2015 Watermain disinfection procedure

This document outlines procedures for disinfecting water mains as part of an addition, modification, replacement, extension, planned maintenance, or emergency repair in a municipal residential drinking water system. The procedures are required to be followed in order to satisfy conditions imposed by the Director in a drinking water works permit.

Published in November 2015

In 2020, we updated these watermain disinfection procedures which were first published in 2015.

The 2020 procedure will take effect through conditions in the Drinking Water Works Permit. In some scenarios, the 2015 Watermain Disinfection Procedure will continue to be in effect.

Read the 2020 Watermain disinfection procedures and learn about the changes.

Preface

For watermains that form part of the distribution system, Drinking Water Works Permit (DWWP) Schedule B, Condition 2.3 (“DWWP Condition 2.3”) requires that all parts in contact with drinking water which are:

- Added, modified, replaced, extended; or

- Taken out of service for inspection, repair or other activities that may lead to Contamination, shall be disinfected before being put into service in accordance with the provisions of the AWWA C651 – Standard for Disinfecting Water Mains or an equivalent procedure.

For the purpose of DWWP Condition 2.3, this document is considered by the Ministry of the Environment and Climate Change (Ministry) as the equivalent procedure which replaces ANSI/AWWA C651 - Standard for Disinfecting Water Mains with respect to the cleaning, tapping, maintenance and repair of watermains, Appurtenances and fittings.

With respect to new watermains, relined watermains and temporary watermains, the provisions of this document, including sections 1.1 and 1.2 shall be followed by operating authorities for compliance with DWWP Condition 2.3. Where this document makes reference to ANSI/AWWA Standard C651, the most current version shall be used.

Service pipes of 100 mm diameter and greater shall be considered as watermains for the purposes of this procedure.

Operating authorities shall use Certified Operators for functions that must be performed by a Certified Operator.

1.0 Addition, modification, replacement, extension and planned maintenance

1.1 New Watermains

Drinking water system operating authorities shall ensure that the most current version of the ANSI/AWWA Standard C651 is followed for addition, modification, replacement and extensions of watermains to an existing distribution system for compliance with DWWP Condition 2.3. However, the backflow protection provisions within ANSI/AWWA Standard C651 shall be mandatory for any work related to this section. The provisions outlined in ANSI/AWWA Standard C651 for final connections to existing mains are also mandatory. The requirements in this section also apply to temporary watermains.

1.1.1 Disinfection of New Watermains

Where the operating authority is chlorinating using the tablet, continuous feed, slug, or spray chlorination methods for disinfecting newly constructed watermains as per the procedures in ANSI/AWWA Standard C651, the minimum contact times, initial chlorine concentrations, and maximum allowable decreases in chlorine concentration as listed in Table 1 shall be used.

Where copper pipe is used for smaller diameter watermains, Table 1 does not apply. Copper watermains shall be disinfected using the Continuous Feed method, with an Initial Chlorine Concentration of ≥ 50 mg/L. Due to the chlorine demand exerted by the copper, no minimum chlorine concentration is required following the 24 hour contact time, and the effectiveness of the disinfection process shall be demonstrated by the Microbiological sampling referred to in section 1.1.2.

| Disinfection Method | Minimum Contact Time | Initial Chlorine Concentration | Maximum Allowable Decrease in Chlorine Concentration |

|---|---|---|---|

| Tablet or Continuous Feed | 24 hours | ≥ 25 mg/L | 40% of the Initial Chlorine Concentration to a Maximum of 50 mg/L |

| Slug | 3 hours | ≥ 100 mg/L | 25 mg/L |

| Spray | 30 minutes | ≥ 200 mg/L | Measurement Not Required |

The following examples are provided to demonstrate the proper use of Table 1.

Example 1

When using the continuous feed method of chlorination with an initial chlorine concentration of 50 mg/L, the maximum allowable decrease in chlorine concentration is 40% of 50 mg/L, or 20 mg/L. Therefore, at least 30 mg/L of chlorine must be present after 24 hours.

Example 2

When using the continuous feed method of chlorination with an initial chlorine concentration of 150 mg/L, the maximum allowable decrease in chlorine concentration is 50 mg/L, because 40% of 150 mg/L is greater than the maximum allowable decrease of 50 mg/L. Therefore, at least 100 mg/L of chlorine must be present after 24 hours.

Example 3

When using the slug method of chlorination, with a minimum contact time of 3 hours, the chlorine concentration shall be measured in the slug at the beginning of the disinfection process, as the slug moves through the watermain, and at the point of discharge. If at any point the chlorine concentration has decreased by more than 25 mg/L, the flow shall be stopped and additional chlorine shall be added to restore the chlorine concentration in the slug to not less than 100 mg/L. For example, if the initial chlorine concentration in the slug is 150 mg/L, then the chlorine concentration must not decrease below 125 mg/L.

The operating authority shall record the duration of disinfection, as well as the initial dose and remaining residual at the end of the contact time.

1.1.2 Microbiological samples for New Watermains

The operating authority shall ensure that the Microbiological samples taken in accordance with ANSI/AWWA Standard C651 shall include as a minimum Escherichia coli and Total Coliforms.

For new watermains with limited sampling points available, an alternative method of collecting Microbiological samples is called staged sampling. Staged sampling shall be performed as follows:

- a flow meter shall be installed to measure flow through the new watermain;

- a sampling point shall be installed at the end of the new watermain (additional sampling points may also be installed along the length of the watermain); and

- flow shall be established and samples shall be collected from the sampling point(s) at intervals that are calculated to represent the lengths of the watermain as required by ANSI/AWWA C651, based on the pipe size and the measured flow rate.

1.2 Relining of Watermains

For relining of existing watermains, the conditions of section 1.1 will apply. Notwithstanding the conditions of section 1.1, return to service will be allowed prior to receiving acceptable Microbiological sample test results if all the following conditions are met:

- the local Medical Officer of Health is consulted prior to the commencement of the project and their advice is documented and followed

- watermain is physically isolated from the remainder of the system through Backflow prevention

- flushing of the watermain has been completed and secondary disinfection has been restored as prescribed in section 3.2.6

1.3 Planned Watermain cleaning

For planned swabbing and hydraulic (e.g. Flushing) watermain cleaning, the requirements of section 3.2.6 – “Restoration of Secondary Disinfection and Return to Normal Service” shall apply.

For all other types of cleaning (e.g. air scouring, ice pigging, etc.), the operating authority shall develop a site specific plan for cleaning, disinfection and sampling in agreement with the local Ministry office (in consultation with the local Medical Officer of Health). The operating authority shall implement the plan as prescribed and the watermain cannot be put back in service until the cleaning, disinfection and sampling is completed as per the plan unless a Water Advisory is declared.

1.4 Planned maintenance of Watermain appurtenances and fittings

The watermain disinfection procedures as defined under section 3 for Category 1 watermain breaks shall apply to the installation/replacement/repairs of Appurtenances and/or fittings. If Contamination is evident or suspected, the procedures defined under section 3 for Category 2 watermain breaks shall apply.

1.5 Tapping of Watermains

Where existing watermains are tapped, the pipe surface at the location of the tap shall be cleaned and disinfected using a minimum 1% sodium hypochlorite solution. Where applicable, the drill/cutting/tapping bits and all surfaces of mainstops, service saddles, tapping sleeves and valves which will come into contact with drinking water shall likewise be cleaned and disinfected using a minimum 1% sodium hypochlorite solution immediately prior to installation. If any of the disinfected surfaces come into contact with the soil and/or water in the excavation prior to use, the cleaning and disinfection procedure shall be repeated.

1.6 Service pipes

Service pipes of 100 mm diameter and greater shall be considered as watermains for the purposes of this procedure, and shall be disinfected and tested in accordance with the requirements of ANSI/AWWA C651 as amended herein, including the mandatory backflow protection provision referred to in section 1.1. For Service pipes of diameter less than 100 mm, operating authorities shall maintain sanitary conditions during installation and/or repairs, and shall clean and flush prior to placing in service.

2.0 Emergency/Unplanned repairs

Drinking water system operating authorities shall ensure that emergency repairs to watermains and Appurtenances are undertaken in accordance with this procedure by any person authorized to perform the repairs.

Operating authorities shall develop and document operating procedures for emergency watermain repairs within their systems. In developing these procedures, operating authorities may use best management practices that go beyond the minimum requirements in this document.

3.0 Watermain disinfection procedures for emergency repairs

This procedure uses a risk management approach to categorize watermain breaks based on the potential for Contamination. The objective of this procedure is to set minimum disinfection requirements to minimize the potential for drinking water health hazards during emergency/unplanned repairs resulting from the physical failure of a watermain or Appurtenance (a “break”).

This procedure also establishes minimum standards for record keeping, and notification to the Ministry and the local Medical Officer of Health.

3.1 Categorization and public agency notification of watermain breaks

Upon completion of the excavation, the Operator-in-Charge (OIC) shall conduct a visual inspection to determine the nature of the break. The OIC will assess the evidence of Contamination or potential Contamination of the watermain before and during the repair procedure, and shall classify the break into one of two categories as per 3.1.1 and 3.1.2.

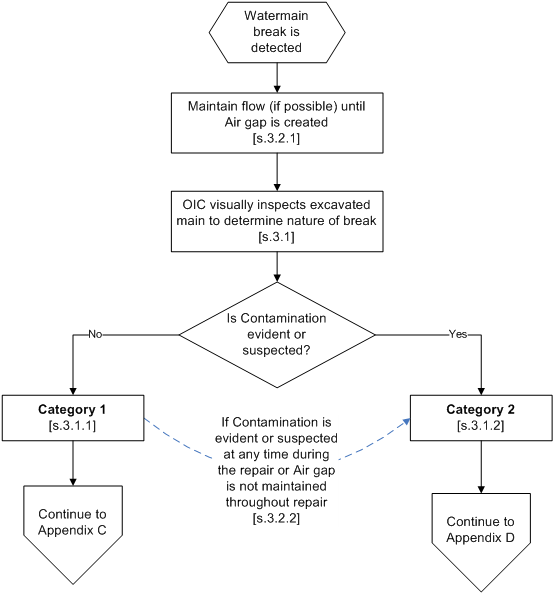

Refer to Appendices A and B for a flowchart and pictures to better understand the criteria to determine the categories of watermain breaks.

3.1.1 Category 1

Watermain breaks with no evident or suspected Contamination are classified as Category 1. Follow the steps described in section 3.2 and 3.3 for repairs.

Contamination is typically not suspected for circumferential breaks or small leaks where flow is maintained from the break until an Air gap is established and where the Air gap is maintained during the repair procedure. If, at any time, Contamination is evident or suspected, the break shall be reclassified as Category 2.

3.1.2 Category 2

Watermain breaks with evident or suspected Contamination are classified as Category 2. Watermain repairs involving more than 6 metres of replaced pipe are also classified as Category 2. Follow the steps described in section 3.2 and 3.4 for repairs.

3.1.3 Public agenct notification

3.1.3.1 Category 1

Category 1 watermain breaks are not defined as an observation of improper disinfection in accordance with Section 16-4 of Schedule 16 of O. Reg. 170, and are not required to be reported to the Spills Action Centre.

This procedure does not require that the local Medical Officer of Health be notified of Category 1 watermain break repairs; however, the local Medical Officer of Health may exercise his/her option to require such notification. Operating Authorities may choose to provide notification to, or seek advice from, the local Medical Officer of Health at any time.

3.1.3.2 Category 2

Category 2 watermain breaks are not required to be reported to the Spills Action Centre unless an operating authority believes that contaminated water was directed to users. If an operating authority believes that contaminated water was directed to users, this will constitute an observation of improper disinfection in accordance with Section 16-4 of Schedule 16 of O. Reg. 170/03, and the reporting and corrective actions of Schedule 16 and the applicable Schedule 17 or 18 of O. Reg. 170/03 shall apply.

This procedure does not require that the local Medical Officer of Health be notified of Category 2 watermain break repairs unless an observation of improper disinfection has been reported as noted above; however, the local Medical Officer of Health may exercise his/her option to require such notification. Operating authorities may choose to provide notification to, or seek advice from, the local Medical Officer of Health at any time.

Notification to the local Ministry office is not required for Category 2 watermain breaks unless:

- a Water Advisory is declared: The local Ministry office shall be notified as soon as reasonably possible during business hours. After business hours, the operating authority shall send an e-mail to the e-mail address specified by local Ministry office no later than 10 AM the next business day; or

- in the Special Cases described in sections 3.4.4 and 3.4.5: The local Ministry office shall be notified as soon as reasonably possible during business hours. After business hours, the operating authority shall contact the Spills Action Centre as soon as reasonably possible.

3.2 Watermain break common disinfection procedure

The following steps must be performed for all emergency watermain repairs (Category 1 and Category 2). Examples of typical steps for Category 1, 2 and for special cases are attached as Appendices C, D and E respectively.

3.2.1 Maintenance of Flow

The operating authority shall determine if flow can be maintained to the break site until the watermain is excavated. This determination shall be based on risks to worker and public safety, the possibility of property damage, and/or adverse impact to the natural environment.

The operating authority will attempt to maintain flow from the break, where possible, until an Air gap is established. Flow may be reduced by throttling valves while maintaining sufficient flow from the break to minimize the potential for Contamination. Flow may be discontinued after an Air gap has been created.

3.2.2 Excavation dewatering

Excavation dewatering shall be continued for the duration of the repairs such that the Air gap between the location of the break in the watermain and the water in the excavation is maintained. If the water level in the excavation rises such that the Air gap is not maintained after flow from the break has been discontinued, then the watermain break shall be classified as Category 2.

3.2.3 Disinfection of pipe and repair parts

All surfaces of pipe and repair parts which will come into contact with drinking water shall be disinfected using a minimum 1% sodium hypochlorite solution immediately prior to installation. If any of the disinfected surfaces come into contact with the water and/or soil in the excavation prior to installation, the surfaces shall be cleaned and the disinfection procedure shall be repeated.

If cutting out a section of pipe, the interior surfaces of the cut ends of the existing watermain shall be disinfected as well, using a minimum 1% sodium hypochlorite solution, swabbed or sprayed as far as can be practically reached.

3.2.4 Installation of repair parts

The repair parts shall be installed while ensuring that Contaminants do not enter the watermain.

3.2.5 Post repair flushing

Flushing shall be conducted following repairs by creating a temporary dead end downstream of the break through valve operation, and Flushing through the location of the repair to a discharge point. Flushed water may be discharged from a hydrant, plumbing or Appurtenances. Where there is no discharge point to allow for Flushing, the operating authority shall tap the watermain on the downstream side of the break and discharge from that point.

Flushing shall continue until the discharged water is free from discoloration, and secondary disinfection has been restored as per 3.2.6.

Dechlorination of discharged water is required for any water that is directed into surface water or if the discharge into the natural environment causes or is likely to cause an adverse effect, as per Condition 10 of Schedule B of the Municipal Drinking Water Licence. The discharged water is deemed to be a Class II spill for the purposes of O. Reg. 675/98 (Classification and Exemption of Spills and Reporting of Discharges) made under the Environmental Protection Act. Discharges of flushed water are also regulated under Condition 4.5 of newer Municipal Drinking Water Licences.

3.2.6 Restoration of secondary disinfection and return to normal service

Flushing shall continue until the disinfectant concentration at the point of Flushing reaches at least 0.2 mg/L free chlorine in a chlorinated system or 1.0 mg/L combined chlorine in a chloraminated system. If these disinfectant concentrations cannot be achieved, Flushing shall continue until the disinfectant concentration at the point of Flushing is representative of the system residual in the break area, determined by sampling upstream of the break area and downstream at the Flushing location, or by using documented benchmarks for the area, as long as free chlorine concentrations are at least 0.05 mg/L in a chlorinated system and combined chlorine concentrations are at least 0.25 mg/L in a chloraminated system.

Upon restoration of secondary disinfection, the system can be returned to normal service, defined as having all valves returned to normal operating position.

3.3 Additional information for Category 1 watermain break repairs

3.3.1 Microbiological samples (optional)

There is no requirement to undertake Microbiological sampling for Category 1 watermain break repairs. Where the operating authority opts to undertake Microbiological sampling, samples shall be considered distribution samples within the meaning of O. Reg. 170/03, and the reporting/corrective actions of Schedule 16 and the applicable Schedule 17 or 18 of O. Reg. 170/03 shall apply.

3.4 Additional requirements for Category 2 watermain break repairs

In addition to the requirements described in section 3.2, the following steps are required for Category 2 watermain break repairs.

3.4.1 Removal of contaminants from watermain

Additional steps shall be undertaken as appropriate to remove Contaminants from the watermain, such as:

- mechanical removal of Contaminants

- flushing into the excavation

- higher velocity flushing after repairs where practical and feasible

3.4.2 Additional disinfection procedures

In addition to the procedures in 3.2.3, site specific disinfection procedures may also be used depending on the severity or nature of the Contamination. The steps may include the disinfection procedures for new watermains as per ANSI/AWWA Standard C651.

3.4.3 Microbiological samples (Mandatory)

After the completion of Flushing and restoration of secondary disinfection, at least one Microbiological sample shall be collected and submitted as soon as reasonably possible, taking into consideration laboratory working hours and transportation timeframes.

The flow shall be directed to ensure that the sample represents water that has passed through the location of the repair. The sampling will typically occur at the point of Flushing, and may take place from sampling ports, hydrants, blow-offs, or premise plumbing. All samples shall be considered distribution samples, taken and tested in accordance with O.Reg 170/03 requirements. The reporting and corrective actions of Schedule 16 and the applicable Schedule 17 or 18 of O. Reg. 170/03 shall apply.

The watermain may be returned to normal service defined as having all valves returned to normal operating position prior to receipt of sample results.

3.4.4 Special case - Sewage contamination

If there is evident or suspected sewage Contamination of a watermain, in addition to the procedures in sections 3.2 and 3.4, the operating authority shall develop and implement a plan with site specific procedures for disinfection and sampling. The sampling plan shall include as a minimum taking two sets of Microbiological samples at least 24 hours apart.

Return to normal service is contingent upon the corrective actions and sampling plan being completed to the satisfaction of the local Ministry office (in consultation with local Medical Officer of Health). The affected watermain(s) may not be put back in service before the corrective actions and sampling plan are completed unless a Water Advisory is declared.

The disinfection requirements for new watermains as per Section 1.1.1 may be used based on agreement between the operating authority and the local Ministry office (in consultation with the local Medical Officer of Health).

3.4.5 Special case - Chemical contamination

If there is evident or suspected chemical Contamination of a watermain, in addition to the procedures in sections 3.2 and 3.4, the operating authority shall develop and implement a plan with site specific procedures for disinfection and/or decontamination and sampling. The operating authority shall finalize the plan in agreement with the local Ministry office (in consultation with the local Medical Officer of Health).

Return to normal service is contingent upon the corrective actions and sampling plan being completed to the satisfaction of the local Ministry office (in consultation with the local Medical Officer of Health). The affected watermain(s) may not be put back in service before the corrective actions and sampling plan are completed unless a Water Advisory is declared.

4.0 Documentation

When performing maintenance and repair activities as per sections 1.4 and 3 of this procedure, the operating authority shall maintain records of the following information as a minimum. The information shall be retained as per the record keeping requirements of Section 27 of O. Reg. 128/04. This section does not require that all of the information be recorded on a single form:

- Date

- Location (e.g. a municipal address)

- Flow maintained at the site until Air gap created? (Yes/No)

- Watermain size and material (e.g. 150 mm cast iron)

- Evident or suspected Contamination of the watermain before or during the repair process? (No = Category 1 / Yes = Category 2)

- If watermain break, indicate type of watermain break (e.g. circumferential, longitudinal, split bell, spiral, rupture, blow-out, hole, leak at main stops/tapping valves, etc.)

- If planned maintenance, indicate type of planned maintenance (e.g. valve replacement)

- Air gap maintained, once established, throughout the repair process? (Yes/No)

- Name of Operator-in-Charge who classified the watermain break as Category 1 or Category 2

- Type of Repair (e.g. clamp, cut out, etc.)

- Pipe and Repair Parts disinfected? (Yes/No)

- Post-repair Flushing undertaken? (Yes/No)

- For Category 2, where additional steps were required under 3.4.1 and 3.4.2, describe these steps.

- For Category 2 – Special Cases, include site specific plan. If chlorine disinfection was used, indicate initial concentration, contact time, final concentration and final concentration as percentage of initial concentration.

- Disinfectant residual on final post repair Flushing. If final disinfectant residual is less than 0.2 mg/L free chlorine in a chlorinated system or 1.0 mg/L combined chlorine in a chloraminated system, then provide the location and results of upstream disinfectant residual(s) or by using documented benchmarks for the area, as per section 3.2.6.

- Microbiological samples taken (Yes/No/Not applicable)

- Date and location(s) of sample(s) (e.g. Chain of custody)

- Date and time of return to normal service

- Water Advisory declared: Date and Time (Yes/No/Not Applicable)

- Public Agency Notification – local Ministry office (Date and Time) (Yes/No/Not Applicable)

- Public Agency Notification – Spills Action Centre (Date and Time) (Yes/No/Not Applicable)

- Public Agency Notification/Direction – local Medical Officer of Health (Date and Time)

(Yes/No/Not Applicable)

5.0 Appendices

Appendix A

Tools to help determine the category of watermain break - flowchart

The following flowchart will help determine the categories of watermain breaks.

Appendix B

Tools to help determine the category of watermain break - pictures

Examples of watermain breaks that are typical of Category 1 are included below for illustrative purposes only:

Figure 1: Circumferential watermain break with flow maintained until after an Air gap was created.

Figure 2: Corrosion hole leak in a watermain with flow maintained until after an Air gap was created.

Examples of watermain breaks that are typical of Category 2 are included below for illustrative purposes only:

Figure 3: Longitudinal watermain break with evident Contamination.

Figure 4: Spiral watermain break with evident Contamination.

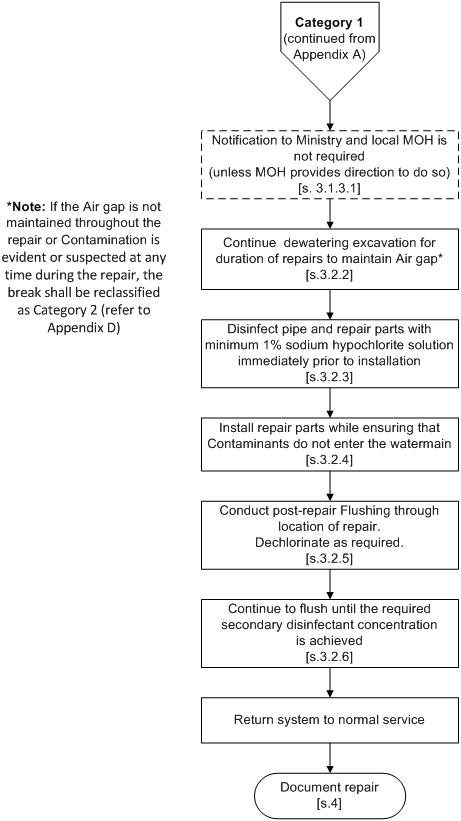

Appendix C

Category 1 flowchart

The following flowchart is an example of the typical steps required for Category 1 watermain breaks Note: These steps also apply to the planned maintenance of watermain Appurtenances and fittings (refer to section 1.4). Any additional directions given by the Ministry and/or the local Medical Officer of Health must be followed.

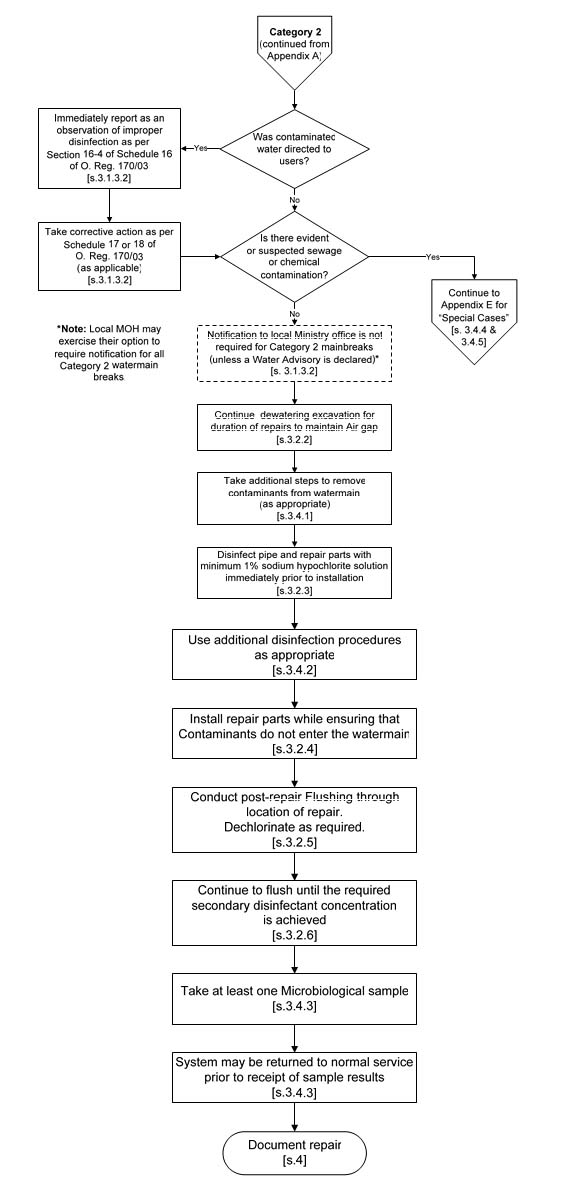

Appendix D

The following flowchart is an example of the typical steps required for Category 2 watermain breaks. Note: The sequence of actions may be varied as appropriate for the specific situation. Any additional directions given by the Ministry and/or the local Medical Officer of Health must be followed.

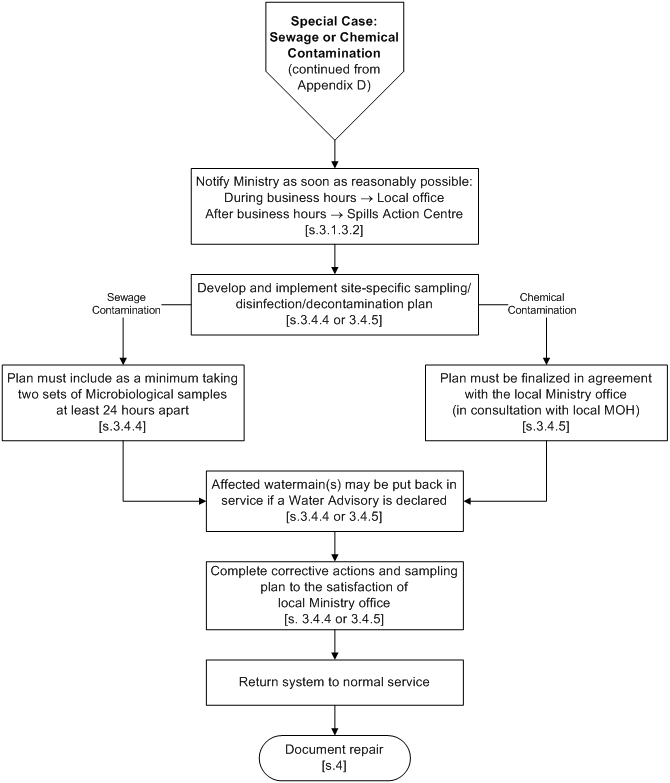

Appendix E

The following flowchart depicts the requirements for special case Contamination (sewage or chemical) as a result of a watermain break.

Appendix F

Definitions

In this procedure,

- ”Water Advisory is declared”

- means a boil or drinking water advisory has been declared for the area being serviced by the affected watermains by the local Medical Officer of Health.

- “Air gap”

- means an air space at the location of the maintenance/repair between the exterior surface of the watermain and the interior surfaces of the excavation, including the water in the excavation, sufficient to prevent water and soil in the excavation from contacting the watermain, fittings, or Appurtenances throughout the maintenance/repair process.

- “Appurtenance”

- means an appurtenance within the meaning of O. Reg. 170/03.

- ”Backflow prevention”

- means the prevention of a reversal of normal flow that could introduce Contamination to the potable water supply; accomplished by an Air gap or a CSA approved backflow preventer selected, installed and tested in accordance with CSA Standard B64.10: ”Selection and Installation of Backflow Preventers”.

- “Certified operator”

- means certified operator within the meaning of O. Reg. 170/03.

- “Contaminant”

- means foreign matter that is not intended to enter a watermain.

- “Contamination”

- means the introduction of a Contaminant into a watermain.

- “Flushing”

- means post repair valve operation to restore secondary disinfection and discharge suspended materials by flowing water through the repaired section of watermain and out of the system. This definition does not include recharging the watermain or a requirement to achieve scouring velocity within the watermain.

- “Higher velocity flushing”

- means Flushing of a watermain with sufficient velocity to discharge settled materials.

- “Isolate”

- means operate valves to ensure that there is no flow of water to the location of the maintenance/repair.

- “Microbiological samples”

- means water samples taken and tested for Escherichia coli and Total Coliforms.

- “Operator-in-Charge”

- means an operator-in-charge within the meaning of O. Reg. 128/04.

- “Service pipe”

- means a service pipe within the meaning of O. Reg. 170/03.

Footnotes

- footnote[1] Back to paragraph At levels over 10 milligrams per litre, a measurement of total chlorine shall be deemed to be equivalent to a measurement of free chlorine.