Operation, maintenance and monitoring

Operation, maintenance and monitoring (6.0)

6.1 History of stormwater management O & M

This chapter focuses on the operation and maintenance requirements for urban SWMPs. Monitoring and maintenance responsibilities are an important component of an effective SWMP and should be clearly defined in watershed/subwatershed plan implementation strategies. Maintenance and monitoring is also required for watershed/subwatershed projects such as natural channel designs and canopy cover restoration. However, this is not addressed in this manual.

During the 1970's and 1980's, stormwater management consisted of "peak shaving" facilities where peak flow under post-development conditions was reduced to that under pre-development conditions (2 year control for erosion, and up to 100 year for flooding). These facilities did not require sediment removal maintenance since the residence time of water within a peak shaving facility was in the order of several hours and there was marginal sediment/pollutant removal. Peak shaving facilities were designed to require as little maintenance as possible. However, regular maintenance is still required for inlet/outlet inspections, emergency spillway repair after a flood, trash removal, etc..

The introduction of stormwater management measures for water quality control has changed operations and maintenance needs. Many pollutants such as metals, bacteria, and nutrients bind to sediment. The design of urban water quality SWMPs is based primarily on sedimentation which requires sediment removal maintenance.

For stormwater facilities serving subdivisions, maintenance is the responsibility of the developer during the construction period (until works are assumed by the municipality). Stormwater facilities located on private property are the responsibility of the owner. In most cases, the municipality requires an easement agreement which specifies a required maintenance schedule and gives the municipality the right to enter the private property and conduct maintenance activities.

6.2 Importance of maintenance

Maintenance is a necessary and important aspect of urban SWMPs design. One of the main reasons for SWMP failures and/or poor performance in the past was a lack of maintenance. Urban SWMP designers should give considerable thought to future long-term maintenance during the design of stormwater management practices.

In order to facilitate maintenance, it is advisable to prepare an annual maintenance report. The report should provide the following information annually:

- Observations resulting from inspection:

- hydraulic operation of the facility (detention time, evidence or occurrence of overflows);

- condition of vegetation in and around facility;

- occurrence of obstructions at the inlet and outlet;

- evidence of spills and oil/grease contamination; and

- frequency of trash build-up.

- Measured sediment depths (where appropriate);

- Monitoring results, if flow or quality monitoring was undertaken;

- Maintenance and operation activities; and

- Recommendations for inspection and maintenance program for the coming year.

6.3 Operation and maintenance activities

There are many factors which influence sedimentation rates and maintenance requirements including: type of SWMP, land use, upstream development, and wildlife. Table 6.1 outlines operation and maintenance activities associated with different types of SWMPs.

Most SWMP monitoring has focussed on determining pollutant removal efficiency rather than maintenance/operations requirements of the facility. Since monitoring for maintenance is not common, the required frequency of maintenance activities is not well defined and activities tend to be performed on an "as required" basis.

One of the most important maintenance requirements for effective SWMP function is the removal of accumulated sediment which is discussed in Section 6.4. "The Storm Water Management Facility Sediment Maintenance Guide" (Greenland International Consulting Inc., 1999) provides additional information on sediment removal maintenance requirements.

Guidance on determining other maintenance requirements and frequency schedules is outlined in the following sections.

6.3.1 Inspections

SWM system inspections determine required maintenance activities. During the first two years of operation, inspections should be made after every significant storm to ensure proper functioning (average is about four inspections per year).

| Item No. | Operation or Maintenance Activity | Type of Stormwater Management Practice | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wet Pond | Wetland | Dry Pond | Infiltration Basin | Infiltration Trench | Filter Strip | Superpipe Storage | Filters | Oil/Grit Separator | Soakaway Pit | Pervious Pipe | Grassed Swales | ||

| 1 | Inspection | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

| 2 | Grass cutting | □ | □ | ■ | ■ | ■ | ■ | ■ | |||||

| 3 | Weed Control | ■ | ■ | ■ | ■ | ■ | □ | ■ | |||||

| 4 | Upland vegetation replanting | □ | □ | □ | □ | □ | □ | □ | |||||

| 5 | Shoreline Fringe and Flood Fringe vegetation replanting | □ | □ | ||||||||||

| 6 | Aquatic vegetation replanting | □ | □ | ||||||||||

| 7 | Removal of accumulated sediments | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■** | ■ | ||

| 8 | Outlet valve adjustment | □ | □ | □ | |||||||||

| 9 | Roof leader filter cleaning/replacement | ■ | |||||||||||

| 10 | Pervious pipe flushing | ■ | |||||||||||

| 11 | Oil/Grit separator or Catchbasin cleaning | ■ | ■ | ||||||||||

| 12 | Closing of infiltration facility inlet for winter months | ■[g] | ■[g] | ■[g] | ■[g] | ||||||||

| 13 | Trash removal | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■* | ■*** | ■ | ■ |

| 14 | Infiltration basin floor tilling | ■ | |||||||||||

- ■

- Normally Required

- □

- May be Required

* Litter removal part of sediment removal.

** diment removal part of catchbasin cleaning.

*** Litter removal by a filter in the rain gutter.

[g] Based on municipality experience and practices (e.g., may not be required if used on a local road with no salting or sanding).

After this initial period, when the SWMP operation has been confirmed, annual inspections may suffice. A greater number of inspections may be required if the SWMP is poorly designed, or other factors such as upstream development which may cause operational or maintenance problems.

As shown in Table 6.1, regular inspections are required for all SWMPs including pre-treatment systems. Table 6.2 outlines some routine questions that could be used when inspecting various SWMPs.

6.3.2 Grass cutting

Frequency

Generally, it is recommended that grass-cutting be limited or eliminated around SWM facilities since allowing grass to grow tends to enhance water quality and provide other benefits for wet facilities. Short grass around a wet stormwater facility provides an ideal habitat for nuisance species such as geese. Allowing the grass to grow is an effective means of discouraging geese.

Grass cutting is one maintenance activity which is solely undertaken to enhance the perceived aesthetics of the facility. The frequency of grass cutting depends on surrounding land uses, and local municipal by-laws. Therefore, grass cutting should be done as infrequently as possible, recognizing the aesthetic concerns of nearby residents.

Methods

Grass around wet facilities should not be cut to the edge of the permanent pool. As a safety precaution, cutting should be done parallel to the shoreline with grass clippings being ejected upland to reduce the potential for organic loadings to the pond.

6.3.3 Weed control

Frequency

Weeds are generally defined as any kind of vegetation which is unwanted in a particular area. In terms of SWMPs, weeds are generally invasive species which cannot provide the intended function of the planting strategy, or non-native species such as purple loosestrife, the spread of which is undesirable. Weed control by-laws should be consulted for local requirements. Weed control may be required annually.

Methods

Weeding should be done by hand to prevent the destruction of surrounding vegetation. The use of herbicides and insecticides should be prohibited near SWMPs since they create water quality problems. The use of fertilizer should also be limited to minimize nutrient loadings to the downstream receiving waters.

| SWMP | Inspection Routine |

|---|---|

| Wet Ponds Wetlands |

|

| Dry Ponds |

|

| Infiltration Basins |

|

| Infiltration Trenches |

|

| Filter Strips |

|

| Buffer Strips | 1. Are there areas of unhealthy or dead vegetation along the buffer strip? (This will indicate the need to re-vegetate the buffer strip.) |

| Filters |

|

| Oil/Grit Separators (OGS) |

|

| Roof Leader Discharge to Soakaway Pits | 1. Are there frequent overflows to the surface during small storm events? (Frequent overflows will indicate that roof leader filter has clogged or the soakaway storage media has become clogged. The filter should be checked for an accumulation of leaves and twigs. If the filter is clean, the pit may need to be reconstructed to restore its performance.) |

| Perforated Pipe Systems |

|

| Grassed Swales |

|

6.3.4 Plantings

Frequency

Upland and flood fringe plantings are generally stable and should not need much maintenance or re-establishment. Shoreline fringe areas are subject to harsher conditions as a result of the frequent wetting and drying associated with this zone. Aquatic plantings are the hardest to initially establish. It is anticipated that vegetation in the aquatic and shoreline fringe zones will require some replanting or enhancement during the first two years of SWM facility operation. Preliminary results of stormwater plantings studies indicate that a healthy vegetative community will establish if proper conditions are created (although the final set of species will often not be those that were originally planted).

Methods

Table 6.1 outlines SWMPs to which planting of vegetation applies. Planting methods can be separated into three main categories based on the wetness level and types of vegetation that will grow in these conditions (terrestrial to aquatic):

Upland/flood fringe

The two types of plantings used are ground cover (grasses, herbs) and woody shrubs and trees. Planting should occur in the spring after water levels have subsided to a stable level. Ground cover could be installed either by hydroseeding or using a custom seed mix in a nutrient rich medium impregnated in a biodegradable mesh-like blanket. Individual shrubs and trees could be planted manually with openings made in the blanket for each planting if necessary.

Shoreline fringe (wet riparian)

Shoreline fringe plantings should be carried out in mid-May to early June but after water levels have subsided to a stable level. Some form of protection of the seed mixture and soil nutrient medium (if required) should be provided in this dynamic zone of water level fluctuation. The biodegradable mesh-like blanket suggested in the upland zone is also highly recommended in this zone to establish ground cover. Shrubs and trees can be planted through openings created in the blanket.

Aquatic fringe/shallow water

The establishment of plantings in this zone will require greater materials handling and growth monitoring both in the short and the long-term. Emergent vegetation is easily planted by hand if the substrate is suitable. Ideally, a firm substrate with at least 10% organics (by volume) allows emergent vegetation to be hand planted. Young shoots, as opposed to rhizomes or corms, are preferable for planting as these plants are already growing with an established root structure (for early stability). The plants should be at least 10 cm tall and planting should occur in late May to early June.

Sprigs or plugs of emergent plant material are preferable for planting since root material is already contained in a suitable growth medium. Submerged rooted plants (including pondweeds) should be planted as mature vegetative growth if planted in late spring to early summer. Mature growth will take advantage of warmer water and sunlight penetration. Plantings in early spring or fall should use vegetative propagules such as turions or rhizome plugs which can germinate in the spring or over the winter and begin growing in the following growing season.

6.3.5 Outlet valve adjustment

Extended detention outlets should be designed to allow for the adjustment of detention times. Information about the effects of detention times on water quality enhancement, erosion, and flooding is still evolving and there may be a need for operational changes in the field to address site-specific or subwatershed related concerns on a case-by-case basis (especially when subwatershed planning has not been undertaken).

6.3.6 Trash removal

Trash removal is an integral part of SWMP maintenance. Generally, a "spring cleanup" is needed to remove trash from all surface SWMPs. Trash removal is then performed as required based on observations during regular inspections.

6.4 Sediment removal maintenance issues

6.4.1 Frequency removal

To ensure long-term effectiveness, the sediment that accumulates in SWMPs (e.g., wet ponds, wetlands and dry ponds) should be periodically removed. The required frequency of sediment removal is dependent on many factors including:

- type of SWMP;

- design storage volume (e.g., if active and permanent pool storage is oversized for sediment storage);

- characteristics of the upstream catchment area (e.g., land use; level of imperviousness; upstream construction activities and effectiveness of sediment and erosion control activities); and

- municipal practices (e.g., sanding).

There is limited data available on sediment accumulation. Monitoring of new ponds and retrofit ponds (converted ponds in older established areas) indicates a significant difference in sediment buildup for different ponds at different time periods. Sediment accumulation will typically be rapid for the entire construction period (including time required for the building, sodding and landscaping of individual lots). Once a catchment area is completely developed and vegetation is established, sediment accumulation drops markedly.

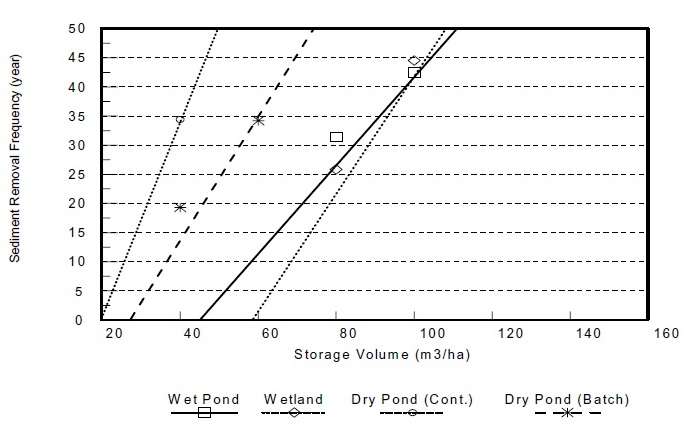

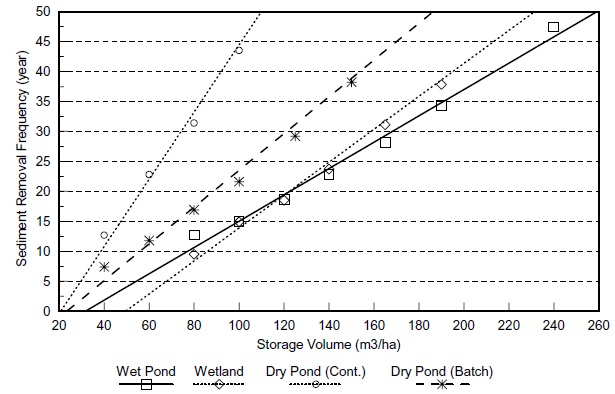

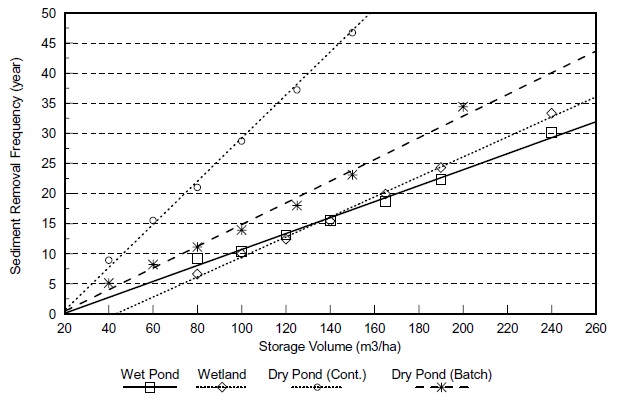

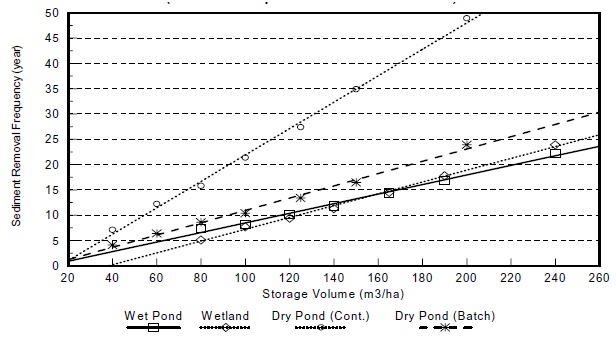

Continuous simulations were performed for end-of-pipe stormwater management facilities to assess the rate of sediment accumulation (see Section 3.3.1). The continuous simulation indicated total suspended solid (TSS) removal efficiencies for different end-of-pipe stormwater management facilities with varying volumes of storage and different levels of imperviousness. The removal efficiencies were converted into volumes of sediment captured by each type of facility on an annual basis. A set of curves was developed which indicate sediment removal frequency for facility type, storage, and level of upstream imperviousness (Figures 6.1 to 6.4).

Sediment accumulation reduces the effective storage volume and the long-term SWMP removal efficiency of suspended solids. The theoretical maintenance frequency for sediment removal can be calculated based on the rate of performance reduction with loss in storage volume. The theoretical performance-storage relationship does not account for conditions such as upstream development and poor sediment and erosion controls. As a result, these maintenance frequencies are only estimates which should be refined based on operational and maintenance experience in the field.

The performance-storage curve becomes asymptotic quickly (a large increase in storage is required for small improvements in the removal performance). This means that for typical SWMP storage volumes there must be a considerable loss in storage to reduce the effectiveness of the facility. It was assumed that 5% was an acceptable reduction in TSS removal efficiency due to gradual sediment accumulation.

The average annual TSS removal efficiency of a SWMP with a certain volume of storage was determined using continuous simulation and a sedimentation model (see Table 3.2 – Chapter 3). The required maintenance frequency for this SWMP was then determined based on the annual sediment accumulation and resulting annual loss in storage. The timeframe to reduce the storage to the point that the annual removal efficiency was 5% less than the original efficiency indicates the maintenance frequency for that SWMP with that particular storage.

If excess storage is provided to lengthen the intervals between required maintenance, the timeframe to reduce the efficiency by 5% below the original efficiency should be calculated. For example, if 80% removal is required, but excess storage is provided resulting in a initial efficiency of 85%, then maintenance would be required when the performance efficiency was reduced by 10% (i.e., 5% below the original target efficiency).

Curves of maintenance frequency by SWMP type, storage, and different levels of upstream imperviousness were calculated based on the continuous simulation results and the requirement for maintenance with a 5% loss in TSS removal performance (Figures 6.1 to 6.4). These curves are best-fit lines based on linear regression over a period of 50 years and indicate that there is a linear relationship between maintenance frequency and SWMP storage.

Figure 6.1: Storage Volume vs. Removal Frequency – for 35% Impervious Catchments

Figure 6.2: Storage Volume vs. Removal Frequency – for 55% Impervious Catchments

Figure 6.3: Storage Volume vs. Removal Frequency – for 70% Impervious Catchments

Figure 6.4: Storage Volume vs. Removal Frequency – for 85% Impervious Catchments

These graphs can be used to determine the required sediment removal frequency given the SWMP type, storage volume, and imperviousness level of catchment basin.

Figures 6.1 to 6.4 also indicate that increased storage capacity increases the maintenance interval (i.e., less frequent maintenance required). These curves are based on the assumption of 5% loss of performance and should not be used for over-sized facilities. In order to allow users to calculate the required maintenance frequency for an oversized SWMP, annual suspended solids loadings in runoff from catchments with different levels of imperviousness and estimated sediment density are provided in Table 6.3.

The values of suspended solids loadings in Table 6.3 were derived from US Environmental Protection Agency (EPA) Stormwater Management Model (SWMM) simulation results and are only intended to be used as estimates for planning purposes. The density of suspended solids was based on a review of the literature of stormwater sediment characteristics and recent pond sediment removal data. The following methodology should be used to calculate the maintenance frequency if storage for the SWMP is oversized (calculation can be easily automated in a spreadsheet format):

- Determine the appropriate total suspended solid (TSS) removal efficiency based on level of protection required for receiving stream (See Table 3.2).

- Subtract 5% to obtain the target maintenance removal efficiency.

- Determine the projected TSS removal efficiency based on the storage provided.

- Calculate the loss in removal performance and loss in storage for each year based on the removal performance at the start of the year, the suspended solids loading rate, and the sediment density. The removal efficiency at the start of the next year will be based on the resulting available storage volume at the end of the year. These calculations are continued until the removal efficiency of the facility at the start of the year is equal to the target maintenance removal efficiency.

| Catchment Imperviousness | Annual Loading (kg/ha) | Wet Density (kg/m³) | Annual Loading (m³/ha) |

|---|---|---|---|

| 35% | 770 | 1,230 | 0.6 |

| 55% | 2,300 | 1,230 | 1.9 |

| 70% | 3,495 | 1,230 | 2.8 |

| 85% | 4,680 | 1,230 | 3.8 |

Alternatively, a conservative estimate of annual sediment accumulation in a SWMP may be obtained by multiplying the annual loading of suspended solids (m3/yr) (see Table 6.3) by the initial removal efficiency for the particular SWMP. Using this method, a calculation is made to determine how long it takes to accumulate the difference in storage volumes between the initial storage and the target maintenance storage volume.

6.4.2 Methods

The methods for sediment removal depend on the type of SWMP implemented. The following sections describe sediment removal techniques for different types of SWMPs.

6.4.2.1 Soakaway pits

Soakaway pits should only be used to infiltrate relatively clean water (rooftops, pervious areas) to reduce the potential for clogging. The roof leader discharge system should have an overflow discharge to the surface and be as close to the ground as possible to minimize the build up of head on the soakaway pit. A plastic mesh or wire mesh filter should be placed near the ground surface just below the overflow pipe so that overflows will occur if the filter becomes plugged. Frequent overflows during small summer storms are a signal that maintenance is required. The filter should be cleaned once a year in the fall (after the leaves have fallen off the trees).

6.4.2.2 Grassed swales

Visual inspection and the aesthetic attributes of swales will indicate the need for maintenance. In areas which receive road runoff, discolouration of the soils or the build-up of a "crust" may indicate the need for mulch (to maintain infiltration properties).

6.4.2.3 Pervious pipe systems

It should be recognized that relatively little is known about maintenance requirements for pervious pipes conveying stormwater since maintenance techniques have not been extensively tested. Monitoring is required to provide a better understanding of the effectiveness (if any) of various techniques. The City of Toronto (Etobicoke) was monitored for a short time and has shown no indications of clogging. A system which has been in place in Ottawa for some time has also performed well.

Pre-treatment of the stormwater before it enters the perforated pipe system is fundamental to the longevity of the system. Maintenance activities relating to the pre-treatment system (grassed swales, oversized catchbasins, street sweeping, manhole oil/grit separators), and source control measures (salting and sanding practices) should be implemented to minimize the volume of particulate matter conveyed to the perforated pipe system.

In addition, the feasibility of seasonal operation of the system should be investigated since most road systems in Ontario require frequent sanding and salting during the winter. Winter operation may degrade groundwater quality and decrease the lifespan of the system by clogging the pipe perforations and the void spaces in the surrounding backfill/storage material.

Catchbasin cleaning is done via the use of a vacuum truck which extends a hose into the sump of the catchbasin and sucks out the material which has been deposited in the sump. As a general rule, catchbasin cleaning should be done annually; however, municipalities should adjust the frequency based on the volume of material removed.

The following three maintenance techniques for storm sewers and leachate collection systems may be applicable to the maintenance of perforated pipe systems; however, further monitoring is required to determine their effectiveness:

Flushing

Sewer flushing is generally undertaken to clean out material which has been deposited in the pipe. A filter sock may be used to prevent fine material from entering the pipe system from the native material. However, this could lead to clogging at the pipe/filter cloth interface which sewer flushing may not be able to remedy. This should be considered in the design of the system.

Radial washing

Radial washing is similar in operation to flushing. The perforated pipe must be connected between manholes and the downstream end plugged or capped. A water hose is connected to the upstream end of the perforated pipe and water is introduced from the surface into the hose. The perforated pipe is essentially pressurized, forcing water out the perforations and hence, cleaning plugged perforations. Radial washing can be performed after flushing if there is considerable sediment deposition in the pipe itself.

Jet flushing

Jet flushing is frequently used in leachate collection systems for landfills to clean the perforated collection pipes. A pressurized hose is attached to an end nozzle which discharges water in various directions to clean the pipe. The pressure in the pipe on the end nozzle also directs the hose further along the pipe (i.e., self directing). There are various nozzle designs available, and one which directs water radially into the perforations would be appropriate for perforated storm sewer applications.

6.4.2.4 Infiltration trench

Maintenance of these systems generally focuses on ensuring that the pre-treatment is operational and adequate. Flushing of pipes in an infiltration trench is generally not feasible since there are typically several pervious pipes within the trench and cleanout locations would have to be provided at both the inlet and outlet of each pipe length. In addition, flushing may not be effective as discussed previously (Section 6.4.2.3). Other than maintaining pre-treatment measures, the only feasible maintenance for infiltration trenches is re-construction.

6.4.2.5 Infiltration basin

Infiltration basins are end-of-pipe stormwater management facilities with highly permeable soils. Accumulation of sediment in these surface storage facilities seals the bottom and reduces the ability of soil to allow infiltration of stormwater. Maintenance of pre-treatment SWMPs and the implementation of source controls (salting and sanding practices) will help prevent sediment build-up.

Pre-treatment will not be totally effective in preventing suspended solids from entering an infiltration basin. Tilling the land may be required to maintain the infiltration potential of the soil. In areas where tilling has been tried, little success has been achieved in maintaining the infiltration potential (Maryland, 1993). Experience indicates that deep tilling must be employed (i.e., a rototiller will not dig deep enough). Planting of deep rooted legumes in an infiltration basin may be beneficial in maintaining the porosity and infiltration potential of the soil. However, consideration must be given to the anticipated growing conditions in the basin (frequency and depth of inundation). Deep basins (> 0.6 m) are not recommended since the weight of water tends to compact the soil. Once an infiltration basin has sealed, remediation is difficult and expensive and may not even be successful.

6.4.2.6 Filters

Filters can either be surface or subsurface end-of-pipe stormwater management facilities. Surface filters may or may not have a grass cover. Filters without a grass cover can be raked to prevent clogging and to remove trash. Maintenance requirements for grass-covered filters, bioretention areas, or subsurface filters are similar to those for infiltration trenches and should focus on ensuring that adequate pre-treatment and source controls are provided.

6.4.2.7 Vegetated filter strips

Maintenance activities for filter strips involve removing sediment from upstream of the level spreader, ensuring that the level spreader is operating in accordance with the design and maintaining the vegetated strip to promote sheet flow. Sediment removal from upstream of the filter strip can be done using a vacuum truck or small grading equipment if there is considerable sedimentation. Given the small drainage areas serviced by these SWMPs, the volume of sediment to remove will be limited.

6.4.2.8 Buffer strips

Buffer strips are generally not engineered and will not provide any location for concentrated collection of sediment. Sediment removal is not proposed since the sediment will be dispersed and removal would destroy the vegetation and the primary buffering capacity in this area.

6.4.2.9 Oil/grit separators

Manhole oil/grit separators (OGS) should be cleaned out using a vacuum truck. Some interceptors discharge low flows containing oil and grit to the sanitary sewer. Although this type of design facilitates maintenance, it is undesirable in the case of a large fuel/oil spill since the sewage treatment plant cannot treat large loadings of these pollutants. Therefore, it is recommended that any outlet to the sanitary sewer from the oil/grit separator be valved and kept closed during everyday operations. Manhole separators or three-chamber separators that incorporate a by-pass should be cleaned out annually and after any known spills have occurred.

6.4.2.10 Wet ponds, dry ponds, and wetlands

Typical grading/excavation equipment such as backhoes and in some instances hydraulic dredging should be used to remove sediment from ponds and wetlands. Certain types of backhoes and loaders have a tendency to tear up the inter-locking block on the hardened floor. Therefore, there has been a shift to using long-reach backhoes. Conventional dredging is not recommended because of the costs and potential to destroy features in the facility (i.e., vegetation and bottom grading).

Regardless of the means selected for sediment removal, the procedure should meet the requirements normally imposed by a sediment and erosion control plan (e.g., no off-site migration of sediment to roads, stormwater conveyance systems or watercourses).

Theoretical sediment removal frequencies for these SWMPs are provided in Section 6.5.

6.4.3 Sediment disposal

Generally, sediment removed from SWMPs will not be contaminated to the point that it would be classified as hazardous waste. However, all sediment which is removed from SWMPs should be tested to determine disposal options. MOE sediment disposal requirements should be consulted for information pertaining to the exact parameters and acceptable levels for different disposal options. Most private laboratories are familiar with the disposal guidelines and can test sediment samples with these in mind.

For example, in order to deposit the sediment on land, it would need to meet inert fill requirements under Regulation 347. For landfill disposal, the sediment would have to be classified as non-hazardous, i.e., not leachate toxic according to TCLP leachate test in Regulation 347 (effective March 31, 2001).

There are three generalized disposal options:

On-site disposal

On-site disposal allows the sediment to be disposed of on any land area that is not regulated (i.e., land other than floodplain, etc..). In the planning stage of land requirements for subdivision/site plan stormwater management requirements, land can be set aside for on-site disposal of sediments to be removed from the various SWMPs. The areas that are used for sediment disposal should be landscaped to provide a natural appearance after each sediment removal operation.

Off-site disposal

It is anticipated that off-site disposal may be preferred by most developers and municipalities since off-site disposal does not reduce the developable area, landscaping/grading does not have to be performed, and there are no perceived liability/health concerns with respect to the surrounding landowners. Off-site disposal can mean disposal at a sanitary landfill or disposal at another area undergoing filling. The decision of where the material is deposited depends on the quality of the sediments and the availability and distance of the alternative fill areas.

Temporary disposal areas are recommended for surface end-of-pipe stormwater management facilities particularly those that do not have a maintenance by-pass since it provides a location for the sediment to dry before transporting it off-site. Where temporary sediment disposal areas (i.e., drying areas) are not feasible due to limited availability of land or high cost, the means of dealing with the un-dewatered sediment should be detailed in the stormwater management plan and approved by the municipality.

Hazardous waste disposal

Although sediment removed from SWMPs is expected to contain contaminants (metals, bacteria, nutrients), it will not likely be classified as hazardous waste. Hazardous waste must be deposited at a hazardous waste facility. Transportation costs and disposal fees are expensive for hazardous waste since licensed haulers must be used to transport the material and there are relatively few facilities in the province.

6.5 Winter operation

Section 4.3 describes general SWMP design modifications which should be considered in cold climates and section 4.5 specific considerations for different types of SWMPs. These sections address both the issue of reduced performance and the susceptibility of SWMPs to damage that may result from cold temperatures.

Infiltration facilities are subject to reductions in capacity due to freezing or saturation of the soil. Surface filters and bioretention areas are generally subject to similar problems. Subsurface filters, while less susceptible than surface filters, may demonstrate poorer performance in the winter due to freezing in underdrain pipes or the filter medium. Filters which utilize organic medium are particularly prone to freezing because they retain water.

There is an increased likelihood of clogging of infiltration facilities and filters during winter operation due to the high sediment loads resulting from road maintenance activities (e.g., sanding and salting). There is an increased risk of groundwater contamination from road salt associated with winter operation of infiltration facilities that receive road runoff.

To prevent groundwater contamination and damage of water quality SWMPs may be activated several weeks before the average annual date of the first frost and deactivated in the spring when snowmelt is complete. In areas with curb and gutter servicing, the road system should be swept before by-passes are deactivated.

In most cases, filters and infiltration systems are part of a treatment train such that runoff which by-passes these SWMPs will still pass through downstream controls.

6.6 Maintenance enhancements

It is important that SWMP planners and designers consider maintenance activities in their design (see Chapter 4 for further details) including:

Access

A maintenance route should be established to allow vehicles access to SWMP. The slope of the access route should accommodate maintenance vehicles (i.e., 4:1 or flatter). Access to stormwater lot level controls may not be possible given the tendency for homeowners to construct fences, gardens, landscaping, etc.. If stormwater lot level or conveyance controls (i.e., enhanced swales or trenches) are proposed along rear lot lines, municipalities can obtain an easement for maintenance. The logistics of maintaining access to the easement will require considerable diligence/effort on the part of the municipality and may not be feasible.

Access to inlet and outlet structures, flow splitters, and by-pass manholes/chambers is also important. Access to an outlet structure for a pond or wetland can be provided by placing the outlet in a chamber in the embankment. Locating the outlet in a chamber enhances the aesthetics of the SWMP and reduces the potential for vandalism.

Forebays

Forebays are applicable for most end-of-pipe stormwater management facilities (wetlands, wet ponds, dry ponds, infiltration basins). Forebays allow the sediment deposits to be concentrated in one location thereby facilitating maintenance operations. To minimize the potential for scour and resuspension, forebays may have a deep permanent pool which should be drawn down for maintenance.

If water will remain in the downstream portion of the facility during maintenance, the berm between the forebay and the rest of the facility will need to be designed as a small dam. In cases where the forebay releases to a dry pond or infiltration basin, a gravity drainable pipe (if physically feasible) can be installed in the berm to draw down the forebay.

In cases where the forebay releases to a wet pond or wetland, there are two options. The water level in the downstream portion of the facility can be lowered until the berm is emergent. Water can then be pumped from the forebay to the downstream portion of the facility until the forebay is dry. Maintaining water in the downstream portion of the facility has the benefit of reducing the impacts to the aquatic and shoreline fringe vegetation. The second option would be to drain both facilities. This could be accomplished by either valved gravity draining maintenance pipes (if feasible) in both the forebay and the downstream portion of the facility, or by pumping if the facilities cannot be gravity drained.

Maintenance/drawdown pipe

Maintenance pipe should be provided to draw down a forebay’s permanent pool for maintenance. This maintenance pipe should be set near or at the bottom of the facility. If gravity drainage is not feasible, the facility will have to be pumped when maintenance is required. If possible, the pond should be drawn down early in the morning or overnight to reduce downstream thermal impacts. A geotextile filter bag should be attached to the end of the maintenance pipe to prevent the discharge of sediment from the facility into the receiving waters.

Pre-treatment

Adequate pre-treatment (oil/grit separators, roof leader filter traps, grassed swales) should be provided for infiltration or filtration SWMPs. These measures are described in Chapter 4.

Maintenance by-pass

Maintenance may take from several days to a week to perform. Storms during this time should be routed around the SWMP (see section 4.6). The by-pass should be located either at the inlet or slightly upstream of the SWMP. In piped systems, this is accommodated by fitting sluice gates to the by-pass pipe and SWMP inlet pipe in an upstream manhole. For maintenance operations, the gate to the SWMP can be closed and the gate to the by-pass pipe opened. This type of system can also be used for the seasonal operation of infiltration systems that accept road runoff.

Over-sizing SWMP storage

Over-sizing the storage provided in a SWMP compared to what is required to achieve performance targets will decrease the maintenance frequency in a SWMP. It is left to the discretion of municipalities to increase volume requirements for reduced maintenance frequency (if desired) beyond provincial/municipal water management requirements.

Sediment disposal areas

Where adequate land is available, sediment removal operations and costs can be reduced if an area is set aside for sediment disposal (e.g., when a stormwater pond is paired with a public park). These areas can be used for either permanent sediment disposal or temporary disposal (to allow the sediment to dry before transporting off-site for permanent disposal). Temporary drying areas are recommended for surface end-of-pipe stormwater management facilities that do not have a maintenance by-pass.

6.7 Monitoring

Stormwater monitoring is typically conducted at two levels:

Watershed and subwatershed monitoring

As noted previously, stormwater is best managed within the context of a watershed and subwatershed plan. These plans will normally contain a monitoring component to track implementation of the plan. The monitoring program will typically include administrative monitoring, water chemistry, biological monitoring, flow and erosion monitoring. These monitoring programs are essential to the success of the Plan. Subwatershed monitoring will normally be conducted or administered by the local conservation authority or municipality.

Facility monitoring

The consensus of opinion among practitioners is that monitoring for chemistry or biotic parameters cannot be justified for each individual facility because to have any scientific validity a large and costly sampling program is required. The approach generally used within the province is physical operation monitoring by the proponent to verify that the facility is operating as designed and detailed pilot site monitoring through research programs to evaluate effectiveness issues. The designer is advised to consult with authorities regarding site-specific requirements because some jurisdictions have additional monitoring requirements.