Alert: inspection of tower crane hoist reduction gear

Learn about the importance of periodic inspections of hoist reduction gear assemblies used on tower cranes.

Issued on May 22, 2024.

Hazard summary

A tower crane hoist reduction gear transmits power from the energy source, such as an electric motor, to the hoist drum that controls the hoisting cable movement that suspends the load of the crane. The hoist reduction gear is like a transmission in a car which converts power from the engine to the drive axels which turn the wheels.

Workers who work near cranes are at risk when the hoist reduction gear assembly on a tower crane fails and that results in an uncontrolled lowering or drop of a load. Adequate, periodic inspections of hoist reduction gear assemblies are necessary to ensure that these critical components are in good condition for safe hoisting operations.

Two recent “near miss” events involving the hoist reduction gear assemblies of two tower cranes occurred where the main shaft bearing failed causing the shaft to become misaligned, which in turn caused the gears to separate. It was determined that both failures were due to the blockage of the bearing lubrication port leading to the seizure and damage of the bearing. The bearing failure of each crane caused the gears that controlled the hoist of the cranes to disengage, which in turn caused the hoisting drums to unspool freely resulting in the loads that were supported by the cranes to drop.

Sequence of failure

The incidents occurred in the following sequence:

- The oil passage became blocked, stopping the flow of oil to the bearing.

- The bearing failed due to the lack of oil, stopping the axial resistance force from the gears.

- The shaft shifted towards the hoisting drum due to the axial gear forces, separating the mating gears.

- The mating gears separated due to the shifting shaft, separating the hoisting drum from the power of the hoisting motor.

- The hoisting drum containing the hoist cable unwound under the weight of the load due to the separation of the gears.

- The load descended uncontrollably due to the freely rotating hoisting drum.

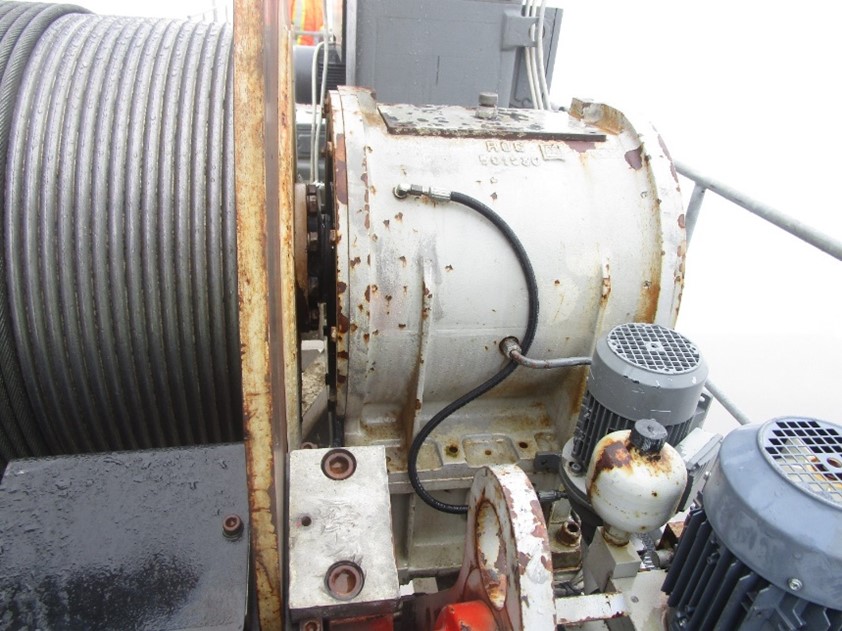

Images of tower crane hoist and reduction gear assembly damage

Listed below are images of the Tower Crane Hoist and Reduction Gear Assembly; these images detail specific components of the gear assembly and areas where damage can occur without proper inspection and regular maintenance.

Key legal requirements

Under the Occupational Health and Safety Act (OHSA) employers have general duties, including the duty to take every precaution reasonable in the circumstances to protect workers and the duty to ensure that equipment provided by the employer is maintained in good condition.

The constructor is to ensure that the measures and procedures prescribed by this Act and the regulations are carried out at the project and every employer and every worker performing work on the project complies with the Act and regulations.

Suppliers must ensure that cranes are in good condition and comply with the Act and regulations.

Workplace parties must ensure a hoist reduction gear is:

- maintained in a condition that does not endanger a worker and used in accordance with the manufacturer’s operating manual, including following the manufacturer’s instructions for conducting periodic inspections and tests of these critical components

- inspected by a competent worker for hazards and to check that it can handle rated capacities, inspections must be performed before the crane is first used at the workplace and thereafter at least once a year or more frequently as recommended by the manufacturer

The crane must not be used:

- while it is defective or hazardous

- when the weather or other conditions are such that its use is likely to endanger a worker while it is being repaired or serviced, unless the repair or servicing requires that it be operated

Every replacement part for a crane must have at least the same safety factor as the part it is replacing.

A competent worker shall perform operational tests on a tower crane to ensure that gearing and all other moving parts are operating correctly. In addition, there are specific requirements set out in regulations under the OHSA that must be complied with at certain workplaces, for example:

Ontario Regulation 213/91 – Construction Projects, sections 93-95, 154, and 157-165.

Recommendations

Inspecting the hoist gear reduction assembly

- Open access panels on the hoist gear reduction assembly to ensure the bearings are intact and in good working order. Further disassembly may be required

- Check for fluid leaks. Test fluid to ensure it is not contaminated with moisture or other debris and replace filter(s) as recommended

- Inspect the main shaft bearings and test the flow rate and pressure of pressure-fed lubrication systems. Ensure all lubrication ports are clear and providing adequate lubrication to all bearings

- Follow crane and/or hoist gear reduction assembly manufacturer’s recommendations to inspect and maintain the hoist gear reduction assembly to ensure critical components are in good condition

Industry standards

Workplaces may also want to refer to the CAN/CSA-Z248-17 Code for Tower Cranes to assist in compliance with the requirements under the OHSA:

- clause 5.6.2: pre-erection inspection

- clause 6: inspection, testing, and repairs

Contact us

If you need more information about safety requirements, please contact the Ministry of Labour, Immigration, Training and Skills Development Health & Safety Contact Centre at

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply the law based on the facts in the workplace.