Barn fires in Ontario

Learn about the leading causes of barn fires in Ontario and how to prevent them.

Introduction

Barn fires are a major concern for Ontario farmers. Along with the sizeable financial loss, farm operation losses include equipment, livestock, business interruption, loss of production and extreme stress on the farm family. The Ministry of Agriculture, Food and Rural Affairs (OMAFRA) brought together several agencies and groups to address the potential for life and/or property loss by identifying best practices in the industry and potential changes to regulation.

The committee published a book titled, Reducing the Risk of Fire on your Farm. The book includes several recommendations to prevent and reduce the impact of fires on the farm.

As farms have grown larger, farm buildings have increased in size and value. When these large structures catch fire, they are more difficult to extinguish and the financial losses are significantly greater. Data from the Ontario Office of the Fire Marshal and Emergency Management indicates while the number of fires has been trending downwards over the past ten years, the value of the losses has been increasing due to the size of the barns and the increase in rebuilding costs.

While response to a fire is important, prevention is critical.

Main causes of barn fires

The Ontario Office of the Fire Marshal and Emergency Management provides yearly data for the causes of barn fires. In each year, the leading causes for preventable, determined fires were:

- mechanical/electrical failure

- misuse of ignition source/equipment

- design/construction/maintenance deficiency

The cause of fire for approximately 40 per cent of cases is reported as undetermined. This is due to the complete loss of the structure and contents, making it very difficult to determine an exact cause.

Primary sources of ignition

The data suggests that the primary sources of ignition fall within the following classes:

- electrical distribution equipment (for example, circuit wiring, distribution equipment, extension cords, etc.)

- heating equipment (for example, central heating, flue pipe, space heaters, etc.)

- open flame (for example, cutting/welding, blow torch, smoking, etc.)

- miscellaneous (for example, chemical reactions, such as spontaneous combustion and lightning)

Electrical distribution equipment — a common cause of ignition

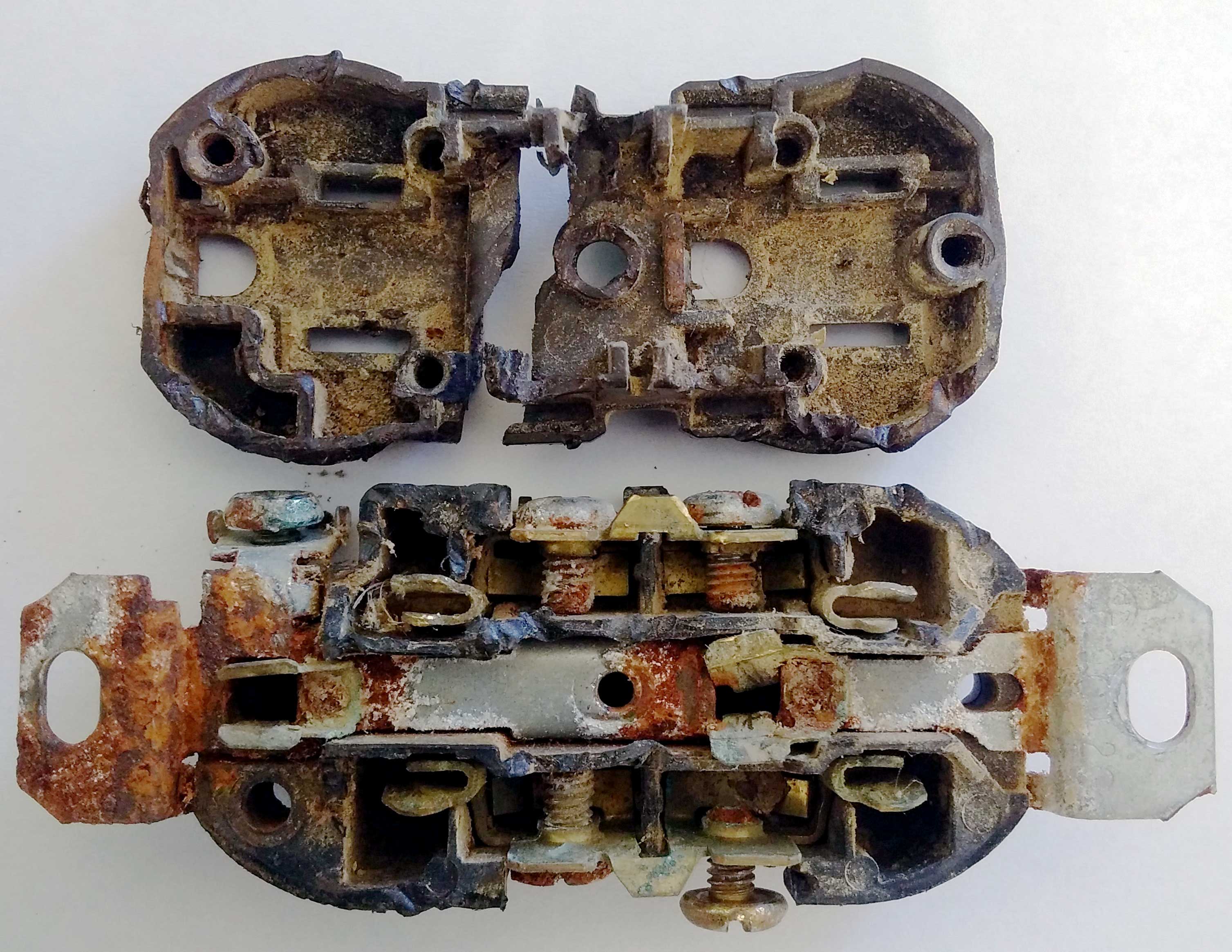

The insurance industry and the Electrical Safety Authority (ESA) have investigated the challenges with electrical systems. The corrosive environment found inside barns has been determined to be the leading cause of degradation or failure of electrical equipment. The degradation is typically corrosion of the exposed metal components (i.e., wires, connections, etc.).

Source: Heartland Farm Mutual, Waterloo, Ontario.

The ESA issued bulletin, 22-3-* Electrical Equipment in Confinement Barns specifies the type of wiring and equipment to be used inside livestock barns. It also recommends that all non-essential equipment and equipment incorporating over current devices are installed in locations separated from the livestock confinement areas and supplied with clean, dry temperature-controlled air.

Equipment maintenance in farm buildings

Have a qualified electrician conduct regular inspections of electrical and mechanical equipment, checking for signs of deterioration and/or corrosion of equipment in farm buildings. All items that are considered unsafe or questionable should be repaired or replaced immediately.

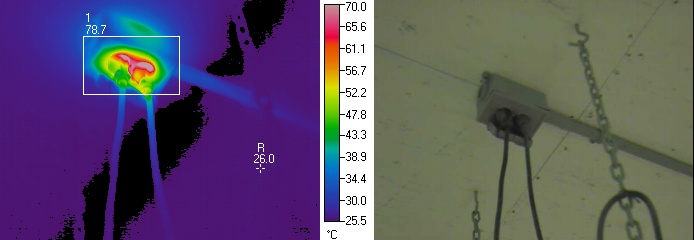

Some insurance companies conduct inspections of electrical equipment (for example, panels and plugs) using infrared cameras to look for hot spots (overheating) as a way to detect corrosion issues.

The OMAFRA fact sheet, Electrical Systems in Barns provides information on how an electrical system can start a fire, applicable regulations and barn electrical maintenance practices.

Source: Randy Drysdale.

General maintenance around farm buildings

Perform regular housekeeping activities around buildings to remove potential combustible materials. This includes mowing of vegetation and the regular removal of garbage inside and around buildings. Trim or remove all trees that are in close proximity to the buildings.

Properly site and manage on-farm fuel storage facilities away from buildings. This ensures flammable vapours released during refuelling of vehicles or filling of storages are not drawn into the buildings but disperse into the atmosphere.

More general and equipment maintenance best management practices are described in OMAFRA fact sheet, 10 Ways to Reduce the Risk of Barn Fire.

How to stop fire spread between farm buildings

The National Farm Building Code of Canada specifies that concealed spaces in ceilings, roof or attics shall be separated by fire stops so that no dimension of such space exceeds 30 meters (100 feet).

The Ontario Building Code prohibits the use of exposed foamed plastic insulation on interior surfaces of buildings. This combustible material must be covered or protected by an appropriate fire rated material if it is used in a building.

Build an all-season roadway, capable of supporting the weight of heavy equipment, around the farm building site and maintained so that it is accessible 365 days of the year.

Equip all buildings with a minimum five-pound ABC fire extinguisher at each exit and in all mechanical and feed rooms. If there is a standby generator housed in the building, the room housing the generator should be equipped with a minimum 10-pound ABC fire extinguisher. This generator room should also be separated from other areas of the barn by fire-rated construction.

Additional information on construction code regulations is found in the OMAFRA fact sheet, Building Permit Requirements to Construct, Expand or Renovate Farm Buildings.

Spontaneous combustion and hay fires

Lives have been lost and hay crops destroyed because of fires caused by spontaneous combustion. If the hay crop is put into the mow above 20-25% moisture content, spontaneous combustion may occur.

A hay crop that is placed too wet into a storage will heat rapidly. If the volume of hay stored is so large that heat loss is restricted, the internal temperature will rise. As the temperature rises above 130°F (55°C), a chemical reaction occurs and may sustain itself. This reaction does not require oxygen, but the flammable gases produced are at a temperature above their ignition point. These gases will ignite when they come in contact with the air.

Check your hay regularly. If you detect a slight caramel odour or a distinct musty smell, chances are your hay is heating.

If you suspect your hay is over-heating, make a simple probe and insert it into the hay mass to check the temperature. A probe can be made from a 3-meter (10 feet) piece of electrical tubing. Rivet a hardwood pointed dowel to one end and drill 8, 4.7-millimeter (3/16 inch) diameter holes in the tube just above the dowel. Drive the probe into the hay mass and lower a candy thermometer on a long string into the probe. Leave the thermometer in the probe for 10 minutes to ensure an accurate reading.

Watch for the following temperatures:

- 65°C (150°F) Entering the Danger Zone. Check temperature daily.

- 70°C (160°F) Danger! Measure temperature every four hours and inspect mow.

- 80°C (175°F) Call the Fire Department! Wet hay down and remove from the barn.

- 85°C (185°F) Hot Spots and Pockets May be Expected. Flames will likely develop when heating hay comes in contact with the air.

- 100°C (212°F) Critical! Temperature rise is rapid above this point. Hay will almost certainly ignite.

Caution: Do not attempt to walk on top of the stored hay mass. Pockets may have already burned out under the hay surface.

Use extreme caution when fighting a hay fire if the hay has been treated with chemical preservatives. Advise the fire fighters if the hay has been treated with preservatives containing ethoxyquin and BHT (butylated hydroxytoluene). These products will produce the very deadly hydrogen cyanide gas when heated above 115°C (240°F). However, hay treated with propionic acid products does not produce hydrogen cyanide during a fire.

In the past, many farmers sprinkled salt on hay as it was placed into storage in an effort to prevent hay fires. Testing has shown that salt has no effect on controlling spontaneous combustion. Dry ice, liquid nitrogen or carbon dioxide gas pumped into the hay will prevent combustion by eliminating the oxygen from the hay mass. Normally to extinguish a hay fire, all of the hay must be removed from the storage in order to locate any hot spots and spray them with water.

Spontaneous combustion is not an accident. By following good storage practices, not only will spontaneous combustion by avoided, but a higher quality of hay will be obtained.

What you can do

Monitoring and inspecting your buildings and equipment goes a long way in preventing a fire on your farm:

- Have your buildings inspected and maintained regularly by a licensed electrical contractor.

- Develop a preventative maintenance and housekeeping schedule to reduce the risks of a fire.

- Monitor the heat conditions of your barn using infrared technologies.

- Work with your local fire department and insurance company to identify problem areas on your farm and fix any trouble areas identified.

- Ensure you have an adequate number of fire extinguishers and they are in good working order.

- Discuss with your family and employees what to do if there is a fire (who to call for help, establish a safe meeting point, etc.).