Achieve compliance on construction sites: excavations, underground work, and work in compressed air

Learn about the requirements in the construction regulation under the Occupational Health and Safety Act for excavations, tunnels and shafts, caissons and cofferdams, and work in compressed air.

Overview

This section includes information about possible means to achieve compliance for requirements in the construction regulation under the Occupational Health and Safety Act concerning:

- excavations

- underground work

- work in compressed air

It does not represent the exhaustive measures and procedures required by the Occupational Health and Safety Act and its regulations related to excavations, tunnels and shafts.

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply and enforce these laws based on the facts they find in the workplace.

Program positions being discussed relate to sections 222 to 331 of the regulation for construction projects: O. Reg. 213/91.

Excavations

Determining soil type in excavations

Issue:

Who can determine what Soil Type is present in an excavation? Does it have to be a soils engineer? How is that determination made?

Position:

No, it does not have to be a soils engineer. A competent worker or competent person should determine the Soil Type (Type 1 through 4) of an excavation. This determination is accomplished via physical and visual examination that extends horizontally from the top of the excavation an equal measurement to the excavation depth.

The examination should at the minimum include penetration by small sharp objects, observing the appearance of the soil condition and indications of its classification as indicated by O. Reg. 213/91 s. 226.

Locate requirements for diagnostic tools piercing the ground

Issue:

Does piercing the ground with a gas sniffer or pogie bar, where no soil is displaced, constitute an excavation requiring locates under section 228?

Position:

No. Based on the definition of an excavation in section 1 of O. Reg. 213/91, piercing the ground with a thin rod without removing any dirt does not meet the definition of an excavation (“the hole that is left in the ground, as a result of moving material”) and therefore locates are not required when using this diagnostic tool.

Locates required when using hydrovac

Issue:

Are locates required when excavating with a hydrovac?

Position:

Yes. When excavating using a hydrovac (as opposed to an excavator), also called “daylighting”, the employer trying to find the underground service is required to have valid locates prior to hydrovac activities taking place.

Prior to excavating, with a hydrovac or any other method, the employer is responsible for following the requirements outlined in section 228 of O. Reg. 213/91 to:

- obtain a valid locate and determine the most appropriate digging method to prevent contact with a buried utility

- notify the utility owner directly or through Ontario One Call and make sure private residents are notified in case an underground utility near the dig area belongs to them

- determine, in consultation with the owner of the utility, the best excavation method for locating all the underground services in the area (using as-built maps, electronic locates, etc.).

- mark the ground and provide locate documentation to the excavator, if utilities exist in the dig area

- request that the owner of the utility supervise the uncovering of the service during the excavation if a service may pose a hazard and it cannot be shut off or disconnected

- request an “all clear” to be provided by the utility owner or Ontario One Call and show it to the inspector upon request, if no utilities exist in the dig area

Locates required when using plows or ditch witches

Issue:

Are locates needed when plows or “ditch witches” are used to pull cable, weeping tile, irrigation hoses or other similar items?

Position:

Yes. During these operations soil is disturbed and is removed by the action of the plows or ditch witches. This meets the definition of an excavation. Locates are required for these services and they need to be marked prior to excavation.

Meaning of locates accuracy

Issue:

What is meant by accuracy, regarding locates?

Position:

Locates should be accurate enough so that any service in or near the excavation area is located and marked to prevent damage during excavation work, thereby eliminating worker endangerment.

It is the employer’s duty to ensure all utilities in and near the area to be excavated are located and marked. Subsection 228(1) of O. Reg. 213/91 identifies the requirements concerning this. While the Ontario “One Call” is a service available to such employers, relying only on the “One Call” service may not be a sufficient precaution.

The employer must exercise ‘due diligence’ (including investigating surroundings for possible undocumented services, questioning private property owners, hiring independent locators, locating the services themselves, etc.) in fulfilling their obligation.

Location of services not mapped to One Call and those on private lands

Issue:

Are employers responsible for locating (and marking) services that have not been mapped (and submitted to One Call or others)? What about services on private lands?

Position:

Yes. While the Ontario One Call is a service available to employers, relying only on the One Call service may not be enough of a precaution.

The employer must exercise “due diligence”, including:

- investigating surroundings for possible undocumented services

- questioning private property owners

- hiring independent locators

- locating the services themselves

- engaging available technologies as needed in fulfilling their duties

Alternate locates agreements

Issue:

Does an Alternate Locates Agreement (ALA) permitted by a utility service absolve the excavator’s employer from the requirements of having locates for that service?

Position:

When an ALA is in place for a particular utility service, the excavator’s employer is deemed to have fulfilled the requirement of clause 228(1)(a) of O. Reg. 213/91 with respect to that service.

An “alternate locate agreement”, as referred to in clause 3-19 of the “Ontario Regional Common Grounds Alliance” (ORCGA) “best practices”, allows a service owner, in lieu of traditionally providing locates and markings as per clause 228(1)(a) of O. Reg. 213/91, to set terms and conditions for the excavation contractor to follow for service installation. This would provide the same level of protection for the health and safety of the workers involved in or around the excavation.

In compliance with s. 3 of the regulation, ALA agreements must also be communicated in writing to the joint health and safety committee or the health and safety representative on the project.

Note: Utility owners have increasingly allowed the use of hydrovac systems to excavate without a traditional “locate” being given.

Locates performed by other contractors

Issue:

Will the ministry accept locates that have been done by other contractors than the excavator’s employer?

Position:

Yes, but it is the excavator’s employer duty to ensure that the locates and markings provided are accurate and up to date. If the excavator decides to use locates (and markings) that were arranged by the constructor or another employer, this could satisfy the needs of a section 3 equivalency, provided that written notice is given to the joint health and safety committee or representative on the project (subsection 3(b)) and it affords protection for the health and safety of workers that is at least equal to the protection under section 228.

Permission from the utility owner should be apparent and up-to-date schematics from the utility owner should be provided to the requestor of the locates.

Expired locates and permission to contractor to update locates

Issue:

How long are locates valid for?

Position:

Generally, the utility or locater will provide a written expiration date on the locate itself. This is typically 30 days from the date of service location, which is in line with the guidelines jointly developed by the Electrical Safety Authority (ESA) and the Technical Standards and Safety Authority (TSSA)

If an expiry date is not indicated, a general rule of 30 days from the date of creation should be considered as the period of validity.

The ministry will not accept expired locates.

Barrier at the top of an excavation as an alternative to guardrail

Issue:

Would a barrier be an acceptable alternative to a guardrail at the top of an excavation?

Position:

Yes, a barrier meeting the requirements of subsection 233 (4) is enough. There is no need for an additional guardrail.

Benching in excavations

Issue:

Is benching of an excavation wall permitted?

Position:

Yes, benching is permitted as a variation although it is not mentioned in O. Reg. 213/91. Benching may be used as an alternative method of worker protection under section 3 of the regulation if notice is provided to the joint health and safety committee or the health and safety representative, and it provides equal or better protection to a worker than the standard requirement. This should be done in a manner that considers the specific soil characteristics at the site.

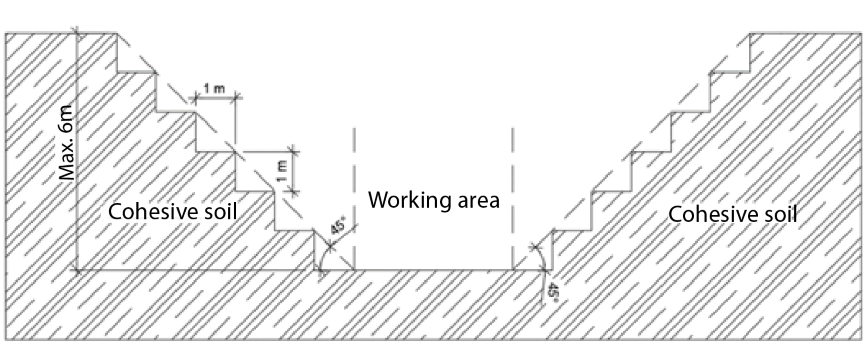

The following conditions must be met (see figure 1 below):

- for each bench the height of the vertical face shall not be greater than the depth of the horizontal face above, and must not exceed 1.2 m

- a benched excavation could be up to a maximum of 6m deep without engineering design

- benching is only permitted in cohesive soils

- the benched surface shall fall under the envelop of a slope having a minimum gradient of one horizontal to one vertical (i.e., slope equal or less than 45°)

- the working area shall be set up away from the face of bottom bench equal to the height of the first bench

- no surcharge or material shall be stored at the top of an excavation closer than the height of the top bench and must be at least 1m from the edge of the excavation

- no benching is permitted in soil type 4

- benching for excavations greater than 6 m deep shall be designed by a licenced engineer

- access to and egress from work areas shall be as per sec. 70 of O. Reg. 213/91

Figure 1: This diagram is an illustration of a type of benching made in a cohesive soil. The total depth of the benches (or steps) does not exceed 6 metres. So, on each side of the excavation wall, and starting at the soil surface level, there are 6 consecutive “steps” each one of which has a vertical depth of 1.0 m followed by horizontal length of 1.0 m. Six times 1.0 m is equal to 6m which is the maximum allowed depth for benching in a cohesive soil. Once this depth has been reached (6 metres in this illustration) the work area for a worker in the excavation must be at least 1.0 m away from each side of the last vertical depth. Furthermore, no material can be stored or sitting for at least 1.0 m from the first step or bench of the excavation.

Excavation becoming a trench

Issue:

Can an excavation become a trench based on the addition of a form wall?

Position:

Yes, it can. Whether an excavation is a “trench” is determined by applying the clear language in O. Reg. 213/91. A trench is defined as “an excavation where the excavation depth exceeds the excavation width”, and the definition applies whether the excavation is dug beside an existing foundation wall or newly constructed foundation wall.

Subsection 1.1 of O. Reg. 213/91 defines the excavation width as follows: “excavation width” means the least horizontal dimension between the two opposite walls of the excavation.

For the purposes of measuring the width of the trench, it shall be determined as the least horizontal distance from one earthen wall to the other side. Where there is a foundation wall in place, the other side, or the opposite wall for the purposes of measuring the width will be the foundation wall.

Once an excavation becomes a trench, any previous written engineer’s opinion for exemption relying on clause 234(2)(h) of O. Reg. 213/91 would not apply and a support system would be required. The soil may not have changed but the reduced area and depth of the trench that worker is now working in has changed increasing the potential risk of the hazard to the worker.

Subsection 234 (1) states that walls of an excavation must be supported by a support system that complies with sections 235, 236, 237, 238, 239 and 241 of O. Reg. 213/91. Subsection 234 (2) waives this requirement when certain stand-alone conditions are met. These conditions include sloping, in accordance with the soil type present.

Clause 234 (2)(h) spells out one of those conditions: it has three elements all of which must be satisfied in order to meet the requirements for an exemption.

The excavation must:

- not be a trench

- not be made in Type 4 soil

- be supported by a professional engineer’s opinion that the walls are stable enough

Only if these three elements are met does the exemption stipulated in clause 234 (2)(h) apply. This clause would allow an excavation that is not a trench, and that is made in Type 1, 2 or 3 soil to be exempted from using a support system if there is a written professional engineer’s opinion confirming the walls were sufficiently stable.

It is also to be noted that in the case of an excavation delineated by a form wall on one side and an earth wall on the other, if it is possible to slope the earth wall in accordance with the Type of soil identified, as outlined in clauses 234(2) (a) to (g) of O. Reg. 213/91. A support system would not then be needed.

Note: the terms “excavation”, “excavation depth”, “excavation width”, and “trench” are defined in section 1 of O. Reg. 213/91

Tunnels and shafts

Application of tunnel and shaft regulations

Issue:

When do the regulations for constructing tunnels, shafts, caissons and cofferdams no longer apply at a tunnel project?

Position:

They apply during the entire tunnel project until the project is complete and has been turned over to the owner for its intended purpose. This is because underground workers are exposed to hazards that include:

- reduced natural communication

- limited ventilation and light

- difficult and limited access and egress

- noise

- air contaminants

- fire, flooding and explosion

Even when the excavation of the underground workplace is completed and the liner is installed, many hazards in the underground construction remain until the project is finished. The safety requirements also include providing adequate emergency procedures, a rescue team and self-rescue respirators and fire protection systems specifically for the underground environment (Part IV of O. Reg. 213/91).

Excavation vs shaft

Issue:

At what point does an excavation become defined as a shaft for regulatory enforcement?

Position:

A tunnel or a boring or augering operation must be present for an excavation to be considered a shaft. The excavation is considered a shaft, if and only if:

- its longitudinal axis is at an angle greater than 45 degrees from the horizontal and

- it is used to pass people or materials into or out of a tunnel or

- it leads to a tunnel or is used as an access to a boring or augering operation

Service shaft and tunnel under construction

Issue:

At what point does a “tunnel under construction” cease to be under construction or a service shaft ceases to be a service shaft?

Position:

A “service shaft” continues be a service shaft until all construction activity associated with the tunnel project has completed. This would be inclusive of all activities described by the definition of “construction” in the Act as well as the provision for “any work… in connection with a project”.

As such, all regulations that speak to specific requirements surrounding a service shaft shall be enforced until construction activity at the tunnel project is complete.

Horizontal bore vs tunnel

Issue:

Does a “horizontal bore” mean “tunnel” if a worker enters it, and if so, do all the tunnel regulations apply?

Position:

If a person can enter a “horizontal bore” made by excavating beneath the overburden it becomes a “tunnel” and all the tunnelling requirements become applicable to the horizontal bore.

Siamese connections for shafts

Issue:

When is a Siamese connection required to be installed at the surface of a shaft?

Position:

A tunnel that will have a diameter of 1.5 m or more when it is completed requires a fire line. When the fire line (and hose) is required to be installed, a Siamese connection must be provided.

Tunnel rescue teams

Issue:

When is a tunnel rescue team needed?

Position:

A tunnel rescue team, trained by a competent person appointed by a Director of the Ministry of Labour, Immigration, Training and Skills Development (MLITSD), is needed whenever workers are working in a tunnel. Section 265 of O. Reg. 213/91 applies to the rescue of workers working underground in a tunnel (i.e. construction of the tunnel and tunneling operations).

Self-rescue respirators

Issue:

When are self-rescue respirators required at a tunnel project?

Position:

If there is a tunnel or shaft leading to a tunnel that a worker can enter then a self-rescue respirator must be given to a worker (section 267).

Internal combustion engine in a tunnel

Issue:

What needs to be in place for internal combustion engines to be used in a tunnel?

Position:

A Ministry of Labour, Immigration, Training and Skills Development’s director’s prior consent needs to be given. Written consent from MLITSD will indicate the exact make, model and serial number of the piece(s) of equipment in question and the document must be available at the tunnel project in written form to be produced to an inspector upon request (section 316). The tunnelling contractor must make a request to the MLITSD director of the regional office where the tunnelling operation will take place, providing details related to the use of the internal combustion engine, including its make, model and serial number.