Temporary field storage of solid manure or other agricultural source materials

Learn to determine how long solid and agricultural source materials can be stored in a specific temporary field storage site. This technical information is for Ontario producers.

ISSN 1198-712X, Published May 2010

Introduction

Ontario Regulation 267/03 ("Regulation") made under the Nutrient Management Act, 2002 (NMA) contains many provisions that apply to those farms required to have a Nutrient Management Strategy (NMS) or Nutrient Management Plan (NMP). Large farms with ≥300 nutrient units (NU) and farms with >5NU – that since December 31, 2005, need a building permit for livestock housing or manure storage – are required to have one or both of these documents.

These operations must, with some exceptions, now be able to store their manure for 240 days. For solid manure this can be achieved by adding the days of all storage available including:

- permanent storage (for example, 3-walled concrete storage)

- in-barn storage (for example, manure pack under animals)

- using a broker to periodically remove manure

- temporary field storage (Figure 1)

For example, a chicken broiler farmer would need 240 days if the farmer:

- builds permanent storage that holds 180 days of solid manure production from the barn

- stores at least 60 more days of manure production in a proper temporary field storage, prior to land application

While temporary field storage creates flexibility for farmers, it must be done properly to reduce the potential for surface or groundwater contamination.

Ontario’s Nutrient Management Act and other legislation

The Nutrient Management Act, 2002 and Regulation regulates the storage, handling and application of nutrients that could be applied to agricultural cropland. The objective is to protect Ontario's surface and groundwater resources. Part VIII, s. 82–86 of the Regulation outlines the standards for Temporary Field Nutrient Storage Sites.

Definition of solid nutrients

Solid, in relation to prescribed materials or nutrients, is: “... having a dry matter content of 18%, or more, or a slump of 150 mm, or less, using the (slump test) set out in Schedule 9 to Regulation 347 made under the Environmental Protection Act, 1990...”

To most farmers, “solid prescribed materials” means “solid manure” that contains bedding such as straw, peat moss, shavings, sawdust or other materials that binds it so it can be stacked and handled with loaders.

There are three ranges of dry matter content of solid prescribed materials dealt with in the requirements for temporary storage in the Regulation. Table 1 gives examples of these ranges.

| % Dry matter | Regulation |

|---|---|

| Greater than 50% dry matter |

|

| Greater than 30%, but less than 50% dry matter |

|

| 18%–30% dry matter |

|

Table 2 examines the differences between temporary field storage and permanent storage.

| Factors | Permanent storage | Temporary field storage |

|---|---|---|

| Storage period | Long-term, usually 240–400 days or more | Short-term, 24 hours to 300 days maximum |

| Proximity to barn | Usually beside the barn where manure produced | Usually far from the barn in or near fields cropped |

| Walls | Usually concrete walls, but not always | Usually no walls, but bales can work temporarily |

| Floor | Usually concrete floor, but not always | Just the original field soil surface in a dry area |

| Location | Always in same place, beside barn/ road access | Changes from field to field as part of the crop rotation |

Determining the maximum days of temporary storage at one location

The Regulation applies if nutrients are stored in a temporary field storage site for longer than 24 hours. Allowable days of temporary storage are based on 10 site characteristics and best management practices. Farmers are “rewarded with days of temporary field storage” for methods protecting surface and groundwater.

Table section 3 sets out 10 tables of site characteristics and best management practices, how each is used to cumulatively determine the maximum allowable time of field storage at each site and the rationale. The storage period is linked to relative environmental risk to surface and groundwater.

The total number of days is cumulative but cannot exceed 300 days. This applies for solid manure and other agricultural source materials.

Even though rules on temporary field storage only apply to farmers required to prepare a NMS or NMP, it is hoped farmers who are not required to prepare these plans will still adhere to the concepts of the site-scoring system. This will help ensure temporary field storage of solid manure and other prescribed materials do not contribute unnecessarily to surface or groundwater contamination.

Table section 3. Temporary field storage of solid manure or other agricultural source material site-scoring system

3.1: % Dry Matter

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

| Nutrients stored in the site have a dry matter content of 50% or more | +60 |

| Nutrients stored in the site have a dry matter content of 30% or more, but less than 50% | +30 |

| Nutrients stored in the site have a dry matter content of 18%, or more, but less than 30% (includes horticultural culled material) | +0 |

Rationale: The higher the dry matter of manure, the more rainfall it can absorb. Poultry farmers with manure >50% dry matter know this when they remove piles and see that rainfall only penetrates up to 125 mm under the surface (Figure 2). Wetter manure sheds rainfall off the sides, or lets it soak through and into the soil. Keeping the pile as “flat” as possible on top helps force the rainfall to soak in and prevent runoff.

3.2: % N and % P Added Together

| Management techniques and field conditions for materialsstored in a temporary field nutrient storage site | Days |

|---|---|

| The % of total nitrogen combined with the % of total phosphorus, both on a wet basis, is less than 0.8% | +60 |

| The % of total nitrogen combined with the % of total phosphorus, both on a wet basis, is at least 0.8%, but less than 1.6% | +30 |

| The % of total nitrogen combined with the % of total phosphorus, both on a wet basis, is 1.6%, or more | +0 |

Rationale: The lower these two nutrients are in manure when placed, the lower the environmental risk if there is runoff. There is a broad range of nutrient contents in solid manure related to species and diet. The following table lists average nutrient contents by dry matter range in the NMAN database for many animals. Manure might vary depending on bedding.

| Manure | 18–30% DM | 30–50% DM | > 50% DM |

|---|---|---|---|

| Poultry | 2.0% | 2.8% | 4.4% |

| Swine | 1.4% | 1.3% | N/A |

| Beef | 0.8% | 1.3% | N/A |

| Sheep | 0.9% | 1.0% | 1.6% |

| Cattle | 0.8% | 0.9% | N/A |

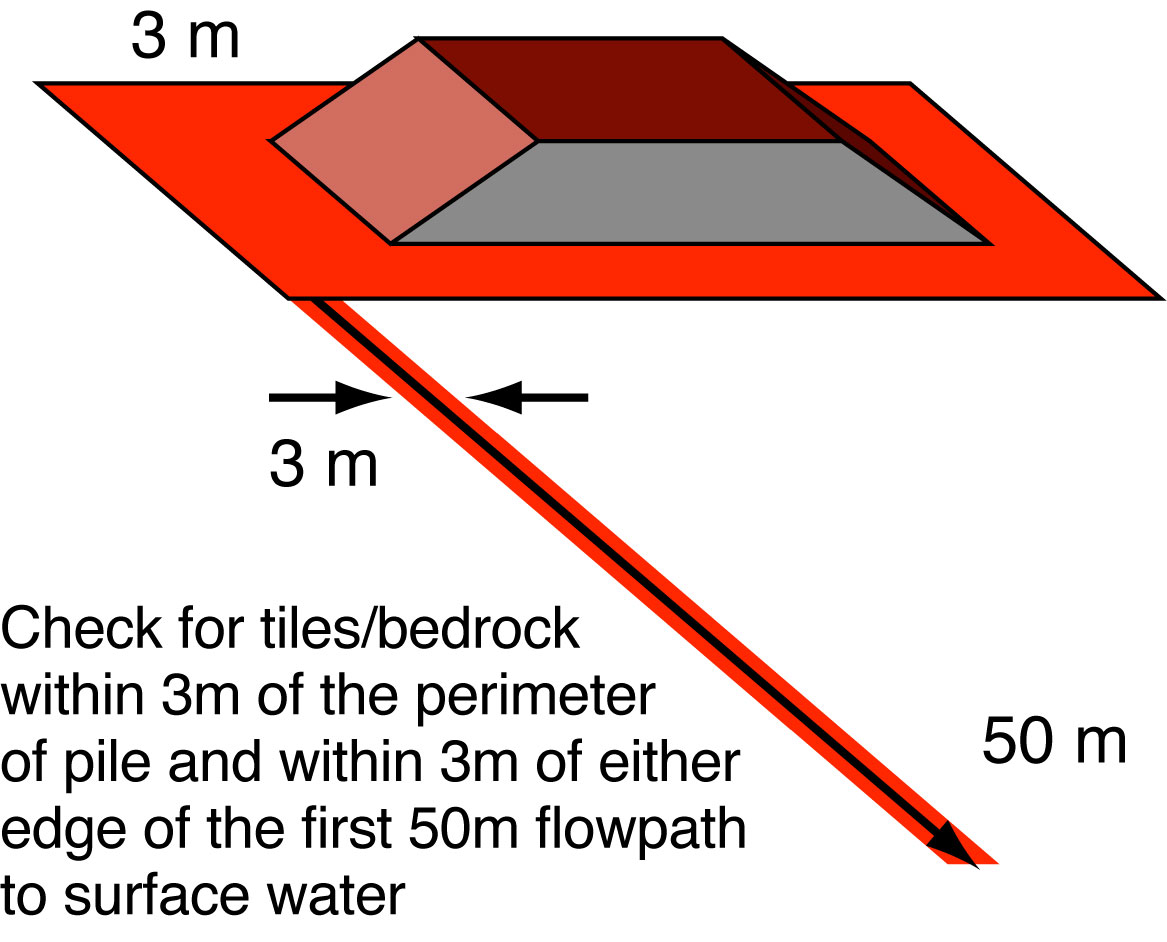

3.3: Drainage tile and bedrock location

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

There are no field drainage tiles at any depth of the soil surface and no bedrock within 0.9 m of the soil surface, located:

|

+0 |

There are field drainage tiles at any depth of the soil surface or bedrock within 0.9 m of the soil surface, located:

|

–60 |

Rationale: If runoff from the pile sides, or leachate through the middle of the temporary field storage occurs, there is less environmental risk if the contaminated water has no conduit for travel to surface or ground water (Figure 3). Conduits can be provided by tile or bedrock under, near, or in the first part of the flow path away from the pile. Most Ontario farms are tiled and many have bedrock near the surface. It is natural to assume, since this a dry place for machinery, that this is a good place to store manure. However, the Regulation encourages farmers to avoid these locations by “taking away” days of storage on sites with these conditions.

3.4: Soil Type (under the site)

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

| The site is situated on soil included in the following hydrologic soil groups as defined by OMAFRA Publication 29, Drainage Guide for Ontario: B, C or D | +30 |

| The site is situated on soil included in the following hydrologic soil groups as defined by OMAFRA Publication 29, Drainage Guide for Ontario: A | +0 |

Rationale: The heavier the soil under a temporary field storage the less opportunity for leachate to percolate down to the groundwater. Clay soils are denser and better at preventing downward percolation than lighter, coarser soils one might find in a peach orchard (Figure 4).

3.5: Perimeter of the Site

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

| The outer edge of the site (of all piles), at the ground surface, has a perimeter of less than 100 m | +30 |

| The outer edge of the site (of all piles), at the ground surface, has a perimeter of 100 m or more | +0 |

Rationale: Piles with a more square and compact footprint will soak up more rainfall than piles of equivalent volume but with a longer and narrower shape since they have less total side perimeter for runoff. The table below shows the perimeter of three piles, all storing 100 tonnes of solid chicken broiler manure, stored 1.2 m deep (4 ft) when dumped from a truck, with one long, two medium, or three short rows of piles.

| Pile type (all connected together) | L × W (m) | Per. (m) |

|---|---|---|

| 1 long row | 84 × 4.25 | 175 |

| 2 medium length rows | 43 × 8.5 | 102 |

| 3 short length rows | 29 × 12.8 | 84 |

3.6: Covers and tarps

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

The site is covered with a rain-shedding tarp that:

|

+120 |

| Site not covered with rain-shedding tarp | +0 |

Rationale: Tarps prevent contaminated runoff since rainfall does not touch the manure. However, tarps are unpopular because they are inconvenient and difficult to anchor against wind removal. Breathable tarps, such as the (partial) one in a compost turning system (Figure 5), are recommended (see Examples 5 and 6).

3.7: Distance to surface water

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

| The site has a flow path to the nearest surface water or water inlet for field tile drainage of 150 m or more | +30 |

| The site has a flow path to the nearest surface water or water inlet for field tile drainage of at least 50 m, but less than 150 m | +0 |

Rationale: If runoff does occur, there is less environmental risk if the runoff has to travel a long distance to surface water or to a water inlet for field tile drains. Surface water is defined in the Regulation. Water inlets for field tile drains, such as water and sediment control basins that collect and drain floodwaters (Figure 6), are not surface water under the Regulation, but temporary field storages still should not be near them.

3.8: Location of the site

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

| The site is situated on the same location, or within 125 m of the same location not more often than once every 3 years | +60 |

| The site is situated on the same location, or within 125 m of the same location more often than once every 3 years | +0 |

Rationale: When temporary field storage is in the same location year after year this is considered permanent storage. This causes a build-up of soil nutrients and can render the site uncroppable. Size piles appropriately to fields and move where needed for the crops. Piles on the ground behind the barn are not temporary field storages (Figure 7).

3.9: Materials removed from site

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

| The site is not situated on the same location, or within 125 m of the same location, more often than once every 3 years, and the materials stored are removed from the site and applied to land during the period between August 15th and October 15th in any year. | +60 |

| The situation described above does not apply to the site | +0 |

Rationale: Many farmers want to spread manure during the drier and later time of summer and early fall, such as after wheat is harvested (Figure 8). During this time, there is usually more evaporation of moisture than is being replaced by rainfall, so there is reduced risk of runoff. The Regulation provides an incentive for temporary field storage manure that will be spread during this drier season, as long as it is also being located on different sites yearly, as in a crop rotation.

3.10: Turning of stored materials

| Management techniques and field conditions for materials stored in a temporary field nutrient storage site | Days |

|---|---|

The pile of materials stored on site:

|

+120 |

| The site described above does not apply | +0 |

Rationale: An increasing number of farmers compost their solid manure for use on their cropland (Figure 9). Long windrows of manure with a lot of straw or wood shavings in them are placed in the field, then turned often to mix and introduce oxygen. This improves the compost process, but also dries the piles and breaks up surface crusting, allowing the piles to act as sponges for most rainfall that lands.

Minimum management requirements under the NMA Regulation

The Regulation outlines several minimum management requirements for storage sites.

- A farmer who receives and stores nutrients on site cannot receive and store more nutrients than is expected to be used for crop production on that farm unit in that operating year.

Rationale: Storage piles should be size-appropriate for the field; a temporary pile is truly temporary when it is used on the field where it is placed. - If more than one type of nutrient is stored on site, the nutrients must be managed in accordance with the most restrictive requirements applicable to any of the nutrients stored in the site.

Rationale: See Example 4 to follow. - If the site is located in an area that is tile-drained, there must be a contingency plan to deal with any contaminated liquid that might get into the tiles.

Rationale: Farmers must be prepared to deal with runoff getting into tile drains. Proving there are, or aren't, tiles under or near a temporary storage site can be difficult. Some ideas include: checking aerial photos of the field; looking for nearby tile outlets; observing the first spots to drain in spring; or asking previous owners and local drainage contractors. Probing at least 1 m deep in more obvious locations for tiles with a metal rod can help, but this is difficult over large areas. - Nutrients must not be stored on site for longer than the maximum time allowed for each nutrient.

Rationale: If there is more than one temporary field storage on the farm in different locations, each one might have a different allowable maximum time at that site based on the scoring system for that site. - The site may be used again the following year if, following the removal of nutrients from the surface after the site ceases to be in use each year, a minimum of 75% vegetative cover is re-established on the site.

Rationale: To be used consecutively for temporary field storage, vegetation must be able to grown again on the area. This can prove difficult when the same site is used annually. - The operator shall provide a sketch of the site showing setback distances, as described earlier, and maintain records for all temporary field storage sites, which include the dates the site was:

- established, then removed

- displaced, mixed or inverted, if applicable

Minimum site requirements under the NMA Regulation

The Regulation outlines minimum site requirements related to location.

- The minimum depth of unconsolidated soil

footnote 3 to bedrock, under the site and within 3 m of the side of the site, must be 0.3 m.

Rationale: This minimizes the potential for runoff to reach bedrock under, or near, a temporary storage site. - The minimum depth of soil above the water table

footnote 4 , under the site and within 3 m of the side of the site, must be 0.9 m.

Rationale: This minimizes potential for runoff to reach the water table under, or near, a temporary storage site. - Nutrients must not be stored on soils with a hydrological soil group of “A” unless the depth to soil is greater than 0.9 m to bedrock.

Rationale: “Hydrologic soil group A” means a soil with rapid infiltration rates as defined by the Drainage Guide for Ontario. There are very few locations in Ontario with these conditions, but if it is suspected, use a metal rod to probe down at least 1 m to check for possible shallow bedrock. - The storage site must not be located in an area that, according to the flood plain mapping provided by the municipality or conservation authority is subject to flooding more than once every 100 years.

Rationale: Storage sites with the potential for flooding are inappropriate. Confirm with the conservation authority that the proposed temporary storage is not in a 1 in 100 year flood plain. - The site must not have a slope greater than 3%.

Rationale: 3% is a vertical drop of 3 m every 100 m distance. Runoff moves quickly on relatively steep slopes. - There must be a flow path that is at least 50 m to the nearest surface water or tile inlet, and located at least 0.3 m above bedrock.

Rationale: Flow path is defined in the Regulation as “a surface channel or depression that conducts liquids away from the area”. - Do not locate the site within:

- 45 m of a drilled well that has a depth of at least 15 m and a watertight casing to a depth of at least 6 m below ground level

- 90 m of any other well, other than a municipal well

- 100 m of a municipal well

- 125 m of a single residence, or within 250 m of a residential area if the area is used for storing agricultural source material

Rationale: Setbacks help minimize risks to drinking water and are greater than those required for permanent storages since there is more risk of runoff.

Examples

The following 6 examples provide temporary field storage characteristics for different manure types.

Example 1 – Horse manure

A temporary field storage for horse manure to be spread on a corn field has these 10 characteristics:

| # | Characteristics | Example 1 | Days |

|---|---|---|---|

| 1 | % dry matter | 38% | +30 |

| 2 | % N added to % P | 0.75% | +60 |

| 3 | Tiles/bedrock under/nearby | none | +0 |

| 4 | Soil type | clay (D) | +30 |

| 5 | Perimeter of pile | 60 m | +30 |

| 6 | Cover | none | +0 |

| 7 | Distance to surface water | 200 m | +30 |

| 8 | Location of site | every year | +0 |

| 9 | Removal date | May | +0 |

| 10 | Turning of pile | not turned | +0 |

Total maximum days allowed at this site = +180 days

The maximum time horse manure can remain at this site is 180 days. One simple way to increase this is to locate the temporary storage on a site not used for temporary field storage in the last two years.

Example 2 – Chicken broiler manure

A temporary field storage for chicken broiler manure in a vineyard has these characteristics:

| # | Characteristics | Example 2 | Days |

|---|---|---|---|

| 1 | % dry matter | 62% | +60 |

| 2 | % N added to % P | 3.4% | +0 |

| 3 | Tiles/bedrock under/nearby | tile present | –60 |

| 4 | Soil type | clay (D) | +30 |

| 5 | Perimeter of pile | 50 m | +30 |

| 6 | Cover | none | +0 |

| 7 | Distance to surface water | 300 m | +30 |

| 8 | Location of site | every year | +0 |

| 9 | Removal date | June | +0 |

| 10 | Turning of pile | not turned | +0 |

Total maximum days allowed at this site = +90 days

The maximum time chicken manure can remain at this site is 90 days. Two ways to increase this would be to locate this temporary storage on a site not used for temporary field storage in the last two years, and one without tiles under it.

Example 3 – Beef manure

A temporary field storage, for beef manure to be spread on a corn field has these characteristics:

| # | Characteristics | Example 3 | Days |

|---|---|---|---|

| 1 | % dry matter | 32% | +30 |

| 2 | % N added to % P | 1.2% | +30 |

| 3 | Tiles/bedrock under/nearby | none | +0 |

| 4 | Soil type | clay (D) | +30 |

| 5 | Perimeter of pile | 150 m | +0 |

| 6 | Cover | none | +0 |

| 7 | Distance to surface water | 500 m | +30 |

| 8 | Location of site | once/3 years | +60 |

| 9 | Removal date | September | +60 |

| 10 | Turning of pile | not turned | +0 |

Total maximum days allowed at this site = +240 days

The maximum time beef manure can remain at this site in temporary field storage is 240 days.

Example 4 – Field stored manure

A temporary field storage of manure is turned frequently and composted in windrows.

| # | Characteristics | Example 4 | Days |

|---|---|---|---|

| 1 | % dry matter | 25% swine 40% cattle |

+0 |

| 2 | % N added to % P | 1.4% swine 1.2% cattle |

+30 |

| 3 | Tiles/bedrock under/nearby | Tile present | –60 |

| 4 | Soil type | Loam (B) | +30 |

| 5 | Perimeter of pile | 300 m | +0 |

| 6 | Cover | none | +0 |

| 7 | Distance to surface water | 500 m | +30 |

| 8 | Location of site | Once/5 years | +60 |

| 9 | Removal date | May | +0 |

| 10 | Turning of pile | C:N is 30:1 | +120 |

Total maximum days allowed at this site = +210 days

To increase storage time above 210 days, find a location without tiles under it. This would increase storage time to 270 days, which for most windrow composting systems is sufficient time to allow proper composting and curing before field application.

Example 5 – Broiler-breeder pullet

After cleaning the manure out of a broiler-breeder pullet barn, a breathable rain-shedding tarp is immediately applied. The resulting temporary field storage has the following characteristics:

| # | Characteristics | Example 5 | Days |

|---|---|---|---|

| 1 | % dry matter | 40% | +30 |

| 2 | % N added to % P | 3.0% | +0 |

| 3 | Tiles/bedrock under/nearby | none | +0 |

| 4 | Soil type | clay (B) | +30 |

| 5 | Perimeter of pile | 75 m | +30 |

| 6 | Cover | yes | +120 |

| 7 | Distance to surface water | 250 m | +30 |

| 8 | Location of site | once/5 years | +60 |

| 9 | Removal date | September | +60 |

| 10 | Turning of pile | not turned | +0 |

Total days = +360 but the maximum allowable days in one location is 300 days.

For all-in/all-out operations such as broiler-breeder pullets, it is easier to use a cover because once it is anchored in place it need not be removed until the manure is spread on the fields. This is difficult when manure is added more frequently.

Example 6 – Composted beef manure

A temporary field storage of beef manure, composted in windrows, with a rain-shedding tarp that can be lifted and replaced during pile turning, has the following characteristics:

| # | Characteristics | Example 6 | Days |

|---|---|---|---|

| 1 | % dry matter | 40% | +30 |

| 2 | % N added to % P | 1.3% | +30 |

| 3 | Tiles/bedrock under/nearby | tile present | –60 |

| 4 | Soil type | sand (A) | +0 |

| 5 | Perimeter of pile | 250 m | +0 |

| 6 | Cover | yes | +120 |

| 7 | Distance to surface water | 75 m | +0 |

| 8 | Location of site | once/2 years | +0 |

| 9 | Removal date | May | +0 |

| 10 | Turning of pile | C:N is 30:1 | +120 |

Total maximum days allowed on this site = +240 days

Even though this temporary field storage site is located on a light soil with tiles under it, the cover and turning of the pile help minimize the risk of contaminated runoff. It is still recommended to avoid tiled areas if possible.

Disclaimer

The information in this fact sheet is provided for informational purposes only and should not be relied upon to determine legal obligations. To determine your legal obligations, consult the relevant law. If legal advice is required, consult a lawyer. In the event of a conflict between the information in this fact sheet and any applicable law, the law prevails.

This fact sheet was written by Hugh Fraser (retired), P. Eng., hort crop protection and post-harvest engineer, OMAFRA and reviewed by: Matt Wilson, environmental specialist, OMAFRA, Don Hilborn (retired), P. Eng., by-products/manure engineer, OMAFRA and Andrew Jamieson, P. Eng., water management engineer, OMAFRA.

Footnotes

- footnote[1] Back to paragraph Adding bedding to manure increases dry matter, so this manure could realistically move to a drier category.

- footnote[2] Back to paragraph Agricultural-source materials less than 18% dry matter, but which pass the ‘slump test’, should be considered in this range for the purpose of the Regulation.

- footnote[3] Back to paragraph Unconsolidated soil has not been compacted, other than through normal field traffic and cultivation.

- footnote[4] Back to paragraph Water table is defined in the Regulation as “In relation to land, the highest level of water found in the ground, as recorded in the water well records for the nearest water wells to the land, or as determined by a test hole dug at or before the placing of materials containing nutrients at a temporary storage site located on the land.”

- footnote[5] Back to paragraph The most restrictive manure type must be considered when determining the score for the % Dry Matter and the % N added to % P, regardless of the relative volume of each.

- footnote[6] Back to paragraph The C:N ratio of the mixture is at the time of placement, as the C:N ratio will decrease over time as composting proceeds.