Inspecting Air Brake Adjustment

Proper brake adjustment is important to your safety and that of other road users. Drivers of vehicles with air brakes must inspect brake adjustment regularly using a reliable inspection method. This chapter explains how to carry out such an inspection.

Brake adjustment must be inspected regularly

The pushrod stroke of each brake chamber is critical to the proper function of a brake system. As the brakes wear, brake pushrod stroke increases. Brake wear occurs at varying rates, depending on the type of vehicle and driving conditions. To determine whether brake adjustment is correct, the pushrod stroke must be inspected at least daily. When brake pushrod stroke exceeds the adjustment limit, the brake is out of adjustment.

Brake pushrod stroke must comply with the Ontario Highway Traffic Act and regulations. Each air brake chamber’s pushrod stroke must not exceed the specified adjustment limits.

Since adjustment limits vary depending on the size and type of air brake chamber, you must be able to identify the particular brake chamber in use. Brake chamber size can be determined by measuring the diameter of the clamp used to hold it together or by locating the size markings on the brake chamber.

The most common brake chamber size is 30. However, there are vehicles using both smaller and larger sizes. For example, sizes 16, 20, 24 and 36 brake chambers may be used.

Measuring the diameter of brake chambers requires a special tool. Locating and reading the size markings on a brake chamber may require removing dirt, corrosion and paint from the surfaces.

You are most likely to determine the size of the brake chambers on any vehicle through your employer or the vehicle owner’s manual. This will avoid the need to measure a brake chamber or locate size markings. The type of brake chamber also affects the specified brake adjustment limit, which can vary by 19 millimetres or more between standard and long-stroke brake chambers. Long-stroke brake chambers can be identified by three visible characteristics:

- The air lines attach to a square port in the brake chamber body.

- A trapezoidal tag is placed under the clamp bolt that indicates the brake chamber’s maximum stroke dimension. (Not the brake adjustment limit.)

- Markings are placed on the brake chamber body to indicate that it is a long-stroke brake chamber, and only long-stroke diaphragms are to be used as replacements.

The most visible and permanent of the markings used to identify long-stroke brake chambers are the square ports. Standard brake chambers have round ports.

It is critical to use correct inspection methods to obtain reliable inspection results. The most reliable method for inspecting brake adjustment is to measure the applied pushrod stroke.

Step-by-step procedure for measuring applied pushrod stroke

It is important to note that the body design and suspension of some vehicles may limit safe access to certain brake components unless the vehicle is supported on a hoist or is over a pit or ramp. Also, some brake systems have covers or housings that conceal the brake linkage, making it impossible to inspect brake adjustment using the techniques described here.

- Secure the vehicle with wheel chocks or blocks.

- Ensure air pressure is above 621 kPa (90 psi) and release the spring brakes.

- Select one of the following methods:

- Method 1: Mark the pushrod at the brake chamber or at a suitable fixed reference point. (Use chalk, soapstone, marker or other similar instrument - marks must be narrow and precise.)

- Method 2: Measure the released position of the pushrod. (Measure and note the distance from a point on the pushrod to a suitable fixed point at the brake chamber. This is measurement number 1.)

- Raise or lower the air pressure by running the engine or pumping the brake pedal until both the primary and secondary air-tank gauges display 621 to 690 kPa (90 to 100 psi).

- Shut off the engine.

- Press and hold the brake pedal in the fully applied position.

- Determine the applied pushrod stroke. (Continue to use the previously selected method).

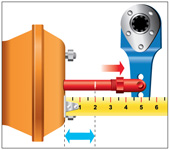

- Method 1: Measure the distance from the brake chamber or fixed reference point to the mark on the pushrod (See Diagram 11-1).

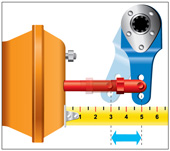

- Method 2: Measure the applied position of the pushrod. (Remeasure and note the distance from the previously selected point on the pushrod to the previously selected fixed point at the brake chamber. This is measurement number 2.) Subtract measurement 1 from measurement 2 to calculate the applied pushrod stroke measurement (See Diagram 11-2).

- Determine the number size (such as 16, 20, 24 or 30) and type (such as standard or long-stroke) of the brake chamber.

- Determine the adjustment limit for the brake chamber. (See the chart here)

- Compare the applied pushrod stroke to the applicable adjustment limit and identify any brake that exceeds the adjustment limit as defective.

Note: All drivers are required to demonstrate an applied pushrod-stroke measurement method for inspecting brake adjustment as part of the Ministry of Transportation air brake endorsement practical examination.

Diagram 11-1: Method 1: Measuring pushrod stroke with spring brakes released

Diagram 11-2: Method 2: Measuring pushrod stroke with service brakes applied

Brake stroke indicators

Brake chamber pushrods are generally marked with some type of indicator that becomes visible when pushrod stroke exceeds the adjustment limit. Brake-stroke indicators can also be fitted to the brake linkage, which include external reference points to provide a visual indication of the applied pushrod stroke.

Pushrod-stroke indicators must be correctly installed and maintained, and drivers must be fully trained in the proper use of brake-stroke indicators to ensure reliable brake-adjustment inspection results are obtained.

Automatic slack or brake adjusters

Automatic slack or brake adjusters are used to avoid the need to regularly perform manual brake re-adjustment. When they are properly installed and maintained, automatic slack adjusters are very reliable.

Inspection of brake adjustment must be carried out whether automatic or manual slack adjusters are used.

Re-adjusting brakes

When brakes with manual slack adjusters are out of adjustment, they must be re-adjusted so that the pushrod stroke is less than the adjustment limit. Only certified technicians may repair and perform brake re-adjustments on manual slack adjusters. In Ontario, drivers can become certified to perform brake re-adjustments on manual slack adjusters. Only those who have obtained certification are permitted to perform brake re-adjustments. This certification does not permit you to manually re-adjust automatic slack adjusters.

Automatic slack adjusters, if they are working properly, do not require regular re-adjustment. If periodic re-adjustments are required, it means that the automatic slack adjuster is defective and must be repaired by a certified technician. Only certified technicians are permitted to perform re-adjustments or repairs on automatic slack adjustors. It is dangerous for someone who is not certified to attempt to adjust the automatic slack adjustors. You may unknowingly damage the brake and cause it to malfunction. Check your automatic slack adjusters often to ensure that the adjustments are correct; however, do not attempt to repair them yourself.

Important: The Ontario Highway Traffic Act and regulations prohibit the operation of a vehicle with a brake that is out of adjustment.

Key points to remember

- Measuring applied pushrod stroke is a reliable method for inspecting brake adjustment.

- Inspection of brake adjustment at each wheel should be performed with air pressure between 621 and 690 kPa (90 and 100 psi), the engine shut off and service brakes fully applied and spring brakes must be released.

- When pushrod stroke exceeds the adjustment limit of the brake chamber the brake is out of adjustment.

- Only qualified individuals may repair or re-adjust brakes.

- Drivers who have a valid Ontario air-brake adjustment certificate are qualified to re-adjust the brakes on vehicles fitted with manual slack adjusters.

- The Ontario Highway Traffic Act and regulations prohibit the operation of a vehicle with a brake that is out of adjustment.