Hog target weight

Learn how to estimate the live shipping weight of hogs to get them to market at the right time. This technical information is for commercial swine producers in Ontario.

Overview

Two key factors determine whether you will make a profit on the hogs you raise:

- maximizing revenue

- reducing the cost of production

Maximizing revenue depends on getting hogs to market at the right time.

The primary factor that determines when to send hogs to market is the target carcass weight, as determined by a hog grading grid.

There are various factors that could affect when you get hogs to market, including:

- pig variation

- space requirements

- holidays

These factors may result in an imperfect fit with the grading grid’s target carcass weight range. You can control or manage some of these factors to maximize your revenue.

Sort loss

Sort loss is the financial loss that results from the reduction in price paid for a pig that does not meet the target carcass weight or lean yield specifications.

Carcasses that miss the grading grid's targets for weight or lean yield don't earn their potential maximum revenue.

While the settlement statement does not itemize the value of this loss, you can estimate the loss by:

- Tallying the numbers of carcasses on the statement that didn't fit into the target.

- Calculating the missed revenue.

Even if the average weight and average lean yield of a group appear to hit the target, many carcasses may lie outside it.

While an average weight for a pen may seem adequate for shipping, it's important to remember that buyers grade and price carcasses individually.

Accurate weekly shipping

In herds where pork producers closely monitor weights and ship hogs weekly, 66% of carcass weights fall within plus-or-minus 4 kilograms of the average weight.

Some grids will accommodate biweekly shipping without penalty if weight is accurately monitored. With a narrow grid, accurate weekly shipping is important.

To minimize lost revenue from sort loss, make sure you:

- pay attention to the grading grid being targeted

- know the shipping weight necessary to achieve the best possible fit with the targeted carcass weight and lean yield

Review regularly

Knowing how shipping weight affects carcass weight and lean yield helps you effectively adjust your shipping strategy.

Understand the growth characteristics of the pigs and the dressing percentage at the packing plant by regularly reviewing:

- shipping weights

- resulting settlement statements

Weigh accurately

Grading grids use a sharp cut-off, not a gradual one, so getting the shipping weight right is a fundamental part of managing the unavoidable variation in hog weights.

Missing the optimum weight class could mean a loss of significant index points, which will result in lost revenue.

Weighing pigs accurately can result in greater returns than any other manual effort in pork production.

Accurately weigh pigs by using:

- accurate weigh scales

- automatic sorters

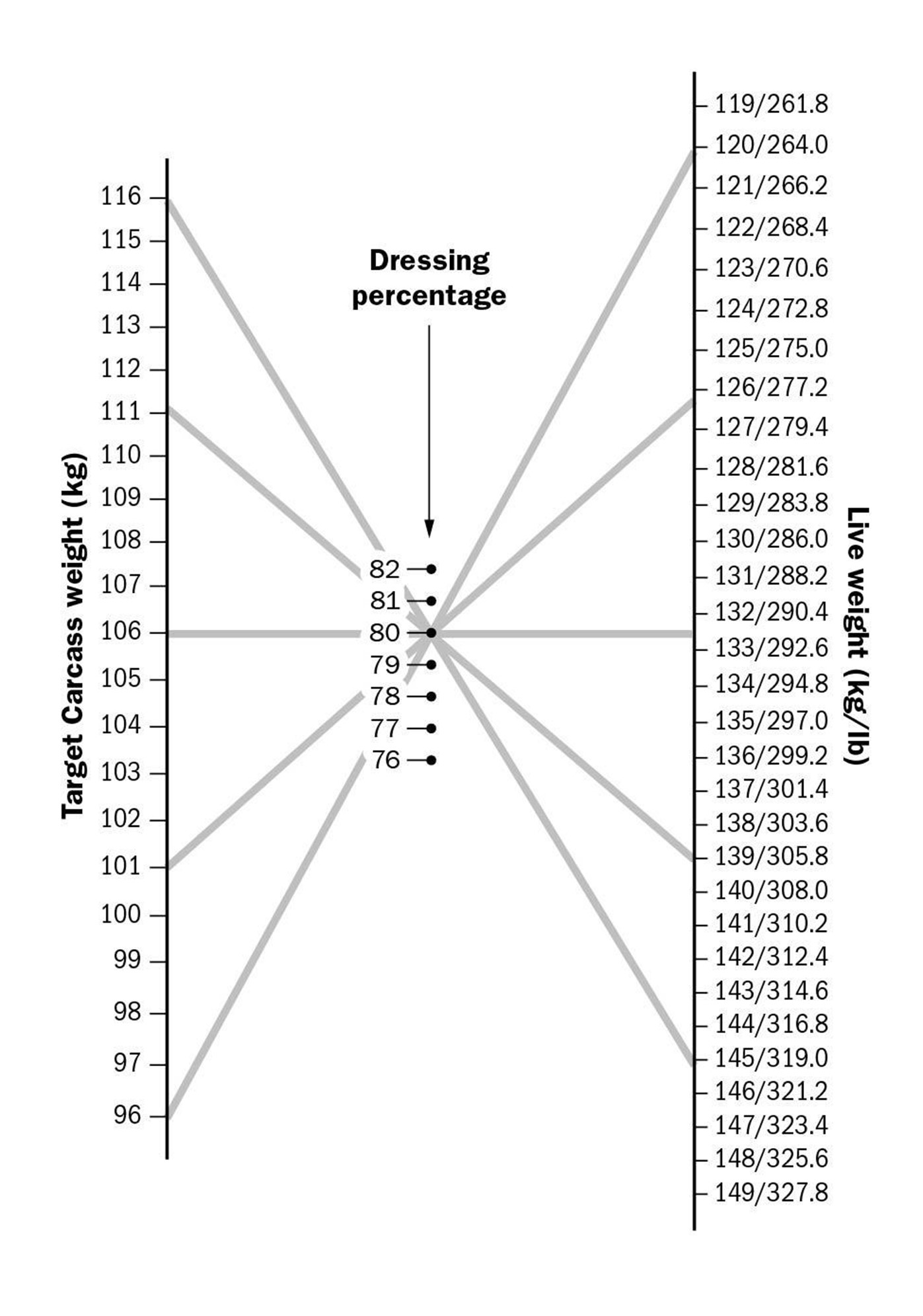

Target weight calculator

The hog target weight calculator is a tool to quickly determine the desired shipping weight for a hog, depending on the target carcass weight and dressing percentage.

The calculator helps you find out:

- the potential carcass weight from shipping hogs at a given live weight

- how a change in dressing percentage could affect carcass weight

How to use the calculator

- Refer to your specific grid for the target carcass weight.

- On the calculator, locate the target carcass weight on the left axis.

- Estimate your dressing percentage. You may take this number from previous records or use 80%.

- Use a straight edge to read across from the target carcass weight, through the dressing percentage, to find the target live weight.

- Reverse the procedure to determine carcass weight based on a given live weight.

Example

Consider a target carcass weight of 110 kilograms and assume a dressing percentage of 80%. Read from 110 kilograms (carcass weight, left side), through the 80% point, to arrive at a target live weight of about 137.5 kilograms on the right side.

Influencing factors

Target carcass weight is influenced by:

- your grading grid

- dressing percentage and live weight

- knowing your grid and targets

- weighing your pigs

Dressing percentage is influenced by:

- transit time

- slaughter time (know your schedule)

- feed withdrawal

- gut fill

- diet composition

Handling

Handling decisions can affect carcass quality. Shipping time is not the time to take chances with the investment already made in a finished animal.

Refer to the resources from Farm & Food Care Ontario on transporting pigs and caring for compromised pigs.

Marginal returns

After pigs have reached the minimum weight demanded by the grading grid, consider whether it is profitable to continue to feed to higher weights. It would be less profitable to feed to higher weights if feed cost is high and market prices are low. An assumption of the grading grid is that the main driver to shipping hogs is not the need to free up the facilities for incoming animals.

Make an informed decision by reviewing the feed conversion ratio of the herd over the relevant weight range.

This is important, since the feed conversion ratio may decline as animals get larger and can only be estimated with any accuracy by measuring it in the barn. Lean yield can also change at heavier weights.

Monitor the feed conversation ratio and weights provided on settlement statements through Ontario Pork’s online data base, so you can:

- make incremental calculations of the added cost of feed

- make incremental calculations of the added value of the carcass

- determine the optimum shipping weight