10. Yield Test

Chapter Description

This chapter discusses the reasons, procedures and methods of measuring water levels in the well and testing the well yield. The requirements under the Wells Regulation are introduced and discussed. It also summarizes what should be done with the discharge water from the testing process, keeping in mind potential contamination and other environmental concerns. This chapter does not cover pumping tests designed to determine aquifer performance and characteristics.

Regulatory Requirements - Yield Test

Relevant Sections - The Wells Regulation

- Well Yield – Sections 14.9 to 14.10

- Installation of Equipment – Section 15.3

The Requirements - Plainly Stated

Unless exempt, the Wells Regulation requires the following when testing the yield of the well:

When to Perform a Test of the Yield of the Well

The person constructing the well must test the yield of a well before the well’s structural stage is complete.

Exemptions – Testing Yield of Well

Testing the yield of the well is not required in any of the following situations:

- the well or activity is exempt from the Wells Regulation,

- a minor alteration,

- an installation of a pump, or

- an alteration that only involves:

- the removal of the casing above the ground surface so that the casing is flush with the ground surface (test holes and dewatering wells only, see “Casing Height When Performing Work On or Near a Well” section of Chapter 11: Maintenance & Repair),

- the addition of casing above the ground surface, or

- the addition or removal of a well pit.

Reminder: For further information on the term “minor operation” see Chapter 2: Definitions & Clarifications, Table 2-1.

Equipment

A person who installs equipment in a well must ensure that the equipment is clean.

Reminder: For further information on the term “clean” see Chapter 2: Definitions & Clarifications, Table 2-2.

When to Measure and Record Water Levels

When testing the well yield, the water level in the well must be measured and recorded as follows:

- immediately before commencement of pumping,

- at 1 minute intervals or more frequently during the first five minutes of pumping,

- at 5 minute intervals or more frequently during the next 25 minutes of pumping,

- at 10 minute intervals or more frequently during the next 30 minutes of pumping,

- at 1 minute intervals or more frequently during the first five minutes after pumping stops,

- at 5 minute intervals or more frequently during the next 25 minutes after pumping stops, and

- at 10 minute intervals or more frequently during the next 30 minutes after pumping stops.

Devices to Use to Record Water Levels

When measuring the water level, the person constructing the well must use a clean plastic or metal tape or an air line or clean electrical device

Exemption – Measuring Water Levels

The above water level measurement requirements do not apply if the design of the well does not allow for the water level in the well to be measured during the yield test.

The water in the well, however, must still be pumped as stated in the “Measuring and Recording the Pumping Rate section of the Plainly Stated.

Measuring and Recording the Pumping Rate

The person constructing the well must

- pump the water from the well, at a steady rate, continuously for at least one hour, and

- record the rate of pumping during the test on the well record.

If water cannot be pumped from the well continuously for one hour, no further measurements are required and the person constructing the well must record the following on the well record:

- the reason pumping was discontinued,

- the rate of pumping and the length of the pumping period, and

- the water level measurements made.

Relevant Guidelines

Procedure D-5-5 titled Technical Guideline for Private Wells: Water Supply Assessment, by Ministry of the Environment, Last Revision, August 1996.

Relevant Sections - Additional Regulations Or Legislation

Ontario Water Resources Act section 30 – Discharge of Polluting Material Prohibited (Impairment of Quality of Any Waters)

Ontario Water Resources Act section 34 – Taking of Water (Permit to Take Water)

Ontario Water Resources Act section 53 – Sewage Works (Environmental Compliance Approval)

Key Concepts

Importance Of The Yield Test

The well yield test provides important information about:

- performance of the well, and

- some initial characteristics of the aquifer at the time that the well is tested.

The yield test information is used for a variety of purposes including, but not limited to:

- determining the sustainable rate at which the well will produce water

- selecting the appropriate pump size and type

- determining if conditions have changed that may indicate problems

Reminder: The yield test, as required by the Wells Regulation, is not for testing aquifer characteristics. For further information on aquifer characteristic testing please see: Technical Guidance Document For Hydrogeological Studies In Support of Category 3 Applications for Permit to Take Water published by the Ministry of the Environment, Operations Division, April 2008.

Reminder: There is no minimum sustained rate for a residential water supply specified in the Wells Regulation. The yield test is a tool to inform the well owner of an estimate of the sustained rate at which the well can be pumped. For further information on residential and livestock water needs see: “Best Management Practices – Water Wells

Pumping Rate And Measurements

The Wells Regulation - The person constructing the well must meet the following measurement and pumping requirements when conducting a test of the yield of the well:

- immediately prior to pumping, the water level must be measured and recorded,

- the well must be pumped continuously, and at a steady rate throughout the test, and the pumping rate must be sustained for at least one hour,

- the pumping rates must be recorded on the well record,

- the pumping water levels must be measured and recorded:

- at 1 minute intervals or more frequently for the first 5 minutes,

- at 5 minute intervals or more frequently for the next 25 minutes, and

- at 10 minute intervals or more frequently for the remaining 30 minutes of the test, and

- the recovery water levels must be measured and recorded at the same time intervals as outlined in the previous bullet.

Reminder: The recovery starts immediately after the pump has been shut off

Best Management Practice – Pumping Rate and Measurements

Installation of a dedicated and portable submersible pump and equipment used only for the purposes of conducting well yield tests (dedicated pump), will assist in conducting a steady rate (constant rate) yield test.

The pumping rate during the yield test should be similar to the intended pumping rate in order to replicate the well’s probable water levels and usage.

The rate selected should take into consideration the volume of water that is in storage in the well to ensure that the test is conducted in a fashion that clearly identifies the sustainable yield of the well.

Pumping rates should be measured accurately and be recorded at least as often as water level measurements at 5 minutes of intervals.

ASTM D5737-95(2006) – “Standard Guide for Methods for Measuring Well Discharge

Water levels should be measured with accurate meters such as an electrical device.

Conducting The Yield Test

The Wells Regulation - To be effective, a pumping test must be accurate. While there are several methods for determining approximate yield, such as the bailer method or the air lift method, only the pump method is an acceptable testing method according to the Wells Regulation.

Only a pump, such as a submersible, jet or shallow lift pump with appropriate control devices and valves, can be used to pump a well continuously, and at a steady rate, for at least one hour.

A bailer cannot be used to conduct the yield test as water is not being pumped at a continuous and steady rate.

Also, using a compressor and blowing air down drill rods cannot be used to conduct the yield test. This action disturbs the water levels in the well during the test and does not produce a continuous and steady rate of pumping. In addition, the bottoms of the drill rods are typically used as the measuring point for water levels. It is impossible to accurately measure the water levels during this disturbance. It is also impossible to accurately measure the water levels after pumping has stopped using this method because the water levels will rise above the bottom of the drill rods.

Permit To Take Water

A Permit to Take Water under the Ontario Water Resources Act is required for many types of water takings, including pumping a well for a yield test, that are greater than 50,000 L/day (11,000 G/day). Therefore, the person constructing the well should estimate the taking of water during the entire test before conducting the test. If the estimate shows the test will take more than 50,000 L/day, then the person constructing the well needs to obtain a Permit To Take Water from the Ministry prior to construction. Visit Permit to Take Water website for more information.

Considerations When Conducting A Yield Test

The person conducting the yield test will need to:

- determine the yield test equipment needed to pump the well. For example:

- determining the size and type of pump such as:

- a submersible pump, and

- a jet pump.

- ensuring the appropriate discharge lines are clean and will not impair the quality of the water. The waterlines should meet potable water specifications (e.g., NSF International).

- determing the type of flow metering and control devices such as:

- a gate valve,

- an orifice or rectangular weir,

- a constant flow restrictor valve (dole valve),

- a rotameter,

- a calibrated bucket or barrel,

- a high capacity flow meter, and

- a manometer

- determining the type of water level measuring devices such as:

- an electrical device (e.g., water level meter, sonic meter, pressure transducer with datalogger),

- an air line, and

- a tape measure.

- determining the size and type of pump such as:

- clean all of the equipment to be used in the well. The person should follow the sanitary practices found in “Sanitary Practices” section in Chapter 8: Well Disinfection, to ensure equipment is clean.

- set the intake in the well at a depth to make best use of available drawdown.

- select an appropriate location for the discharge. The person should follow the “Handling Water Discharge” in this chapter for further guidance.

- prevent any backflow of water down through the riser and discharge pipes and into the well. This is important to minimize the risk of contamination and interference with recovery water level measurements.

- measure and record the static water level.

- Begin pumping at a steady rate and pump continuously for at least one hour. Pumping rates should be measured accurately and should be recorded at least as often as water level measurements after 5 minutes of pumping. See the “Best Management Practice – Pumping Rate and Measurements” in this chapter.

- measure and record the pumping water level measurements. See the “Pumping Rate and Measurements” section and “Recording Yield Test Results” section in this chapter.

- shut down the pump at the end of the pumping portion of the test. The exact time and water level when the pumping stops must be observed and recorded. This is time zero of the recovery portion of the test.

- measure and record recovery water levels for at least the next hour. See “Pumping Rate and Measurements” section and “Recording Yield Test Results” section in this chapter.

Best Management Practice – Extending the Pumping Time Past Minimum Requirement

A longer pumping test provides more information to:

- determine the sustainable yield of the well, and

- provide greater confidence that the well can sustain the desired rate.

Handling Water Discharge

The discharge water from a yield test must not cause an adverse effect to the natural environment and should not affect the yield test. To reduce risks, the following should be considered:

- during the yield test, water should be discharged a sufficient distance away from the well being pumped to minimize or eliminate recharge of this water to the aquifer during the test,

- water discharged during the yield test should not be allowed to pond or collect near the well, and

- the location of the discharge take potential environmental impacts such as erosion, impairment of surface water bodies and off-site flooding into consideration (see Sewage Works Approvals section in this chapter).

Sewage Works And Other Discharge Approvals

A sewage works Certificate of Approval under the Ontario Water Resources Act may be required if the person discharges the water from the well owner’s property and the discharge capacity exceeds 10,000 litres per day. It is important for the person to determine if an environmental compliance approval is required before discharging the well water during the testing of the well yield. A guide to explain the sewage works process can be found on Ontario.ca.

If the discharge of water will be into a sanitary or storm sewer during a yield test, the person may require an approval for the discharge of water to the sanitary and storm sewer collection system. In cases where water well be discharged into a sanitary or storm sewer, a person should contact the applicable upper and lower tier municipalities early in the planning process to determine if any specific approvals are required by the municipality along with the process to obtain the required approvals.

Recording Yield Test Results

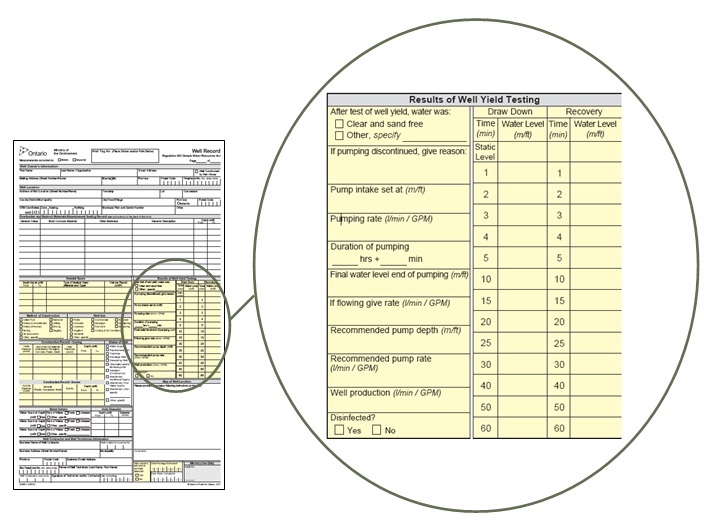

Figure 10-1 shows the details that are required on the well record. Further details are shown in Chapter 9: Equipment Installation and Chapter 13: Well Records, Documentation, Reporting & Tagging.

Figure 10-1: Well Record - Test Of Well Yield

- After test of well yield, water was:

- Clear and sand free

- Other, specify

- If pumping discontinued, give reason

- Pump intake set at (m or ft)

- Pumping rate (l/min or GPM)

- Duration of pumping: hours + minutes

- Final water level end of pumping (m or ft)

- If flowing give rate (l/min or GPM)

- Recommended pump depth (m or ft)

- Recommended pump rate (l/min or GPM)

- Well production (l/min or GPM)

- Disinfested? Yes or No

- Draw Down

- Time (minute)

- Water level (m or ft)

- Recovery

- Time (minute)

- Water level (m or ft)

- Static level

Reasons For Discontinuing The Yield Test

The Wells Regulation - If water cannot be pumped from the well continuously for one hour, no further measurements are required and the following must be recorded on the well record:

- Reason pumping was discontinued

- Rate of pumping and the length of the pumping period

- Water level measurements made. This includes all recovery water level measurements made after pumping stops. Recovery water levels must be measured and recorded:

- at 1 minute intervals, or more frequently, for the first 5 minutes after pumping stops,

- at 5 minute intervals, or more frequently, for the next 25 minutes after pumping stops, and

- at 10 minute intervals, or more frequently, for the remaining 30 minutes after pumping stops.

Some reasons for discontinuing the test include:

- the well running dry,

- encountering poor water quality, or

- the pumping of the groundwater is causing a quantity or quality interference problem with other wells.

Reminder: Equipment breakdown is not an acceptable reason for discontinuing the yield test as it is expected that the test will be re-done. Use well maintained equipment and fully charged generator sets.

Best Management Practice – Re-Doing Yield Test if the Well is Pumped Dry

If the initial yield test shows the well cannot be pumped for one hour, the person constructing the well should have obtained enough information to estimate well’s actual sustainable yield. To provide the well purchaser with an understanding of the well’s actual sustainable rate, the person constructing the well should re-do the yield test at the lower estimated rate using the minimum requirements of the Wells Regulation outlined in this chapter. The information gathered from the second test can be provided on the well record in place of the initial test.

Data Accuracy

The yield test data provides important information for the person installing the pump, the well purchaser and the well owner. It is important to fill out the well record with care and as accurately as possible. The yield of a well can change significantly over time. The well record data provide necessary background information to assist in the determination and resolution of potential problems with the well. This could include water quality, quantity or operational problems.

For example:

- The original well record showed a recommended pumping rate of 45 LPM (10 GPM) and the static water level of 5 m (16ft). A current pumping test shows that the well is yielding 5 LPM (1.1 GPM) and the static water level of 20 m (65ft). The decrease in the flow and the lower static water level suggests a problem associated with the aquifer as opposed to a problem with the pump equipment. This could be a result of nearby water taking or clogging of the well by biofilm or mineralization.

In many locations, the well records provide the only usable information on aquifer withdrawal rates. For example:

- Professional Geoscientists or Professional Engineers use the background information found on area well records to prepare for studies to evaluate area aquifers,

- in real estate transactions, the pumping test information is used to assist in determining if the well will meet the demands of the purchaser,

- a person constructing a new well can use area well records to estimate the rate of flow for a potential new well, and

- well records can assist a person constructing a well with determining the type of equipment to bring to the site.

Yield Test Terminology And Formulas

The following formulas illustrate how the data, collected during the yield test, can be used to determine drawdown and other characteristics to assist in determining equipment requirements as well as assist in troubleshooting.

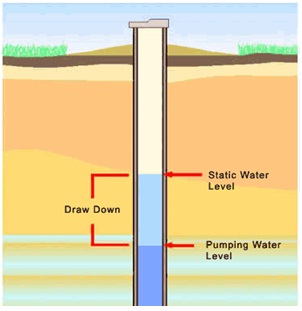

Drawdown

The following formulas illustrate how the data, collected during the yield test, can be used to determine drawdown and other characteristics to assist in determining equipment requirements as well as assist in troubleshooting.

Drawdown = PWL − SWL

This difference represents the force that causes water to flow through an aquifer toward a well at the rate that water is being withdrawn from the well. The drawdown can be expected to increase as the pumping rate is increased.

Figure 10-2: Drawdown Diagram

Residual Drawdown

After pumping is stopped, the water level rises and approaches the original static water level. During water level recovery, the distance between the recovery water level (RWL) and the initial static water level (SWL) is called residual drawdown.

Residual Drawdown = RWL − SWL

Specific Capacity

Specific capacity is the pumping rate divided by the drawdown (L/min/m or GPM/foot). The specific capacity is a measure of the drawdown caused by the pumping rate and is used as a basis for determining the well’s performance. The specific capacity usually changes with both pumping rate and time.

Specific Capacity of a well = Pumping Rate ÷ Drawdown

Example:

- The pump is located 18 m (60ft) below ground surface and draws the water down to 15 m (50ft). The static water level is 9 m (30ft). The well is pumping at 45 L/min (10 GPM)

Drawdown = 15 m − 9 m = 6 m (50ft − 30ft = 20ft)

Specific Capacity = 45L⁄min⁄6 m = 7.5 L/min/m (10 GPM⁄20ft = 0.5 GPM/ft)

Footnotes

- footnote[1] Back to paragraph Agriculture and Agri-food Canada, Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA). 2003. “Best Management Practices - Water Wells, Revised Edition.” 2003.

- footnote[2] Back to paragraph (DOI: 10.1520/D5737-95R06). ASTM International, West Conshohocken, PA, ASTM website.

- footnote[3] Back to paragraph Agriculture and Agri-food Canada, Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA). 2003. Best Management Practices - Water Wells, Revised Edition, 2003.