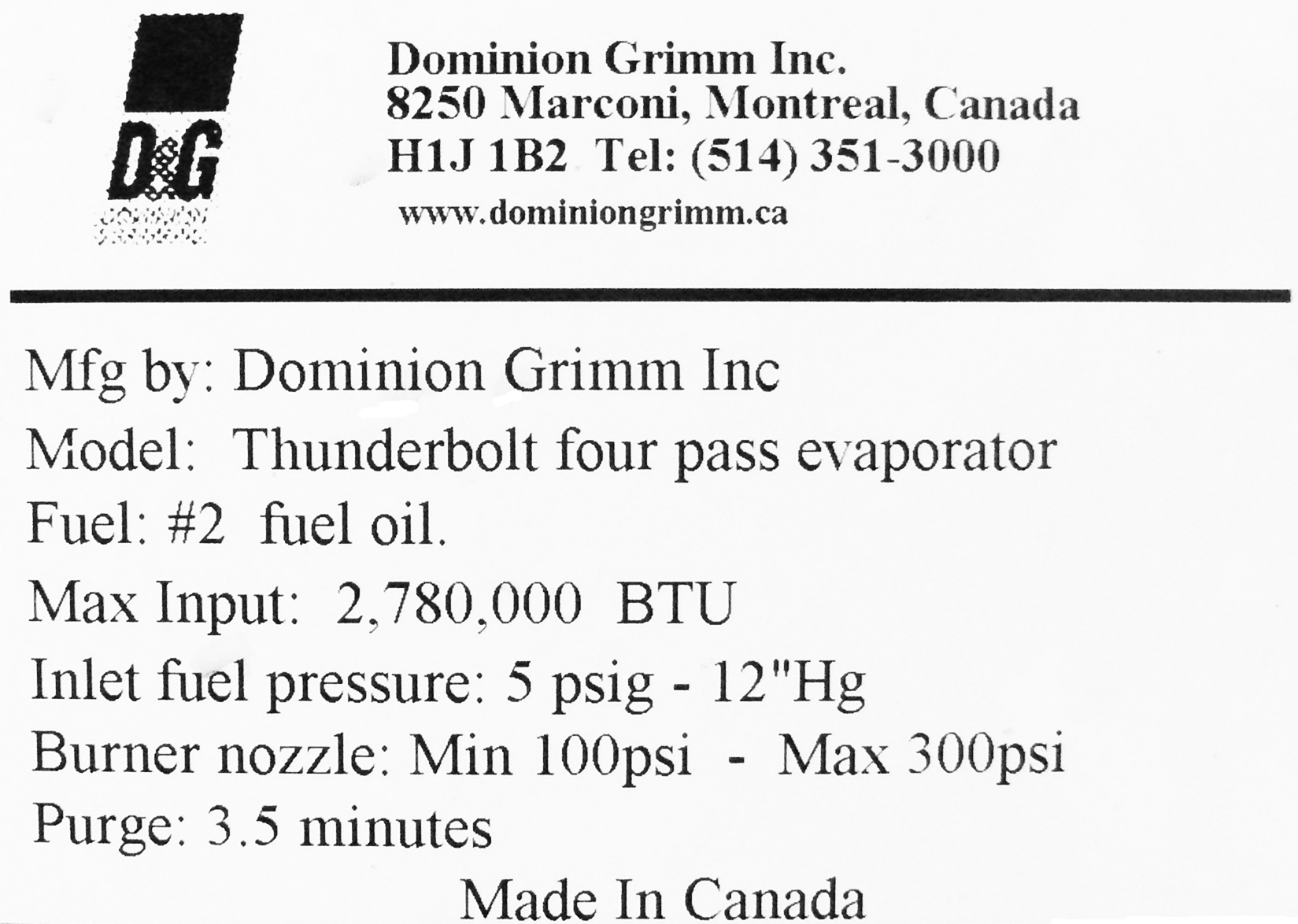

4. Picture of the rating plate

Provide a photocopy of the rating plate for the appliance. The evaporator/burner manufacturer can provide the rating plate information required for TSSA field approval. The rating plate should be permanently affixed to the appliance in an accessible location. Custom rating plates shall contain a 4.5 cm x 3.5 cm (1.625 in. × 1.25 in.) space for the TSSA field approval label. Figures 5 and 6 show examples of the type of information required.

Optional documentation

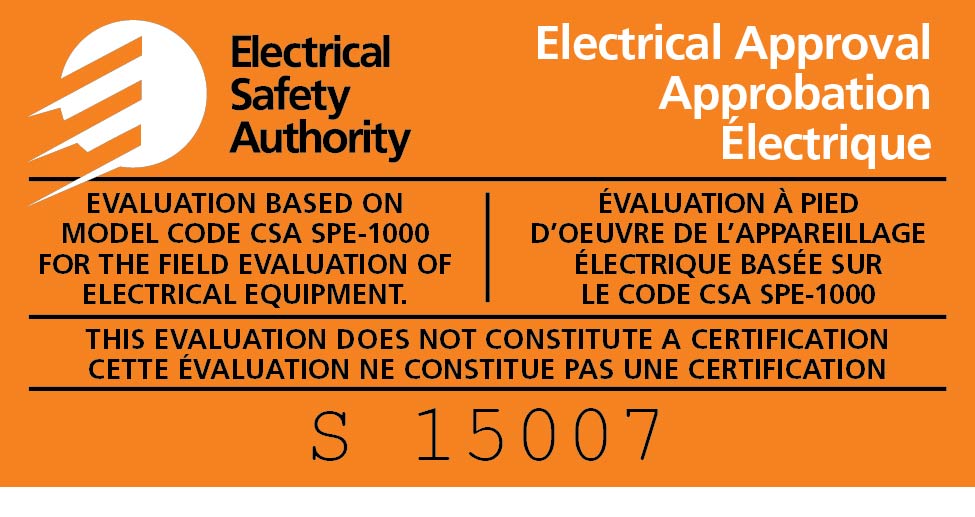

5. Electrical approval

Before TSSA inspection, ensure that you have the required approval under the Electrical Code — either an inspection report or a label attached to the appliance issued by a field evaluation agency recognized under the Ontario Electrical Safety Code and O. Reg. 438/07 (Figure 7). eSafe provides examples of recognized field evaluation agency markings. For further details on the necessary electrical equipment approvals, contact any of the recognized field evaluation agencies. For permits, inspections and an ESA Request for Electrical Field Evaluation, refer to eSafe.

The inspector will also look for code compliance with items such as:

- an emergency shut-off switch or breaker at the entrance to the room housing the appliance, no more than 10 m from the appliance

- anti-short protection sleeves at BX wire connections

- a properly fused unit

Other considerations

Vent (chimney) modifications

Modifications to the vent may be required, such as the addition of a barometric damper to adjust the draft and/or the removal of manually operated dampers in the venting system. For example, when the OBT is testing the evaporator, if the draft in the vent is excessive, the flue gas temperature in the vent and composition of the flue gases may exceed the Code allowance. To reduce the overdraft in the vent, the technician is required to add a barometric damper to bring the appliance into Code compliance (Figure 8).

Where a vent passes through combustible materials, (such as roof structure, insulated ceiling), provide appropriate heat shields or separation distances. The OBT will determine if the appliance is compliant during the initial inspection. Modifications to non-compliant equipment, such as an insulated chimney where the vent passes through a concealed space, that is, insulated ceiling, are required (Figure 9).

Fuel storage

Verify the fuel storage is compliant with Ontario Installation Code for Oil-Burning Equipment, 2015. Discuss the requirements for fuel storage with the oil burner technician.

Low sap level shut-off

Install a shut-off sensor that detects low-sap level in the float box to the flue pan or into the flue pan (Figures 10 and 11).

Conclusion

To resolve the current non-compliance situation, the TSSA has a process in place where existing oil-fired equipment is Field Approved to meet the Ontario Installation Code for Oil-Burning Equipment, 2015. Ontario maple syrup producers, using oil-fired equipment, are encouraged to obtain field approval prior to the next maple syrup season to ensure that fuel suppliers will deliver oil to their equipment.

This fact sheet was written by Todd Leuty, agroforestry specialist, Ministry of Agriculture, Food and Rural Affairs (OMAFRA), Daniel Ward, P. Eng., poultry and other livestock housing and equipment, OMAFRA and Helmut Spieser, P. Eng., field crop conditioning and environment, OMAFRA. Reviewed by Tim Chakowski, Kemptville College, University of Guelph, and Zenon Fraczkowski, P. Eng., engineering manager, Fuels Safety Program, TSSA.