Construction projects on flat roofs

Learn how to comply with the construction regulation under the Occupational Health and Safety Act when working on flat roofs.

This guide does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply the law based on the facts in the workplace.

Introduction

This page is a tool designed to facilitate compliance with the minimum acceptable standards outlined for construction work on flat roofs in the Occupational Health and Safety Act and Ontario Regulation 213/91 for Construction Projects. It is limited to specific scenarios related to work on flat roofs.

A flat roof is a roof which is almost level in contrast to the many types of sloped roofs. The slope of a roof is properly known as its pitch and the pitch of a flat roof does not exceed 5° or a slope of 1 (vertical) to 12 (horizontal).

Each scenario will review compliance to ensure the intent of the Construction Regulation is being met. The scenarios will review compliance in the areas of:

- access and egress to the roof

- methods of fall protection to ensure worker safety is protected

- acceptable use of guardrails, bump lines (barriers), anchors

- skylights, leading edge and perimeter edge work

In each scenario, the best practice would start with a job analysis, followed by work planning and work procedures discussed and implemented by all workplace parties.

Scenarios

Scenario 1: Installation of a new AC Unit — roof hatch

In this scenario, workers are performing construction activities at the centre of the roof, such as away from any perimeter edge. This access is considered the best case scenario for flat roof work activities. If workers are not exposed to any fall hazards as contemplated in section 26 of O. Reg. 213/91, there is no need for guardrails or fall protection equipment. Workers have the added convenience of a roof hatch to access the roof. The height of the roof to the ground is greater than 3 metres.

In normal conditions where workers have a firm footing (different considerations may apply if the roof was wet due to adverse weather conditions) this type of work does not expose workers to a fall hazard — provided of course the roof hatch is closed or barricaded when not in use. When in use, the roof hatch is an opening in the work surface and thus should be protected by a guardrail system as required by subsection 26.3(2) of O. Reg. 213/91. Alternatively it should be closed and in compliance with paragraph 2 of subsection 26.3(2).

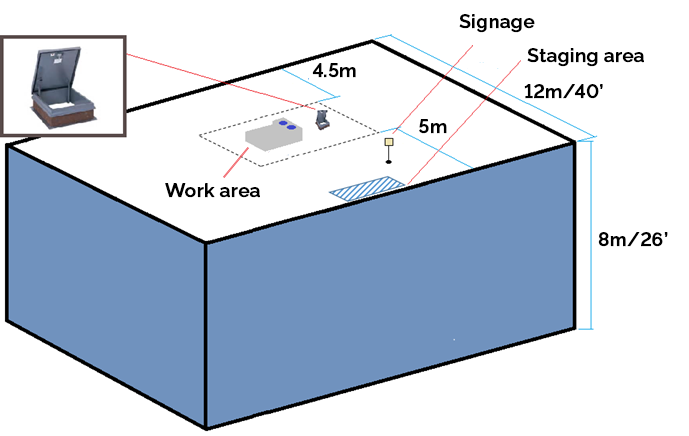

Diagram of work at the centre of a roof using a roof hatch

The diagram shows the roof of a building which is 8 metres high with a depth of 12 metres. Access to the roof is provided through a roof hatch located in the middle of the roof and more than 4.5 metres from any roof edge. The work area in the middle of the roof and including the hatch location is 5 metres away from the face of the building and 4.5 metres away from its back; it is also more than 5 metres from each side of the building surrounding. Within it is located the location of the AC unit to be installed.

Outside the work area, towards the front of the building, there is a sign. Further from the sign towards the front of the building, there is a “staging area” that is that extends from the front edge of the building a few metres back. It has a width of approximately 3 metres.

Considerations for scenario 1

- Ensure the employer has a job plan and procedures to be followed. Clear instructions must be provided so workers are aware of the fall hazards and other risks associated with the work.

- Verify that workers are not being exposed to any fall hazard at the perimeter edge of the roof.

- The workplace parties must ensure the roof hatch or opening remains closed, guarded or otherwise adequately protected to prevent any worker from accessing or performing work near the open hatch, or opening.

- Staging area — If a worker is required to approach the edge and may be exposed to a fall hazard as contemplated in section 26 (for example. if the worker has to approach the edge to provide signals to a crane operator and may thus be exposed to a fall hazard at the edge of the roof), the worker must be protected using the highest ranked practicable method of fall protection. In addition, warning signs as outlined in clause 44(3)(a) of O. Reg. 213/91 are also required.

However, if a worker is not required whatsoever to approach the area near the edge and is not exposed to a fall hazard as contemplated in section 26, the fall protection requirements in sections 26.1 to 26.9 of O. Reg. 213/91 do not apply.

Scenario 2: Installation of a new AC unit — ladder access

In this scenario workers are performing construction duties at the centre of the roof, such as away from any perimeter edge. If workers are not exposed to any fall hazards, there is no requirement for guardrails or fall protection equipment. A worker has an unobstructed travel path from the top of the ladder to the work area. The height of the roof to the ground is greater than 3 metres. This type of work does not expose workers to a fall hazard.

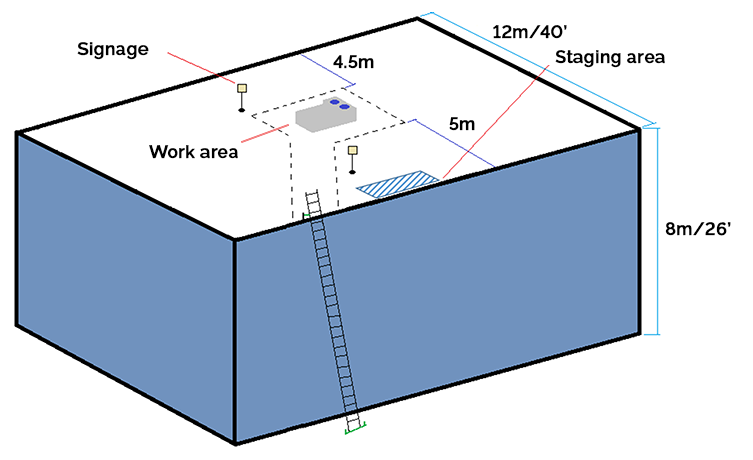

Diagram of AC unit installation work at the centre of a roof

The diagram shows the roof of a building which is 8metres high with a depth of 12 metres. Access to the roof is provided through a ladder placed at the front of the building. The work area in the middle of the roof and is 5 metres away from the face of the building and 4.5 metres away from its back; it is also more than 5 metres from each side of the building surrounding it. Within it the location of the AC unit to be installed.

A route to the work area is from the ladder placed on the front edge of the building. Outside the work area, towards the front of the building, and towards its back too, there are signs. Further from the sign towards the front of the building, there is a “staging area” that extends from the front edge of the building a few metres back. It also has a width of approximately 3 metres.

Considerations for scenario 2

- Workers must have safe unobstructed access from the ladder to the area of the roof where work is being performed. A safe distance from the perimeter edge of the roof of a minimum 6’–6” (2 metres) must be established at all times including the distance needed to perform work around the area. If this cannot be accomplished, a guardrail system must be in place along the perimeter.

- The employer should have a job plan and procedures to be followed. Clear instructions should be provided so workers are aware of the fall hazards and other risks associated with the work to be done.

- The employer or their representative must be able to verify that workers are not being exposed to any fall hazard at the perimeter edge of the roof. If evidence to the contrary is found, work procedures must be changed or a guardrail must be installed in that area.

- Workers accessing the ladder must not carry equipment or materials, as these may pose a hazard and interfere with maintaining three-limb contact. Alternate means should be used to lift equipment. In addition to the three-limb contact, the worker using the ladder must be able to have a firm footing and no obstruction or slippery conditions must be present at the top of the ladder.

- Staging area — If a worker is required to approach the edge and may be exposed to a fall hazard as contemplated in section 26 (for example, if the worker has to approach the edge to provide signals to a crane operator and may thus be exposed to a fall hazard while working at the edge of the roof), the worker must be protected using the highest ranked practicable method of fall protection.

- Depending on the duration, location, and nature of the work to be undertaken — including material to be lifted to the roof surface — employers need to consider the use of an elevated work platform as a primary means of access or egress to the roof surface. Also for the tools and equipment, the elevated work platform or another type of lifting device should be used.

Note: ascending or descending the ladder while maintaining three-limb contact and ensuring firm footing at all times with both hands free of equipment or material would constitute an acceptable risk level for the worker.

Scenario 3: Work being done on the entire surface of a flat roof — complete guardrail system

Work can consist of re-roofing, installing solar panels, or carrying out any other construction activities. Workers may be exposed to fall hazards greater than 3 metres, as they will be performing work near the perimeter edge. Such situations require the use of guardrails where practicable. Assessing if it is practicable accounts for the type of work, its duration and complexity.

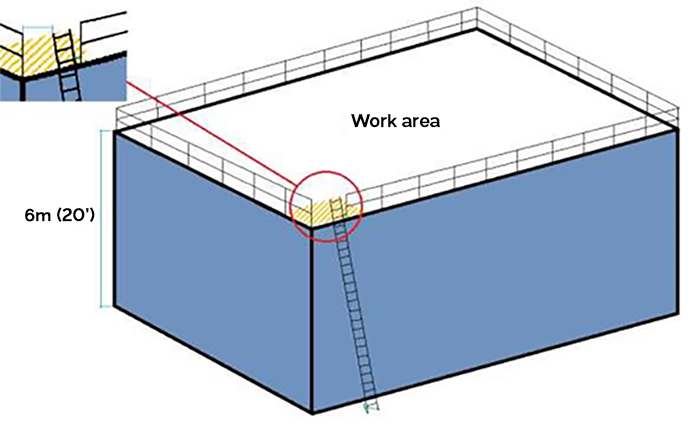

Diagram of a work area that includes an entire roof

The diagram shows the roof of the building with a guardrail on its four sides; the guardrail is interrupted only at one corner at the face of the building to allow the placement of a ladder which is used as a means of access to or egress from the work area. The work area in this scenario is the entirety of the roof surface. The roof is 6 metres high from the ground. The detail of where the ladder is placed is magnified to show only limited interruption of the guardrails to allow space for a worker using the ladder to get to the roof or off the roof.

Considerations for scenario 3

- When work is being performed on the entire surface of a roof, and workers may be exposed to falling more than 3 metres from the roof perimeter, guardrails should be installed. In those rare instances where guardrails may interfere with the work being done, the guardrails may be removed temporarily to complete the task at hand, provided the workers are adequately protected in compliance with section 26.1(2).

- In order to access the roof surface from the ladder an unobstructed opening must be provided to ensure a safe transition from the ladder to the roof while at all times maintaining three-point contact prior to leaving the ladder. Swivel gates seem to provide the best protection in such instances and are recommended. In their absence the opening must allow workers to safely access the roof surface. However, it must not be so wide that it could expose workers performing work adjacent to the ladder to a fall hazard. Where work is being done in close proximity to the opening, the fall exposure hazard must be controlled using the hightest ranked practicable method of fall protection.

- When workers are temporarily removing guardrails to receive materials, workplace parties must always ensure that they have an adequate method of fall protection and that they have temporary measures in place to warn other workers in the vicinity of the opening. See (“Temporary Removal of Guardrails”).

Scenario 4: Work being done to a small portion of a large roof

It is very common for work to be done in a small area or portion of a larger roof. The new installation of an industrial system, or the replacement of a roof top unit are examples of construction work where the construction regulation is applicable. In these smaller projects, a combination of fall protection methods may be used.

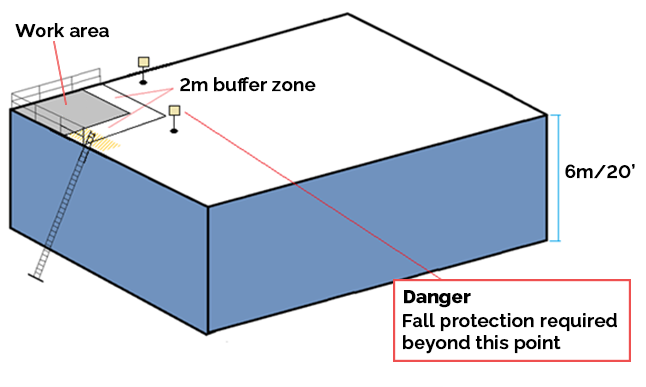

Diagram of work in the corner of a roof

The diagram shows the roof of the building with a guardrail surrounding the the work area and extending a bit more beyond it on the edge of the roof, which makes an additional buffer zone of 2 m width on each of the sides surrounding the work area.

The work area is located at one of the corners of the building. Is back side intersects with one side of the building. A ladder which is used as a means of access to or egress from the work area is placed at the edge of the buffer zone on the side of the building.

Two signs are placed outside the buffer zones, one on each side, to warn the workers of the danger of falling, and that they need fall protection beyond that point. The roof of the building is 6 m high from the ground.

Considerations for scenario 4

- Where workers are exposed to the perimeter edge, wherever practicable a guardrail must be installed.

- Where no work is being performed at or near the perimeter edge and where no worker may be exposed to a fall hazard as contemplated in section 26, guardrails are not required. Other means may be deployed to avert workers approaching the edge. For instance delineating an area no closer than 2 m from the edge and putting signs warning of the fall hazard may suffice.

- In re-roofing applications, barriers are required as per section 207 of O. Reg. 213/91. In all other construction activities, barriers to enclose a safe perimeter are considered best practice.

- A buffer zone must be considered to allow for space where the work area and guardrails end. Ensure a buffer zone of at least 2 metres from an edge is maintained where workers are performing work and a guardrail is not practicable. This is the minimum distance legislated by section 207 and is considered a best practice — along with warning signs — to ensure workers have a safe zone and are not exposed to a fall hazard when work does not fall within the parameters of section 207 (such as, not re-roofing, or repairing or re-surfacing a flat roof).

- As a best practice, employers should develop procedures to be carried out on a roof top to help protect workers from falls and to comply with the regulatory requirements.

Scenario 5: Leading edge construction activity being performed on the flat roof — guardrails combined with barriers

Guardrails being utilized in combination with barriers (bump lines). This scenario can apply to re-roofing or other construction activities. In the case of re-roofing, barriers must be installed as prescribed by section 207. In all other cases, such barriers are considered a best practice.

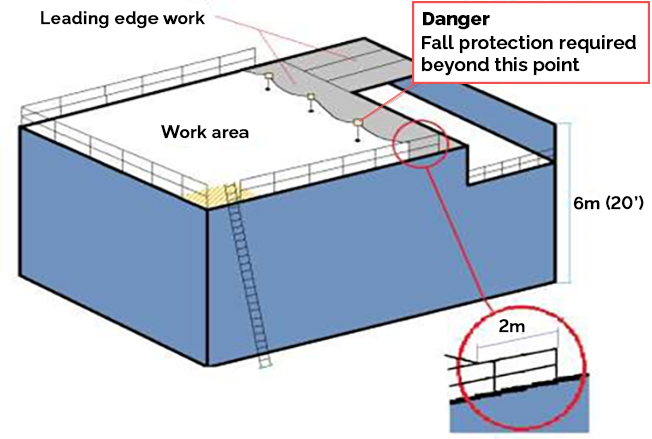

Diagram of leading edge construction

The diagram shows the roof of the building where leading edge work is being carried out. Leading edge work is done with a guardrail surrounding three edges of a quadrated surface while at the fourth edge, as work advances fall protection is used by the worker pushing the edge forward.

There is a guardrail on three sides of the four-sided surface of the roof, interrupted only by the placement of the ladder through which workers have access to the roof. The guardrail extends two meters beyond the work area on both sides of the advancing edge, providing a buffer zone on both sides. The advancing edge is delineated by a barrier (signs and connecting rope) warning workers not to go beyond it unless they wear fall protection equipment. The roof of the building is 8 m high from the ground.

Considerations for scenario 5

- Under section 207 of the Construction Regulation a barrier (such as a “bump line” barrier) must be placed on a built up roof when re-roofing is in progress. However, where section 207 does not apply, workplace parties may, as a best practice, place barriers as a physical warning device to prevent workers from getting close to an edge or being exposed to a fall hazard. A barrier must always be used in conjunction with appropriate signage (section 44) and installed at a minimum distance of 6’–6” (2 metres) from the edge. If work is to be performed between the barrier and the edge, the worker must be adequately protected using the highest ranked practicable fall protection method in compliance with s.26.1(2).

- If the roof height is below 3 metres but formwork is in place and the worker has access to the open side and may be exposed to a fall of 2.4 meters or greater a guardrail is also required by paragraph 3 of subsection 26.3(1).

- Warning signs are also required in accordance with subsection 44(1) of O. Reg. 213/91, warning workers of potential fall hazards.

- Ensure a buffer zone of at least 2 metres is maintained where workers are performing work close to where the guardrail ends — should it not cover the full perimeter edge of the roof. This is the minimum distance required by section 207 for built-up roofing work, and is considered a best practice to ensure workers have a safe zone protecting them from being exposed to a fall hazard, even when work is not re-roofing.

Scenario 6: Workers performing construction duties throughout the surface area of the roof — multiple fall hazards

A thorough hazard assessment and work planning must be performed prior to starting the work. Such a work plan is useful to protect workers from all fall hazards — at the perimeter edges, as well as around any opening or surface area that may not be capable of taking the loads applied to it (such as a skylight surface,whether the skylight is installed or not). Many fall protection options are available, some of which are illustrated below.

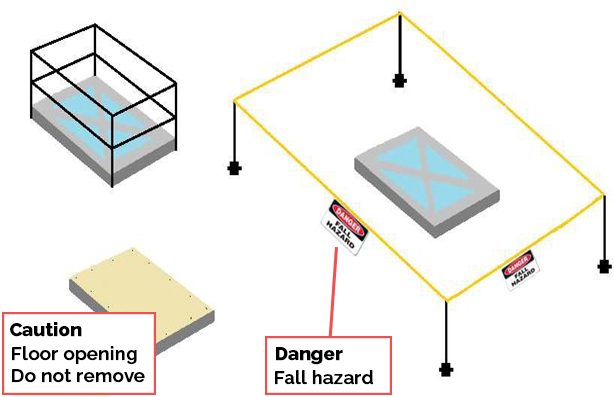

Diagram of fall protection methods when there are skylights or roof openings

The diagram shows different methods of fall protection that may be used around a skylight or an opening made to place a skylight on the roof of a building, namely:

- a guardrail around the perimeter of the skylight or its dedicated location

- a secured covering over the skylight surface or its location, or alternatively

- a fence, or a physical boundary surrounding the skylight or its dedicated location that is located at least 2 metres from each of its sides, along with caution signs warning against the hazard of exposure to a fall

Should the worker maintain the 2 metre distance from each side of the skylight they are not exposed to a fall hazard as contemplated in section 26.

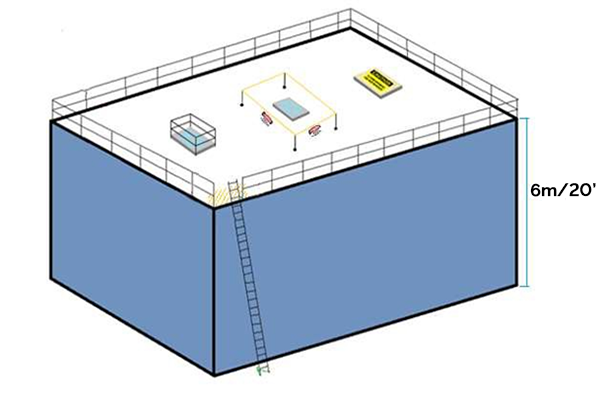

Diagram showing different fall protection methods in place around skylights on a roof

The diagram shows the roof of a building 6 metres high from the ground that is accessed through a ladder placed at one front corner of the roof. The whole roof edge is protected by a guardrail only interrupted at the location of the ladder

There are two skylights on the roof, one of which is surrounded by a guardrail at its border, while the other has its borders surrounded by a barrier situated 2 metres from each of its sides, along with danger signs warning about the fall hazard. There is also a protective cover securely in place over over a roof opening.

Considerations for scenario 6

Determine if guardrails are practicable in the circumstances and at the various given stages of the work. If guardrails are not practicable, because they interfere with the work, or erecting them would take as much time as completing the task at hand then other considerations are examined.Following the highest ranked method of fall protection that is practicable: fall hazards must be eliminated through limited access, barriers, or personal protective equipment.

Conducting a hazard assessment, along with setting up an appropriate job plan, is recommended so that all workplace parties understand their roles and duties, and follow the adequately planned procedures which would protect them.

Any fall protection method used must be implemented in accordance with the requirements outlined in the construction regulation (O. Reg. 213/91).

- If bump line barriers or other barriers are used to protect workers from the hazard posed by skylights, openings, or other susceptible surfaces, they should be installed in conjunction with appropriate signage and installed at a minimum distance of 6’–6” (2 metres) from the edge. If work is to be performed between the barrier and the edge, and a guardrail or a cover would interfere with the work to be done, a worker must be adequately protected using the highest ranked practicable fall protection method in compliance with s.26.1(2).

- In those instances where section 207 of the regulation applies, complying with this section is deemed to provide sufficient protection for the workers. There is no additional need for guardrails in such instances as required under section 26 as long as the workers do not go beyond the line delineated by the barrier.

- Though modern skylights may be designed to meet local building codes, this does not necessarily mean that they are able to support any and all loads that may be applied to them while construction activities are taking place. Adequate supporting documentation from the manufacturer or an engineer must be provided should the workplace parties deem them safe to take any load applied to them, and hence not need additional cover, barrier, or safety device to protect the workers from falling against, onto, or through them.

- Finally, a reminder that a cover installed on top of the skylight as per paragraph 2 of subsection 26.3(2) would achieve adequate protection to the workers and compliance with the regulation.

Scenario 7: New solar panel installation to existing commercial flat roof.

No guardrails being used anywhere on the roof, however, the employer is utilizing bump lines as the only measure of safety. Work is being done within 2 metres of the roof edge. Therefore, “bump line” barriers alone are not adequate protection in this application.

Photo of an incorrect installation of a barrier

Considerations for scenario 7

Workers must be adequately protected by a guardrail system when exposed to a fall hazard. In the picture above, we see an inadequate use of a barrier. If workers have access to the perimeter edge and are performing work that may bring them to within 2 metres (6’–6”) of the edge, guardrails are required.

Where there is a need to remove a portion of the guardrail system temporarily to perform work, workers working within 2 m (6’–6”) of the edge, would be required to use the highest ranked practicable fall protection method as required by section 26.1(2) of the regulation. In addition, optionally — when the roof is not being reconstructed or repaired — a section 207 type barrier and section 44 signs could be used to alert the other workers of the open edge.

Solar panel installations to existing flat roofs may place considerable loads on the roof structure that may or may not be designed for the additional loads. Design drawings (engineering) are required to ensure the adequacy of the installation. This needs to be requested [O. Reg. 213/91, subsection 31(1)] when dealing with large scale commercial solar panel applications.

The employer must take all reasonable measures and procedures to ensure that the roof structure is capable of withstanding all loads that may apply to it including those imposed from the added solar systems.

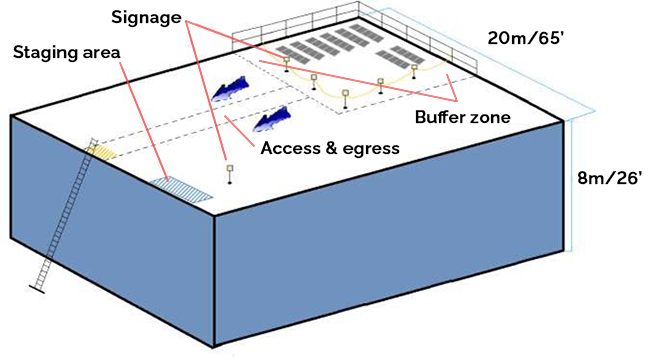

Diagram of fall protection measures for solar panel installation on a flat roof

The diagram shows the roof of a building 6 m high from the ground that is accessed through a ladder placed at one side of the roof perimeter. A staging area is located next to the ladder on the side where it lays.

There are solar panels at the side opposite to the one where the ladder is placed. The solar panels are located at the corner delineated by the side (opposite to the ladder side and the back side of the building.

The edges of the roof where the solar panels are laid, are protected by a guardrail which extends on each side, 2 m beyond the work area, providing a “buffer zone” for fall protection. At the edge of that buffer zone, signs are provided to alert against the falling hazard.

There is also signage next to the staging area towards the middle of the roof. The roof diagram also shows a passage corridor or boundary leading from the ladder to the solar panels area in the middle of the roof and away from the edges. Two arrows are drawn in the direction of the ladder, next to the solar panels work area, indicating the egress direction from the roof.

Protective measures must be installed that protect workers in the immediate vicinity where the work is being performed. This type of work is typically observed on large surface area roof tops (for example, grocery stores) where it is not practicable to install guardrails around the entire perimeter of the roof. Employers must determine if all the hazards are being adequately controlled and that the construction regulation requirements are fulfilled.

The above picture illustrates solar panels being installed on a large surface area flat roof by using a combination of safety devices:

- Guardrails are required due to the close proximity of the flat roof perimeter edge to the solar panels.

- Barriers are installed to create a safe perimeter zone where workers can perform work safely away from any edge. Note that the bump lines are at least 2 m from the extremity of the guardrail line on each side (leaving a buffer zone of 2 m from the edge).

- Signage is installed to warn workers they require fall protection outside the safe perimeter.

- Where work is performed outside the safe zone, where a worker is exposed to a fall hazard, a worker must be adequately protected using the highest ranked practicable fall protection method in compliance with section 26.1(2).

- The guardrails, bump lines, and signage move along as the work proceeds from one end to the other. The bump line barrier and signs here are a recommended best practice, but not required by the regulation in this instance as it is not the roof that is being repaired or built.

- Workers who are expected to provide signals to a crane or other lifting device must be protected against fall hazards at the edge through a guardrail or a personal fall protection system in situations where the guardrail interferes with the lifting operation.

Temporary removal of guardrails

In all cases when guardrails are installed and require temporary removal, precautions must be taken to protect workers who are now potentially exposed to a fall hazard. Furthermore, all workers in the vicinity must be made aware of the potential hazard and temporary measures must be put in place.

Where use of guardrails is not practicable, personal protective equipment is used to protect workers who may be exposed to the fall hazard, namely who are within 2 m from the edge. Temporary barriers and signage are used to warn workers, who are approaching the potential hazard.

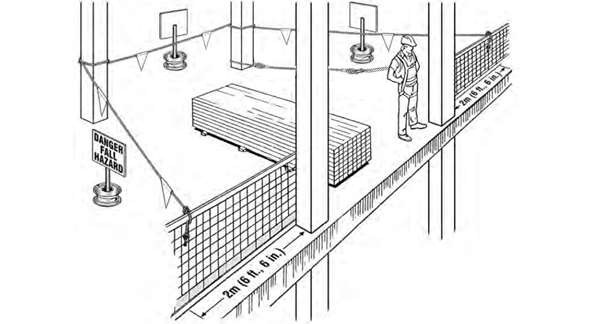

Diagram of fall protection where guardrails are temporarily removed

Source: Infrastructure Health and Safety Association, Construction Health and Safety Manual

The illustration depicts the edge of a floor, protected by a guardrail system which is interrupted at a certain width to allow receiving material. A worker is wearing a personal fall protection system attached to a pole and standing by stacked material in the unguarded area. Behind the pole where the worker’s fall protection system is attached — more than 2 m from the open edge — there is a barrier along with warning signs to the fall hazard.

While guardrails are the first consideration outlined by subsection 26.1(1), if they are not practicable, other means may be deployed using the highest ranked method of fall protection that is practicable — outlined in subsection 26.1(2). Also, depending on the work conditions and circumstances, the highest ranked suitable method of fall protection, from a travel restraint system, to fall restricting systemor other fall arrest system, or safety nets may be used to protect workers against falls.

Resources

See Achieve compliance on construction sites: fall prevention for reference to the topics discussed on this page. They relate to:

- the meaning of “fall” and calculating “falling” distance for section 26

- the interpretation of “may be exposed to the hazard of falling”

- the practicability of installing guardrails

- bump line barriers

- application of the 30” limitation of lanyard length for a dorsal attachment to a travel restraint system

- fall protection for skylights, roof hatches, and other types of non structural coverings on roofs

- parapet clamps and moveable anchors

- requirements for a leading edge (LE) self-retracting device