6. Constructing the Hole, Casing & Covering the Test Hole or Dewatering Well

Chapter Description

This chapter covers common test hole or dewatering well construction methods and materials used in Ontario. The minimum requirements for the hole, casing and well screen and advantages and disadvantages of test holes or dewatering wells constructed using different equipment and materials are also covered. This chapter is structured to parallel the steps involved in the construction of the hole, installation of the casing, creation of the annular space and, where used, installation of the well screen and filter pack material. The filling of sealant in the annular space is covered in Chapter 7: Annular Space & Sealing. Multi-level monitoring test hole installations are covered in Chapter 8: Multi-Level Monitoring Test Holes. The requirements listed in this chapter do not apply to shallow works or other exempted wells discussed in Chapter 3: Exemptions: Wells, Activities & Experienced Professionals.

Regulatory Requirements - Hole & Casing

Relevant Sections - The Wells Regulation

Log & Field Notes – Section 12.1

Covering of Well – Section 12.2

Surface Drainage – Section 12.3

Well Pits – Subsections 12(7.1), 12(9) paragraphs 1 to 3

Casing – Section 13

Deepening of Wells – Section 13.1

Annular Space – Subsection 14.2(1), Subsection 14.2(2) paragraph 2, Subsection 14.3(1), Subsection 14.4(1), Subsection 14.4(2) paragraph 3, Subsection 14.4(3)

Double Walled Casing – Section 14.6

Information – Subsection 16(3)

Abandonment – Subsection 21(7)

The Requirements - Plainly Stated

Reminder - Figures 6-24 to Figures 6-33 at the end of this chapter show many of the requirements listed in the Plainly Stated section.

The Wells Regulation requires a person constructing a test hole or dewatering well to meet the following, unless an exemption is provided in this section or in Chapter 3: Exemptions: Wells, Activities & Experienced Professionals

Log Book and Field Notes

The person constructing a well must have an onsite, current and detailed:

- log of overburden and bedrock materials encountered when advancing the hole, and

- field notes regarding the construction of the well.

Exemptions - Log Book

The person constructing the well is required to keep up-to-date field notes but is not required to have a log of overburden and bedrock materials if the person is constructing the well by the use of a driven point (e.g., some direct push technology, or jetting).

Reminder - For further information on log books and field notes see Chapter 15: Well Records, Documentation, Reporting & Tagging.

Covering the Well

Whenever a test hole or dewatering well is left unattended during construction, the person constructing the test hole or dewatering well must cover the upper open end of the well securely in order to prevent the entry of surface water and other foreign materials.

Minimum Depth of a New Well

If a new well, other than a test hole or dewatering well, is being constructed, it must be at least 6 m (19.7′) deep unless the only useful aquifer is shallower.

In cases where the only useful aquifer if less than 6 m (19.7′) deep, the well, other than a test hole or dewatering well, must be at least 3 m (10′) deep.

Reminder - For clarification of the term “useful aquifer” see Chapter 2: Definitions & Clarifications, Table 2-3).

Exemptions - Minimum Depth of a New Test Hole or Dewatering Well

The minimum well depth requirements stated above do not apply to a new test hole or dewatering well. Other depth requirements may apply to the construction of a test hole or dewatering well (see the following two sections).

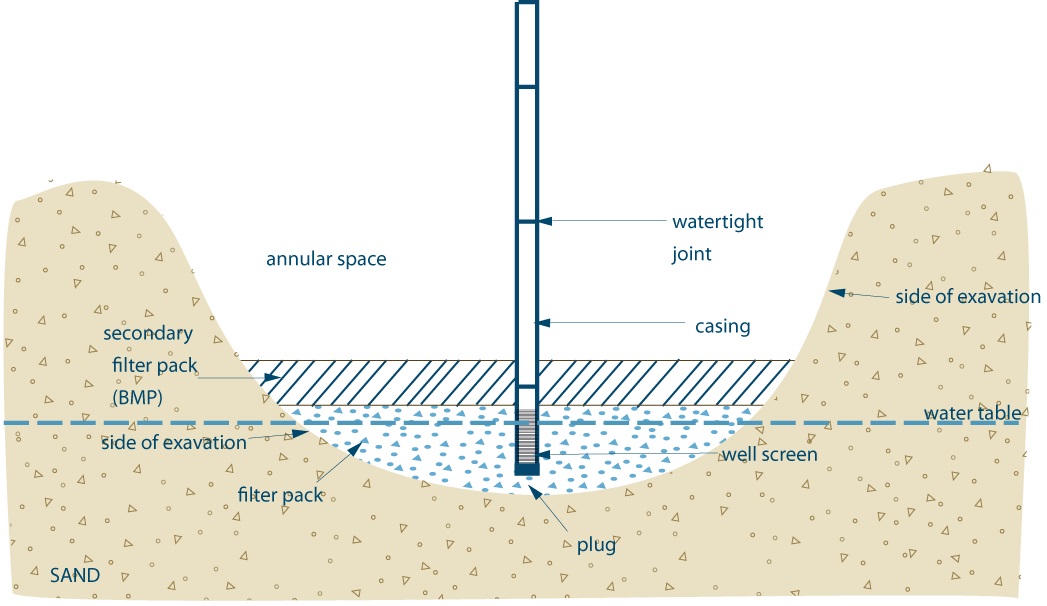

Minimum Depth of a New Test Hole or Dewatering Well with a Well Screen

In cases where a new well with a well screen is constructed by a method other than digging or by the use of a driven or jetted point, the annular space shall be filled with clean, washed gravel or sand:

- from the bottom of the well screen to at least the top of the well screen, and

- not closer than six metres to the ground surface, unless the only useful aquifer available necessitates a shallower well, in which case the top of the gravel or sand shall not be closer than 2.5 metres to the ground surface.

Reminder - Where a well screen is placed in a shallow aquifer (i.e. < 6 m deep), the depth of the new test hole or dewatering well must be such that the top of the gravel or sand in the annular space will not be closer than 2.5 metres (8.2’) to the ground surface.

Exemption - Minimum Depth of a New Test Hole or Dewatering Well with a Well Screen

The depth requirement for the top of the sand and gravel layer does not apply if the new test hole or dewatering well is scheduled to be abandoned not later than 180 days after completion of its structural stage.

This requirement does not apply if the well is constructed with a casing surrounded by a larger permanent outer casing (sometimes referred to as a double walled casing).

The depth requirement for the top of the sand and gravel layer does not apply to wells constructed by digging or by the use of a driven or jetted point.

Reminder - See Chapter 7: Annular Space & Sealing and Chapter 8: Multi-Level Monitoring Test Holes for further information on requirements for a casing surrounded by a permanent outer casing.

Records of Site Condition Regulation - *See the notes below this “Plainly Stated” section for requirements related to monitoring wells constructed as part of an ESA under O. Reg 153/04.

Well Casing and Well Screen Materials for a New Well

The casing and well screen for a new well must:

- be made of new materials,

- be clean and free of contamination, and

- not cause contamination of the water with which they are in contact.

Reminder - The requirement for a casing and well screen to be made of new materials prohibits the re-use of a casing or well screen that was previously installed in a finished well (i.e. where its structural stage has been completed). The requirement for a casing to be made of new materials does not apply to starter (working) casing.

Exemptions (180 Day Rule) - Well Casing and Well Screen Materials for a New Test Hole or Dewatering Well

The requirement for use of new materials for casing and well screen does not apply to a test hole or dewatering well if abandonment of the test hole or dewatering well is scheduled to take place not later than 180 days after completion of the structural stage of the test hole or dewatering well.

Records of Site Condition Regulation - See the notes below this “Plainly Stated” section for requirements related to monitoring wells constructed as part of an ESA under O. Reg 153/04.

Well Casing Sections for a New Test Hole or Dewatering Well

- Any casing must be watertight.

- Only continuous sections of casing (e.g., no holes or perforations or slots in the well casing) can be used in the construction of a new well.

Well Casing Seams for a New Test Hole or Dewatering Well

Any seams in the casing must be permanent and watertight.

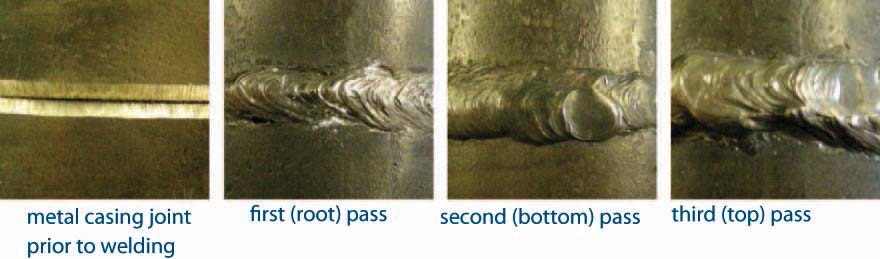

Well Casing Joints for a New Test Hole or Dewatering Well

Joints in the casing are not allowed, unless they:

- achieve a permanent, watertight bond, such as welded steel joints, and

- are made such that the jointed casing does not impair the quality of water with which it comes in contact.

Concrete Well Casing and Casing Joints for a New Test Hole or Dewatering Well

If the casing is concrete:

- it must be fully cured and commercially manufactured,

- the concrete sections must be properly aligned so the joints are flush and the casing is centered, and

- the sections must be joined with a mastic sealing material that remains pliable and waterproof and is approved for potable water use by NSF International.

Reminder - For clarification of the terms “permanent,” “watertight” and “waterproof” see Chapter 2: Definitions & Clarifications, Table 2-3.

Exemption (30 Day Rule) - Well Casing for a New Test Hole or Dewatering Well

A new test hole or dewatering well is not required to be cased if both of the following conditions exist,

- abandonment of the test hole or dewatering well is scheduled to take place not later than 30 days after completion of the structural stage of the test hole or dewatering well, and

- the person constructing the test hole or dewatering well covers the upper open end of the well securely in a manner sufficient to prevent the entry of surface water and other foreign materials whenever the test hole or dewatering well is left unattended.

Casing Material Specifications

The minimum casing specifications (e.g. wall thickness, ASTM standard, potable water use) for new wells in the Wells Regulation do not apply to test holes or dewatering wells. Information on casing material including strength, advantages and disadvantages can be found in the “Casing Material” section on page 66 of this chapter.

Minimum Length of Well Casing Underground for a New Water Supply Well

Where the useful aquifer is greater than 6 m (19.7′) below the original ground surface, the casing for a new well, other than a test hole or dewatering well, must extend at least 6 m (19.7′) below the original ground surface.

If the only useful aquifer is located between 3 m to 6 m (10′ - 19.7′) below the ground surface, the casing for a new well, other than a test hole or dewatering well must extend at least 2.5 m (8.2′) below the level of the original ground surface.

Reminder - For clarification of the terms “useful aquifer”, “permanent”, “watertight” and “waterproof” see Chapter 2: Definitions & Clarifications, Table 2-3.

Exemption - Minimum Length of Well Casing Underground for a New Test Hole or Dewatering Well

The minimum well casing length below the ground surface specified for a water supply well does not apply to a new test hole or dewatering well without a well screen or a new test hole or dewatering well with a well screen that has been constructed by digging, jetting or by the use of a driven point.

If a well screen is installed in some new test holes and dewatering wells, casing may need to extend to at least 2.5 metres below the ground surface (see the “Minimum Depth of a New Test Hole or Dewatering Well with a Well Screen” section and its exemptions in this section of this chapter).

Surface Drainage (Earth Mounding) around the Well

The person constructing the test hole or dewatering well must ensure that the slope of the ground surface (surface drainage) is such that water will not collect or pond near the well. Proper surface drainage can be ensured by properly mounding with earth around the well and outward from the well to direct surface drainage away from the well.

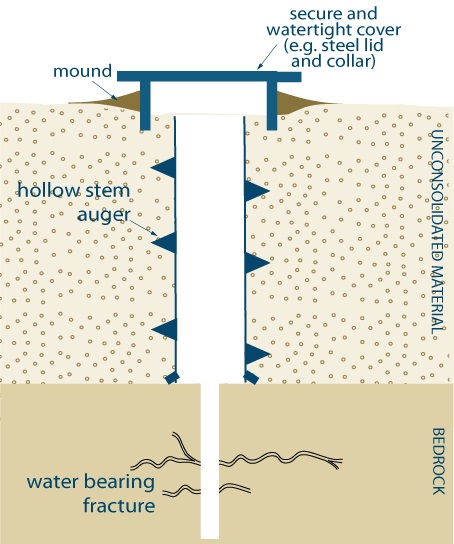

Extent of Casing for a New Test Hole or Dewatering Well in an Overburden Aquifer

Unless exempt, a new test hole or dewatering well that obtains water from an overburden formation must be cased:

- from the water intake zone,

- to at least 40 cm (16″) above the highest point on the ground surface within 3 m (10′) radially from the outside of the casing after the land is properly mounded for surface drainage as measured on completion of the well’s structural stage.

There are a number of exemptions to these casing requirements which will be discussed in this “Plainly Stated” section [e.g. an uncased well, a well constructed by use of a driven point and a well completed with a flush-mounted well pit (vault)].

Reminder - For clarification of the term “well’s structural stage” see Chapter 2: Definitions & Clarifications, Table 2-3.

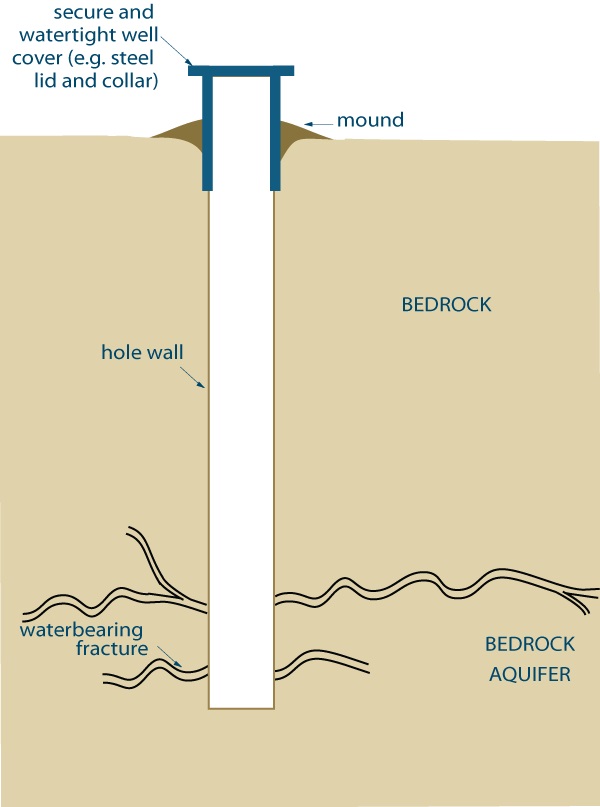

Extent of Casing for a New Test Hole or Dewatering Well in a Bedrock Aquifer

Unless exempt, a new test hole or dewatering well that obtains water from a bedrock formation must be cased:

- from the bedrock,

- to at least 40 cm (16″) above the highest point on the ground surface within 3 m (10′) radially from the outside of the casing after the land is properly mounded for surface drainage as measured on completion of the well’s structural stage.

There are a number of exemptions to these casing requirements which will be discussed in this “Plainly Stated” section [e.g. an uncased well, a well constructed by use of a driven point and a well completed with a flush-mounted well pit (vault)].

Sealing Casing in Bedrock for New Water Supply Wells

If the aquifer is located in a bedrock zone that is not weathered, the casing of a new drilled well, other than a test hole or dewatering well, must be sealed into the bedrock with suitable sealant to prevent impairment of the quality of the groundwater and the water in the well.

Exemption - Sealing Casing in Bedrock for New Test Holes or Dewatering Well

The requirement to seal a new casing for a water supply well into bedrock does not apply to test holes or dewatering wells.

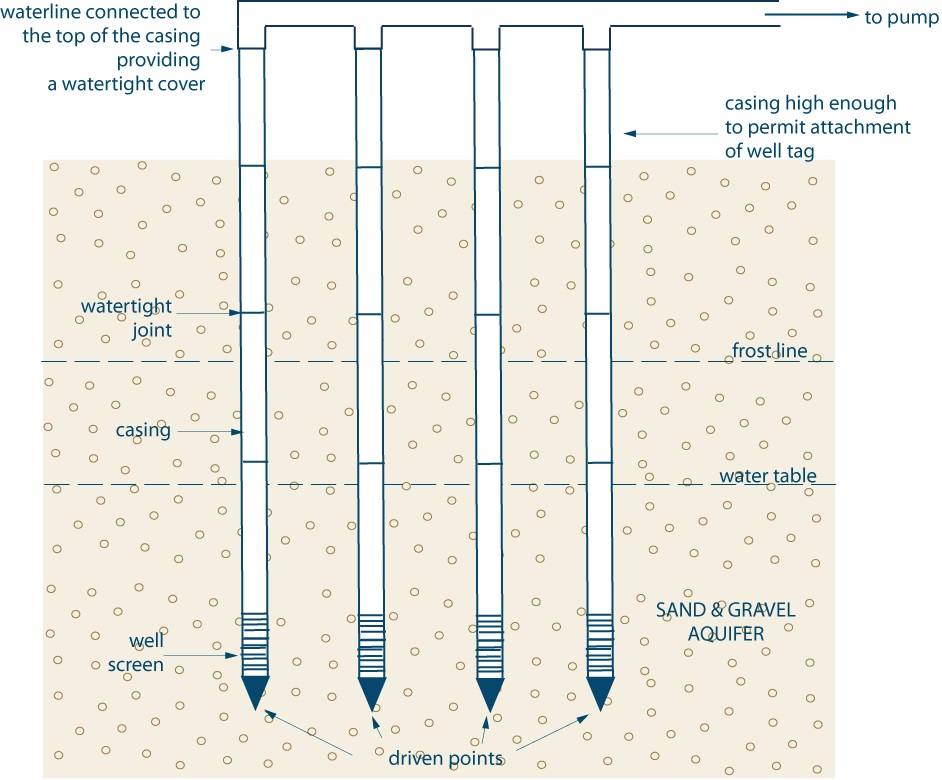

Exemption - Casing Height 40 cm Above Ground for New Driven Point or Jetted Point Test Holes and Dewatering Wells

An exemption to the minimum casing height requirement of 40 cm (16″) above the ground surface exists if the new well is made by the use of a jetted point or driven point, and it has a visible, permanent marker.

In these cases, the casing must:

- extend a sufficient height to permit the attachment of a well tag, and

- be at least as high as the highest point on the ground surface within a 3 m (10′) radius of the well’s casing for any new well after ground surface is properly mounded with earth to direct surface drainage away from the well as measured on completion of the well’s structural stage.

The permanent marker must also identify the location of the well and be visible at all times of the year.

Reminder - For additional information on casing height and surface drainage see Chapter 9: Completing the Test Hole or Dewatering Well Structure.

Reminder - For clarification of the terms “water intake zone,” “water producing zone” and “weathered bedrock” see Chapter 2: Definitions & Clarifications, Table 2-3.

Exemptions - Well Casing Height for a New Test Hole or Dewatering Well Completed with a Flush-Mounted Well Cover

A new cased test hole or cased dewatering well is not required to be cased above the ground surface if the well:

- is located where vehicle or pedestrian traffic is likely to pass directly over the well,

- is completed with a flush-mounted watertight commercially manufactured well cover sufficient to prevent entry of surface water and other foreign materials into the well, and

- has a cover that is sufficiently strong, durable and well-installed to protect the well from damage, or the well cover is covered with a metal plate that is sufficiently large and sufficiently strong, durable and well-installed to protect the well cover and the well from damage.

Reminder - For additional information on flush-mounted well covers, casing height and surface drainage see Chapter 9: Completing the Test Hole or Dewatering Well Structure.

Reminder - For additional information on flush-mounted well pits (vaults) see Chapter 12: Equipment Installation.

Casing Height and Mounding for a New Test Hole or Dewatering Well in a Well Pit that Does Not Use a Flush-Mounted Well Cover

If a new drilled well is constructed with a well pit that does not conform to the above requirements for a flush-mounted well cover, the top of the casing of the drilled well must be at least 40 cm (16″) above the floor of the well pit.

The well pit must be cased from the bottom of the well pit to at least 40 cm (16″) above the highest point on the ground surface within 3 m (10′) radially from the outside of the casing as measured upon completion of the well’s structural stage.

The ground surface around the new well pit must be properly mounded to prevent ponding near the well.

New Well Pit Construction for Wells

All new well pits are banned in Ontario, with the exception of:

- wells constructed by diamond drilling equipment that are used in connection with mineral exploration and

- test holes or dewatering wells completed with a properly constructed flush-mounted well pit (vault).

Reminder - See Chapter 12: Equipment Installation for well pit construction requirements.

Equipment and Attachments

A lightning rod is not allowed to be attached, directly or indirectly, to the casing of a well.

Deepening of an Existing Test Hole or Dewatering Well

If the well is deepened, all of the casing requirements and exemptions for new test holes and dewatering wells apply, but the existing casing can continue to be used if it appears sound.

A well is not allowed to be constructed by penetrating through the bottom of a bored or dug well by:

- means of drilling,

- the use of a jetted point, or

- the use of a driven point.

Information – Encountering Natural Gas

Where a test hole or dewatering well is constructed and natural gas is encountered, the person constructing the well must immediately notify the well purchaser, the owner of the land on which the well is situated and the Director that the condition exists.

Reminder - Detailed information, other construction requirements and annular space sealing requirements for new multi-level monitoring test hole installations are covered in Chapter 8: Multi-Level Monitoring Test Holes.

Reminder - The regulatory exemptions regarding test holes and dewatering wells allow for well technicians, engineers and geoscientists to use their professional expertise to design and install test holes and dewatering wells on a case by case basis as each situation is different.

Relevant Records of Site Condition Regulation Requirements

Records of Site Condition Regulation - Starting on July 1, 2011, O. Reg. 153/04 prescribes that the provisions of the Ontario Water Resources Act and of Regulation 903 of the Revised Regulations of Ontario, 1990 (Wells) made under that Act, that would apply to a test hole but for section 1.1, and subsections 13 (2), 14.1 (2), 14.2 (3), 14.3 (2), 14.4 (4) and 14.5 (3) of that regulation, apply to a monitoring well installed for the purpose of,

- a phase one environmental site assessment; and

- a phase two environmental site assessment.

Implications for the Qualified Person

The qualified person shall ensure that phase one and phase two environmental site assessments (ESAs) are conducted in accordance with the requirement stated above.

Implications for Casing, Well Screen and Annular Space for a New Test Hole

With respect to casing, well screen and annular space size and filling, the above requirement in O. Reg. 153/04 means that, if a new test hole is constructed and is scheduled to be abandoned not later than 180 days after the completion of its structural stage, and is to be used as a monitoring well in an ESA being conducted in support of a record of site condition, then:

- casing and well screen must be new material and the exemption for a test hole stated in this chapter does not apply,

- the annular space size and filling exemptions for a test hole stated in this chapter do not apply, and

- the annular space size and filling requirements for a test hole stated in Chapter 7: Annular Space & Sealing, Table 7-1A and Table 7-1B do apply.

Reminder - The above annular space requirements have been added to this chapter because of the minimum size of hole that is required to be created for an annular space and the installation of filter pack material in the annular space. The above requirement in O. Reg. 153/04 also affects obligations such as shallow works and annular space filling for monitoring wells. See Chapter 3: Exemptions: Wells, Activities & Experienced Professionals and Chapter 7: Annular Space & Sealing for further information.

Records of Site Condition Regulation - Please refer to O. Reg. 153/04 for RSC requirements.

Reminder - For clarification on the term “monitoring well” in the Records of Site Condition regulation see Chapter 2: Definitions & Clarifications, Table 2-2.

Implications for Well Screen Design and Placement

Records of Site Condition Regulation - Starting on July 1, 2011, amendments to O. Reg. 153/04 came into force and apply to phase two environmental site assessments (ESAs) conducted in support of records of site conditions (RSCs). For any such RSC submitted on or after this date, where a groundwater sampling method is to be used to characterize contamination or determine if the concentration of a contaminant is above, at, or below and applicable site condition standard or standard specified in a risk assessment for the contaminant, the following requirements apply to the construction of a well:

- where a monitoring well is being used, well screens shall not exceed 3.1 m (10′) in length, based on the saturated length of the screen, and

- where petroleum hydrocarbons or light non-aqueous phase liquids may be present on, in or under a phase two property, sampling depth intervals, including screened intervals of monitoring wells, shall be positioned to intersect the water table.

Implications for the Qualified Person

The qualified person shall ensure that the phase two ESA is conducted in accordance with requirements stated above, in addition to the requirements set out in O. Reg. 153/04.

Implications for Monitoring Well Construction SOPs and QA/QC

Starting on July 1, 2011, amendments to O. Reg. 153/04 came into force and apply to phase two environmental site assessments (ESAs) conducted in support of records of site conditions (RSCs). For any such RSC submitted on or after this date, the qualified person is responsible for, among other things, developing a sampling and analysis plan that will adequately assess all areas of the phase two property including the development of standard operating procedures (SOPs) for borehole drilling, soil sampling and monitoring well installation. The qualified person shall ensure there is a sampling and analysis plan that includes a quality assurance and quality control program (QA/QC). See O. Reg. 153/04 for the QA/QC requirements.

Relevant Sections - Additional Regulations or Lesgislation

Ontario Regulation 213/91 (Construction Projects) as amended made under the Occupational Health and Safety Act

Ontario Regulation 387/04 (Water Taking) as amended made under Ontario Water Resources Act

Ontario Regulation 153/04 (Records of Site Condition) as amended made under Environmental Protection Act

Relevant Standards

ASTM D 5783-95 (2006) – “Standard Guide for Use of Direct Rotary Drilling with Water-Based Drilling Fluid for Geoenvironmental Exploration and the Installation of Subsurface Water-Quality Monitoring Devices,” (DOI: 10.1520/D5783-95R06)

ASTM D 5782-95 (2006) – “Standard Guide for Use of Direct Air-Rotary Drilling for Geoenvironmental Exploration and the Installation of Subsurface Water-Quality Monitoring Devices,” (DOI: 10.1520/D5782-95R06)

ASTM D 5088-02 (2008) – “Standard Practice for Decontamination of Field Equipment Used at Waste Sites,” (DOI: 10.1520/D5088-02R08)

ASTM D 5092-04e1 – “Standard Practice for Design and Installation of Ground Water Monitoring Wells,” (DOI: 10.1520/D5092-04E01)

ASTM D 5781-95 (2006) – “Standard Guide for Use of Dual-Wall Reverse-Circulation Drilling for Geoenvironmental Exploration and Installation of Subsurface Water-Quality Monitoring Devices,” (DOI: 10.1520/D5781-95R06)

ASTM D 5784-95 (2006) – “Standard Guide for Use of Hollow-Stem Augers for Geoenvironmental Exploration and Installation of Subsurface Water-Quality Monitoring Devices,” (DOI: 10.1520/D5784-95R06)

ASTM D 5787-95 (2009) – “Standard Practice for Monitoring Well Protection,” (DOI: 10.1520/D5787-95R09)

ASTM D 5876-95 (2005) – “Standard Guide for Use of Direct Rotary Wireline Casing Advancement Drilling Methods for Geoenvironmental Exploration and Installation of Subsurface Water-Quality Monitoring Devices,” (DOI: 10.1520/D5876-95R05)

ASTM D 6282-98 (2005) – “Standard Guide for Direct Push Soil Sampling for Environmental Site Characterizations,” (DOI: 10.1520/D6282-98R05)

ASTM D 6914-04e1 – “Standard Practice for Sonic Drilling for Site Characterization and the Installation of Subsurface Monitoring Devices,” (DOI: 10.1520/D6914-04E01)

ASTM D6151-08 – “Standard Practice for Using Hollow-Stem Augers for Geotechnical Exploration and Soil Sampling” (DOI: 10.1520/D6151-97R03)

ASTM D5088 – 02(2008) – “Standard Guide for Decontamination of Field Equipment Used at Nonradioactive Waste Sites,” (DOI:10.1520/D5088-02R08)

ASTM D5608 – 01(2006) – “Standard Guide for Decontamination of Field Equipment Used at Low Level Radioactive Waste Sites,” (DOI:10.1520/D5608-01R06)

Key Concepts

Constructing the Hole

Prior to constructing a hole, the person constructing a test hole or dewatering well should research and assess the site and surrounding area using the considerations outlined in Chapter 5: Siting Considerations & Initial Planning. Proper research and assessment covers the location of aquifers, the nature of geological formations, the sources and types of contaminants, the purpose of the test hole or dewatering well and site accessibility.

Successful completion of a test hole or dewatering well depends on the use of equipment and materials that are appropriate for the environmental conditions and geological formations encountered at a site. It is important to consider the characteristics of the drill rig or other well construction equipment including the cutting action and any flushing medium (i.e., type drilling fluid and its circulation path).

Casing

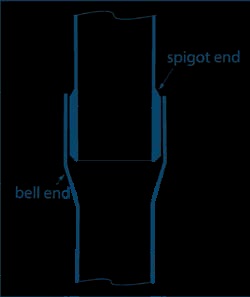

Definition - The Wells Regulation defines casing as “pipe, tubing or other material installed in a well to support its sides, but does not include a well screen.”

Casing acts to stabilize the hole, prevents unconsolidated overburden materials from entering the test hole or dewatering well, accommodates the pumping equipment, and may be used to seal off or isolate unwanted formations.

Making the casing choice that is best for the specific situation involves consideration of the formation, the production capacity of the aquifer, the uses planned for the test hole or dewatering well, the size of the hole and many other factors.

Reminder - In some situations casing is not required for test holes or dewatering wells. Typically, uncased test holes or dewatering wells are used for short-term measurements or water takings and then plugged and sealed (i.e., properly abandoned). A new test hole or dewatering well is not required to be cased as long as the abandonment of the well is scheduled to take place not later than 30 days after the completion of the well’s structural stage and the person constructing the well covers the upper open end of the well securely to prevent the entry of surface water and other foreign materials when the well is left unattended. For additional information and examples of permitted uncased test holes or dewatering wells see page 62 of this chapter.

Well Screen

Definition - The Wells Regulation defines a “well screen” as perforated pipe or tubing, unsealed concrete tiles or other material installed in a well to filter out particulate matter and form the water intake zone.

To prevent water bearing formation collapse into the test hole or dewatering well and reduce sediment or particles in the well water, a well screen should be installed in all unconsolidated formations, in most semi-consolidated formations and sometimes in bedrock.

What to Consider When Constructing a Test Hole or Dewatering Well

Persons constructing test holes or dewatering wells should research, and be familiar with, the geologic formations in the areas where they construct the wells.

Geologic Formations

Geological materials encountered during test hole or dewatering well construction could include:

- overburden formations – such as clay, silt, sand, gravel, or stones

- bedrock formations – such as sandstone, limestone, granite, or other bedrock

Reminder - See Chapter 2: Definitions & Clarifications, Table 2-1, for definitions of “overburden” and “bedrock.”

Advancing holes require construction equipment and tools, cutting actions and flushing media appropriate to the geologic formations encountered in each specific hole.

Location of The Aquifer

Well purchasers, with the assistance of their licensed well technicians or environmental consultants (i.e. Professional Engineers or Professional Geoscientists), can assess and review groundwater reports and well records near the area of the proposed test hole or dewatering well to understand the subsurface conditions and their implications prior to constructing test holes or dewatering wells.

Contaminated Sites

If there is any known or suspected contamination at the site, it is important to consider the following questions:

- What decontamination procedures must be established from hole to hole?

- How are water and/or soil to be contained if contaminated?

- Where will contaminated water and/or soil be stored or disposed of?

- Who will handle the storage and disposal of contaminated water and/or soil?

- What additional health and safety precautions should be taken?

- What is the contingency plan for the rescue of any affected personnel, including identification and location of medical and emergency resources for the site?

Reminder - See Chapter 5: Siting Considerations & Initial Planning for further information on geologic formations, aquifer locations, contaminated sites and environmental site characterization.

Accessibility or Space to Work on the Site

It is important that the proper authorization to access and enter the property and to do the work be obtained from the owner of the land and any other party that has an interest in the land (e.g. tenant).

Site access or space to work on the site is an important consideration. Overhead or underground utilities or obstructions may not allow certain equipment (e.g., a drilling rig) to be admitted. Small working space or long distances from roadways may also limit equipment access to the test hole or dewatering well site. In certain situations, separation distances from sources of contaminants should also be considered (e.g. establishing background groundwater quality).

Reminder - See Chapter 5: Siting Considerations & Initial Planning for further information on accessibility or space to work at the test hole or dewatering well site.

Purpose of the Test Hole or Dewatering Well

There are many reasons to construct a test hole or dewatering well. This may dictate what type of construction method and equipment are appropriate to construct a test hole or dewatering well.

The reasons for constructing a test hole or dewatering well include:

- Dewatering for construction

- Testing and monitoring

- Locating groundwater and contaminants

- Pumping water into an aquifer (recharge well)

- Injecting products to treat contaminated groundwater

- Using pump and treat systems to capture, treat and dispose of free product (portion of the contaminant that is not dissolved in water) and contaminated groundwater

Impact of the Hole

Before constructing the test hole or dewatering well, it is important to consider what impact the well construction may have on the environment around it.

Reminder - It is very difficult to correct mistakes after the fact. It is important, therefore, to utilize and execute best management practices throughout the test hole or dewatering well construction process.

Constructing Test Holes or Dewatering Wells by Different Methods

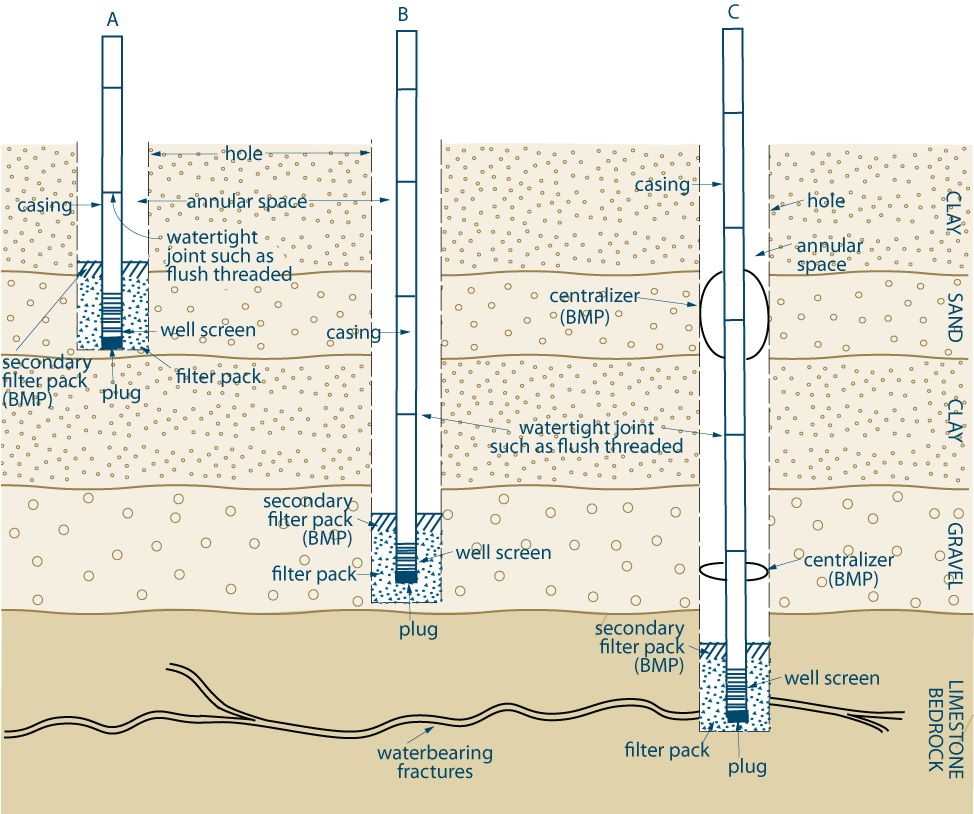

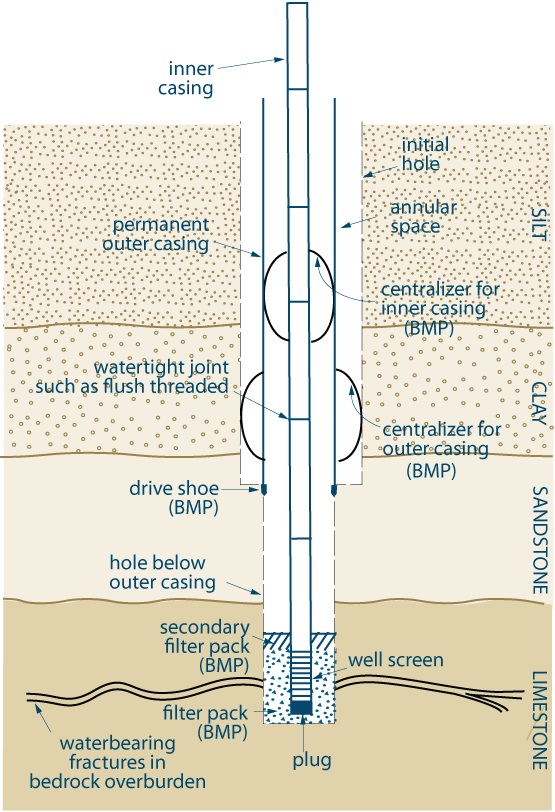

The following sections provide the key considerations when constructing the hole. Figure 6-24 to Figure 6-33, on pages 119 to 128 of this chapter, further illustrate well construction considerations.

Choosing a Construction Method

The construction method:

- should be able to penetrate the geological formation,

- should allow the person constructing the test hole or dewatering well to get representative samples of geological formation material, to identify the boundaries of permeable zones and contaminated zones,

- must allow for the proper recording of formations, including aquifers, encountered during construction,

- must not contaminate the groundwater or the environment, and

- unless otherwise exempt, must meet the minimum depth and diameter requirements of the Wells Regulation (Figure 6-24 to Figure 6-33, on pages 119 to 128 of this chapter).

In many cases, the same equipment is used to construct more than one test hole or dewatering well for a project. Where there is no risk of contamination, the equipment does not have to be cleaned after each test hole or dewatering well is constructed before it can be re-used. Nonetheless, the construction method chosen must not contaminate the groundwater and the environment.

Table 6-1 provides methods, characteristics and some general advantages and disadvantages of various well construction systems in particular formations

| Well Construction System | Characteristics | Advantages | Disadvantages |

|---|---|---|---|

| Hollow- and Solid-Stem Auger |

|

|

|

| Direct Push |

|

|

|

| Driving |

|

|

|

| Jetting |

|

|

|

| Conventional Rotary Drilling Water or Mud |

|

|

|

| Conventional Rotary Drilling Air |

|

|

|

| Reverse Circulation Rotary |

|

|

|

| Dual Wall Reverse Circulation Rotary |

|

|

|

| Dual Rotary/ Casing Advancement |

|

|

|

| Down-the-Hole Hammer (Air Percussion Rotary) |

|

|

|

| Cored Hole / Diamond Drilling |

|

|

|

| Cable Tool |

|

|

|

| Bucket Auger |

|

|

|

| Excavator |

|

|

|

| Sonic |

|

|

|

| Horizontal (Directional) Drilling |

|

|

|

Table 6-2 provides some general information on the speed of the construction equipment, which is used in a particular environment and formation, to construct different types of wells. The table does not provide a ranking system necessarily but instead deals with ease of use in specific overburden and bedrock.

Rate of Penetration: 1=Impossible 2=Difficult 3=Slow 4=Medium 5= Rapid 6=Very Rapid

| Type of Formation | Cable Tool | Direct Rotary (with fluids) | Direct Rotary (with air) | Down-the-hole air | Drill-through casing hammer4 | Reverse Rotary (with fluids)4 | Reverse Rotary (Dual Wall) | Hydraulic Percussion | Jetting | Driven ** | Auger | Sonic | Direct Push*** | Digging |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dune sand | 2 | 5 | Not Recommended | Not Recommended | 6 | 5* | 6 | 5 | 5 | 3 | 3-4 | 5-6 | 5-6 | 5 |

| Loose sand and gravel | 2 | 5 | Not Recommended | Not Recommended | 6 | 5* | 6 | 5 | 5 | 3 | 3-4 | 5-6 | 5-6 | 5 |

| Quicksand and flowing sand | 2 | 5 | Not Recommended | Not Recommended | 6 | 5* | 6 | 5 | 5 | Not Applicable | 1 | 4-5 | 1 | * |

| Loose boulders in alluvial fans or glacial drift | 3-2 | 2-1 | Not Recommended | Not Recommended | 5 | 2-1 | 4 | 1 | 1 | Not Applicable | 3 | 3-4 | 2-3 | 2 |

| Clay and silt | 3 | 5 | Not Recommended | Not Recommended | 5 | 5 | 5 | 3 | 3 | Not Applicable | 3 | 5-6 | 5 | 3 |

| Firm shale | 5 | 5 | Not Recommended | Not Recommended | 5 | 5 | 5 | 3 | Not Applicable | Not Applicable | Not Applicable | 2 | Not Applicable | Not Applicable |

| Sticky shale | 3 | 5 | Not Recommended | Not Recommended | 5 | 3 | 5 | 3 | Not Applicable | Not Applicable | Not Applicable | 2-3 | Not Applicable | Not Applicable |

| Brittle shale | 5 | 5 | Not Recommended | Not Recommended | 5 | 5 | 5 | 3 | Not Applicable | Not Applicable | Not Applicable | 2-3 | Not Applicable | Not Applicable |

| Sandstone – poorly cemented | 3 | 4 | Not Recommended | Not Recommended | Not Applicable | 4 | 5 | 4 | Not Applicable | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable |

| Sandstone – well cemented | 3 | 3 | 5 | Not Recommended | Not Applicable | 3 | 5 | 3 | Not Applicable | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable |

| Chert nodules | 5 | 3 | 3 | Not Recommended | Not Applicable | 3 | 3 | 5 | Not Applicable | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable |

| Limestone | 5 | 5 | 5 | 6 | Not Applicable | 5 | 5 | 5 | Not Applicable | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable |

| Limestone with chert nodules | 5 | 3 | 5 | 6 | Not Applicable | 3 | 3 | 5 | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable | |

| Limestone with small cracks or fractures | 5 | 3 | 5 | 6 | Not Applicable | 2 | 5 | 5 | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable | |

| Limestone – cavernous | 5 | 3-1 | 2 | 5 | Not Applicable | 1 | 5 | 1 | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable | |

| Dolomite | 5 | 5 | 5 | 6 | Not Applicable | 5 | 5 | 5 | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable | |

| Basalts – thin layers in sedimentary rocks | 5 | 3 | 5 | 6 | Not Applicable | 3 | 5 | 5 | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable | |

| Basalts – thick layers | 3 | 3 | 4 | 5 | Not Applicable | 3 | 4 | 3 | Not Applicable | Not Applicable | Not Recommended | Not Applicable | Not Applicable | |

| Basalts – highly fractured (lost circulation zones) | 3 | 1 | 3 | 3 | Not Applicable | 1 | 4 | 1 | Not Applicable | Not Recommended | Not Applicable | Not Applicable | ||

| Metamorphic rocks | 3 | 3 | 4 | 5 | Not Applicable | 3 | 4 | 3 | Not Applicable | Not Recommended | Not Applicable | Not Applicable | ||

| Granite | 3 | 3 | 5 | 5 | Not Applicable | 3 | 4 | 3 | Not Applicable | Not Recommended | Not Applicable | Not Applicable |

* Assuming sufficient hydrostatic pressure is available to contain active sand (under high confining pressures)

** Driven means manual and mechanically assisted methods (hand held electric or pneumatic rotary hammers)

*** Direct push means cone penetration testing (CPT) rigs or trucks or track driven machines with hydraulic powered percussion hammers or vibratory heads

**** Digging in quicksand and flowing sand is not recommended because the hole is not cased as it is advanced and the formation will likely slough.

Construction Method and Contamination

While various well construction methods can be used in the construction of test holes and dewatering wells, the potential presence of contaminants makes some methods more appropriate than others in certain situations.

For example, some methods require the use of large amounts of water which can:

- become contaminated, requiring special containment and disposal procedures,

- cause the contaminant to move, further spreading the impacted area, and/or

- dilute any contaminant that is present, and therefore, affect the integrity of samples.

Other methods can generate large amounts of overburden or cuttings, which also require special containment and disposal.

Construction Method for Controlling and Collecting Groundwater

In addition to the considerations in the “Choosing a Construction Method” section on page 21 of this chapter, construction of dewatering systems used to control and/or collect groundwater should consider the following:

- size and depth of excavation for construction dewatering,

- proposed methods of excavation and ground support for construction dewatering,

- types and depths of proposed foundations,

- proximity of existing structures and their foundations,

- planned schedule for dewatering (e.g., how quickly the groundwater needs to be lowered to install a structure),

- formation characteristics (e.g., flowing well conditions),

- nature of contamination at the site for a remediation system, and

- nature of contamination off-site to reduce the risk of mobilizing contaminants.

Open pumping and pre-drainage systems are two types of dewatering systems used to control and/or collect groundwater. Open pumping systems consist of pumping excavations. Pre-drainage systems consist of well points, suction wells, deep wells, ejector systems and horizontal drains. Table 6-3 provides characteristics, advantages and disadvantages of pre-drainage systems. For further explanation, advantages and disadvantages of open pumping systems see Tables 16.1 and 16.2 from Construction Dewatering and Groundwater Control – New Methods and Applications: Third Edition

| Conditions | Well Point System | Suction Wells | Deep Wells | Ejector Wells | Horizontal Drains |

|---|---|---|---|---|---|

| Silty & clayey sands | Good | Poor | Poor to Fair | Good | Gooda |

| Clean sands & gravel | Good | Good | Good | Poor | Good |

| Stratified soils | Good | Poor | Poor to fair | Goodc | Good |

| Clay or rock at sub-grade | Fair to good | Poor | Poor | Fair to good | Goodb |

| Conditions | Well Point System | Suction Wells | Deep Wells | Ejector Wells | Horizontal Drains |

|---|---|---|---|---|---|

| High hydraulic conductivity | Good | Good | Good | Poor | Good |

| Low hydraulic conductivity | Good | Poor | Poor to fair | Good | Good |

| Proximate recharge | Good | Poor | Poor | Poor to good | Good |

| Remote recharge | Good | Good | Good | Good | Good |

| Conditions | Well Point System | Suction Wells | Deep Wells | Ejector Wells | Horizontal Drains |

|---|---|---|---|---|---|

| Rapid drawdown | OK | OK | Unsatisfactory | OK | OK |

| Slow drawdown | OK | OK | OK | OK | OK |

| Conditions | Well Point System | Suction Wells | Deep Wells | Ejector Wells | Horizontal Drains |

|---|---|---|---|---|---|

| Shallow (<6.1 m (20′) below water table) | OK | OK | OK | OK | OK |

| Deep (>6.1 m (20′) below water table) | Multiple stages required | Multiple stages required | OK | OK | Special equipment |

| Cramped | Interferences | Interferences | OK | OK | May be OK |

| Conditions | Well Point System | Suction Wells | Deep Wells | Ejector Wells | Horizontal Drains |

|---|---|---|---|---|---|

| Normal spacing | 1.5 – 3 m (5 – 10′) | 6 – 12 m (20 – 40′) | >15 m (>50′) | 3 – 6 m (10 – 20′) |

| Conditions | Well Point System | Suction Wells | Deep Wells | Ejector Wells | Horizontal Drains |

|---|---|---|---|---|---|

| Per Unit | 0.4 – 95 L/m (0.1 – 21 gpm) | 190 – 2,270 L/min (42—500 gpm) | 0.4 – 11,360 L/min (0.1 – 2,499gpm) | 0.4 – 150 L/min (0.1 – 33 gpm) | |

| Total System | Low -18,930 L/m (Low – 4,164 gpm) | 7,570 – 94,635 L/m (1,165 – 20,817 gpm) | Low – 227,125 L/min (Low – 49,962 gpm) | Low – 3,785 L/min (Low-833 gpm) | Low – 7,570 L/min (Low – 1,165 gpm) |

| Efficiency with accurate design | Good | Good | Fair | Poor | Good |

a If backfilled with sand or gravel.

b If keyed into clay or rock.

c If double pipe ejectors with well screen full length are used.

Reminder - Take all possible precautions to ensure that any contaminated water, soil, vapours or airborne contaminants are contained during all phases of construction.

If groundwater is anticipated to discharge or is discharging from a well during construction at a volume of more than 50,000 litres (11,000 Imp gal) on any one day, a Permit To Take Water under the Ontario Water Resources Act may be required. More information on Permit To Take Water approvals can be found in Chapter 5: Siting Considerations & Initial Planning and on Ontario.ca.

Reminder - The person constructing the well should ensure that the groundwater, drill cuttings and other materials discharging from the well do not cause environmental impacts such as erosion, impairment of surface water courses and off-site flooding. The use of settling pits on the property may be needed to contain the materials and prevent the above problems. A sewage works environmental compliance approval under the Ontario Water Resources Act may be required if the person constructing the well discharges the water, drill cuttings or other material and the discharge capacity exceeds 10,000 litres per day. A guide to explain the sewage works process can be found on Ontario.ca.

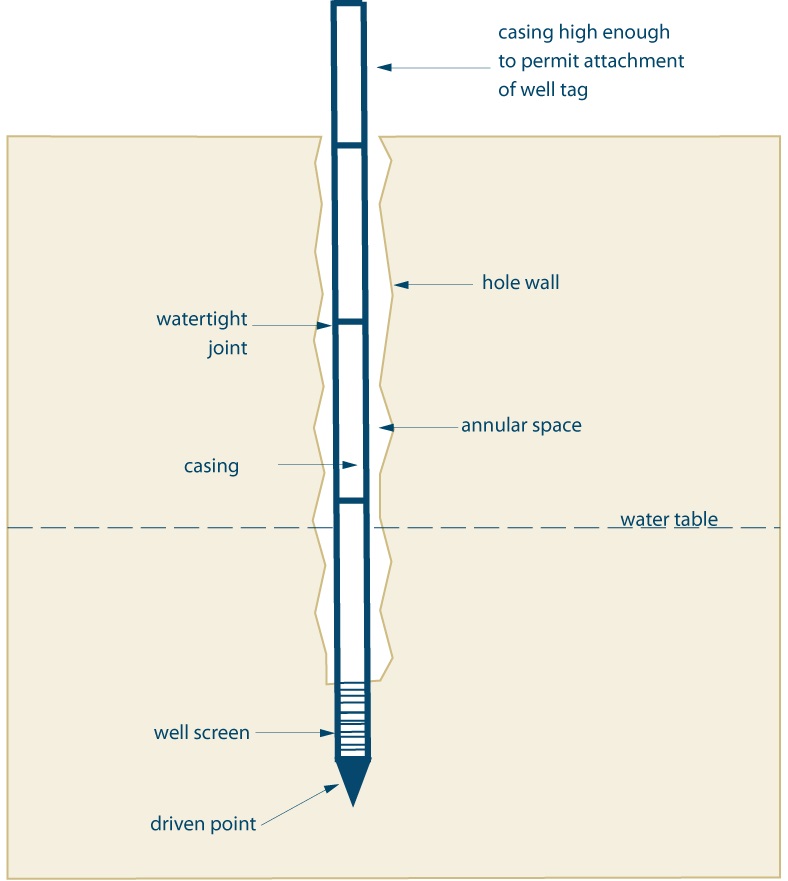

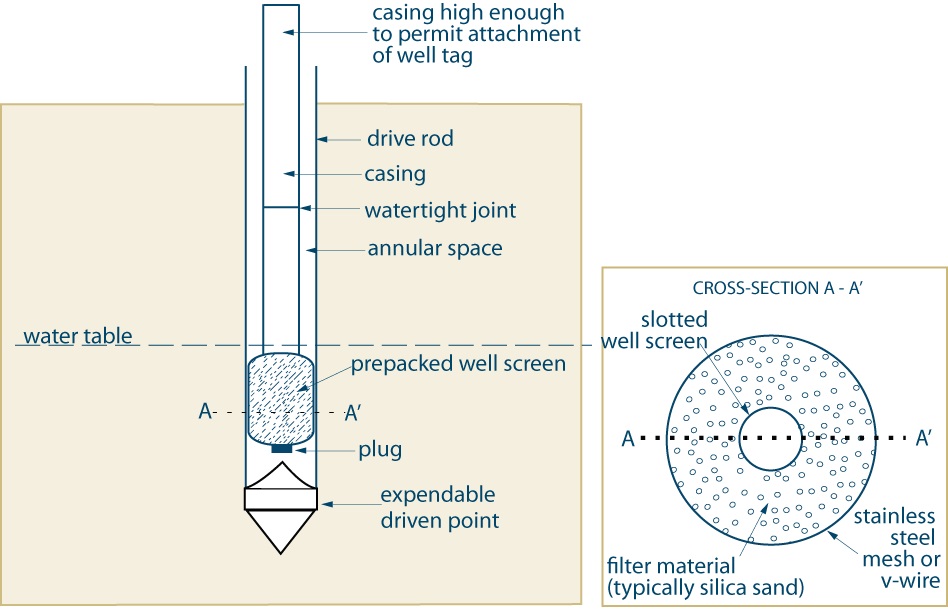

Figure 6-1: Equipment Used for Driven Point Well Construction

Figure 6-1 shows a typical steel well point. A well point is installed by attaching it to a length of casing using a coupling and exerting force with a sledgehammer or a driver to the drive cap. A driver is weighted and fits over the cap and is most commonly used in conjunction with a tripod and pulley system. To drive the well point deeper, additional lengths of casing attached with couplings are used.

Depending on the formation in which the well is being constructed, the person constructing the well may pre-construct the hole using one of the other methods listed above in Table 6-3.

Well points may also be jetted into place, installed using a slide hammer (Figure 6-2), or installed with the use of a hydraulically powered direct push rig, such as the one shown in Figure 6-3.

Figure 6-2: Slide Hammer - A Method of Manual Direct Push

Figure 6-2 shows two people using a slide hammer to drive a rod into the ground. Depending on the conditions of the soil, this method may be used to drive wells to depths of 10 m (33′) or more. A test hole (e.g., piezometer) may be installed by this method.

Figure 6-3: Direct Push Rig

Figure 6-3 shows a direct push rig, which is hydraulically powered. It uses percussion and static force to push the sampling equipment into the ground. The greater force allows larger diameter tools to be driven into the ground.

Figure 6-4: Sonic Drill Rig

Figure 6-4 shows a sonic drill rig which uses high-frequency vibration combined with down-pressure and rotation to advance drilling tools into the ground.

Figure 6-5: Auger Rig Using Hollow-Stem Auger Flight

Auger rigs like the one shown in Figure 6-5 are commonly used in the geotechnical and environmental drilling industries for both soil testing and groundwater investigations. This rig is powered by a deck mounted engine, capable of extremely high rotational torque. Depth, however, will limit the machine’s rotational torque capabilities. A lot of energy is required to advance a hole due to the large surface area of augers.

Flushing Methods

Drilling fluids (flushing media) are an important consideration when choosing a construction method. During certain well construction, drilling fluids will help to do the following:

- Lubricate the drill bit, string and bearings to prevent breakdowns

- Clean and cool the bit to allow for continued long periods of drilling without having to replace the bit

- Stabilize the hole by exerting enough pressure to prevent caving

- Seal the hole wall to reduce fluid loss to the formation

- Lift well cuttings from the bottom of the hole to surface to allow drilling to continue into the formation

There are three main flushing methods:

- Fluid-based [e.g., water; water and bentonite (clay additives); water and polymeric additives; and water, bentonite (clay additives), and polymeric additives]

- Air-based (e.g., dry air; air and water mist; air with a film of water containing a foam; and air, foam and film strengthening materials, such as polymers and bentonite)

- Dry or mechanical-based (uses a mechanical action)

For additional information on flushing media (drilling fluids) see:

- Table 7: Advantages and Disadvantages of Flushing Methods for Drilling Monitoring Wells, from the Fleming College Continuing Education Course Manual: Monitoring Wells – Construction (for Ontario Well Technicians),

- Practical Handbook of Environmental Site Characterization and Ground-Water Monitoring, Second Edition

footnote 8 , - Chapters 16, 17 and 18 of Construction, Dewatering and Groundwater Control – New Methods and Applications, Third Edition

footnote 9 , and - Chapter 8: Drilling Fluids, from Groundwater and Wells, Third Edition

footnote 10 .

Reminder - The use of flushing media with polymeric additives (or polymers) may not be appropriate where a test hole is installed as part of a groundwater quality sampling program. Increased biological activity causing considerable alterations to groundwater quality lasting a long period of time has been cited as a cause for concern and resulted in the restriction of the use of flushing media with polymeric additives for the construction of test holes in certain jurisdictions of the United States (US EPA, 1991). The Professional Geoscientist or Professional Engineer responsible for the environmental project should assess the geological conditions and scope of the project to determine if the use of flushing media with polymeric additives for the construction of test holes is appropriate, on a case by case basis.

The use of any flushing media with polymeric additives should be clearly documented

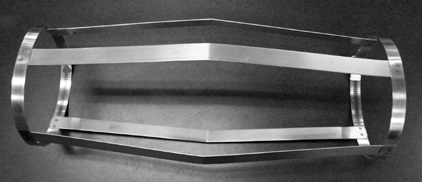

Size of the Test Hole or Dewatering Well

During construction of a well, an annular space is created when the size of the hole in the ground is larger than the casing and well screen diameter.

A properly filled annular space around a casing will:

- isolate a discrete zone,

- prevent migration of surface water and other foreign materials into the well and aquifers,

- prevent migration of groundwater and/or contaminants between water bearing formations and subsurface formations,

- prevent migration of groundwater and/or contaminants between water bearing formations and the ground surface,

- prevent aquifer depressurization by stopping the upward migration of water along the casing, or

- prevent gas migration.

Where an annular space is created, the space must be large enough to ensure:

- filter pack (clean washed gravel and sand) can be placed beside a well screen, if applicable, and

- suitable sealant (grout) can fill and adhere around the entire outer well casing to prevent surface water, groundwater, natural gas and other foreign materials from migrating along the outside of the well casing.

Figures 6-24 to 6-33 at the end of this chapter show many of the requirements listed in Table 6-4.

Table 6-4 may not apply to situations where an inner casing is surrounded by a larger diameter permanent outer casing. For further information see the double walled casing requirements in the “Plainly Stated” section of Chapter 7: Annular Space & Sealing.

Additional details on annular space sealing requirements for test holes and dewatering wells that will be in use for longer than 180 days can be found in Chapter 7: Annular Space & Sealing, Table 7-1.

In the case of a test hole or dewatering well constructed by use of a driven point that creates an annular space, see Chapter 7: Annular Space & Sealing, for annular space sealing considerations.

| Bored Well with Concrete Casing ≥ 6 m Deep | Bored Well with Concrete Casing < 6 m (19.7’) Deep | Dug (or Excavated) Well, Jetted Well or Wells Constructed by the Use of a Driven Point | Drilled Well or Any Other Well ≥ 6 m Deep That is not Listed on this Table | Drilled Well or Any Other Well < 6 m (19.7’) Deep That is not Listed on this Table | |

|---|---|---|---|---|---|

| Minimum Depth of Annular Space below Ground Surface at the Diameter Specified in the Next Row | ≥6 m (19.7′)** | Where no well screen is installed:

|

No minimum | > 6 m (19.7′)** | Where no well screen is installed:

|

| Minimum Diameter of Hole Greater than Outer Casing Diameter to Create Annular Space | ≥15.2 cm (6″) from the ground surface to ≥ 2.5 m (8.2′) below the ground surface | ≥15.2 cm (6″) from the ground surface to ≥ 2.5 m (8.2′) below the ground surface | No minimum | ≥ 7.6 cm (3″) | ≥ 7.6 cm (3″) |

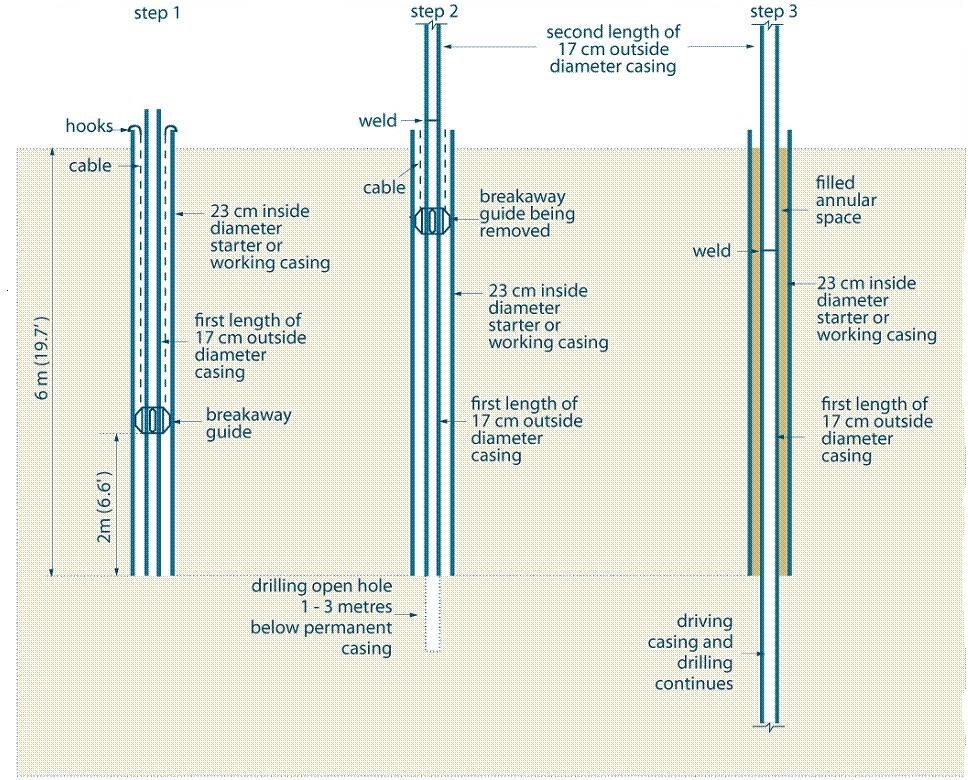

| Minimum Diameter of Hole Greater than Outer Casing Diameter to Create Annular Space | ≥ 7.6 cm (3″) from >2.5 m (8.2′) below the ground surface | ≥ 7.6 cm (3″) from >2.5 m (8.2′) below the ground surface | No minimum | If rotary drilling equipment is used and centralizers are attached to casing > 6 m below the ground surface: ≥ 5.1 cm (2″) | If rotary drilling equipment is used and centralizers are attached to casing > 6 m below the ground surface: ≥ 5.1 cm (2″) |

| Minimum Diameter of Hole Greater than Outer Casing Diameter to Create Annular Space | ≥ 7.6 cm (3″) from >2.5 m (8.2′) below the ground surface | ≥ 7.6 cm (3″) from >2.5 m (8.2′) below the ground surface | No minimum | If cable tool equipment is used and a breakaway guide is attached 2 m above the bottom of any casing: ≥ 5.1 cm (2″) | If cable tool equipment is used and a breakaway guide is attached 2 m above the bottom of any casing: ≥ 5.1 cm (2″) |

* For new test holes or dewatering wells not scheduled to be abandoned within 180 days after completion of the well’s structural stage (see the text before Table 6-4).

** If any annular space is created below 6 m below the ground surface, it must be sealed as described in Chapter 7: Annular Space & Sealing.

*** The requirement does not apply to situations where an inner casing is surrounded by a larger diameter permanent outer casing (see the text before Table 6-4 and exemptions in “Plainly Stated” section of this chapter).

Best Management Practice – Determining the Size of the Test Hole or Dewatering Well Where Casing is Installed

A person constructing a cased well should create a hole diameter of sufficient size that will allow for:

- Best Management Practice – Determining the Size of the Test Hole or Dewatering Well Where Casing is Installed

- suitable sealant to be placed in the annular space around the casing and adhere to the casing and formation.

In most subsurface conditions, a person constructing a cased well should create a test hole or dewatering well diameter that is at least 10 cm to 20 cm (4″ to 8″) larger than the outer diameter of the casing. The larger size of hole facilitates the proper placement of the suitable sealant and filling materials in the annular space using a tremie pipe.

Care should be taken in determining the size of the hole. The person constructing the hole should ensure that the hole is able to accommodate a casing of sufficient size to allow for the installation of necessary downhole equipment (e.g., pumps, pressure transducers, and water level meters).

Reminder - The same minimum hole diameter and annular space requirements and exemptions apply whether the casing is cylindrical or not, See Table 6-4 for additional details. For additional information on annular space and sealing requirements, see Chapter 7: Annular Space & Sealing.

Best Management Practice – Size of the Test Hole or Dewatering Well Annular Space

A person constructing a test hole or dewatering well should always apply the minimum specifications in Table 6-4, the “Determining the Size of the Test Hole or Dewatering Well” BMP above and the Optimum Artificial Filter Pack Characteristics” BMP in the Artificial Filter Packs section of this Chapter, regardless of the length of time that a well is scheduled to be in operation.

Constructing Straight and Plumb Holes

No single drilling construction method is best for every type of test hole or dewatering well or every geologic condition. Each situation may call for a change in the cutting action, flushing medium and equipment, as the construction progresses.

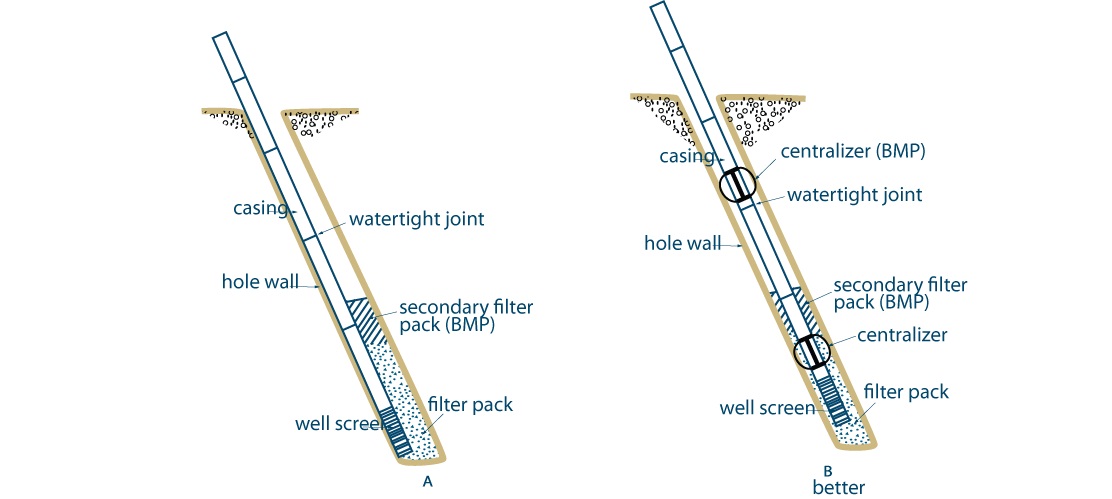

A crucial part of constructing a good vertical hole is ensuring that the hole is straight and plumb to minimize problems with placing the casing, placing filling material or suitable sealant in the annular space around the entire well screen and casing, installing monitoring equipment and collecting samples.

Common Causes of Crooked Vertical Holes

No single drilling construction method is best for every type of test hole or dewatering well or every geologic condition. Each situation may call for a change in the cutting action, flushing medium and equipment, as the construction progresses.

A crucial part of constructing a good vertical hole is ensuring that the hole is straight and plumb to minimize problems with placing the casing, placing filling material or suitable sealant in the annular space around the entire well screen and casing, installing monitoring equipment and collecting samples.

Common Causes of Crooked Vertical Holes

Some of the more common reasons that a hole is not straight include:

- Excessive pull down on drill string

- Drilling aggressively through varying hard and soft formations

- Deflecting off boulders

- Collaring hole on sloping bedrock surface

Figure 6-6: A Crooked Hole as a Result of Drilling Tools Deflecting Off Boulders

Reminder - During construction, a common practice is to use a mirror to reflect sunlight down the hole to permit a visual check on the straightness of the hole. The mirror observation method can be used to check for straightness if a plumb-bob is lowered down the hole. Specifically, a mirror can be used above the water level or when the test hole or dewatering well is dry to check the following:

- straightness of the hole,

- water levels,

- water entry points in cascading conditions or during pumping,

- condition of the hole or casing,

- occurrence of obstructions in the hole such as boulders, and

- occurrence of water leakage and unconsolidated material at bedrock – casing interface.

The person constructing the test hole or dewatering well using rotary drilling equipment should use a mirror and watch the drill string when drilling and tripping in/out to see if the drill string stays in the centre of the casing in the collar area. If the drill string does not stay in the centre of the casing, the hole is not plumb and straight. If using this method, the person constructing the well should ensure that:

- the rig is stable and level, and

- a new or well maintained drill string is used to minimize the degree of deviation within the string.

Similarly, the person constructing the test hole or dewatering well using cable tool drilling equipment should look at the relationship of the drill cable to the top of the casing. If the cable is always centred in the casing, then the hole is plumb and straight. If the cable is not centred, then the hole is not plumb and straight.

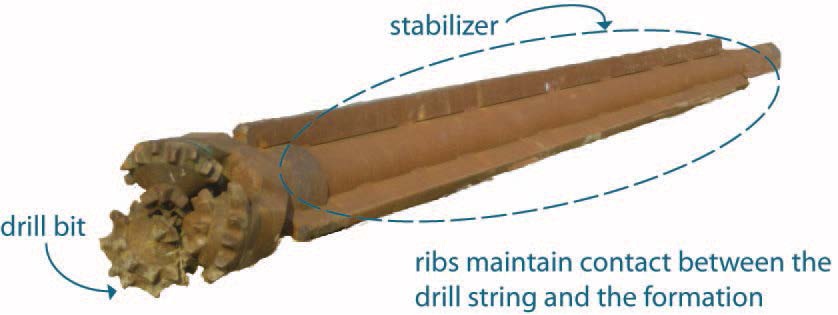

Best Management Practice – Using Stabilizers and Good Construction Techniques

To help minimize the occurrence of crooked or out of plumb holes, good construction techniques should be used in combination with stabilizers on the drilling tools and inclinometers to measure the angle of the holes.

Figure 6-7: A Drill Bit Stabilizer

Figure 6-7 shows a drill bit stabilizer. The circled portion shows the stabilizer has three ribs attached to the rod. The use of a stabilizer such as the one shown here, will help keep the hole straight by maintaining wall contact over a long distance.

Best Management Practice – Straight Holes when Diamond Drilling

When diamond drilling is used to construct the test hole or dewatering well, the person constructing the well should implement the following procedures to ensure a straight hole:

- Properly maintain the downhole equipment (e.g., reaming shells and core barrels)

- Ensure the rig is stable and level

Drilling Straight Non-Vertical Holes (Directional Drilling)

When drilling non-vertical holes, it is important to maintain the desired angle and keep the hole straight. Maintaining the desired angle is difficult as the equipment will naturally migrate up or down, depending on the amount of thrust. Figure 6-8 (below) illustrates this deviation. Deviation can be avoided by applying consistent and adequate thrust to the drill string.

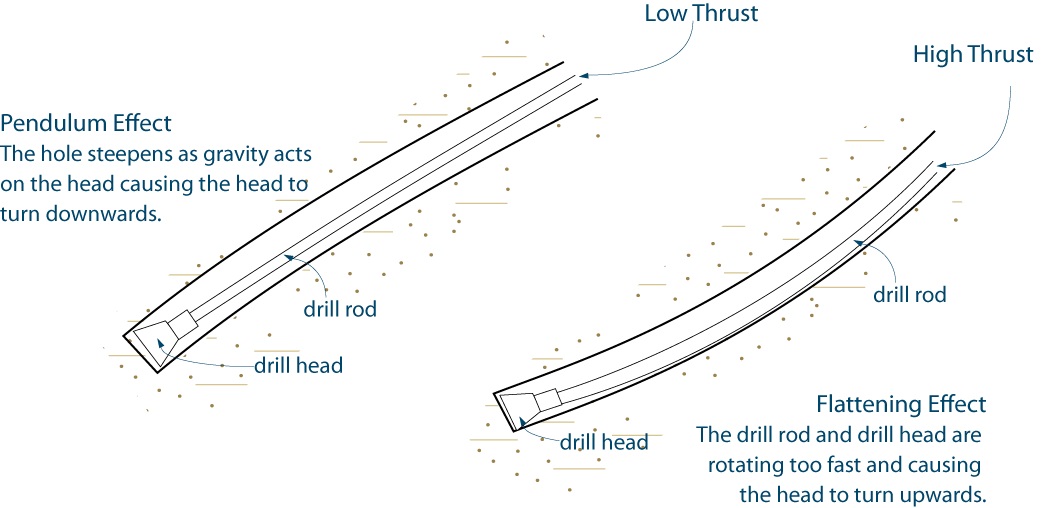

Figure 6-8: Deviation in Non-Vertical Holes

The left side of Figure 6-8 shows a cross section of the pendulum effect that can occur when drilling non-vertical holes. If the drill rod is not turning fast enough, gravity will pull the drill head down causing the hole to steepen as the drill head turns further and further downwards.

The right side of Figure 6-8 shows the opposite scenario where the drill rod is turning at a higher rate of speed which can result in the Flattening Effect. The drill rod is rotating too fast and is causing the drill head to turn upwards and the drill hole starts to flatten.

Best Management Practice – Drilling Straight Non-Vertical Holes

When using directional drilling to construct test holes and dewatering wells, using the following equipment will help keep the hole straight:

- Steerable downhole motors

- Heavy drill collars in conjunction with stabilizers

- Wedges to control the deviation and maintain the desired angle

- A larger diameter drill stem

Creation of Unintended Cavities, Voids and Spaces Outside the Hole Area

Several factors can contribute to the creation of a cavity, void or space during test hole or dewatering well construction. These include:

- Cutting action

- Drilling system

- Flushing medium

- Local geology

- Casing accessories such as drive shoes, casing welds, weld rings and couplings

- Drill cuttings being pushed out of the hole

Best Management Practice – Reducing the Risk of Creating Spaces and Voids

To reduce the risk of unintended small voids and spaces that may be difficult to fill and seal, the person constructing the drilled test hole or dewatering well should:

- Not use a drive shoe with a larger outside diameter than the casing (Table 6-10).

- Minimize the thickness of multiple pass welds (Table 6-7).

- Avoid using a weld ring as it can create a larger annular space. Instead, a thicker walled casing [e.g. 6.4 mm (0.250″) – Table 6-10] should be used to increase the surface area at the ends of the casing to be welded. As an alternative, the person constructing the test hole or dewatering well should corner cut the casing end at a 45 degree angle. The thicker casing provides a stronger welded joint, without causing a larger annular space. (Table 6-10).

- Minimize the use of band and coupled casing. Welded casing sections should be used instead.

- Use minimum volumes of air or water-based flushing media with good drilling practices to minimize hole erosion and avoid losing circulation.

For a well constructed by the use of a driven point, the person constructing the well should verify that the widest part of the driven point matches the outside diameter of the casing or screen. A wider point could create a very small annular space that is difficult to seal.

If any voids are created on the outside of a casing as a result of the well construction activity, see Chapter 7: Annular Space & Sealing for an explanation of how to seal the voids.

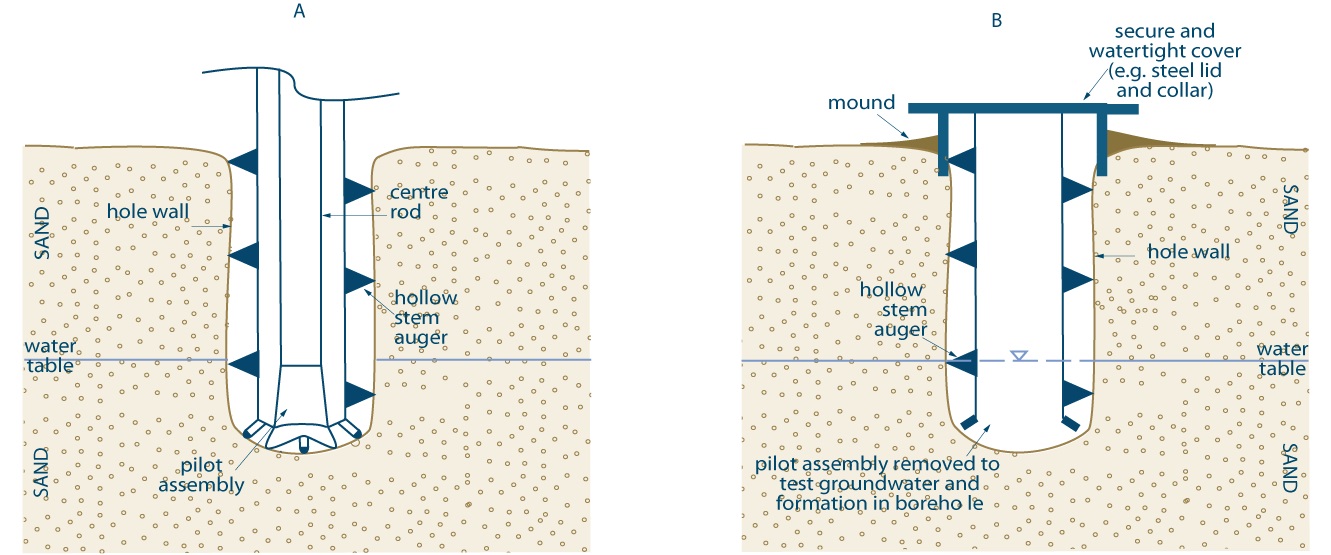

Covering the Hole

An open hole or excavation is not only a safety hazard for children, farm animals and other living things, it is also an open and direct pathway into the aquifer or other subsurface formation. An open test hole or dewatering well can allow contaminants from spills near the test hole or dewatering well to enter the open hole and impair the aquifer.

The Wells Regulation - The Wells Regulation requires that whenever a test hole or dewatering well, other than a shallow works, under construction is left unattended, including during a minor alteration or the installation of a pump, the person constructing the well must cover the upper open end of the test hole or dewatering well securely in a manner sufficient to prevent the entry of surface water and other foreign materials into the well.

The Wells Regulation - The person constructing the well must also ensure that the surface drainage is such that water will not collect or pond in the vicinity of the well.

Temporary covers need to prevent surface water or other foreign materials from entering the hole, and be secure enough to prevent physical hazards and vandalism. Covering a test hole or dewatering well may include installing a lockable watertight well cap on top of the test hole or dewatering well and sealing the cover to the well casing.

Best Management Practice – Covering Test Holes or Dewatering Wells Without Casing

In situations where casing is not required, a temporary vertical tube and horizontal cover that is larger than the hole should be installed into the ground and around the test hole or dewatering well to prevent hole collapse and the entry of surface water and other foreign materials. For further information see Figure 6-27 to Figure 6-29.

Reminder - For further information on wells without casing and other best management practices see the “Exemption from the Requirement to Case the Test Hole or Dewatering Well” section in this chapter.

Reminder - For information on best management practices to cover a shallow works please see Chapter 3: Exemptions: Wells, Activities & Experienced Professionals.

A person constructing a test hole or dewatering well also must ensure a cover meets the Ontario regulation for Construction Projects (Ontario Regulation 213/91) of the Occupational Health and Safety Act requirements to prevent physical accidents at the well site for the public and workers. The person constructing the test hole or dewatering well should also take other reasonable steps to secure the site. As such, leaving the drill rods and other tools in the hole and placing a piece of plywood on top of the well is not a proper well cover.

Recording Geological Information

The Wells Regulation - The Wells Regulation requires that the person constructing a new test hole or dewatering well make a log of the overburden and bedrock materials (geological formations) and keep up to date field notes at the well site. This requirement also applies if the person is deepening the well.

A test hole or dewatering well that is constructed by use of a driven point is exempt from the requirement to make and keep a log of overburden and bedrock materials but field notes are required to be made, kept up to date, and be available at the well site.

Reminder - See Chapter 15: Well Record, Documentation, Reporting & Tagging for further information on log book and field notes, and an example of a log book entry sheet.

| Major Divisions | Subdivisions | Field Identification | Other Properties |

|---|---|---|---|

| Coarse-Grained Soils / Sediments | Gravel |

|

|

| Coarse-Grained Soils / Sediments | Sand |

|

|

| Fine-Grained Soils / Sediments | Silt |

|

|

| Fine-Grained Soils / Sediments | Clay |

|

|

| Soil/Sediment Mixture | Glacial Till |

|

|

| Other | Fill |

|

|

| Other | Cobbles |

|

|

| Other | Boulders |

|

|

Reminder - Table 6-5 provides information on one of several grain-size scales used. A grainsize scale widely used and accepted by geologists, the Udden-Wentworth grain-size scale, is described in Sedimentary Rocks in the Field

The person constructing the test hole or dewatering well should collect representative samples at measured depths and at intervals that will show the complete geological character of the hole. For example, formation samples could be collected at 1.5 m (5′) intervals and at every change in formation materials. The field notes should document the:

- changes in formation materials including the top and bottom of each material/unit encountered,

- observed characteristics of each formation/unit,

- depth to groundwater, water quality, natural gas and any other observations (e.g. staining, sheen, odour), and

- materials and equipment used at the site and in the test hole or dewatering well, and

- location information.

Reminder - See Chapter 15: Well Record, Documentation, Reporting & Tagging for further information on log book and field notes and an example of a log book entry sheet.

Overburden and Bedrock Sampling

There are four main types of sample collection methods used for environmental site characterization work. These are:

- Bulk

- Representative

- Undisturbed

- Composite

There are various soil samplers such as:

- Solid-barrel

- Thin wall tube

- Continuous tube

- Rotary

- Piston

Records of Site Condition Regulation - Implications for Monitoring Well Construction SOPs and QA/QC

Starting on July 1, 2011, amendments to O. Reg. 153/04 came into force and apply to phase two environmental site assessments (ESAs) conducted in support of records of site conditions (RSCs). For any such RSC submitted on or after this date, the qualified person is responsible for, among other things, developing a sampling and analysis plan that will adequately assess all areas of the phase two property including the development of standard operating procedures (SOPs) for activities such as borehole drilling, soil sampling and monitoring well installation.

The qualified person shall ensure there is a sampling and analysis plan that includes a quality assurance and quality control program (QA/QC). See O. Reg 153/04 for the QA/QC requirements.

Records of Site Condition Regulation - Please refer to O. Reg. 153/04 for RSC requirements

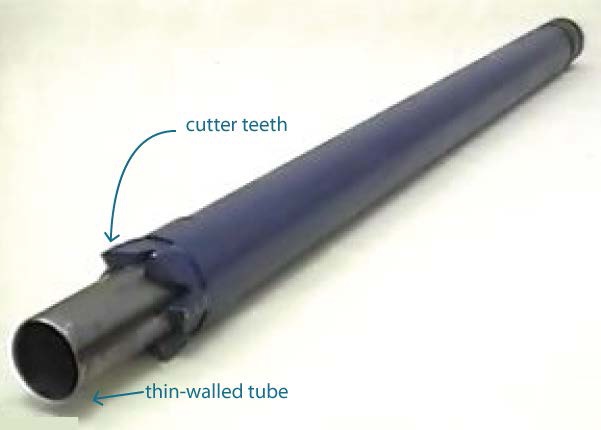

Figure 6-9: Pitcher Barrel Samplers - Rotary and Thin Wall Tube Sampler Combined

Figure 6-9 shows a pitcher barrel sampler, which combines a thin-walled tube with the ability for over-coring (see cutter teeth). The tube compresses if hard soils are encountered.

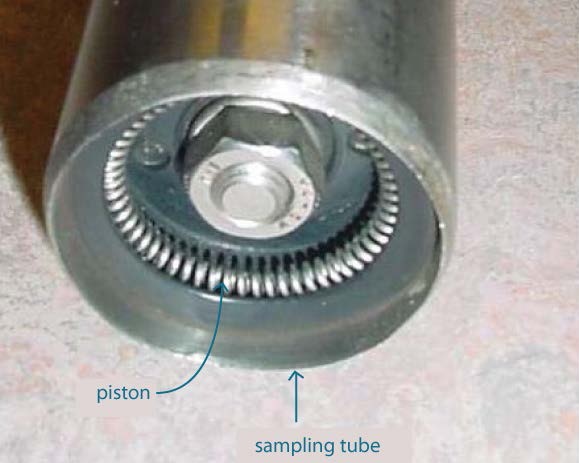

Figure 6-10: Bottom View of Piston Soil Samler

Figure 6-10 shows a piston soil sampler, which is used to retrieve discrete samples of soft silts, clays and sometimes sands from the bottom of a hole. The piston rests at the bottom of the hole and the outer sampling tube is pushed into the material being sampled. The piston prevents soil material from above the desired sampling depth from entering into the tube

There are additional types of samplers for direct push equipment including:

- sealed and unsealed single rods, and

- dual tube samplers such as:

- split-barrel,

- solid-barrel precone, and

- wire-line.

Figure 6-11: Split-Barrel Tube Sampler Closed (Left) and Open (Right)

For environmental site characterization work, rock coring is done to obtain samples of solid, fractured or weathered bedrock formations using diamond or carbide bit drilling methods. There are two main types of coring systems: conventional and wire-line (see Figure 6-12).

The wire-line method of coring is more effective than conventional rock coring because the wire-line core casing can be retrieved through the centre of the outer barrel. This differs from conventional rock coring, which involves removing the entire drill string, which is terminated with a core casing.

Wire-lines can be used for rock coring and overburden (soil) sampling.

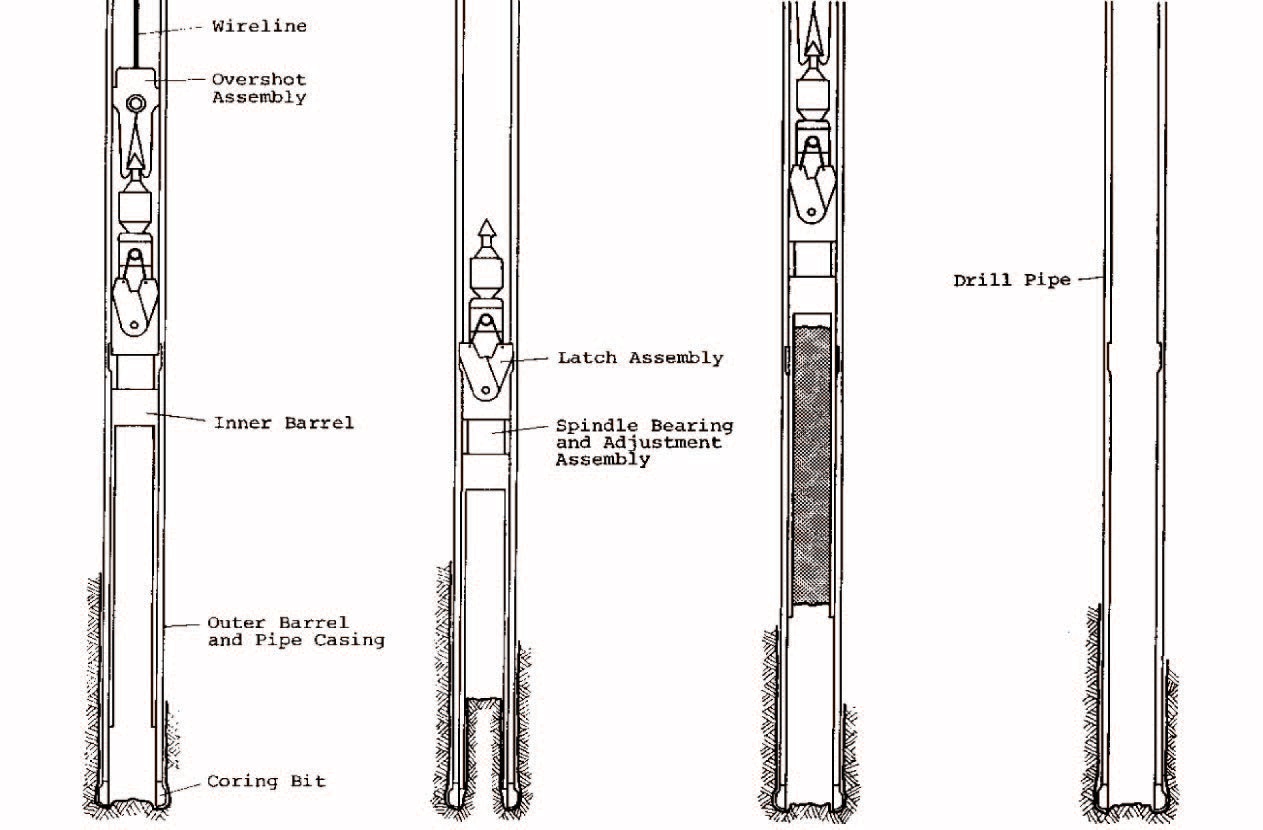

Figure 6-12: Different Wire-Line Core Casing

Figure 6-13: Wire-Line Rock Coring

Figure 6-13 shows four cross-sections of a vertical hole.

The cross-section on the left shows an overshot assembly attached to a wireline going into the hole. The sides of the hole (or outer barrel) are supported with a pipe casing. A coring bit is attached to the bottom of the pipe casing. An inner barrel is located within the outer barrel and is attached to the overshot assembly. There is a caption below the cross-section diagram that states “Inner barrel being lowered into position”.

The second cross-section from the left shows the latch assembly at the bottom of the overshot assembly in the hole. A spindle bearing and adjustment assembly is located below the latch assembly. The sides of the hole (or outer barrel) are supported with a pipe casing. A coring bit is attached to the bottom of the pipe casing. An inner barrel is located within the outer barrel and is attached to the overshot assembly. Rock core is entering the bottom of the inner barrel. There is a caption below the cross-section diagram that states “Obtaining core, outer barrel rotating, inner barrel stationary”.

The third cross-section from the left shows an overshot assembly attached to a wireline going into the hole. The sides of the hole (or outer barrel) are supported with a pipe casing. A coring bit is attached to the bottom of the pipe casing. An inner barrel is located within the outer barrel and is attached to the overshot assembly. Rock core is located within the entire inner barrel. There is a caption below the cross-section diagram that states “Lifting inner barrel and core out of hole”.

The fourth cross-section from the left shows the sides of the hole (or outer barrel) are supported with a pipe casing. There is a caption below the cross-section diagram that states “Outer barrel and coring bit remain in hole”.

- Inner barrel being bowered into position

- Obtaining core, outer barrel rotating, inner barrel stationary

- Lifting inner barrel and core out of hole

- Outer barrel and coring bit remain in hole

Best Management Practice – Sampling Overburden (Soil) and Bedrock

Overburden and bedrock sampling protocols should consider these ASTM international standards (as amended from time to time):

- ASTM D6151 – 08 “Standard Practice for Using Hollow-Stem Augers for Geotechnical Exploration and Soil Sampling” (DOI: 10.1520/D6151-97R03)

footnote 22 - ASTM D6169 – 98(2005) “Standard Guide for Selection of Soil and Rock Sampling Devices Used with Drilling Rigs for Environmental Investigations” (DOI: 10.1520/D6169-98R05)16

- ASTM D4547 – 09, “Standard Guide for Sampling Waste for Volatile Organic Compounds” (DOI: 10.1520/D4547-09) 16

- ASTM D5434 – 09, “Standard Guide for Field Logging of Subsurface Explorations of Soil and Rock” (DOI: 10.1520/D5434-09) 16

- ASTM D6282 – 98(2005), “Standard Guide for Direct-Push Soil Sampling for Environmental Site Characterization” (DOI: 10.1520/D6282-98R05) 16

In addition, the following references will also assist in developing soil and bedrock sampling protocols:

- The Practical Handbook of Environmental Site Characterization and Ground-Water Monitoring, Second Edition

footnote 23 - Guidance on Sampling and Analytical Methods for Use at Contaminated Sites in Ontario

footnote 24 (available on Ontario.ca).

Reminder - The person constructing the well must ensure that any overburden and bedrock core samples are properly stored and disposed of to prevent any adverse effect to the natural environment.

Encountering Gas, Contamination and Water Quality Problems

The Wells Regulation requires that the person constructing the test hole or dewatering well notify the well purchaser, the owner of the land on which the well is located and the Director if natural gas is encountered.

Definition - Natural gas or other gas is a gas produced from a well that has the potential to create conditions for explosions, poisoning, fire, asphyxiation or other adverse effects at the well site, within the water distribution system connected to the well or within buildings connected to wells. Some problematic gases produced by wells in Ontario can include methane, hydrogen sulphide, propane, butane, benzene, carbon dioxide and other hydrocarbon-based gases.

It is important to be prepared for site-specific conditions, which may include soil and groundwater contamination. Indications of contamination include:

- discolouration or milky colour of the water,

- air bubbles in the water,

- sheens on the water,

- soil staining,

- unexpected or foul odours, and

- hissing or degassing sounds.

Best Management Practice – Using Gas Detection Equipment

There is a variety of direct reading instruments used for gas detection including the following:

- combustible gas indicators to measure the risk of fire and explosion, and

- oxygen deficiency meters to assess the level of oxygen in the air.

It is important that the person constructing the test hole or dewatering well be familiar with:

- gas detection equipment operation and limitations, and

- the geology and types of naturally occurring gases that may be encountered in the area.

This information may be available from well records and existing hydrogeological reports.

The person constructing the test hole or dewatering well should use gas detection equipment during any well construction in case gas is encountered.

In some cases gas may accumulate in wells after construction. In areas prone to have natural gas, the person constructing the test hole or dewatering well should use gas detection equipment at least one week after the well has been constructed as a precautionary measure. Also, any person sampling or performing work on a well in areas prone to have natural gas should use gas detection equipment.

Best Management Practice – Encountering Unexpected Contamination or Gas

If unexpected contamination or gas is encountered in the construction (including alteration) of the test hole or dewatering well, the person constructing the test hole or dewatering well should stop work immediately to reduce serious dangers to the site crew, well owner and the environment.

To meet the obligation of reporting natural gas to the Director, the person constructing the test hole or dewatering well should contact the Ministry of the Environment through the Ministry’s Spills Action Centre (SAC) at 1-800-268-6060. The SAC is available to take calls 24 hours a day, 365 days a year.

Unexpected contamination that is encountered should be reported to the Ministry of the Environment local district office and well owner.

The Ministry can offer assistance and notify other agencies to help reduce serious dangers to the site crew, well owner and the environment.

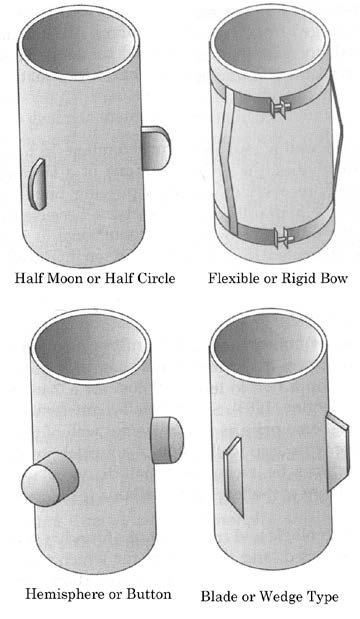

Best Management Practice – Constructing the Hole in Areas Prone to Explosive Gases